Carbolic Acid Contributions to Non-VOC Paint Innovations

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid Paint Tech Evolution

The evolution of carbolic acid in paint technology represents a significant milestone in the development of non-VOC (Volatile Organic Compound) paint innovations. This journey began in the early 20th century when carbolic acid, also known as phenol, was first recognized for its potential in paint formulations. Initially, its use was limited due to its strong odor and potential health hazards.

In the 1950s, researchers discovered that carbolic acid could be modified to create phenolic resins, which offered improved durability and chemical resistance in paints. This breakthrough led to the development of phenolic-based coatings that found applications in industrial settings where harsh conditions prevailed. However, these early formulations still contained high levels of VOCs, which posed environmental and health concerns.

The 1970s marked a turning point in paint technology with the growing awareness of environmental issues. This period saw increased efforts to reduce VOC emissions in paints, prompting researchers to explore new ways of utilizing carbolic acid derivatives. The focus shifted towards developing water-based phenolic resins that could maintain the desirable properties of traditional phenolic coatings while significantly reducing VOC content.

By the 1990s, advanced polymerization techniques enabled the creation of low-VOC phenolic dispersions. These innovations allowed for the formulation of paints that combined the durability of phenolic resins with improved environmental performance. This era also saw the introduction of phenol-formaldehyde resins modified with renewable resources, further enhancing the sustainability profile of carbolic acid-based paints.

The early 2000s witnessed a surge in research aimed at completely eliminating VOCs from phenolic paint formulations. Scientists explored novel crosslinking mechanisms and developed hybrid systems that incorporated carbolic acid derivatives with other eco-friendly components. These efforts resulted in the creation of ultra-low VOC and zero-VOC phenolic paints that maintained excellent adhesion, chemical resistance, and durability.

In recent years, the focus has shifted towards enhancing the functionality of carbolic acid-based paints. Researchers have been exploring the incorporation of nanoparticles and smart materials into phenolic resin systems to create self-healing, anti-microbial, and even energy-harvesting coatings. These advancements are pushing the boundaries of what's possible with non-VOC paint technologies, opening up new applications in sectors ranging from construction to aerospace.

The ongoing evolution of carbolic acid in paint technology continues to drive innovation in the field of sustainable coatings. Current research is exploring bio-based sources of phenolic compounds and investigating novel polymerization techniques to further improve the performance and environmental profile of these paints. As regulations become increasingly stringent and consumer demand for eco-friendly products grows, the role of carbolic acid and its derivatives in non-VOC paint innovations is expected to remain crucial in shaping the future of the coatings industry.

In the 1950s, researchers discovered that carbolic acid could be modified to create phenolic resins, which offered improved durability and chemical resistance in paints. This breakthrough led to the development of phenolic-based coatings that found applications in industrial settings where harsh conditions prevailed. However, these early formulations still contained high levels of VOCs, which posed environmental and health concerns.

The 1970s marked a turning point in paint technology with the growing awareness of environmental issues. This period saw increased efforts to reduce VOC emissions in paints, prompting researchers to explore new ways of utilizing carbolic acid derivatives. The focus shifted towards developing water-based phenolic resins that could maintain the desirable properties of traditional phenolic coatings while significantly reducing VOC content.

By the 1990s, advanced polymerization techniques enabled the creation of low-VOC phenolic dispersions. These innovations allowed for the formulation of paints that combined the durability of phenolic resins with improved environmental performance. This era also saw the introduction of phenol-formaldehyde resins modified with renewable resources, further enhancing the sustainability profile of carbolic acid-based paints.

The early 2000s witnessed a surge in research aimed at completely eliminating VOCs from phenolic paint formulations. Scientists explored novel crosslinking mechanisms and developed hybrid systems that incorporated carbolic acid derivatives with other eco-friendly components. These efforts resulted in the creation of ultra-low VOC and zero-VOC phenolic paints that maintained excellent adhesion, chemical resistance, and durability.

In recent years, the focus has shifted towards enhancing the functionality of carbolic acid-based paints. Researchers have been exploring the incorporation of nanoparticles and smart materials into phenolic resin systems to create self-healing, anti-microbial, and even energy-harvesting coatings. These advancements are pushing the boundaries of what's possible with non-VOC paint technologies, opening up new applications in sectors ranging from construction to aerospace.

The ongoing evolution of carbolic acid in paint technology continues to drive innovation in the field of sustainable coatings. Current research is exploring bio-based sources of phenolic compounds and investigating novel polymerization techniques to further improve the performance and environmental profile of these paints. As regulations become increasingly stringent and consumer demand for eco-friendly products grows, the role of carbolic acid and its derivatives in non-VOC paint innovations is expected to remain crucial in shaping the future of the coatings industry.

Non-VOC Paint Market Dynamics

The non-VOC paint market has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations on volatile organic compound emissions. This market segment has emerged as a key focus for paint manufacturers and consumers alike, seeking sustainable and eco-friendly alternatives to traditional solvent-based paints.

The global non-VOC paint market is expanding rapidly, with a compound annual growth rate (CAGR) projected to exceed 6% over the next five years. This growth is primarily fueled by the construction industry's shift towards green building practices and the rising demand for healthier indoor environments. Residential and commercial sectors are the major contributors to this market expansion, with a notable increase in adoption across healthcare facilities, educational institutions, and hospitality venues.

Consumer preferences are evolving, with a growing emphasis on products that offer both environmental benefits and high performance. This trend has led to increased research and development efforts in non-VOC paint formulations, including those incorporating carbolic acid derivatives. These innovations aim to address common concerns associated with traditional non-VOC paints, such as durability, color retention, and ease of application.

Regulatory frameworks play a crucial role in shaping the non-VOC paint market dynamics. Governments worldwide are implementing stricter guidelines on VOC emissions, particularly in developed regions like North America and Europe. These regulations are not only driving the adoption of non-VOC paints but also influencing product development strategies among manufacturers.

The competitive landscape of the non-VOC paint market is characterized by a mix of established paint manufacturers and innovative startups. Major players are investing heavily in research and development to enhance their product portfolios and gain a competitive edge. Collaborations between paint manufacturers and chemical companies are becoming more common, fostering the development of advanced non-VOC formulations.

Regional market dynamics vary significantly, with mature markets like North America and Europe showing steady growth, while emerging economies in Asia-Pacific and Latin America present high-growth opportunities. The Asia-Pacific region, in particular, is expected to witness the fastest growth rate in the non-VOC paint market, driven by rapid urbanization, increasing disposable incomes, and growing environmental consciousness.

Challenges in the non-VOC paint market include the higher production costs compared to traditional paints, which can impact pricing and market penetration. Additionally, performance issues such as longer drying times and reduced durability in certain applications continue to be areas of focus for improvement. The integration of carbolic acid derivatives in non-VOC paint formulations is being explored as a potential solution to address some of these challenges, offering promising avenues for market expansion and product enhancement.

The global non-VOC paint market is expanding rapidly, with a compound annual growth rate (CAGR) projected to exceed 6% over the next five years. This growth is primarily fueled by the construction industry's shift towards green building practices and the rising demand for healthier indoor environments. Residential and commercial sectors are the major contributors to this market expansion, with a notable increase in adoption across healthcare facilities, educational institutions, and hospitality venues.

Consumer preferences are evolving, with a growing emphasis on products that offer both environmental benefits and high performance. This trend has led to increased research and development efforts in non-VOC paint formulations, including those incorporating carbolic acid derivatives. These innovations aim to address common concerns associated with traditional non-VOC paints, such as durability, color retention, and ease of application.

Regulatory frameworks play a crucial role in shaping the non-VOC paint market dynamics. Governments worldwide are implementing stricter guidelines on VOC emissions, particularly in developed regions like North America and Europe. These regulations are not only driving the adoption of non-VOC paints but also influencing product development strategies among manufacturers.

The competitive landscape of the non-VOC paint market is characterized by a mix of established paint manufacturers and innovative startups. Major players are investing heavily in research and development to enhance their product portfolios and gain a competitive edge. Collaborations between paint manufacturers and chemical companies are becoming more common, fostering the development of advanced non-VOC formulations.

Regional market dynamics vary significantly, with mature markets like North America and Europe showing steady growth, while emerging economies in Asia-Pacific and Latin America present high-growth opportunities. The Asia-Pacific region, in particular, is expected to witness the fastest growth rate in the non-VOC paint market, driven by rapid urbanization, increasing disposable incomes, and growing environmental consciousness.

Challenges in the non-VOC paint market include the higher production costs compared to traditional paints, which can impact pricing and market penetration. Additionally, performance issues such as longer drying times and reduced durability in certain applications continue to be areas of focus for improvement. The integration of carbolic acid derivatives in non-VOC paint formulations is being explored as a potential solution to address some of these challenges, offering promising avenues for market expansion and product enhancement.

Carbolic Acid Paint Challenges

The development of non-VOC paints faces several significant challenges related to carbolic acid contributions. One of the primary obstacles is achieving the desired performance characteristics without relying on traditional volatile organic compounds (VOCs). Carbolic acid, also known as phenol, presents unique properties that can potentially address some of these challenges, but its integration into paint formulations is not without difficulties.

A major hurdle is maintaining paint stability and shelf life when incorporating carbolic acid. The compound's reactivity can lead to unwanted chemical interactions with other paint components, potentially causing degradation or changes in viscosity over time. This necessitates careful formulation and extensive stability testing to ensure product longevity.

Another challenge lies in achieving optimal drying and curing times for carbolic acid-based paints. The absence of traditional VOCs, which often contribute to faster drying, means that alternative mechanisms must be developed to ensure practical application and efficient curing. This is particularly crucial for industrial and commercial applications where rapid turnaround times are essential.

The impact of carbolic acid on paint adhesion and durability also presents a significant challenge. While it may offer certain benefits in terms of antimicrobial properties, its incorporation must not compromise the paint's ability to adhere to various substrates or its resistance to weathering and wear. Balancing these properties requires extensive research and development efforts.

Color stability and consistency pose another challenge in carbolic acid-based non-VOC paints. The compound's potential to interact with pigments or undergo oxidation over time may lead to color shifts or fading. Developing stable color formulations that maintain their integrity throughout the paint's lifecycle is crucial for market acceptance and product reliability.

Environmental and health considerations also play a role in the challenges faced by carbolic acid paint innovations. While the goal is to reduce VOC emissions, the use of carbolic acid must be carefully managed to ensure that it does not introduce new health or environmental risks. This includes addressing potential odor issues and ensuring that the final product meets stringent safety and environmental regulations.

Lastly, cost-effectiveness and scalability present ongoing challenges in the development of carbolic acid-based non-VOC paints. The need for specialized formulations and potentially higher-grade raw materials can increase production costs. Balancing these costs with performance benefits and market demand requires strategic planning and innovative approaches to manufacturing and supply chain management.

A major hurdle is maintaining paint stability and shelf life when incorporating carbolic acid. The compound's reactivity can lead to unwanted chemical interactions with other paint components, potentially causing degradation or changes in viscosity over time. This necessitates careful formulation and extensive stability testing to ensure product longevity.

Another challenge lies in achieving optimal drying and curing times for carbolic acid-based paints. The absence of traditional VOCs, which often contribute to faster drying, means that alternative mechanisms must be developed to ensure practical application and efficient curing. This is particularly crucial for industrial and commercial applications where rapid turnaround times are essential.

The impact of carbolic acid on paint adhesion and durability also presents a significant challenge. While it may offer certain benefits in terms of antimicrobial properties, its incorporation must not compromise the paint's ability to adhere to various substrates or its resistance to weathering and wear. Balancing these properties requires extensive research and development efforts.

Color stability and consistency pose another challenge in carbolic acid-based non-VOC paints. The compound's potential to interact with pigments or undergo oxidation over time may lead to color shifts or fading. Developing stable color formulations that maintain their integrity throughout the paint's lifecycle is crucial for market acceptance and product reliability.

Environmental and health considerations also play a role in the challenges faced by carbolic acid paint innovations. While the goal is to reduce VOC emissions, the use of carbolic acid must be carefully managed to ensure that it does not introduce new health or environmental risks. This includes addressing potential odor issues and ensuring that the final product meets stringent safety and environmental regulations.

Lastly, cost-effectiveness and scalability present ongoing challenges in the development of carbolic acid-based non-VOC paints. The need for specialized formulations and potentially higher-grade raw materials can increase production costs. Balancing these costs with performance benefits and market demand requires strategic planning and innovative approaches to manufacturing and supply chain management.

Carbolic Acid Paint Solutions

01 VOC content measurement in carbolic acid

Methods and devices for measuring the volatile organic compound (VOC) content in carbolic acid, also known as phenol. These techniques may involve gas chromatography, mass spectrometry, or other analytical methods to quantify the VOC levels in carbolic acid samples.- VOC content measurement in carbolic acid: Methods and devices for measuring the volatile organic compound (VOC) content in carbolic acid, also known as phenol. These techniques may involve gas chromatography, mass spectrometry, or other analytical methods to quantify the VOC levels in carbolic acid samples.

- Reduction of VOC emissions in carbolic acid production: Processes and systems designed to minimize VOC emissions during the manufacturing of carbolic acid. These may include improved reactor designs, enhanced distillation techniques, or the use of catalysts to reduce the formation of volatile byproducts.

- Carbolic acid purification to reduce VOC content: Purification methods aimed at reducing the VOC content in carbolic acid. These techniques may involve adsorption, extraction, or advanced separation processes to remove volatile impurities and improve the purity of the final product.

- VOC monitoring systems for carbolic acid storage: Specialized monitoring systems and equipment designed to detect and measure VOC emissions from carbolic acid storage facilities. These systems may employ sensors, alarms, and data logging capabilities to ensure compliance with environmental regulations and worker safety standards.

- Environmental impact assessment of carbolic acid VOCs: Studies and methodologies for assessing the environmental impact of VOCs released from carbolic acid production and use. This may include air quality modeling, risk assessment techniques, and the development of mitigation strategies to minimize the ecological footprint of carbolic acid-related VOC emissions.

02 Reduction of VOC emissions in carbolic acid production

Processes and technologies aimed at reducing VOC emissions during the production of carbolic acid. This may include improved reactor designs, catalytic processes, or the use of scrubbers and other emission control systems to minimize the release of volatile organic compounds.Expand Specific Solutions03 Carbolic acid purification to remove VOCs

Purification techniques for removing volatile organic compounds from carbolic acid. These methods may involve distillation, adsorption, or other separation processes to reduce the VOC content and improve the purity of the final product.Expand Specific Solutions04 VOC-compliant formulations containing carbolic acid

Development of formulations that include carbolic acid while maintaining low VOC content to meet environmental regulations. This may involve the use of alternative solvents, encapsulation techniques, or other formulation strategies to reduce overall VOC emissions.Expand Specific Solutions05 Monitoring and control systems for carbolic acid VOC emissions

Implementation of monitoring and control systems to track and manage VOC emissions associated with carbolic acid in industrial settings. This may include the use of sensors, data analytics, and automated control systems to ensure compliance with environmental standards and optimize production processes.Expand Specific Solutions

Key Non-VOC Paint Innovators

The carbolic acid contributions to non-VOC paint innovations market is in a growth phase, driven by increasing environmental regulations and consumer demand for eco-friendly products. The market size is expanding as more companies invest in research and development of low-VOC and zero-VOC paint formulations. Technologically, the field is advancing rapidly, with companies like Dow Global Technologies, BASF Coatings, and Asian Paints leading innovation. These firms are developing novel carbolic acid-based additives and binders to enhance paint performance while reducing volatile organic compounds. Other key players such as Kansai Paint and Covestro are also making significant strides in this area, indicating a competitive and dynamic market landscape.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies LLC has developed innovative non-VOC paint formulations utilizing carbolic acid derivatives. Their approach involves incorporating phenolic compounds as reactive diluents in waterborne coatings[1]. These compounds act as co-solvents during application but become chemically bound in the final film, reducing VOC emissions. The company has also explored the use of phenol-formaldehyde resins as crosslinking agents in low-VOC systems[2]. Additionally, Dow has patented a method for producing low-VOC alkyd resins using phenolic compounds as modifiers, which enhances the drying properties and durability of the resulting coatings[3].

Strengths: Extensive expertise in polymer chemistry and resin technology. Large R&D capabilities for developing novel formulations. Weaknesses: May face challenges in scaling up production of new resins. Potential regulatory hurdles for introducing new chemical compounds in coatings.

BASF Coatings GmbH

Technical Solution: BASF Coatings GmbH has made significant strides in non-VOC paint innovations using carbolic acid derivatives. They have developed a series of water-based acrylic dispersions incorporating phenol-modified epoxy resins, which provide excellent adhesion and corrosion resistance[4]. BASF has also introduced a line of high-solid polyurethane coatings using phenolic polyols as reactive diluents, achieving VOC levels below 250 g/L while maintaining high performance[5]. Furthermore, the company has patented a process for producing low-VOC alkyd resins using phenol-formaldehyde condensates as modifiers, improving the drying speed and hardness of the final coating[6].

Strengths: Strong position in the global coatings market. Extensive research capabilities and technical expertise. Weaknesses: High investment costs for developing and implementing new technologies. Potential challenges in meeting diverse regional regulatory requirements.

Carbolic Acid Paint Patents

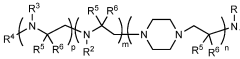

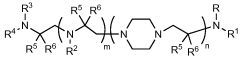

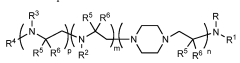

Aminoalcohol compounds and their use as zero or low VOC additives for paints and coatings

PatentWO2013016269A1

Innovation

- Aminoalcohol compounds with specific structures are used as neutralizing agents and freeze-thaw stabilizers, providing low or no VOC and low amine odor, while maintaining performance properties such as scrub resistance and corrosion resistance, and are synthesized by reacting amines with alkylene or arylene oxides.

Non-VOC neutralizing agents for coatings

PatentActiveCA2866869C

Innovation

- The use of neutralized zwitterionic compounds, specifically amino acids with a pKa2 of at least 9.0, such as neutralized isoleucine, which form a film and effectively neutralize paint formulations without adding VOCs, maintaining a stable pH and reducing odor concerns.

Environmental Regulations Impact

Environmental regulations have played a pivotal role in shaping the development and adoption of non-VOC paint innovations, particularly those involving carbolic acid contributions. The increasing global focus on reducing volatile organic compound (VOC) emissions has led to stringent regulations in many countries, driving the paint industry towards more environmentally friendly solutions.

In the United States, the Environmental Protection Agency (EPA) has implemented strict guidelines on VOC content in paints and coatings. The Clean Air Act and subsequent amendments have set limits on VOC emissions, forcing manufacturers to reformulate their products. Similarly, the European Union has introduced the VOC Solvents Emissions Directive, which has been progressively tightened over the years.

These regulations have created a significant market demand for non-VOC and low-VOC paint alternatives. Carbolic acid, also known as phenol, has emerged as a key component in meeting these regulatory requirements. Its unique properties allow for the development of water-based and solvent-free paint formulations that comply with stringent environmental standards.

The impact of these regulations extends beyond product formulation. They have influenced manufacturing processes, requiring companies to invest in new technologies and equipment to reduce VOC emissions during production. This has led to the development of innovative application methods and advanced curing techniques that minimize environmental impact.

Furthermore, environmental regulations have spurred research and development efforts in the field of non-VOC paints. Government incentives and funding programs have been established to support the transition to greener technologies. This has accelerated the pace of innovation, leading to breakthroughs in carbolic acid-based paint formulations that offer improved performance while meeting regulatory standards.

The regulatory landscape has also shaped consumer preferences and market dynamics. As awareness of environmental issues grows, consumers are increasingly demanding eco-friendly paint options. This shift in consumer behavior, driven by regulatory pressures, has created new market opportunities for companies specializing in non-VOC paint technologies.

However, the impact of environmental regulations is not uniform across all regions. Developing countries often have less stringent VOC regulations, creating challenges for global paint manufacturers who must navigate varying standards. This has led to the development of adaptable formulations that can be easily modified to meet different regional requirements.

In conclusion, environmental regulations have been a powerful catalyst for innovation in non-VOC paint technologies, particularly those leveraging carbolic acid contributions. They have reshaped the industry landscape, driving technological advancements, altering market dynamics, and ultimately contributing to a more sustainable future for the paint and coatings sector.

In the United States, the Environmental Protection Agency (EPA) has implemented strict guidelines on VOC content in paints and coatings. The Clean Air Act and subsequent amendments have set limits on VOC emissions, forcing manufacturers to reformulate their products. Similarly, the European Union has introduced the VOC Solvents Emissions Directive, which has been progressively tightened over the years.

These regulations have created a significant market demand for non-VOC and low-VOC paint alternatives. Carbolic acid, also known as phenol, has emerged as a key component in meeting these regulatory requirements. Its unique properties allow for the development of water-based and solvent-free paint formulations that comply with stringent environmental standards.

The impact of these regulations extends beyond product formulation. They have influenced manufacturing processes, requiring companies to invest in new technologies and equipment to reduce VOC emissions during production. This has led to the development of innovative application methods and advanced curing techniques that minimize environmental impact.

Furthermore, environmental regulations have spurred research and development efforts in the field of non-VOC paints. Government incentives and funding programs have been established to support the transition to greener technologies. This has accelerated the pace of innovation, leading to breakthroughs in carbolic acid-based paint formulations that offer improved performance while meeting regulatory standards.

The regulatory landscape has also shaped consumer preferences and market dynamics. As awareness of environmental issues grows, consumers are increasingly demanding eco-friendly paint options. This shift in consumer behavior, driven by regulatory pressures, has created new market opportunities for companies specializing in non-VOC paint technologies.

However, the impact of environmental regulations is not uniform across all regions. Developing countries often have less stringent VOC regulations, creating challenges for global paint manufacturers who must navigate varying standards. This has led to the development of adaptable formulations that can be easily modified to meet different regional requirements.

In conclusion, environmental regulations have been a powerful catalyst for innovation in non-VOC paint technologies, particularly those leveraging carbolic acid contributions. They have reshaped the industry landscape, driving technological advancements, altering market dynamics, and ultimately contributing to a more sustainable future for the paint and coatings sector.

Health Safety Considerations

The incorporation of carbolic acid in non-VOC paint formulations necessitates careful consideration of health and safety aspects. Carbolic acid, also known as phenol, is a toxic compound that can cause severe burns and systemic poisoning upon exposure. Therefore, stringent safety measures must be implemented throughout the production, handling, and application processes of these innovative paints.

In manufacturing facilities, proper ventilation systems and personal protective equipment (PPE) are crucial. Workers must wear chemical-resistant gloves, protective eyewear, and respiratory protection to minimize the risk of exposure. Adequate training on the safe handling of carbolic acid and emergency response procedures should be provided to all personnel involved in the production process.

During paint application, professional users and consumers must be informed about the potential health risks associated with carbolic acid-containing paints. Clear labeling and comprehensive safety data sheets (SDS) should accompany the products, detailing proper usage, storage, and disposal methods. It is essential to emphasize the importance of using these paints in well-ventilated areas and avoiding skin contact or inhalation of fumes.

Environmental considerations are equally important. Proper disposal methods for unused paint and contaminated materials must be established to prevent soil and water pollution. Manufacturers should develop recycling programs or safe disposal guidelines to minimize environmental impact and protect ecosystems from carbolic acid contamination.

Long-term exposure risks must also be evaluated. While the incorporation of carbolic acid in non-VOC paints aims to reduce volatile organic compound emissions, the potential for off-gassing of phenol over time should be thoroughly investigated. Indoor air quality assessments and long-term exposure studies are necessary to ensure the safety of occupants in painted environments.

Regulatory compliance is a critical aspect of health and safety considerations. Manufacturers must adhere to local, national, and international regulations governing the use of carbolic acid in consumer products. This includes obtaining necessary certifications, conducting rigorous safety testing, and maintaining transparent communication with regulatory bodies regarding the paint's composition and potential risks.

Ongoing research and development efforts should focus on finding safer alternatives or developing encapsulation technologies that can further reduce the risks associated with carbolic acid in paint formulations. This proactive approach will help address potential health and safety concerns while continuing to advance non-VOC paint innovations.

In manufacturing facilities, proper ventilation systems and personal protective equipment (PPE) are crucial. Workers must wear chemical-resistant gloves, protective eyewear, and respiratory protection to minimize the risk of exposure. Adequate training on the safe handling of carbolic acid and emergency response procedures should be provided to all personnel involved in the production process.

During paint application, professional users and consumers must be informed about the potential health risks associated with carbolic acid-containing paints. Clear labeling and comprehensive safety data sheets (SDS) should accompany the products, detailing proper usage, storage, and disposal methods. It is essential to emphasize the importance of using these paints in well-ventilated areas and avoiding skin contact or inhalation of fumes.

Environmental considerations are equally important. Proper disposal methods for unused paint and contaminated materials must be established to prevent soil and water pollution. Manufacturers should develop recycling programs or safe disposal guidelines to minimize environmental impact and protect ecosystems from carbolic acid contamination.

Long-term exposure risks must also be evaluated. While the incorporation of carbolic acid in non-VOC paints aims to reduce volatile organic compound emissions, the potential for off-gassing of phenol over time should be thoroughly investigated. Indoor air quality assessments and long-term exposure studies are necessary to ensure the safety of occupants in painted environments.

Regulatory compliance is a critical aspect of health and safety considerations. Manufacturers must adhere to local, national, and international regulations governing the use of carbolic acid in consumer products. This includes obtaining necessary certifications, conducting rigorous safety testing, and maintaining transparent communication with regulatory bodies regarding the paint's composition and potential risks.

Ongoing research and development efforts should focus on finding safer alternatives or developing encapsulation technologies that can further reduce the risks associated with carbolic acid in paint formulations. This proactive approach will help address potential health and safety concerns while continuing to advance non-VOC paint innovations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!