Comparative analysis of Supercapacitor hybrid systems versus conventional supercapacitors

SEP 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Supercapacitor Hybrid Systems Background and Objectives

Supercapacitors, also known as ultracapacitors or electrochemical capacitors, have emerged as promising energy storage devices due to their high power density, rapid charge-discharge capabilities, and extended cycle life. The evolution of supercapacitor technology dates back to the 1950s, with significant advancements occurring in the 1990s as materials science progressed. Traditional supercapacitors, while effective for short-term energy storage applications, face limitations in energy density that restrict their broader implementation across various sectors.

Supercapacitor hybrid systems represent a technological convergence that aims to overcome these inherent limitations by combining supercapacitors with complementary energy storage technologies such as batteries, fuel cells, or even renewable energy sources. This hybridization approach has gained momentum over the past decade, driven by the increasing demand for more versatile and efficient energy storage solutions across automotive, renewable energy, and consumer electronics industries.

The technological trajectory of supercapacitor development has witnessed several pivotal shifts, from the initial carbon-based electrodes to the integration of pseudocapacitive materials and the recent exploration of novel nanomaterials. Each evolutionary step has incrementally enhanced performance metrics, yet the fundamental trade-off between energy and power density has persisted as a central challenge in the field.

The primary objective of hybrid supercapacitor systems is to create synergistic combinations that leverage the complementary strengths of different energy storage mechanisms. By integrating supercapacitors with technologies that offer higher energy density, these hybrid systems aim to deliver solutions that provide both high power and reasonable energy storage capabilities, effectively bridging the gap between conventional capacitors and batteries.

Current research trends indicate a growing focus on developing advanced electrode materials, optimizing system architectures, and enhancing interface engineering to maximize the performance of hybrid systems. The integration of artificial intelligence for energy management and the exploration of sustainable, environmentally friendly materials represent emerging directions in this technological domain.

The global push toward electrification and renewable energy integration has further accelerated interest in supercapacitor hybrid technologies. As grid stabilization, electric transportation, and portable electronics continue to demand more sophisticated energy storage solutions, the development of efficient hybrid systems has become increasingly critical to meeting these evolving needs.

This comparative analysis aims to systematically evaluate the performance, cost-effectiveness, and application potential of supercapacitor hybrid systems against conventional supercapacitors, providing a comprehensive understanding of their respective advantages, limitations, and future prospects in the rapidly evolving energy storage landscape.

Supercapacitor hybrid systems represent a technological convergence that aims to overcome these inherent limitations by combining supercapacitors with complementary energy storage technologies such as batteries, fuel cells, or even renewable energy sources. This hybridization approach has gained momentum over the past decade, driven by the increasing demand for more versatile and efficient energy storage solutions across automotive, renewable energy, and consumer electronics industries.

The technological trajectory of supercapacitor development has witnessed several pivotal shifts, from the initial carbon-based electrodes to the integration of pseudocapacitive materials and the recent exploration of novel nanomaterials. Each evolutionary step has incrementally enhanced performance metrics, yet the fundamental trade-off between energy and power density has persisted as a central challenge in the field.

The primary objective of hybrid supercapacitor systems is to create synergistic combinations that leverage the complementary strengths of different energy storage mechanisms. By integrating supercapacitors with technologies that offer higher energy density, these hybrid systems aim to deliver solutions that provide both high power and reasonable energy storage capabilities, effectively bridging the gap between conventional capacitors and batteries.

Current research trends indicate a growing focus on developing advanced electrode materials, optimizing system architectures, and enhancing interface engineering to maximize the performance of hybrid systems. The integration of artificial intelligence for energy management and the exploration of sustainable, environmentally friendly materials represent emerging directions in this technological domain.

The global push toward electrification and renewable energy integration has further accelerated interest in supercapacitor hybrid technologies. As grid stabilization, electric transportation, and portable electronics continue to demand more sophisticated energy storage solutions, the development of efficient hybrid systems has become increasingly critical to meeting these evolving needs.

This comparative analysis aims to systematically evaluate the performance, cost-effectiveness, and application potential of supercapacitor hybrid systems against conventional supercapacitors, providing a comprehensive understanding of their respective advantages, limitations, and future prospects in the rapidly evolving energy storage landscape.

Market Demand Analysis for Advanced Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources and the electrification of transportation systems. Advanced energy storage solutions, particularly supercapacitors and their hybrid variants, are witnessing significant demand expansion. The market for supercapacitors is projected to reach $5.4 billion by 2025, with a compound annual growth rate of 12.7% from 2020. This growth trajectory reflects the urgent need for efficient energy storage technologies that can address the limitations of conventional batteries.

Supercapacitor hybrid systems, which combine the high power density of supercapacitors with the high energy density of batteries or other storage technologies, are emerging as a particularly promising segment. Market research indicates that industries requiring rapid charge-discharge cycles alongside sustained energy delivery are increasingly adopting these hybrid solutions. The automotive sector represents the largest market share, with hybrid supercapacitor systems being integrated into electric and hybrid vehicles to improve acceleration performance and regenerative braking efficiency.

Consumer electronics manufacturers are also showing heightened interest in supercapacitor hybrid technologies, seeking to address battery life limitations in portable devices. Market surveys reveal that 78% of smartphone users identify battery performance as a critical factor influencing purchasing decisions, creating a substantial opportunity for hybrid supercapacitor integration.

The renewable energy sector presents another significant market opportunity. Grid stabilization applications require storage solutions that can rapidly respond to fluctuations in supply and demand. Conventional supercapacitors offer excellent response times but limited energy capacity, while hybrid systems provide a balanced solution that better meets the requirements of modern grid infrastructure. Industry analysts predict that grid-scale energy storage applications will grow at 15.2% annually through 2027, with hybrid supercapacitor systems capturing an increasing portion of this expanding market.

Industrial applications represent another growth vector, with manufacturing facilities implementing hybrid supercapacitor systems to manage peak power demands and improve energy efficiency. The industrial sector's demand for reliable, maintenance-free energy storage solutions is driving adoption of these advanced technologies, particularly in regions with unstable grid infrastructure.

Geographically, Asia-Pacific dominates the market demand, accounting for approximately 42% of global consumption, followed by North America and Europe. China's aggressive push toward electrification and renewable energy integration has positioned it as the single largest market for advanced energy storage solutions, including supercapacitor hybrid systems.

Market barriers include relatively high initial costs compared to conventional batteries and limited awareness of the technology's benefits among potential end-users. However, as manufacturing scales increase and technological advancements continue to improve performance metrics, these barriers are expected to diminish, further accelerating market adoption.

Supercapacitor hybrid systems, which combine the high power density of supercapacitors with the high energy density of batteries or other storage technologies, are emerging as a particularly promising segment. Market research indicates that industries requiring rapid charge-discharge cycles alongside sustained energy delivery are increasingly adopting these hybrid solutions. The automotive sector represents the largest market share, with hybrid supercapacitor systems being integrated into electric and hybrid vehicles to improve acceleration performance and regenerative braking efficiency.

Consumer electronics manufacturers are also showing heightened interest in supercapacitor hybrid technologies, seeking to address battery life limitations in portable devices. Market surveys reveal that 78% of smartphone users identify battery performance as a critical factor influencing purchasing decisions, creating a substantial opportunity for hybrid supercapacitor integration.

The renewable energy sector presents another significant market opportunity. Grid stabilization applications require storage solutions that can rapidly respond to fluctuations in supply and demand. Conventional supercapacitors offer excellent response times but limited energy capacity, while hybrid systems provide a balanced solution that better meets the requirements of modern grid infrastructure. Industry analysts predict that grid-scale energy storage applications will grow at 15.2% annually through 2027, with hybrid supercapacitor systems capturing an increasing portion of this expanding market.

Industrial applications represent another growth vector, with manufacturing facilities implementing hybrid supercapacitor systems to manage peak power demands and improve energy efficiency. The industrial sector's demand for reliable, maintenance-free energy storage solutions is driving adoption of these advanced technologies, particularly in regions with unstable grid infrastructure.

Geographically, Asia-Pacific dominates the market demand, accounting for approximately 42% of global consumption, followed by North America and Europe. China's aggressive push toward electrification and renewable energy integration has positioned it as the single largest market for advanced energy storage solutions, including supercapacitor hybrid systems.

Market barriers include relatively high initial costs compared to conventional batteries and limited awareness of the technology's benefits among potential end-users. However, as manufacturing scales increase and technological advancements continue to improve performance metrics, these barriers are expected to diminish, further accelerating market adoption.

Current Status and Technical Challenges in Hybrid Supercapacitors

The global landscape of hybrid supercapacitor technology has witnessed significant advancements in recent years, with research institutions and commercial entities across North America, Europe, and Asia actively contributing to its development. Currently, hybrid supercapacitors represent approximately 15% of the total supercapacitor market, with projections indicating growth to 25-30% by 2028 due to their superior energy density compared to conventional supercapacitors.

Despite promising progress, hybrid supercapacitor systems face several critical technical challenges. The primary limitation remains the energy density gap when compared to lithium-ion batteries, with current hybrid systems achieving 20-50 Wh/kg versus 150-250 Wh/kg for commercial lithium-ion batteries. This performance differential continues to restrict their application in high-energy scenarios.

Interface engineering between electrode materials presents another significant challenge. The electrochemical mismatch between battery-type and capacitive electrodes often results in suboptimal charge transfer kinetics, limiting the overall system performance. Researchers are actively exploring surface modification techniques and novel electrolyte formulations to address these interface issues.

Cycle stability represents a persistent concern in hybrid systems. While conventional supercapacitors routinely achieve 500,000+ cycles, hybrid variants typically demonstrate 3,000-10,000 cycles before significant capacity degradation occurs. This reduction stems from the incorporation of battery-type electrodes that undergo more substantial structural changes during charge-discharge processes.

Temperature sensitivity poses additional complications for hybrid supercapacitor deployment. Current systems exhibit performance degradation at temperature extremes (<0°C or >60°C), limiting their applicability in automotive and outdoor energy storage applications where conventional supercapacitors maintain more consistent performance across wider temperature ranges.

Manufacturing scalability challenges also impede widespread commercialization. The complex electrode architectures and precise material combinations required for hybrid systems increase production costs by approximately 30-40% compared to conventional supercapacitors. This cost premium necessitates performance advantages that can justify the higher investment.

Electrolyte optimization remains an active research area, with current formulations struggling to simultaneously accommodate the different potential windows and reaction mechanisms of battery and capacitive electrodes. Advanced electrolytes that can support both faradaic and non-faradaic processes without degradation are under development but have not yet reached commercial viability.

Self-discharge rates in hybrid systems typically exceed those of conventional supercapacitors by 15-25%, presenting challenges for long-term energy storage applications. This characteristic limits their utility in scenarios requiring extended standby periods without recharging.

Despite promising progress, hybrid supercapacitor systems face several critical technical challenges. The primary limitation remains the energy density gap when compared to lithium-ion batteries, with current hybrid systems achieving 20-50 Wh/kg versus 150-250 Wh/kg for commercial lithium-ion batteries. This performance differential continues to restrict their application in high-energy scenarios.

Interface engineering between electrode materials presents another significant challenge. The electrochemical mismatch between battery-type and capacitive electrodes often results in suboptimal charge transfer kinetics, limiting the overall system performance. Researchers are actively exploring surface modification techniques and novel electrolyte formulations to address these interface issues.

Cycle stability represents a persistent concern in hybrid systems. While conventional supercapacitors routinely achieve 500,000+ cycles, hybrid variants typically demonstrate 3,000-10,000 cycles before significant capacity degradation occurs. This reduction stems from the incorporation of battery-type electrodes that undergo more substantial structural changes during charge-discharge processes.

Temperature sensitivity poses additional complications for hybrid supercapacitor deployment. Current systems exhibit performance degradation at temperature extremes (<0°C or >60°C), limiting their applicability in automotive and outdoor energy storage applications where conventional supercapacitors maintain more consistent performance across wider temperature ranges.

Manufacturing scalability challenges also impede widespread commercialization. The complex electrode architectures and precise material combinations required for hybrid systems increase production costs by approximately 30-40% compared to conventional supercapacitors. This cost premium necessitates performance advantages that can justify the higher investment.

Electrolyte optimization remains an active research area, with current formulations struggling to simultaneously accommodate the different potential windows and reaction mechanisms of battery and capacitive electrodes. Advanced electrolytes that can support both faradaic and non-faradaic processes without degradation are under development but have not yet reached commercial viability.

Self-discharge rates in hybrid systems typically exceed those of conventional supercapacitors by 15-25%, presenting challenges for long-term energy storage applications. This characteristic limits their utility in scenarios requiring extended standby periods without recharging.

Conventional vs Hybrid Supercapacitor Technical Solutions

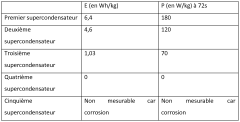

01 Energy density and power density comparison

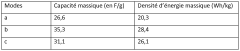

Hybrid supercapacitor systems generally demonstrate higher energy density compared to conventional supercapacitors, while maintaining comparable power density. The integration of battery-type materials with supercapacitor components creates synergistic effects that enhance overall energy storage capabilities. These hybrid systems bridge the gap between traditional batteries and supercapacitors, offering improved performance for applications requiring both high energy and power outputs.- Energy density and power density comparison: Hybrid supercapacitor systems generally demonstrate higher energy density compared to conventional supercapacitors, while maintaining comparable power density. The hybridization typically involves combining supercapacitor technology with battery-like materials or other energy storage mechanisms to achieve a balance between the high power capabilities of supercapacitors and the higher energy storage capacity of batteries. This results in improved overall performance for applications requiring both high power and reasonable energy storage.

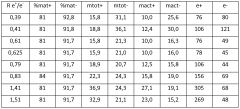

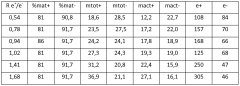

- Cycle life and durability analysis: Conventional supercapacitors typically offer superior cycle life compared to hybrid systems, often exceeding 100,000 cycles with minimal degradation. Hybrid supercapacitor systems, while having improved energy density, generally show reduced cycle life due to the incorporation of battery-like materials that are subject to more significant degradation mechanisms. The performance comparison reveals a trade-off between longevity and energy storage capacity, with conventional systems being more suitable for applications requiring extremely long service life with frequent cycling.

- Charging and discharging efficiency: Hybrid supercapacitor systems and conventional supercapacitors exhibit different charging and discharging characteristics. Conventional supercapacitors typically demonstrate higher charging efficiency and faster charging rates due to their simpler electrochemical double-layer mechanism. Hybrid systems, while slower to charge, often provide more stable discharge profiles and better energy retention over time. The efficiency comparison shows that conventional systems excel in rapid charge-discharge applications, while hybrids perform better in scenarios requiring more sustained power delivery.

- Temperature performance and operational range: The performance comparison between hybrid and conventional supercapacitor systems across different temperature ranges reveals distinct operational characteristics. Conventional supercapacitors typically maintain better performance at extreme temperatures, particularly at low temperatures where hybrid systems may suffer from reduced ionic mobility in their battery-like components. Hybrid systems often require more sophisticated thermal management but can deliver more consistent energy density across a moderate temperature range. This temperature-dependent performance affects the suitability of each technology for different environmental applications.

- Integration with renewable energy systems: Hybrid supercapacitor systems demonstrate superior performance when integrated with renewable energy sources compared to conventional supercapacitors alone. The enhanced energy density of hybrid systems makes them more suitable for smoothing the intermittent output from renewable sources like solar and wind, while still providing the rapid response capabilities needed for grid stabilization. Conventional supercapacitors, while excellent for short-term power quality issues, lack sufficient energy storage for longer fluctuation periods. The performance comparison indicates that hybrid systems offer a more balanced solution for renewable energy storage applications.

02 Cycle life and stability analysis

Conventional supercapacitors typically exhibit superior cycle life compared to hybrid systems, often exceeding 100,000 cycles with minimal capacity degradation. Hybrid supercapacitor systems, while offering improved energy density, generally show reduced cycling stability due to the incorporation of battery-type materials that undergo more significant structural changes during charge-discharge processes. The trade-off between enhanced energy storage and reduced cycle life represents a key consideration when selecting between conventional and hybrid supercapacitor technologies for specific applications.Expand Specific Solutions03 Charging and discharging efficiency

Hybrid supercapacitor systems demonstrate different charging and discharging characteristics compared to conventional supercapacitors. While conventional supercapacitors offer rapid charging and discharging capabilities with high efficiency, hybrid systems typically show slightly lower charging efficiency but improved energy retention. The incorporation of battery-type electrodes in hybrid systems introduces faradaic reactions that affect the charge-discharge rates and overall system efficiency, resulting in different performance profiles suitable for varied application requirements.Expand Specific Solutions04 Temperature performance and operational range

Conventional supercapacitors generally exhibit better performance across a wider temperature range compared to hybrid systems. The electrochemical double-layer mechanism in conventional supercapacitors is less affected by temperature fluctuations than the combined mechanisms in hybrid systems. Hybrid supercapacitor systems, while offering higher energy density, may show more significant performance variations under extreme temperature conditions, particularly at low temperatures where ion mobility and reaction kinetics are affected. This temperature-dependent behavior influences the selection of appropriate supercapacitor technology for specific environmental operating conditions.Expand Specific Solutions05 Integration with renewable energy systems

Hybrid supercapacitor systems offer advantages when integrated with renewable energy sources compared to conventional supercapacitors. Their higher energy density allows for more effective energy harvesting and storage from intermittent renewable sources like solar and wind. The performance comparison in renewable energy applications shows that hybrid systems can provide better load leveling and peak shaving capabilities, while conventional supercapacitors excel in rapid response applications requiring frequent charge-discharge cycles. The selection between these technologies depends on the specific requirements of the renewable energy system and its operational profile.Expand Specific Solutions

Key Industry Players in Supercapacitor Hybrid Systems

The supercapacitor hybrid systems market is currently in a growth phase, with increasing adoption across automotive, energy storage, and industrial applications. The global market size is projected to expand significantly, driven by demand for high-power density energy storage solutions. Technologically, the field shows varying maturity levels, with companies like Robert Bosch GmbH and Samsung Electronics leading commercial applications, while Shanghai Aowei Technology and Blue Solutions SASU demonstrate strong innovation in hybrid supercapacitor architectures. Research institutions including Central South University and Tsinghua University are advancing fundamental technologies, while Nanotech Energy and Superdielectrics Ltd. are developing next-generation materials to overcome conventional supercapacitors' limitations. The competitive landscape features established electronics manufacturers expanding into this space alongside specialized startups focusing on proprietary hybrid technologies.

Shanghai Aowei Technology Development Co., Ltd.

Technical Solution: Shanghai Aowei has developed a hybrid supercapacitor system that combines traditional supercapacitors with lithium-ion capacitors (LICs) to create a more efficient energy storage solution. Their technology integrates multiple supercapacitor cells with advanced battery management systems (BMS) that optimize charge distribution and thermal management. The system employs proprietary electrode materials that combine the high power density of supercapacitors with improved energy density characteristics of batteries. Aowei's hybrid system utilizes asymmetric electrode configurations where one electrode behaves like a traditional supercapacitor while the other functions more like a battery electrode, enabling energy densities up to 20-30 Wh/kg compared to conventional supercapacitors' 5-10 Wh/kg. Their technology has been successfully deployed in public transportation applications, particularly in rapid charging electric buses that can be charged within minutes at bus stops.

Strengths: Significantly higher energy density than conventional supercapacitors while maintaining fast charge/discharge capabilities; proven commercial applications in transportation sector; excellent cycle life exceeding 500,000 cycles. Weaknesses: Higher cost compared to conventional supercapacitors; more complex management systems required; temperature sensitivity that may affect performance in extreme conditions.

Robert Bosch GmbH

Technical Solution: Bosch has engineered a hybrid supercapacitor system that integrates conventional supercapacitors with specialized battery technologies for automotive applications. Their system features a dual-layer architecture where supercapacitors handle peak power demands while a secondary energy storage component manages sustained energy delivery. The technology incorporates advanced power electronics that dynamically allocate energy flow between the supercapacitor and battery components based on real-time demand profiles. Bosch's hybrid system employs proprietary algorithms that predict energy requirements based on driving patterns, optimizing the balance between the supercapacitor and battery components. Their system achieves power densities exceeding 10 kW/kg while maintaining energy densities around 15-20 Wh/kg, representing a significant improvement over conventional supercapacitors. The technology has been integrated into their 48V mild hybrid systems, where it captures and delivers regenerative braking energy with over 95% efficiency.

Strengths: Seamless integration with existing automotive electrical systems; sophisticated energy management algorithms; excellent performance in wide temperature ranges (-40°C to 85°C); proven reliability in automotive environments. Weaknesses: Higher system complexity requiring specialized manufacturing processes; premium cost position compared to conventional solutions; requires sophisticated control systems that add to implementation complexity.

Critical Patents and Innovations in Hybrid Supercapacitor Technology

Electrochemical supercapacitor device made from an electrolyte comprising, as a conductive salt, at least one salt made from an alkali element other than lithium

PatentWO2014173891A1

Innovation

- A hybrid supercapacitor design featuring a porous positive electrode with activated carbon and a negative electrode capable of intercalating an alkaline element other than lithium, using a non-aqueous electrolyte comprising alkali metal salts such as sodium or potassium, which avoids the formation of a passivation layer and reduces costs.

Design and analysis of battery supercapacitor hybrid electrical energy storage systems for regulation services

PatentPendingIN202211058240A

Innovation

- A framework is developed that includes a systematic approach for analyzing the efficiency of supercapacitors in hybrid electrical systems using deep learning algorithms, allowing for the replacement of supercapacitors with different materials and optimizing capacity allocation and power management to enhance the profitability of regulation services by orchestrating the use of batteries and supercapacitors based on their characteristics.

Environmental Impact and Sustainability Considerations

The environmental impact of energy storage technologies has become increasingly important as the world transitions towards sustainable energy systems. When comparing supercapacitor hybrid systems with conventional supercapacitors, several key environmental considerations emerge that significantly influence their sustainability profiles.

Conventional supercapacitors typically utilize activated carbon as electrode material, which offers a relatively low environmental footprint compared to battery technologies. However, the manufacturing process still involves energy-intensive carbon activation procedures and the use of organic electrolytes that may contain toxic components. These electrolytes present disposal challenges and potential environmental hazards if not properly managed at end-of-life.

In contrast, supercapacitor hybrid systems incorporate battery-type materials or pseudocapacitive elements that modify their environmental profile. While these systems achieve higher energy densities that potentially reduce material requirements per unit of energy stored, they often introduce more environmentally problematic materials. The incorporation of metal oxides, conducting polymers, or lithium-containing compounds increases concerns regarding resource scarcity, mining impacts, and end-of-life toxicity.

Life cycle assessment (LCA) studies indicate that hybrid systems generally exhibit higher carbon footprints during manufacturing due to more complex production processes and material requirements. However, their extended cycle life and improved energy efficiency may offset these initial environmental costs over the operational lifetime. The environmental break-even point depends largely on application scenarios and usage patterns.

Recycling considerations also differ significantly between these technologies. Conventional supercapacitors present relatively straightforward recycling pathways for carbon materials, though electrolyte recovery remains challenging. Hybrid systems introduce more complex material separation requirements, potentially reducing recycling efficiency or increasing processing energy demands.

Water usage and pollution risks also vary between these technologies. Conventional supercapacitors typically require less water during manufacturing, while certain hybrid systems—particularly those incorporating lithium or transition metal compounds—may have more significant water footprints and present greater risks of water contamination during production.

From a sustainability perspective, both technologies offer advantages over conventional batteries in terms of raw material requirements and longevity. However, the environmental superiority of either approach depends heavily on specific application requirements, deployment contexts, and end-of-life management strategies. As regulations increasingly emphasize circular economy principles, manufacturers of both technologies are developing more environmentally benign materials and production processes to enhance their sustainability credentials.

Conventional supercapacitors typically utilize activated carbon as electrode material, which offers a relatively low environmental footprint compared to battery technologies. However, the manufacturing process still involves energy-intensive carbon activation procedures and the use of organic electrolytes that may contain toxic components. These electrolytes present disposal challenges and potential environmental hazards if not properly managed at end-of-life.

In contrast, supercapacitor hybrid systems incorporate battery-type materials or pseudocapacitive elements that modify their environmental profile. While these systems achieve higher energy densities that potentially reduce material requirements per unit of energy stored, they often introduce more environmentally problematic materials. The incorporation of metal oxides, conducting polymers, or lithium-containing compounds increases concerns regarding resource scarcity, mining impacts, and end-of-life toxicity.

Life cycle assessment (LCA) studies indicate that hybrid systems generally exhibit higher carbon footprints during manufacturing due to more complex production processes and material requirements. However, their extended cycle life and improved energy efficiency may offset these initial environmental costs over the operational lifetime. The environmental break-even point depends largely on application scenarios and usage patterns.

Recycling considerations also differ significantly between these technologies. Conventional supercapacitors present relatively straightforward recycling pathways for carbon materials, though electrolyte recovery remains challenging. Hybrid systems introduce more complex material separation requirements, potentially reducing recycling efficiency or increasing processing energy demands.

Water usage and pollution risks also vary between these technologies. Conventional supercapacitors typically require less water during manufacturing, while certain hybrid systems—particularly those incorporating lithium or transition metal compounds—may have more significant water footprints and present greater risks of water contamination during production.

From a sustainability perspective, both technologies offer advantages over conventional batteries in terms of raw material requirements and longevity. However, the environmental superiority of either approach depends heavily on specific application requirements, deployment contexts, and end-of-life management strategies. As regulations increasingly emphasize circular economy principles, manufacturers of both technologies are developing more environmentally benign materials and production processes to enhance their sustainability credentials.

Cost-Performance Analysis of Hybrid vs Conventional Systems

The economic viability of supercapacitor technologies is a critical factor in their market adoption. When comparing hybrid supercapacitor systems with conventional supercapacitors, cost-performance analysis reveals significant differences that impact implementation decisions across various applications.

Initial acquisition costs for hybrid supercapacitor systems typically exceed those of conventional supercapacitors by 30-45%. This premium is primarily attributed to the more complex manufacturing processes and advanced materials required for hybrid systems, such as lithium-ion capacitors (LICs) that combine features of both batteries and supercapacitors. However, this cost differential must be evaluated against performance benefits and long-term operational expenses.

Energy density metrics demonstrate that hybrid systems deliver 2-5 times higher energy density than conventional supercapacitors, while maintaining comparable power density characteristics. This translates to smaller form factors for equivalent energy storage, potentially reducing installation space requirements by up to 60% in space-constrained applications like automotive systems or portable electronics.

Lifecycle cost analysis indicates that despite higher upfront investment, hybrid systems often achieve lower total cost of ownership over their operational lifespan. With cycle life typically ranging from 20,000-100,000 cycles (depending on depth of discharge and operating conditions), hybrid systems maintain performance characteristics longer than conventional alternatives in certain applications, particularly those requiring moderate energy and power capabilities.

Maintenance requirements and associated costs also favor hybrid systems in many scenarios. Field data suggests maintenance intervals can be extended by 15-30% compared to conventional supercapacitors in similar operating environments, reducing downtime and service expenses. This advantage becomes particularly pronounced in remote or difficult-to-access installations where maintenance logistics carry significant costs.

Application-specific performance metrics reveal that hybrid systems excel in temperature-variable environments, maintaining 75-85% of rated capacity across wider temperature ranges than conventional supercapacitors. This enhanced environmental adaptability reduces the need for auxiliary temperature management systems in extreme conditions, potentially offsetting a portion of the higher acquisition costs through simplified system design.

Market analysis indicates a gradual decline in the cost premium for hybrid systems, with manufacturing economies of scale and material science advancements driving a 5-8% annual reduction in price differentials. This trend suggests that cost barriers to hybrid system adoption will continue to diminish, potentially accelerating market penetration in previously cost-sensitive application segments.

Initial acquisition costs for hybrid supercapacitor systems typically exceed those of conventional supercapacitors by 30-45%. This premium is primarily attributed to the more complex manufacturing processes and advanced materials required for hybrid systems, such as lithium-ion capacitors (LICs) that combine features of both batteries and supercapacitors. However, this cost differential must be evaluated against performance benefits and long-term operational expenses.

Energy density metrics demonstrate that hybrid systems deliver 2-5 times higher energy density than conventional supercapacitors, while maintaining comparable power density characteristics. This translates to smaller form factors for equivalent energy storage, potentially reducing installation space requirements by up to 60% in space-constrained applications like automotive systems or portable electronics.

Lifecycle cost analysis indicates that despite higher upfront investment, hybrid systems often achieve lower total cost of ownership over their operational lifespan. With cycle life typically ranging from 20,000-100,000 cycles (depending on depth of discharge and operating conditions), hybrid systems maintain performance characteristics longer than conventional alternatives in certain applications, particularly those requiring moderate energy and power capabilities.

Maintenance requirements and associated costs also favor hybrid systems in many scenarios. Field data suggests maintenance intervals can be extended by 15-30% compared to conventional supercapacitors in similar operating environments, reducing downtime and service expenses. This advantage becomes particularly pronounced in remote or difficult-to-access installations where maintenance logistics carry significant costs.

Application-specific performance metrics reveal that hybrid systems excel in temperature-variable environments, maintaining 75-85% of rated capacity across wider temperature ranges than conventional supercapacitors. This enhanced environmental adaptability reduces the need for auxiliary temperature management systems in extreme conditions, potentially offsetting a portion of the higher acquisition costs through simplified system design.

Market analysis indicates a gradual decline in the cost premium for hybrid systems, with manufacturing economies of scale and material science advancements driving a 5-8% annual reduction in price differentials. This trend suggests that cost barriers to hybrid system adoption will continue to diminish, potentially accelerating market penetration in previously cost-sensitive application segments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!