What technical strategies optimize Supercapacitor hybrid systems cycling performance and energy retention

SEP 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Supercapacitor Hybrid Systems Background and Objectives

Supercapacitor hybrid systems represent a significant advancement in energy storage technology, combining the high power density of supercapacitors with the high energy density of batteries or other energy storage devices. The evolution of these hybrid systems can be traced back to the early 2000s when researchers began exploring ways to overcome the limitations of individual energy storage technologies. Since then, the field has witnessed remarkable progress, driven by the growing demand for efficient energy storage solutions in various applications, including renewable energy integration, electric vehicles, and portable electronics.

The technological trajectory of supercapacitor hybrid systems has been characterized by continuous improvements in materials science, electrode design, and system integration. Early systems faced challenges related to energy density, cycle life, and system complexity. However, advancements in nanomaterials, electrolytes, and manufacturing processes have significantly enhanced the performance and reliability of these systems. The development of novel carbon-based materials, metal oxides, and conducting polymers has played a crucial role in pushing the boundaries of what these hybrid systems can achieve.

Current research trends in supercapacitor hybrid systems focus on addressing key performance metrics, particularly cycling performance and energy retention. These aspects are critical for the commercial viability and widespread adoption of these technologies. Cycling performance refers to the ability of the system to maintain its capacity over numerous charge-discharge cycles, while energy retention relates to the system's capability to store energy efficiently with minimal self-discharge over time.

The primary technical objectives in this field include developing strategies to enhance the interface between different components of the hybrid system, optimizing the energy management systems, and designing novel materials with improved electrochemical properties. Researchers aim to achieve longer cycle life, higher energy density, improved rate capability, and reduced self-discharge rates. Additionally, there is a growing emphasis on developing environmentally friendly and cost-effective solutions that can be scaled up for commercial applications.

Looking forward, the field is expected to witness breakthroughs in advanced materials, innovative system architectures, and intelligent control strategies. The integration of artificial intelligence and machine learning algorithms for optimizing the performance of these hybrid systems represents a promising direction. Furthermore, the development of flexible and wearable supercapacitor hybrid systems opens up new possibilities for applications in smart textiles, healthcare devices, and Internet of Things (IoT) technologies.

The ultimate goal is to create supercapacitor hybrid systems that offer the best of both worlds: the high power density and long cycle life of supercapacitors, combined with the high energy density of batteries, all while maintaining excellent energy retention capabilities across diverse operating conditions and applications.

The technological trajectory of supercapacitor hybrid systems has been characterized by continuous improvements in materials science, electrode design, and system integration. Early systems faced challenges related to energy density, cycle life, and system complexity. However, advancements in nanomaterials, electrolytes, and manufacturing processes have significantly enhanced the performance and reliability of these systems. The development of novel carbon-based materials, metal oxides, and conducting polymers has played a crucial role in pushing the boundaries of what these hybrid systems can achieve.

Current research trends in supercapacitor hybrid systems focus on addressing key performance metrics, particularly cycling performance and energy retention. These aspects are critical for the commercial viability and widespread adoption of these technologies. Cycling performance refers to the ability of the system to maintain its capacity over numerous charge-discharge cycles, while energy retention relates to the system's capability to store energy efficiently with minimal self-discharge over time.

The primary technical objectives in this field include developing strategies to enhance the interface between different components of the hybrid system, optimizing the energy management systems, and designing novel materials with improved electrochemical properties. Researchers aim to achieve longer cycle life, higher energy density, improved rate capability, and reduced self-discharge rates. Additionally, there is a growing emphasis on developing environmentally friendly and cost-effective solutions that can be scaled up for commercial applications.

Looking forward, the field is expected to witness breakthroughs in advanced materials, innovative system architectures, and intelligent control strategies. The integration of artificial intelligence and machine learning algorithms for optimizing the performance of these hybrid systems represents a promising direction. Furthermore, the development of flexible and wearable supercapacitor hybrid systems opens up new possibilities for applications in smart textiles, healthcare devices, and Internet of Things (IoT) technologies.

The ultimate goal is to create supercapacitor hybrid systems that offer the best of both worlds: the high power density and long cycle life of supercapacitors, combined with the high energy density of batteries, all while maintaining excellent energy retention capabilities across diverse operating conditions and applications.

Market Analysis for Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources and the need for grid stabilization. Supercapacitor hybrid systems represent a significant segment within this expanding market, offering unique advantages in high-power applications requiring rapid charge-discharge cycles. Current market valuations place the global supercapacitor market at approximately $3.5 billion, with projections indicating a compound annual growth rate (CAGR) of 21.8% through 2028.

Consumer electronics currently dominates supercapacitor applications, accounting for roughly 35% of market share. However, automotive and transportation sectors are rapidly emerging as key growth drivers, particularly with the acceleration of electric vehicle adoption worldwide. The integration of supercapacitors in regenerative braking systems and start-stop applications has created substantial market opportunities, with this segment expected to grow at a CAGR of 23.5% over the next five years.

Industrial applications represent another significant market vertical, where supercapacitor hybrid systems are increasingly deployed in uninterruptible power supplies, grid stabilization, and heavy machinery. This sector currently holds approximately 28% of the market share and is projected to maintain steady growth as industries seek more efficient energy management solutions.

Geographically, Asia-Pacific leads the market with approximately 45% share, driven primarily by extensive manufacturing capabilities in China, Japan, and South Korea. North America and Europe follow with 25% and 20% market shares respectively, with both regions showing increased investment in advanced energy storage technologies to support renewable energy integration.

Market competition is intensifying as established players and new entrants vie for position. Key market participants include Maxwell Technologies (now part of Tesla), Skeleton Technologies, Nippon Chemi-Con, and LS Mtron. Strategic partnerships between supercapacitor manufacturers and automotive OEMs have become increasingly common, signaling the technology's growing importance in transportation applications.

Consumer demand for faster charging capabilities and longer device operation has created significant pull for improved supercapacitor technologies. The market increasingly values solutions that optimize cycling performance and energy retention, with consumers willing to pay premium prices for devices offering superior power management. Industry surveys indicate that 78% of commercial users prioritize cycling longevity when selecting energy storage solutions, while 65% consider energy retention capabilities a critical decision factor.

Regulatory frameworks supporting clean energy initiatives and carbon reduction goals are providing additional market tailwinds. Government incentives for energy storage deployment in various countries have created favorable market conditions, with global policy support expected to drive an additional $12 billion in market opportunity by 2030.

Consumer electronics currently dominates supercapacitor applications, accounting for roughly 35% of market share. However, automotive and transportation sectors are rapidly emerging as key growth drivers, particularly with the acceleration of electric vehicle adoption worldwide. The integration of supercapacitors in regenerative braking systems and start-stop applications has created substantial market opportunities, with this segment expected to grow at a CAGR of 23.5% over the next five years.

Industrial applications represent another significant market vertical, where supercapacitor hybrid systems are increasingly deployed in uninterruptible power supplies, grid stabilization, and heavy machinery. This sector currently holds approximately 28% of the market share and is projected to maintain steady growth as industries seek more efficient energy management solutions.

Geographically, Asia-Pacific leads the market with approximately 45% share, driven primarily by extensive manufacturing capabilities in China, Japan, and South Korea. North America and Europe follow with 25% and 20% market shares respectively, with both regions showing increased investment in advanced energy storage technologies to support renewable energy integration.

Market competition is intensifying as established players and new entrants vie for position. Key market participants include Maxwell Technologies (now part of Tesla), Skeleton Technologies, Nippon Chemi-Con, and LS Mtron. Strategic partnerships between supercapacitor manufacturers and automotive OEMs have become increasingly common, signaling the technology's growing importance in transportation applications.

Consumer demand for faster charging capabilities and longer device operation has created significant pull for improved supercapacitor technologies. The market increasingly values solutions that optimize cycling performance and energy retention, with consumers willing to pay premium prices for devices offering superior power management. Industry surveys indicate that 78% of commercial users prioritize cycling longevity when selecting energy storage solutions, while 65% consider energy retention capabilities a critical decision factor.

Regulatory frameworks supporting clean energy initiatives and carbon reduction goals are providing additional market tailwinds. Government incentives for energy storage deployment in various countries have created favorable market conditions, with global policy support expected to drive an additional $12 billion in market opportunity by 2030.

Current Challenges in Supercapacitor Cycling Performance

Despite significant advancements in supercapacitor technology, several critical challenges persist in optimizing cycling performance and energy retention in hybrid systems. One of the primary issues is capacity fading during extended cycling, particularly evident in hybrid systems that combine supercapacitors with batteries or other energy storage components. This degradation manifests as a gradual decrease in energy density and power capability, typically accelerating after several thousand cycles.

Self-discharge represents another significant challenge, with hybrid supercapacitor systems often experiencing energy losses of 5-20% within the first 24 hours after charging. This phenomenon is exacerbated by operating temperature variations and becomes particularly problematic in applications requiring long-term energy storage without frequent recharging opportunities.

Interface resistance between different components in hybrid systems creates impedance issues that reduce overall system efficiency. The electrochemical mismatch between supercapacitors and batteries in hybrid configurations often leads to uneven charge distribution and suboptimal performance, with efficiency losses of 10-15% commonly observed in practical applications.

Temperature sensitivity remains a persistent challenge, as supercapacitor performance can vary significantly across operating temperature ranges. Most commercial systems show optimal performance between 20-40°C, with notable degradation outside this range. In extreme conditions, cycling performance can deteriorate by up to 30%, severely limiting application in harsh environments.

Material stability issues, particularly in electrode materials and electrolytes, contribute significantly to performance degradation. Carbon-based electrodes experience structural changes during extended cycling, while electrolyte decomposition accelerates at higher voltages and temperatures. These chemical and physical changes directly impact the electrode-electrolyte interface, a critical factor in maintaining stable cycling performance.

Voltage balancing in series-connected supercapacitor cells presents another technical hurdle. Without sophisticated management systems, individual cells may experience voltage imbalances of up to 20%, leading to premature aging of certain components and overall system failure. This challenge becomes particularly acute in large-scale applications requiring numerous cells.

Manufacturing consistency and quality control also impact cycling performance, with variations in material properties and assembly techniques leading to performance discrepancies between nominally identical systems. Industry data suggests performance variations of 5-15% between units from the same production batch, highlighting the need for more standardized manufacturing protocols.

Self-discharge represents another significant challenge, with hybrid supercapacitor systems often experiencing energy losses of 5-20% within the first 24 hours after charging. This phenomenon is exacerbated by operating temperature variations and becomes particularly problematic in applications requiring long-term energy storage without frequent recharging opportunities.

Interface resistance between different components in hybrid systems creates impedance issues that reduce overall system efficiency. The electrochemical mismatch between supercapacitors and batteries in hybrid configurations often leads to uneven charge distribution and suboptimal performance, with efficiency losses of 10-15% commonly observed in practical applications.

Temperature sensitivity remains a persistent challenge, as supercapacitor performance can vary significantly across operating temperature ranges. Most commercial systems show optimal performance between 20-40°C, with notable degradation outside this range. In extreme conditions, cycling performance can deteriorate by up to 30%, severely limiting application in harsh environments.

Material stability issues, particularly in electrode materials and electrolytes, contribute significantly to performance degradation. Carbon-based electrodes experience structural changes during extended cycling, while electrolyte decomposition accelerates at higher voltages and temperatures. These chemical and physical changes directly impact the electrode-electrolyte interface, a critical factor in maintaining stable cycling performance.

Voltage balancing in series-connected supercapacitor cells presents another technical hurdle. Without sophisticated management systems, individual cells may experience voltage imbalances of up to 20%, leading to premature aging of certain components and overall system failure. This challenge becomes particularly acute in large-scale applications requiring numerous cells.

Manufacturing consistency and quality control also impact cycling performance, with variations in material properties and assembly techniques leading to performance discrepancies between nominally identical systems. Industry data suggests performance variations of 5-15% between units from the same production batch, highlighting the need for more standardized manufacturing protocols.

Current Technical Solutions for Performance Optimization

01 Electrode materials for enhanced cycling performance

Advanced electrode materials can significantly improve the cycling performance and energy retention of supercapacitor hybrid systems. These materials include carbon-based composites, metal oxides, and conductive polymers that offer high surface area and stable electrochemical properties. The incorporation of these materials helps to minimize capacity fading during repeated charge-discharge cycles, leading to improved long-term performance and energy retention capabilities.- Electrode materials for enhanced cycling performance: Advanced electrode materials can significantly improve the cycling performance and energy retention of supercapacitor hybrid systems. These materials include carbon-based composites, metal oxides, and conductive polymers that offer high surface area and stable structures. The incorporation of these materials helps to minimize capacity fading during repeated charge-discharge cycles, leading to improved long-term performance and energy retention capabilities.

- Electrolyte optimization for energy retention: The composition and properties of electrolytes play a crucial role in determining the energy retention capabilities of supercapacitor hybrid systems. Optimized electrolytes with high ionic conductivity and electrochemical stability can reduce internal resistance and self-discharge rates. Advanced electrolyte formulations, including gel electrolytes and ionic liquids, can enhance the operational voltage window and improve the overall energy density and retention during cycling.

- Thermal management systems for cycling stability: Effective thermal management is essential for maintaining the cycling performance and energy retention of supercapacitor hybrid systems. Temperature fluctuations can significantly impact the electrochemical processes and accelerate degradation mechanisms. Implementing dedicated cooling systems, heat dissipation structures, and temperature monitoring controls helps to maintain optimal operating conditions, thereby extending cycle life and preserving energy storage capabilities.

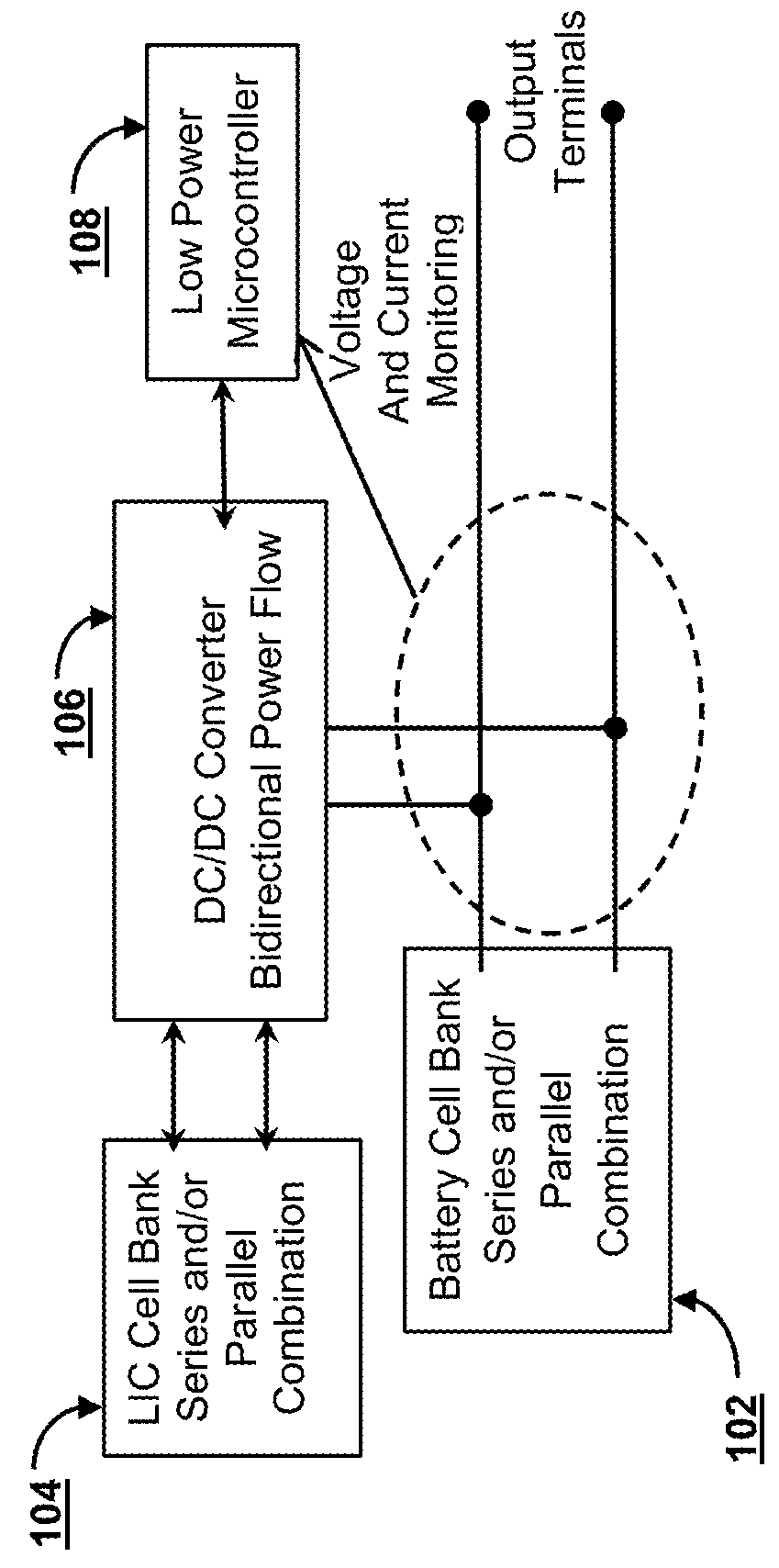

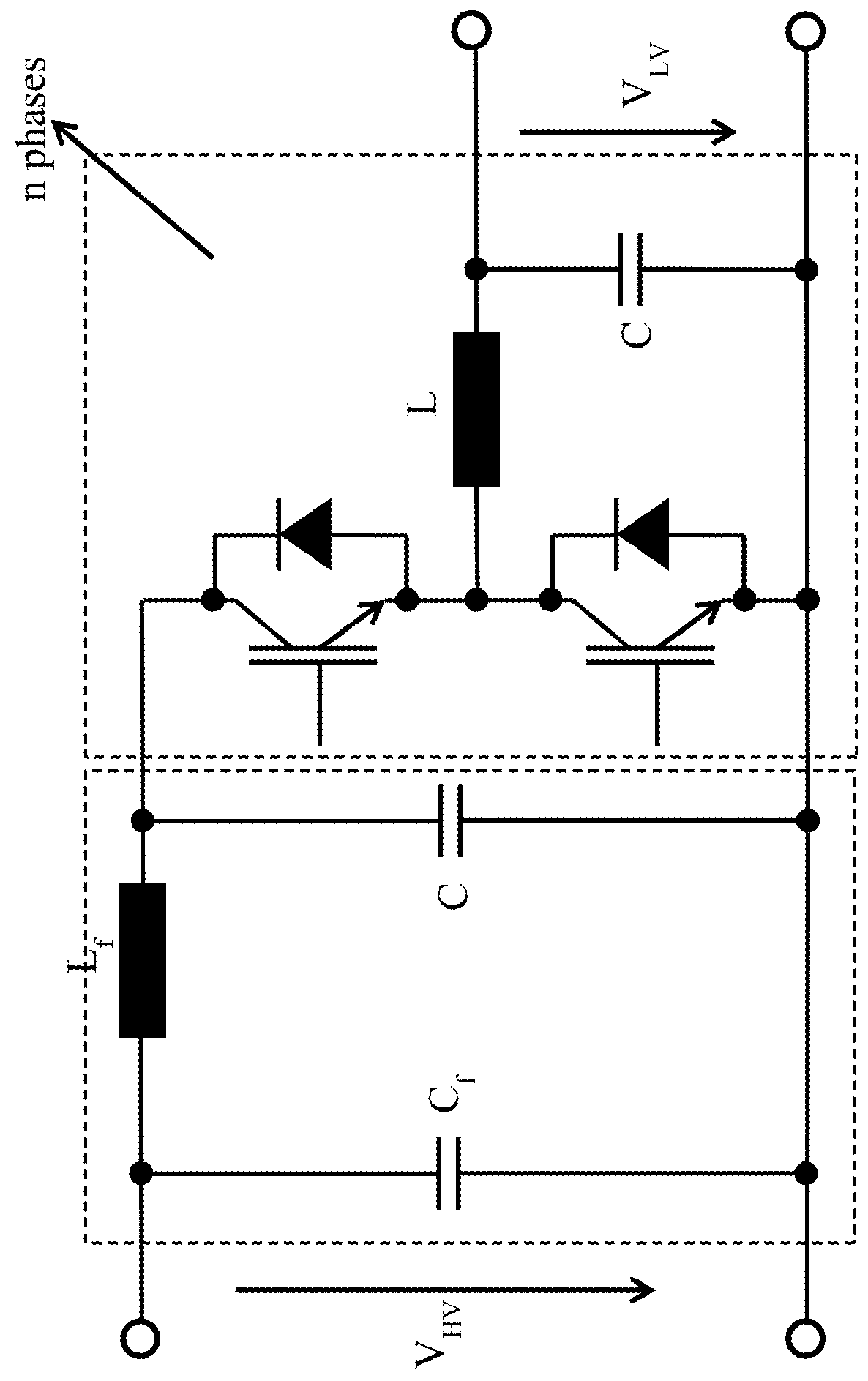

- Hybrid energy storage system architectures: Innovative system architectures that combine supercapacitors with other energy storage technologies can optimize cycling performance and energy retention. These hybrid configurations leverage the high power density of supercapacitors and the high energy density of batteries or other storage devices. Advanced control strategies and power management algorithms enable efficient energy distribution between the different components, reducing stress on individual elements and extending the overall system lifetime.

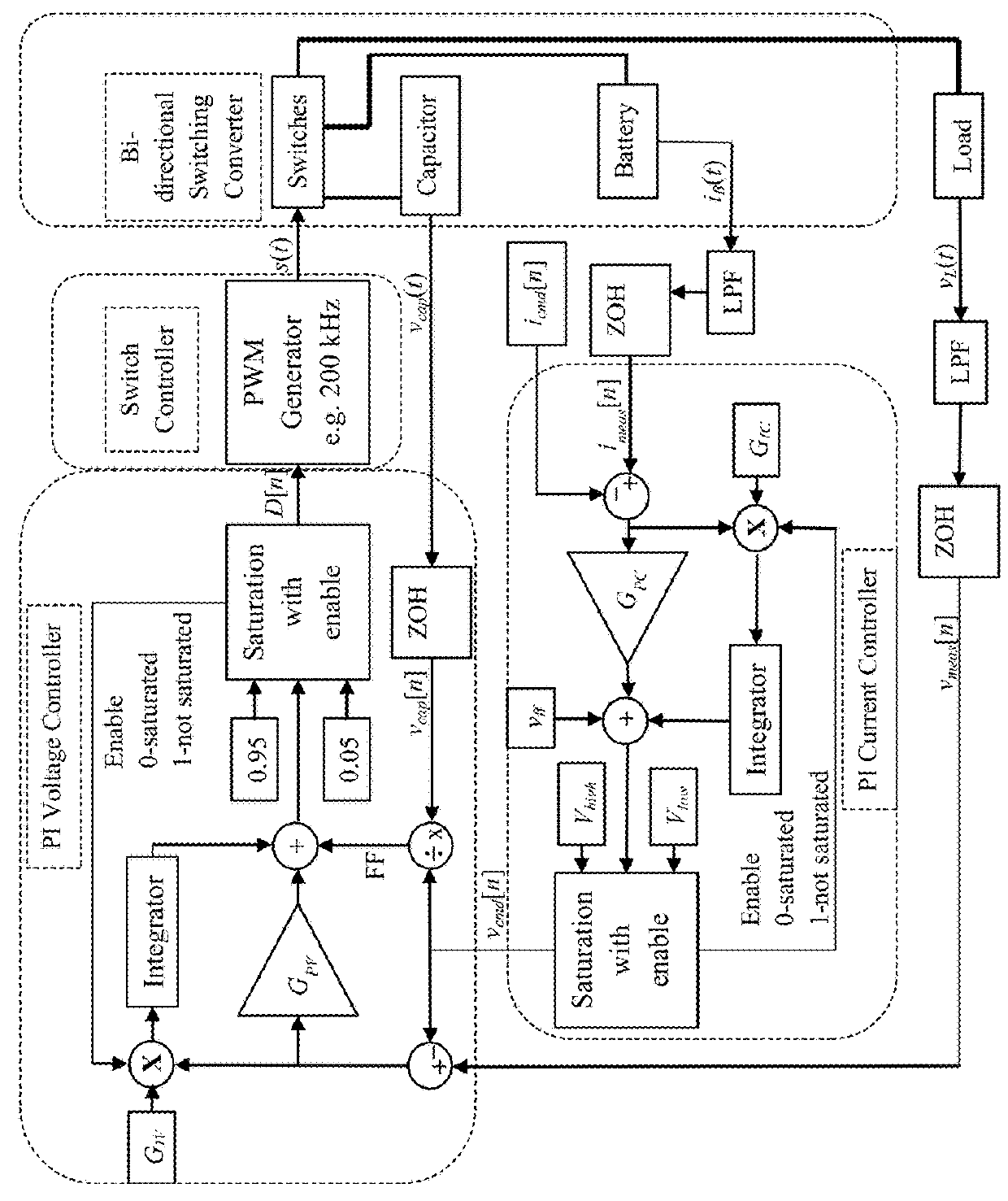

- Advanced charge-discharge control strategies: Sophisticated charge-discharge control strategies are critical for optimizing the cycling performance and energy retention of supercapacitor hybrid systems. These include adaptive current control, voltage limitation techniques, and state-of-charge management algorithms. By implementing intelligent control systems that monitor and adjust operating parameters in real-time, the degradation mechanisms can be minimized, leading to improved cycle life, enhanced energy efficiency, and better long-term energy retention capabilities.

02 Electrolyte optimization for energy retention

The composition and properties of electrolytes play a crucial role in determining the energy retention capabilities of supercapacitor hybrid systems. Optimized electrolytes with high ionic conductivity and electrochemical stability can reduce internal resistance and self-discharge rates. Advanced electrolyte formulations, including ionic liquids and gel electrolytes, help maintain charge storage capacity over extended cycling periods, thereby enhancing the overall energy retention of the system.Expand Specific Solutions03 Thermal management systems for cycling stability

Effective thermal management is essential for maintaining the cycling performance and energy retention of supercapacitor hybrid systems. Heat generation during rapid charge-discharge cycles can degrade the electrochemical properties of the system components. Implementing cooling mechanisms and temperature control strategies helps to prevent thermal runaway and ensures stable operation under various conditions, thereby extending the cycle life and preserving energy storage capabilities.Expand Specific Solutions04 Hybrid energy storage system architecture

The architectural design of hybrid supercapacitor systems significantly impacts cycling performance and energy retention. Integrating supercapacitors with batteries or other energy storage technologies in optimized configurations allows for leveraging the high power density of supercapacitors while maintaining energy density. Advanced control algorithms and power management strategies enable efficient energy distribution between storage components, reducing stress on individual elements and enhancing overall system durability and energy retention.Expand Specific Solutions05 Novel encapsulation and packaging techniques

Innovative encapsulation and packaging methods contribute to improved cycling performance and energy retention in supercapacitor hybrid systems. Hermetic sealing techniques and advanced packaging materials protect the internal components from environmental factors such as moisture and contaminants that can accelerate degradation. These protective measures help maintain the electrochemical stability of the system over extended periods, resulting in consistent performance and enhanced energy retention throughout the operational lifetime.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The supercapacitor hybrid systems market is currently in a growth phase, with increasing adoption across automotive and energy sectors. Market size is projected to expand significantly as companies like Volkswagen AG, Peugeot SA, and Robert Bosch GmbH integrate these systems into electric vehicles for improved energy recovery and power delivery. Technical maturity varies across applications, with companies demonstrating different specialization levels. Samsung Electro-Mechanics and GODI India focus on materials advancement, while automotive manufacturers like FCA and Next.e.GO Mobile concentrate on system integration. Research institutions including Huazhong University of Science & Technology and Loughborough University are driving fundamental innovations in cycling performance optimization. State Grid Corp. of China and NEC Laboratories represent the utility-scale implementation segment, working on grid stabilization applications with enhanced energy retention capabilities.

Samsung Electro-Mechanics Co., Ltd.

Technical Solution: Samsung Electro-Mechanics has pioneered a hybrid supercapacitor system utilizing graphene-enhanced electrode materials to significantly improve cycling stability and energy retention. Their technical approach combines high-surface-area graphene with traditional activated carbon to create composite electrodes with superior charge distribution characteristics. The system employs a proprietary electrolyte formulation that reduces internal resistance and minimizes leakage current, addressing key factors in energy retention degradation. Samsung's solution features a multi-layer electrode design that optimizes ion transport pathways, reducing diffusion limitations during rapid charge/discharge cycles. Their hybrid system incorporates advanced cell balancing technology that monitors individual supercapacitor voltages and adjusts charge distribution to prevent overcharging and extend cycle life. The company has also developed specialized packaging techniques that improve thermal conductivity and reduce moisture ingress, both critical factors affecting long-term performance stability.

Strengths: Industry-leading energy density while maintaining high power capabilities; exceptional cycling stability (>1 million cycles with minimal degradation); advanced manufacturing processes ensure consistent quality. Weaknesses: Higher production costs compared to conventional supercapacitors; temperature sensitivity at extreme operating conditions; requires specialized charging protocols for optimal performance.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced hybrid energy storage system combining supercapacitors with lithium-ion batteries for automotive applications. Their technical approach focuses on intelligent power management algorithms that dynamically distribute power demands between supercapacitors and batteries based on real-time operating conditions. The system employs a dual-converter topology that allows independent control of both energy sources, optimizing the supercapacitor's cycling performance through precise voltage regulation and temperature management. Bosch's solution incorporates adaptive state-of-charge control that maintains supercapacitors within optimal operating windows (typically 40-80% SoC) to maximize cycle life while ensuring sufficient energy availability. Their system also features regenerative braking optimization that prioritizes supercapacitor charging during deceleration events, reducing thermal stress on batteries and improving overall energy retention. Advanced thermal management systems actively regulate supercapacitor temperature to prevent degradation at operating extremes.

Strengths: Superior integration with existing automotive electrical architectures; comprehensive thermal management system extends supercapacitor lifespan; sophisticated power distribution algorithms maximize efficiency. Weaknesses: Higher system complexity increases potential failure points; requires substantial computing resources for real-time optimization; relatively higher implementation cost compared to single-storage solutions.

Key Patents and Innovations in Energy Retention

Hybrid super-capacitor / rechargeable battery system

PatentActiveUS20180166892A1

Innovation

- A hybrid super-capacitor/battery system incorporating a DC/DC converter and a hybrid algorithm that integrates battery management, super-capacitor management, and load management systems to control power flow, optimizing performance by reducing battery stress and extending cycle life through bidirectional energy routing.

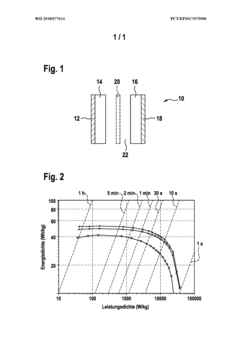

Optimized hybrid supercapacitor

PatentWO2018077614A1

Innovation

- A hybrid supercapacitor design with electrodes composed of 87.5 to 96.5% active material, 2.5 to 7.5% conductive additive, and 1 to 5% binder, where the positive electrode is a mixture of 30 to 40% LiMn2O4 and 60 to 70% activated carbon, and the negative electrode is a mixture of 20 to 30% Li4Ti5O2 and 70 to 80% activated carbon, optimized to achieve increased energy and power density.

Materials Science Advancements for Supercapacitors

Recent advancements in materials science have significantly propelled supercapacitor technology forward, addressing key challenges in energy density, cycling stability, and operational efficiency. Carbon-based materials remain at the forefront, with graphene derivatives exhibiting exceptional surface areas exceeding 2,000 m²/g, facilitating superior charge storage capabilities. Researchers have developed novel synthesis methods for reduced graphene oxide (rGO) that maintain structural integrity during extensive cycling, resulting in capacity retention rates above 95% after 10,000 cycles.

Metal oxides and hydroxides have emerged as promising pseudocapacitive materials, with manganese dioxide (MnO2) and nickel hydroxide (Ni(OH)2) demonstrating theoretical capacitances of 1,370 F/g and 2,082 F/g respectively. These materials, when integrated into hybrid systems, contribute significantly to enhanced energy density while maintaining the power characteristics inherent to supercapacitors.

Conductive polymers, particularly polyaniline (PANI) and polypyrrole (PPy), have undergone substantial refinement to address historical limitations in cycling stability. Recent innovations in polymer cross-linking techniques have yielded composites that maintain structural integrity during charge-discharge processes, reducing capacity fade by up to 40% compared to conventional formulations.

Electrolyte innovations have paralleled electrode material developments, with ionic liquids demonstrating expanded voltage windows of 3.5-4.0V, substantially increasing energy density capabilities. Novel aqueous electrolytes with additives that suppress hydrogen and oxygen evolution have extended operational voltage ranges while maintaining safety advantages inherent to water-based systems.

Interface engineering between electrode materials and electrolytes represents a critical frontier, with atomic layer deposition (ALD) techniques enabling precise control of surface functionalities. These modifications have demonstrated 30-50% improvements in charge transfer kinetics while simultaneously enhancing cycling stability through reduced parasitic reactions.

Hierarchical porous structures incorporating macro, meso, and micropores have revolutionized ion transport dynamics within electrode materials. These architecturally designed structures facilitate rapid ion diffusion while maximizing available surface area, addressing the traditional power-energy trade-off that has limited supercapacitor applications.

Composite materials combining carbon-based substrates with metal oxides or conductive polymers have demonstrated synergistic effects, where the carbon component provides conductivity and structural stability while the active material contributes pseudocapacitive behavior. These hybrid materials have achieved energy densities approaching 50 Wh/kg while maintaining power densities above 10 kW/kg, positioning them as viable solutions for applications requiring both high energy and power characteristics.

Metal oxides and hydroxides have emerged as promising pseudocapacitive materials, with manganese dioxide (MnO2) and nickel hydroxide (Ni(OH)2) demonstrating theoretical capacitances of 1,370 F/g and 2,082 F/g respectively. These materials, when integrated into hybrid systems, contribute significantly to enhanced energy density while maintaining the power characteristics inherent to supercapacitors.

Conductive polymers, particularly polyaniline (PANI) and polypyrrole (PPy), have undergone substantial refinement to address historical limitations in cycling stability. Recent innovations in polymer cross-linking techniques have yielded composites that maintain structural integrity during charge-discharge processes, reducing capacity fade by up to 40% compared to conventional formulations.

Electrolyte innovations have paralleled electrode material developments, with ionic liquids demonstrating expanded voltage windows of 3.5-4.0V, substantially increasing energy density capabilities. Novel aqueous electrolytes with additives that suppress hydrogen and oxygen evolution have extended operational voltage ranges while maintaining safety advantages inherent to water-based systems.

Interface engineering between electrode materials and electrolytes represents a critical frontier, with atomic layer deposition (ALD) techniques enabling precise control of surface functionalities. These modifications have demonstrated 30-50% improvements in charge transfer kinetics while simultaneously enhancing cycling stability through reduced parasitic reactions.

Hierarchical porous structures incorporating macro, meso, and micropores have revolutionized ion transport dynamics within electrode materials. These architecturally designed structures facilitate rapid ion diffusion while maximizing available surface area, addressing the traditional power-energy trade-off that has limited supercapacitor applications.

Composite materials combining carbon-based substrates with metal oxides or conductive polymers have demonstrated synergistic effects, where the carbon component provides conductivity and structural stability while the active material contributes pseudocapacitive behavior. These hybrid materials have achieved energy densities approaching 50 Wh/kg while maintaining power densities above 10 kW/kg, positioning them as viable solutions for applications requiring both high energy and power characteristics.

Environmental Impact and Sustainability Considerations

The environmental impact of supercapacitor hybrid systems extends far beyond their operational efficiency. These systems offer significant sustainability advantages compared to traditional energy storage technologies, particularly in terms of lifecycle environmental footprint. Supercapacitors typically utilize materials with lower toxicity profiles than conventional batteries, reducing end-of-life disposal concerns and environmental contamination risks. The absence of heavy metals and toxic electrolytes in many supercapacitor designs represents a substantial ecological advantage.

Manufacturing processes for supercapacitor components generally require less energy and produce fewer emissions than comparable battery technologies. This reduced embodied energy contributes to a lower carbon footprint across the product lifecycle. Additionally, the exceptional cycling durability of supercapacitors—often exceeding 500,000 cycles—significantly extends their operational lifespan, thereby reducing resource consumption and waste generation associated with frequent replacements.

The optimization of cycling performance and energy retention in supercapacitor hybrid systems directly enhances their sustainability profile. Improved cycling efficiency minimizes energy losses during charge-discharge cycles, reducing the overall energy consumption throughout the system's operational life. Enhanced energy retention capabilities decrease the frequency of recharging events, further lowering the cumulative energy requirements for system maintenance.

Resource efficiency represents another critical environmental consideration. Many advanced supercapacitor designs incorporate abundant materials like carbon derivatives, reducing dependence on rare earth elements and conflict minerals that plague other energy storage technologies. Research into bio-derived carbon sources for electrode materials offers promising pathways toward renewable material sourcing, potentially enabling carbon-negative manufacturing processes.

End-of-life management strategies for supercapacitor hybrid systems present both challenges and opportunities. While their components are generally less environmentally hazardous than battery alternatives, developing efficient recycling protocols remains essential for maximizing material recovery and minimizing waste. Emerging design approaches that prioritize disassembly and material separation can facilitate more effective recycling processes, creating closed-loop material cycles.

The integration of supercapacitor hybrid systems into renewable energy infrastructure amplifies their environmental benefits. By enabling more efficient energy harvesting from intermittent renewable sources, these systems can accelerate the transition away from fossil fuel dependence. Their rapid charge-discharge capabilities make them particularly valuable for smoothing output fluctuations in solar and wind generation, potentially reducing reliance on environmentally problematic backup power sources.

Manufacturing processes for supercapacitor components generally require less energy and produce fewer emissions than comparable battery technologies. This reduced embodied energy contributes to a lower carbon footprint across the product lifecycle. Additionally, the exceptional cycling durability of supercapacitors—often exceeding 500,000 cycles—significantly extends their operational lifespan, thereby reducing resource consumption and waste generation associated with frequent replacements.

The optimization of cycling performance and energy retention in supercapacitor hybrid systems directly enhances their sustainability profile. Improved cycling efficiency minimizes energy losses during charge-discharge cycles, reducing the overall energy consumption throughout the system's operational life. Enhanced energy retention capabilities decrease the frequency of recharging events, further lowering the cumulative energy requirements for system maintenance.

Resource efficiency represents another critical environmental consideration. Many advanced supercapacitor designs incorporate abundant materials like carbon derivatives, reducing dependence on rare earth elements and conflict minerals that plague other energy storage technologies. Research into bio-derived carbon sources for electrode materials offers promising pathways toward renewable material sourcing, potentially enabling carbon-negative manufacturing processes.

End-of-life management strategies for supercapacitor hybrid systems present both challenges and opportunities. While their components are generally less environmentally hazardous than battery alternatives, developing efficient recycling protocols remains essential for maximizing material recovery and minimizing waste. Emerging design approaches that prioritize disassembly and material separation can facilitate more effective recycling processes, creating closed-loop material cycles.

The integration of supercapacitor hybrid systems into renewable energy infrastructure amplifies their environmental benefits. By enabling more efficient energy harvesting from intermittent renewable sources, these systems can accelerate the transition away from fossil fuel dependence. Their rapid charge-discharge capabilities make them particularly valuable for smoothing output fluctuations in solar and wind generation, potentially reducing reliance on environmentally problematic backup power sources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!