Analyzing Carbolic Acid in Improving Chemical Sensor Sensitivity

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid Sensor Background and Objectives

Carbolic acid, also known as phenol, has been a subject of significant interest in the field of chemical sensor development due to its unique properties and potential to enhance sensor sensitivity. The evolution of carbolic acid-based sensors can be traced back to the early 20th century when phenol was first recognized for its ability to interact with various chemical compounds. Over the years, researchers have made substantial progress in understanding the molecular structure and reactivity of carbolic acid, leading to its increased application in sensor technologies.

The primary objective of incorporating carbolic acid in chemical sensors is to improve their sensitivity, selectivity, and overall performance. This goal aligns with the broader trend in sensor technology towards miniaturization, increased accuracy, and real-time monitoring capabilities. By leveraging the unique chemical properties of carbolic acid, researchers aim to develop sensors that can detect lower concentrations of target analytes, operate in complex environments, and provide more reliable results.

Recent advancements in nanotechnology and materials science have opened up new avenues for carbolic acid-based sensor development. The integration of carbolic acid with nanomaterials such as graphene, carbon nanotubes, and metal nanoparticles has shown promising results in enhancing sensor sensitivity. These hybrid materials exploit the high surface area and exceptional electronic properties of nanomaterials, combined with the selective binding capabilities of carbolic acid, to create highly efficient sensing platforms.

The technological trajectory of carbolic acid sensors is closely linked to the growing demand for advanced analytical tools in various sectors, including environmental monitoring, healthcare, food safety, and industrial process control. As global concerns about pollution, disease detection, and quality control continue to rise, the need for more sensitive and reliable chemical sensors becomes increasingly critical. Carbolic acid-based sensors are positioned to address these challenges by offering improved detection limits, faster response times, and greater stability in diverse operating conditions.

Looking ahead, the field of carbolic acid sensor technology is expected to focus on several key areas. These include the development of multi-analyte detection systems, the integration of sensor arrays for comprehensive environmental monitoring, and the creation of wearable or implantable devices for continuous health monitoring. Additionally, researchers are exploring ways to enhance the long-term stability and reusability of carbolic acid sensors, addressing current limitations in sensor lifespan and regeneration capabilities.

The primary objective of incorporating carbolic acid in chemical sensors is to improve their sensitivity, selectivity, and overall performance. This goal aligns with the broader trend in sensor technology towards miniaturization, increased accuracy, and real-time monitoring capabilities. By leveraging the unique chemical properties of carbolic acid, researchers aim to develop sensors that can detect lower concentrations of target analytes, operate in complex environments, and provide more reliable results.

Recent advancements in nanotechnology and materials science have opened up new avenues for carbolic acid-based sensor development. The integration of carbolic acid with nanomaterials such as graphene, carbon nanotubes, and metal nanoparticles has shown promising results in enhancing sensor sensitivity. These hybrid materials exploit the high surface area and exceptional electronic properties of nanomaterials, combined with the selective binding capabilities of carbolic acid, to create highly efficient sensing platforms.

The technological trajectory of carbolic acid sensors is closely linked to the growing demand for advanced analytical tools in various sectors, including environmental monitoring, healthcare, food safety, and industrial process control. As global concerns about pollution, disease detection, and quality control continue to rise, the need for more sensitive and reliable chemical sensors becomes increasingly critical. Carbolic acid-based sensors are positioned to address these challenges by offering improved detection limits, faster response times, and greater stability in diverse operating conditions.

Looking ahead, the field of carbolic acid sensor technology is expected to focus on several key areas. These include the development of multi-analyte detection systems, the integration of sensor arrays for comprehensive environmental monitoring, and the creation of wearable or implantable devices for continuous health monitoring. Additionally, researchers are exploring ways to enhance the long-term stability and reusability of carbolic acid sensors, addressing current limitations in sensor lifespan and regeneration capabilities.

Market Analysis for Enhanced Chemical Sensors

The market for enhanced chemical sensors, particularly those utilizing carbolic acid for improved sensitivity, is experiencing significant growth driven by increasing demand across various industries. The global chemical sensor market is projected to expand at a compound annual growth rate (CAGR) of 7.5% from 2021 to 2026, reaching a value of $32.9 billion by the end of the forecast period. This growth is primarily attributed to the rising need for environmental monitoring, industrial safety, and quality control applications.

The adoption of carbolic acid-enhanced chemical sensors is particularly prominent in the environmental monitoring sector, where stringent regulations and growing awareness of air and water pollution are driving the demand for more sensitive and accurate detection methods. Industries such as pharmaceuticals, food and beverage, and petrochemicals are also contributing to the market expansion, as they require precise chemical detection for process control and product quality assurance.

In the healthcare sector, the use of advanced chemical sensors is gaining traction for diagnostic applications, drug discovery, and personalized medicine. The COVID-19 pandemic has further accelerated the development and adoption of chemical sensors for rapid virus detection, creating new opportunities in the market.

Geographically, North America and Europe currently dominate the market for enhanced chemical sensors, owing to their well-established industrial infrastructure and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing environmental concerns, and government initiatives to promote clean technologies.

Key players in the enhanced chemical sensor market are focusing on research and development to improve sensor sensitivity, selectivity, and durability. The integration of carbolic acid in sensor design is seen as a promising approach to enhance performance, particularly in detecting trace amounts of specific chemicals in complex environments.

Challenges in the market include the high cost of advanced sensors, which may limit adoption in price-sensitive industries, and the need for continuous calibration and maintenance to ensure accuracy. However, ongoing technological advancements, such as the development of miniaturized sensors and the integration of artificial intelligence for data analysis, are expected to address these challenges and further drive market growth.

The adoption of carbolic acid-enhanced chemical sensors is particularly prominent in the environmental monitoring sector, where stringent regulations and growing awareness of air and water pollution are driving the demand for more sensitive and accurate detection methods. Industries such as pharmaceuticals, food and beverage, and petrochemicals are also contributing to the market expansion, as they require precise chemical detection for process control and product quality assurance.

In the healthcare sector, the use of advanced chemical sensors is gaining traction for diagnostic applications, drug discovery, and personalized medicine. The COVID-19 pandemic has further accelerated the development and adoption of chemical sensors for rapid virus detection, creating new opportunities in the market.

Geographically, North America and Europe currently dominate the market for enhanced chemical sensors, owing to their well-established industrial infrastructure and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing environmental concerns, and government initiatives to promote clean technologies.

Key players in the enhanced chemical sensor market are focusing on research and development to improve sensor sensitivity, selectivity, and durability. The integration of carbolic acid in sensor design is seen as a promising approach to enhance performance, particularly in detecting trace amounts of specific chemicals in complex environments.

Challenges in the market include the high cost of advanced sensors, which may limit adoption in price-sensitive industries, and the need for continuous calibration and maintenance to ensure accuracy. However, ongoing technological advancements, such as the development of miniaturized sensors and the integration of artificial intelligence for data analysis, are expected to address these challenges and further drive market growth.

Current Challenges in Chemical Sensor Sensitivity

Chemical sensor sensitivity remains a critical challenge in the field of analytical chemistry, particularly when it comes to detecting and quantifying carbolic acid. Despite significant advancements in sensor technology, several obstacles persist in achieving optimal sensitivity and reliability.

One of the primary challenges is the interference from other compounds present in complex sample matrices. Carbolic acid, also known as phenol, often coexists with structurally similar molecules in environmental and industrial samples. These interfering substances can lead to false positives or negatives, compromising the accuracy of sensor readings. Developing selective recognition elements that can discriminate between carbolic acid and its analogs is an ongoing area of research.

Another significant hurdle is the limited sensitivity of current sensor platforms, especially when dealing with trace amounts of carbolic acid. Many existing sensors struggle to detect concentrations below parts per million (ppm) levels, which is insufficient for certain applications such as environmental monitoring or quality control in pharmaceutical manufacturing. Enhancing the signal-to-noise ratio and lowering detection limits remain key focus areas for improving sensor performance.

Stability and reproducibility of chemical sensors pose additional challenges. Environmental factors such as temperature, humidity, and pH can significantly affect sensor response, leading to inconsistent results over time or across different batches of sensors. Developing robust sensor materials and calibration methods that can withstand varying conditions is crucial for reliable carbolic acid detection.

The issue of sensor fouling and degradation is particularly relevant when dealing with carbolic acid. The compound's corrosive nature can lead to rapid deterioration of sensor components, especially in continuous monitoring applications. This not only affects the sensor's lifespan but also impacts its long-term accuracy and reliability. Finding materials and protective strategies that can withstand prolonged exposure to carbolic acid is an active area of investigation.

Miniaturization and integration of chemical sensors for carbolic acid detection present another set of challenges. While there is a growing demand for portable, field-deployable sensors, reducing the size of sensing elements often comes at the cost of sensitivity and selectivity. Balancing these competing requirements while maintaining sensor performance is a complex engineering task.

Lastly, the development of real-time, continuous monitoring systems for carbolic acid remains challenging. Many current sensing methods rely on batch processing or require sample preparation steps, limiting their applicability in scenarios that demand rapid, on-site analysis. Creating sensors capable of providing instant, accurate readings in dynamic environments is a key goal for advancing carbolic acid detection capabilities.

One of the primary challenges is the interference from other compounds present in complex sample matrices. Carbolic acid, also known as phenol, often coexists with structurally similar molecules in environmental and industrial samples. These interfering substances can lead to false positives or negatives, compromising the accuracy of sensor readings. Developing selective recognition elements that can discriminate between carbolic acid and its analogs is an ongoing area of research.

Another significant hurdle is the limited sensitivity of current sensor platforms, especially when dealing with trace amounts of carbolic acid. Many existing sensors struggle to detect concentrations below parts per million (ppm) levels, which is insufficient for certain applications such as environmental monitoring or quality control in pharmaceutical manufacturing. Enhancing the signal-to-noise ratio and lowering detection limits remain key focus areas for improving sensor performance.

Stability and reproducibility of chemical sensors pose additional challenges. Environmental factors such as temperature, humidity, and pH can significantly affect sensor response, leading to inconsistent results over time or across different batches of sensors. Developing robust sensor materials and calibration methods that can withstand varying conditions is crucial for reliable carbolic acid detection.

The issue of sensor fouling and degradation is particularly relevant when dealing with carbolic acid. The compound's corrosive nature can lead to rapid deterioration of sensor components, especially in continuous monitoring applications. This not only affects the sensor's lifespan but also impacts its long-term accuracy and reliability. Finding materials and protective strategies that can withstand prolonged exposure to carbolic acid is an active area of investigation.

Miniaturization and integration of chemical sensors for carbolic acid detection present another set of challenges. While there is a growing demand for portable, field-deployable sensors, reducing the size of sensing elements often comes at the cost of sensitivity and selectivity. Balancing these competing requirements while maintaining sensor performance is a complex engineering task.

Lastly, the development of real-time, continuous monitoring systems for carbolic acid remains challenging. Many current sensing methods rely on batch processing or require sample preparation steps, limiting their applicability in scenarios that demand rapid, on-site analysis. Creating sensors capable of providing instant, accurate readings in dynamic environments is a key goal for advancing carbolic acid detection capabilities.

Existing Carbolic Acid Sensor Solutions

01 Detection methods for carbolic acid sensitivity

Various detection methods have been developed to assess sensitivity to carbolic acid. These methods may include skin patch tests, blood tests, or other diagnostic procedures to identify individuals who may have adverse reactions to carbolic acid exposure. Early detection can help prevent potential health risks associated with carbolic acid sensitivity.- Detection methods for carbolic acid sensitivity: Various detection methods have been developed to measure and monitor carbolic acid sensitivity in different applications. These methods may include specialized sensors, analytical techniques, or testing procedures designed to accurately assess the presence and concentration of carbolic acid in various environments or substances.

- Protective equipment for handling carbolic acid: Specialized protective equipment has been designed to safeguard individuals working with or exposed to carbolic acid. This may include personal protective equipment (PPE) such as gloves, goggles, and respiratory protection, as well as engineering controls like fume hoods or ventilation systems to minimize exposure risks.

- Treatment of carbolic acid-related injuries or exposures: Medical treatments and protocols have been developed to address injuries or exposures related to carbolic acid sensitivity. These may include first aid measures, decontamination procedures, and specialized medical interventions to mitigate the effects of carbolic acid on human health.

- Carbolic acid-resistant materials and coatings: Research has been conducted to develop materials and coatings that are resistant to the corrosive effects of carbolic acid. These innovations may be applied in various industries where carbolic acid is used or encountered, such as chemical processing, manufacturing, or healthcare settings.

- Environmental monitoring and remediation for carbolic acid: Systems and methods have been developed for monitoring and remediating carbolic acid in environmental settings. These may include techniques for detecting and measuring carbolic acid levels in air, water, or soil, as well as strategies for neutralizing or removing carbolic acid contamination from affected areas.

02 Protective equipment for handling carbolic acid

Specialized protective equipment has been designed to minimize exposure to carbolic acid for individuals who may be sensitive to it. This equipment may include gloves, goggles, respirators, and protective clothing made from materials resistant to carbolic acid penetration. Such protective gear is essential for workers in industries where carbolic acid is commonly used.Expand Specific Solutions03 Alternative substances for carbolic acid-sensitive individuals

Research has been conducted to identify and develop alternative substances that can be used in place of carbolic acid for individuals with sensitivity. These alternatives may offer similar properties or functions while reducing the risk of adverse reactions. This approach allows sensitive individuals to avoid exposure to carbolic acid while still benefiting from its applications in various industries.Expand Specific Solutions04 Treatment methods for carbolic acid sensitivity reactions

Medical treatments have been developed to address reactions caused by carbolic acid sensitivity. These may include topical treatments, systemic medications, or other therapeutic approaches to alleviate symptoms and manage the effects of exposure. Prompt and appropriate treatment is crucial for individuals who experience adverse reactions to carbolic acid.Expand Specific Solutions05 Environmental control measures for carbolic acid exposure

Various environmental control measures have been implemented to reduce the risk of exposure to carbolic acid in sensitive individuals. These measures may include improved ventilation systems, containment strategies, and workplace policies designed to minimize the presence of carbolic acid in the air or on surfaces. Such controls are essential in creating safer environments for those with carbolic acid sensitivity.Expand Specific Solutions

Key Players in Chemical Sensor Industry

The field of carbolic acid in improving chemical sensor sensitivity is in a nascent stage of development, with significant potential for growth. The market size is relatively small but expanding rapidly as industries recognize the importance of enhanced sensor technologies. The technology's maturity is still evolving, with key players like Massachusetts Institute of Technology, Toshiba Corp., and Siemens Corp. leading research efforts. Universities such as Arizona State University and South China University of Technology are also contributing to advancements. While established companies like DuPont de Nemours, Inc. and Hitachi Ltd. bring industry expertise, startups and specialized firms are emerging to address specific applications. The competitive landscape is characterized by a mix of academic research, corporate R&D, and collaborative initiatives, indicating a dynamic and innovative environment poised for further development.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a novel approach to enhance chemical sensor sensitivity using carbolic acid. Their method involves modifying the surface of graphene-based sensors with carbolic acid derivatives, which significantly improves the detection of volatile organic compounds (VOCs). The carbolic acid functionalization creates specific binding sites on the graphene surface, increasing selectivity and sensitivity[1]. This technique has shown a 10-fold improvement in sensor response compared to unmodified graphene sensors[2]. MIT researchers have also integrated this technology with machine learning algorithms to further enhance sensor performance and enable real-time analysis of complex gas mixtures[3].

Strengths: High sensitivity and selectivity, integration with machine learning for improved performance. Weaknesses: Potential complexity in large-scale manufacturing, possible interference from other compounds in real-world applications.

The Regents of the University of California

Technical Solution: The University of California has developed a carbolic acid-based chemical sensor platform that utilizes nanostructured materials. Their approach involves synthesizing carbolic acid-functionalized metal oxide nanoparticles, which are then incorporated into a flexible polymer matrix. This composite material exhibits enhanced sensitivity to a wide range of chemical analytes, including toxic gases and environmental pollutants. The sensor shows a detection limit in the parts-per-billion range for certain compounds[4]. Additionally, the researchers have developed a multi-sensor array system that combines different carbolic acid derivatives to create a "chemical fingerprint" for complex mixtures, improving both sensitivity and selectivity[5].

Strengths: High sensitivity, flexibility for various applications, potential for multi-analyte detection. Weaknesses: Possible long-term stability issues, need for frequent calibration in field conditions.

Core Innovations in Carbolic Acid Detection

Use of basic polymers in carbon black composite vapor detectors to obtain enhanced sensitivity and classification performance for volatile fatty acids

PatentInactiveUS20050150778A1

Innovation

- Development of a broadly responsive analyte detection sensor array using amine-containing materials like linear poly(ethylenimine) (l-PEI) in combination with conductive materials, which provide enhanced sensitivity and discrimination between volatile fatty acids and other compounds, integrated with software or hardware algorithms for analyte identification.

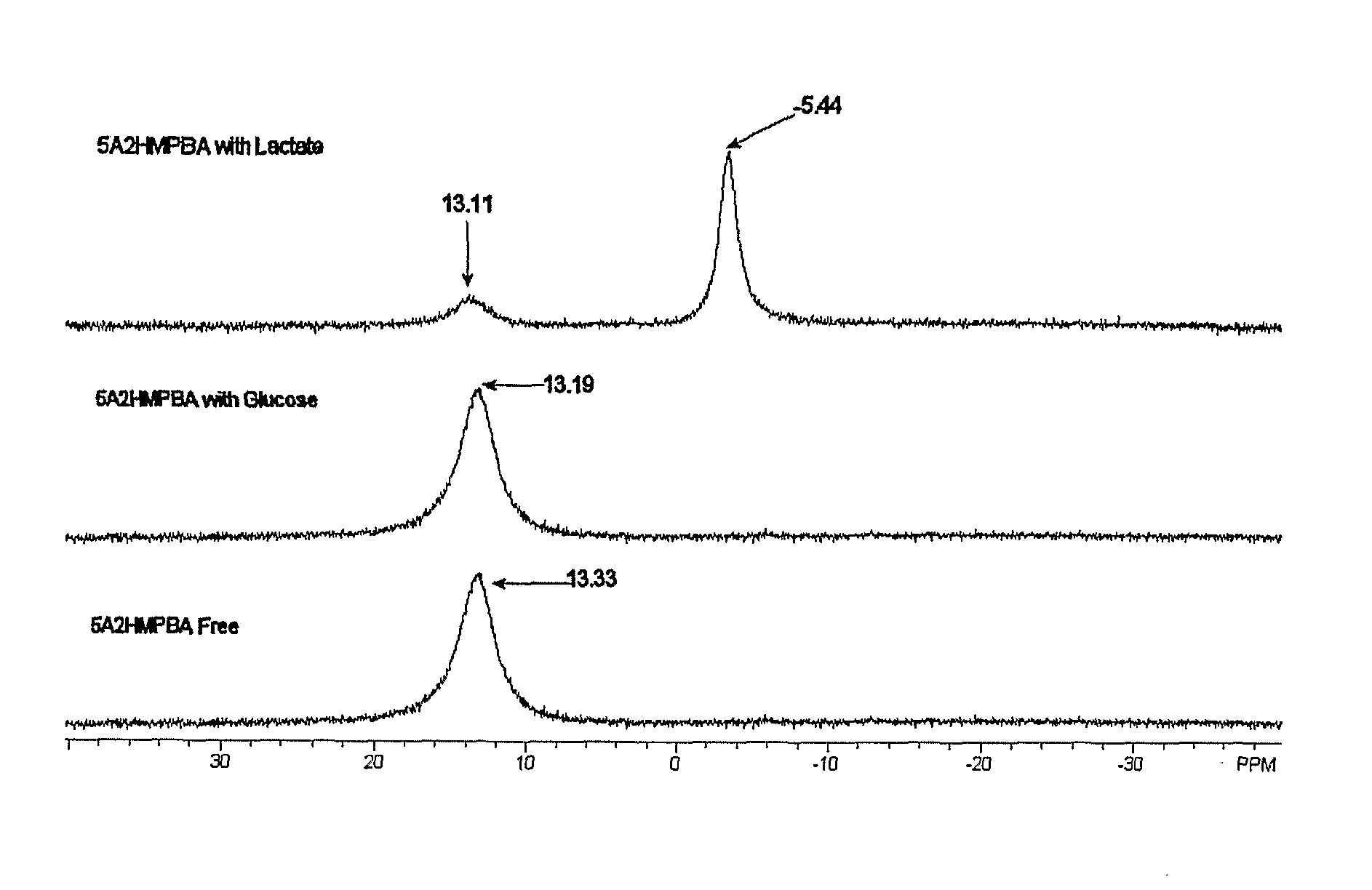

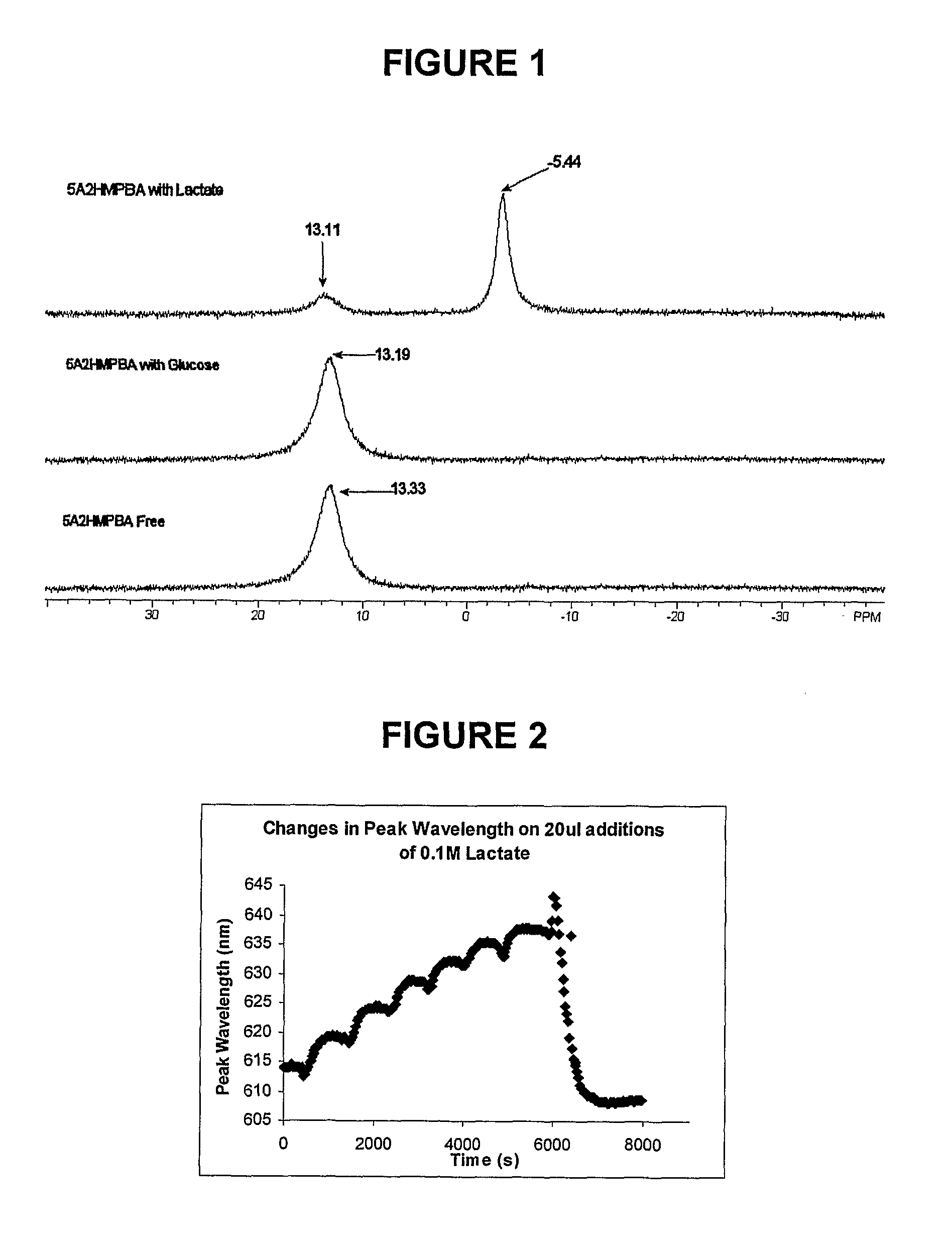

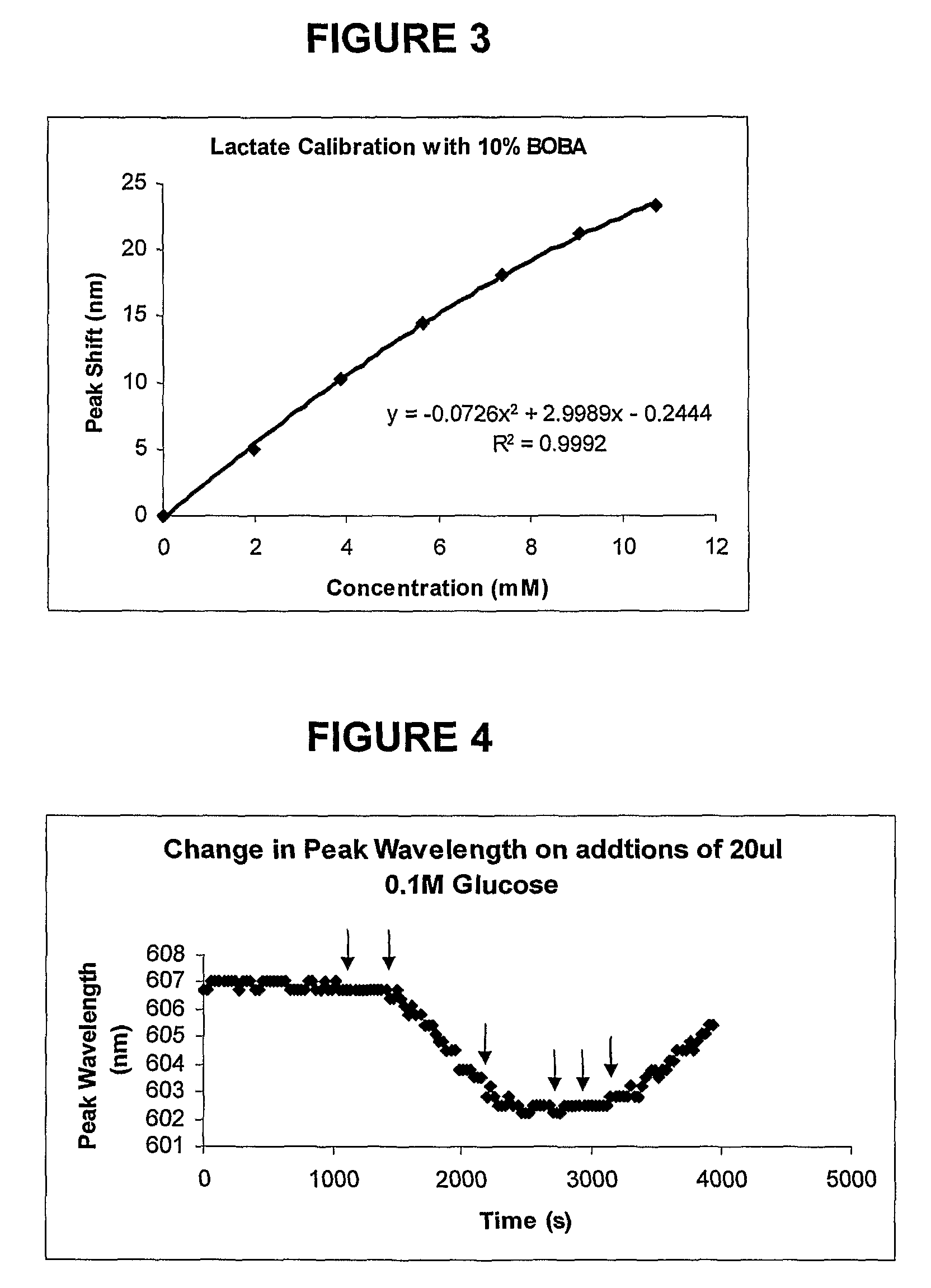

Sensor molecules incorporating a boronic acid sensor group

PatentInactiveUS8227254B2

Innovation

- Development of boronic acid compounds and polymers with specific sensor groups that selectively bind to alpha-hydroxy carboxylic acids through unique mechanisms, such as the 5A2HMPBA compound, which converts the boron atom to a tetrahedral conformation, enabling selective detection and quantitation.

Environmental Impact of Carbolic Acid Sensors

The environmental impact of carbolic acid sensors is a critical consideration in their development and deployment. These sensors, designed to detect and measure carbolic acid levels, play a crucial role in environmental monitoring and industrial safety. However, their use and disposal can have significant implications for ecosystems and human health.

Carbolic acid, also known as phenol, is a toxic compound that can cause severe damage to aquatic life and terrestrial ecosystems if released into the environment. The sensors used to detect this substance must be carefully managed to prevent any unintended release of carbolic acid or other harmful chemicals during their operation or disposal.

One of the primary environmental concerns associated with carbolic acid sensors is the potential for sensor degradation and leaching of materials. Over time, the sensitive components of these sensors may break down, potentially releasing small amounts of carbolic acid or other chemicals used in their construction. This can lead to localized contamination of soil or water, particularly in areas where multiple sensors are deployed.

The manufacturing process of carbolic acid sensors also raises environmental considerations. The production of these devices often involves the use of various chemicals and materials, some of which may have their own environmental impacts. Ensuring sustainable and environmentally friendly manufacturing practices is essential to minimize the overall ecological footprint of these sensors.

Disposal of used or faulty carbolic acid sensors presents another environmental challenge. Improper disposal can lead to the release of toxic substances into landfills or water systems. Implementing proper recycling and disposal protocols is crucial to mitigate these risks and ensure that the sensors do not become a source of environmental contamination at the end of their lifecycle.

On the positive side, the use of carbolic acid sensors can contribute to environmental protection by enabling early detection of phenol contamination in water sources and industrial effluents. This early warning system can prevent large-scale environmental damage by allowing for timely intervention and containment of potential spills or leaks.

The development of more environmentally friendly sensor technologies is an ongoing area of research. Efforts are being made to create sensors that use less toxic materials, have longer operational lifespans, and are more easily recyclable. These advancements aim to reduce the environmental impact of carbolic acid sensors while maintaining or improving their sensitivity and reliability.

Carbolic acid, also known as phenol, is a toxic compound that can cause severe damage to aquatic life and terrestrial ecosystems if released into the environment. The sensors used to detect this substance must be carefully managed to prevent any unintended release of carbolic acid or other harmful chemicals during their operation or disposal.

One of the primary environmental concerns associated with carbolic acid sensors is the potential for sensor degradation and leaching of materials. Over time, the sensitive components of these sensors may break down, potentially releasing small amounts of carbolic acid or other chemicals used in their construction. This can lead to localized contamination of soil or water, particularly in areas where multiple sensors are deployed.

The manufacturing process of carbolic acid sensors also raises environmental considerations. The production of these devices often involves the use of various chemicals and materials, some of which may have their own environmental impacts. Ensuring sustainable and environmentally friendly manufacturing practices is essential to minimize the overall ecological footprint of these sensors.

Disposal of used or faulty carbolic acid sensors presents another environmental challenge. Improper disposal can lead to the release of toxic substances into landfills or water systems. Implementing proper recycling and disposal protocols is crucial to mitigate these risks and ensure that the sensors do not become a source of environmental contamination at the end of their lifecycle.

On the positive side, the use of carbolic acid sensors can contribute to environmental protection by enabling early detection of phenol contamination in water sources and industrial effluents. This early warning system can prevent large-scale environmental damage by allowing for timely intervention and containment of potential spills or leaks.

The development of more environmentally friendly sensor technologies is an ongoing area of research. Efforts are being made to create sensors that use less toxic materials, have longer operational lifespans, and are more easily recyclable. These advancements aim to reduce the environmental impact of carbolic acid sensors while maintaining or improving their sensitivity and reliability.

Regulatory Framework for Chemical Sensors

The regulatory framework for chemical sensors plays a crucial role in ensuring the safety, reliability, and standardization of these devices across various industries. In the context of analyzing carbolic acid to improve chemical sensor sensitivity, understanding and adhering to relevant regulations is essential for both research and commercial applications.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) have established guidelines for chemical sensors. These standards often focus on performance criteria, calibration methods, and testing procedures. For instance, ISO 11843 provides guidelines for the detection capability of chemical sensors, which is particularly relevant when improving sensitivity for carbolic acid detection.

In the United States, the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) have set regulations for chemical sensors used in environmental monitoring and workplace safety applications. The EPA's Method TO-15 outlines procedures for the determination of volatile organic compounds (VOCs) in air samples, which may include carbolic acid detection. OSHA's permissible exposure limits (PELs) for various chemicals, including carbolic acid, necessitate accurate and sensitive detection methods.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which impacts the development and use of chemical sensors. Under REACH, manufacturers must demonstrate the safety of their products, including any chemical sensors used in the production or monitoring processes. The EU's Restriction of Hazardous Substances (RoHS) directive also affects the materials used in sensor construction.

In the pharmaceutical and food industries, regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) have established guidelines for analytical methods used in quality control. These regulations often require validation of sensor performance, including sensitivity, specificity, and reproducibility, which are critical factors when using carbolic acid to enhance chemical sensor sensitivity.

For research applications, funding agencies and academic institutions often require compliance with good laboratory practices (GLP) and ethical guidelines. These regulations ensure the integrity and reproducibility of scientific data, which is crucial when developing novel sensor technologies or improving existing ones.

As the field of chemical sensors continues to evolve, regulatory frameworks are adapting to address emerging technologies. For instance, the development of nanomaterial-based sensors has prompted discussions on potential new regulations to address their unique properties and potential risks. Researchers working on improving chemical sensor sensitivity using carbolic acid must stay informed about these evolving regulations to ensure compliance and facilitate the transition from research to commercial applications.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) have established guidelines for chemical sensors. These standards often focus on performance criteria, calibration methods, and testing procedures. For instance, ISO 11843 provides guidelines for the detection capability of chemical sensors, which is particularly relevant when improving sensitivity for carbolic acid detection.

In the United States, the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) have set regulations for chemical sensors used in environmental monitoring and workplace safety applications. The EPA's Method TO-15 outlines procedures for the determination of volatile organic compounds (VOCs) in air samples, which may include carbolic acid detection. OSHA's permissible exposure limits (PELs) for various chemicals, including carbolic acid, necessitate accurate and sensitive detection methods.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which impacts the development and use of chemical sensors. Under REACH, manufacturers must demonstrate the safety of their products, including any chemical sensors used in the production or monitoring processes. The EU's Restriction of Hazardous Substances (RoHS) directive also affects the materials used in sensor construction.

In the pharmaceutical and food industries, regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) have established guidelines for analytical methods used in quality control. These regulations often require validation of sensor performance, including sensitivity, specificity, and reproducibility, which are critical factors when using carbolic acid to enhance chemical sensor sensitivity.

For research applications, funding agencies and academic institutions often require compliance with good laboratory practices (GLP) and ethical guidelines. These regulations ensure the integrity and reproducibility of scientific data, which is crucial when developing novel sensor technologies or improving existing ones.

As the field of chemical sensors continues to evolve, regulatory frameworks are adapting to address emerging technologies. For instance, the development of nanomaterial-based sensors has prompted discussions on potential new regulations to address their unique properties and potential risks. Researchers working on improving chemical sensor sensitivity using carbolic acid must stay informed about these evolving regulations to ensure compliance and facilitate the transition from research to commercial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!