The Use of Carbolic Acid in Biodegradable Straw Manufacturing

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid in Biostraw: Background and Objectives

Carbolic acid, also known as phenol, has emerged as a promising component in the manufacturing of biodegradable straws, marking a significant advancement in sustainable packaging solutions. This innovative application addresses the growing global concern over plastic pollution, particularly in single-use items like drinking straws. The use of carbolic acid in biostraw production represents a convergence of chemical engineering and environmental science, aiming to create a product that maintains functionality while minimizing ecological impact.

The development of biodegradable straws using carbolic acid is rooted in the broader context of the circular economy and the urgent need to reduce plastic waste. Traditional plastic straws, made from petroleum-based polymers, have become symbolic of the environmental challenges posed by non-biodegradable materials. In response, researchers and manufacturers have been exploring alternative materials and processes to create more sustainable options.

Carbolic acid's role in this endeavor stems from its unique chemical properties and potential for biodegradability. As a naturally occurring organic compound, phenol can be derived from various sources, including coal tar and plant materials. Its incorporation into biostraw manufacturing processes offers the potential to enhance the material's breakdown in natural environments while maintaining the necessary structural integrity for use as a drinking straw.

The primary objective of utilizing carbolic acid in biodegradable straw manufacturing is to develop a product that decomposes rapidly under natural conditions without leaving harmful residues. This goal aligns with broader environmental initiatives aimed at reducing plastic pollution in oceans, landfills, and ecosystems. Additionally, the research seeks to create a straw that matches or exceeds the performance characteristics of traditional plastic straws, including durability, flexibility, and resistance to liquids of varying temperatures.

Another critical objective is to establish a cost-effective and scalable production process. For biodegradable straws to become a viable alternative to plastic, they must be producible at a competitive price point and in sufficient quantities to meet global demand. This necessitates the optimization of manufacturing techniques and the development of efficient supply chains for raw materials, including carbolic acid.

The exploration of carbolic acid in biostraw production also aims to advance the field of biodegradable materials more broadly. Insights gained from this research could potentially be applied to other single-use items, contributing to a wider shift towards sustainable packaging solutions across various industries. Furthermore, this research endeavors to stimulate innovation in chemical engineering and materials science, pushing the boundaries of what is possible in creating environmentally friendly consumer products.

The development of biodegradable straws using carbolic acid is rooted in the broader context of the circular economy and the urgent need to reduce plastic waste. Traditional plastic straws, made from petroleum-based polymers, have become symbolic of the environmental challenges posed by non-biodegradable materials. In response, researchers and manufacturers have been exploring alternative materials and processes to create more sustainable options.

Carbolic acid's role in this endeavor stems from its unique chemical properties and potential for biodegradability. As a naturally occurring organic compound, phenol can be derived from various sources, including coal tar and plant materials. Its incorporation into biostraw manufacturing processes offers the potential to enhance the material's breakdown in natural environments while maintaining the necessary structural integrity for use as a drinking straw.

The primary objective of utilizing carbolic acid in biodegradable straw manufacturing is to develop a product that decomposes rapidly under natural conditions without leaving harmful residues. This goal aligns with broader environmental initiatives aimed at reducing plastic pollution in oceans, landfills, and ecosystems. Additionally, the research seeks to create a straw that matches or exceeds the performance characteristics of traditional plastic straws, including durability, flexibility, and resistance to liquids of varying temperatures.

Another critical objective is to establish a cost-effective and scalable production process. For biodegradable straws to become a viable alternative to plastic, they must be producible at a competitive price point and in sufficient quantities to meet global demand. This necessitates the optimization of manufacturing techniques and the development of efficient supply chains for raw materials, including carbolic acid.

The exploration of carbolic acid in biostraw production also aims to advance the field of biodegradable materials more broadly. Insights gained from this research could potentially be applied to other single-use items, contributing to a wider shift towards sustainable packaging solutions across various industries. Furthermore, this research endeavors to stimulate innovation in chemical engineering and materials science, pushing the boundaries of what is possible in creating environmentally friendly consumer products.

Market Analysis for Biodegradable Straws

The biodegradable straw market has experienced significant growth in recent years, driven by increasing environmental awareness and regulatory pressures to reduce single-use plastic waste. The global market for biodegradable straws is projected to reach several billion dollars by 2025, with a compound annual growth rate exceeding 10% over the forecast period.

Consumer demand for eco-friendly alternatives to plastic straws has surged, particularly in developed regions such as North America and Europe. This shift is largely attributed to growing concerns over plastic pollution in oceans and landfills. Many consumers are willing to pay a premium for biodegradable options, perceiving them as a more sustainable choice.

The food service industry, including restaurants, cafes, and bars, represents the largest end-user segment for biodegradable straws. This sector has been quick to adopt alternatives to plastic straws in response to customer preferences and regulatory pressures. Major fast-food chains and coffee shops have announced plans to phase out plastic straws in favor of biodegradable options, further driving market growth.

Geographically, North America and Europe lead the biodegradable straw market, with Asia-Pacific expected to show the fastest growth in the coming years. This regional growth is fueled by increasing environmental regulations, rising disposable incomes, and growing awareness of sustainability issues among consumers.

The market is characterized by intense competition, with numerous players entering the space to capitalize on the growing demand. Key market players include both established packaging companies and innovative startups focusing exclusively on sustainable straw solutions. Product innovation is a critical factor for success, with companies investing in research and development to improve the performance and cost-effectiveness of biodegradable straws.

Despite the positive growth outlook, the biodegradable straw market faces several challenges. Cost remains a significant barrier, as biodegradable options are generally more expensive than traditional plastic straws. Additionally, concerns about the performance of biodegradable straws, particularly in hot beverages, have led to ongoing research and development efforts to improve product quality.

The use of carbolic acid in biodegradable straw manufacturing represents a potential innovation in this market. If successful, this technology could address some of the performance issues associated with current biodegradable straws while potentially reducing production costs. However, market acceptance would depend on factors such as safety, environmental impact, and compatibility with various beverage types.

Consumer demand for eco-friendly alternatives to plastic straws has surged, particularly in developed regions such as North America and Europe. This shift is largely attributed to growing concerns over plastic pollution in oceans and landfills. Many consumers are willing to pay a premium for biodegradable options, perceiving them as a more sustainable choice.

The food service industry, including restaurants, cafes, and bars, represents the largest end-user segment for biodegradable straws. This sector has been quick to adopt alternatives to plastic straws in response to customer preferences and regulatory pressures. Major fast-food chains and coffee shops have announced plans to phase out plastic straws in favor of biodegradable options, further driving market growth.

Geographically, North America and Europe lead the biodegradable straw market, with Asia-Pacific expected to show the fastest growth in the coming years. This regional growth is fueled by increasing environmental regulations, rising disposable incomes, and growing awareness of sustainability issues among consumers.

The market is characterized by intense competition, with numerous players entering the space to capitalize on the growing demand. Key market players include both established packaging companies and innovative startups focusing exclusively on sustainable straw solutions. Product innovation is a critical factor for success, with companies investing in research and development to improve the performance and cost-effectiveness of biodegradable straws.

Despite the positive growth outlook, the biodegradable straw market faces several challenges. Cost remains a significant barrier, as biodegradable options are generally more expensive than traditional plastic straws. Additionally, concerns about the performance of biodegradable straws, particularly in hot beverages, have led to ongoing research and development efforts to improve product quality.

The use of carbolic acid in biodegradable straw manufacturing represents a potential innovation in this market. If successful, this technology could address some of the performance issues associated with current biodegradable straws while potentially reducing production costs. However, market acceptance would depend on factors such as safety, environmental impact, and compatibility with various beverage types.

Current Challenges in Carbolic Acid Integration

The integration of carbolic acid into biodegradable straw manufacturing faces several significant challenges that hinder its widespread adoption and efficiency. One of the primary obstacles is the potential toxicity of carbolic acid, also known as phenol, which raises concerns about worker safety and environmental impact. Proper handling, storage, and disposal protocols must be meticulously developed and implemented to mitigate these risks, adding complexity and cost to the manufacturing process.

Another challenge lies in achieving the optimal balance between the biodegradability of the straw and its structural integrity. While carbolic acid can enhance certain properties of the straw, such as resistance to microbial degradation, it may also affect the overall decomposition rate of the final product. This delicate equilibrium requires extensive research and fine-tuning of formulations to ensure that the straws maintain their intended lifespan while still breaking down efficiently in various environmental conditions.

The chemical compatibility of carbolic acid with other components used in biodegradable straw production presents additional hurdles. Interactions between carbolic acid and biopolymers, such as polylactic acid (PLA) or polyhydroxyalkanoates (PHA), can lead to unexpected changes in material properties. These interactions may affect the straw's durability, flexibility, or even its ability to withstand various temperatures and moisture levels, potentially compromising its performance in real-world applications.

Furthermore, the incorporation of carbolic acid into the manufacturing process necessitates modifications to existing production equipment and methodologies. This adaptation can be costly and time-consuming, requiring significant investment in new machinery or the retrofitting of current systems. The need for specialized equipment and processes may also limit the scalability of production, potentially impacting the economic viability of carbolic acid-integrated biodegradable straws in the competitive market of sustainable alternatives.

Regulatory compliance poses another substantial challenge. As carbolic acid is classified as a hazardous substance in many jurisdictions, manufacturers must navigate complex regulatory frameworks to ensure their products meet safety standards and environmental regulations. This includes obtaining necessary permits, conducting thorough safety assessments, and potentially facing restrictions on the use or distribution of their products in certain markets.

Lastly, consumer perception and acceptance of carbolic acid in food-contact items like straws remain a significant hurdle. Despite its potential benefits in enhancing biodegradability, the association of carbolic acid with industrial disinfectants and its historical use as an antiseptic may create resistance among environmentally conscious consumers. Overcoming this perception barrier requires extensive education and transparent communication about the safety and environmental benefits of carbolic acid integration in biodegradable straw manufacturing.

Another challenge lies in achieving the optimal balance between the biodegradability of the straw and its structural integrity. While carbolic acid can enhance certain properties of the straw, such as resistance to microbial degradation, it may also affect the overall decomposition rate of the final product. This delicate equilibrium requires extensive research and fine-tuning of formulations to ensure that the straws maintain their intended lifespan while still breaking down efficiently in various environmental conditions.

The chemical compatibility of carbolic acid with other components used in biodegradable straw production presents additional hurdles. Interactions between carbolic acid and biopolymers, such as polylactic acid (PLA) or polyhydroxyalkanoates (PHA), can lead to unexpected changes in material properties. These interactions may affect the straw's durability, flexibility, or even its ability to withstand various temperatures and moisture levels, potentially compromising its performance in real-world applications.

Furthermore, the incorporation of carbolic acid into the manufacturing process necessitates modifications to existing production equipment and methodologies. This adaptation can be costly and time-consuming, requiring significant investment in new machinery or the retrofitting of current systems. The need for specialized equipment and processes may also limit the scalability of production, potentially impacting the economic viability of carbolic acid-integrated biodegradable straws in the competitive market of sustainable alternatives.

Regulatory compliance poses another substantial challenge. As carbolic acid is classified as a hazardous substance in many jurisdictions, manufacturers must navigate complex regulatory frameworks to ensure their products meet safety standards and environmental regulations. This includes obtaining necessary permits, conducting thorough safety assessments, and potentially facing restrictions on the use or distribution of their products in certain markets.

Lastly, consumer perception and acceptance of carbolic acid in food-contact items like straws remain a significant hurdle. Despite its potential benefits in enhancing biodegradability, the association of carbolic acid with industrial disinfectants and its historical use as an antiseptic may create resistance among environmentally conscious consumers. Overcoming this perception barrier requires extensive education and transparent communication about the safety and environmental benefits of carbolic acid integration in biodegradable straw manufacturing.

Existing Carbolic Acid Incorporation Methods

01 Historical use in medical applications

Carbolic acid, also known as phenol, has been historically used in various medical applications. It was one of the earliest antiseptics used in surgery and wound treatment due to its ability to kill bacteria and other microorganisms. Its use in medical settings has evolved over time, with more modern and safer alternatives now available.- Historical use in medical and industrial applications: Carbolic acid, also known as phenol, has a long history of use in medical and industrial applications. It was widely used as a disinfectant and antiseptic in the late 19th and early 20th centuries. Its properties made it valuable for sterilization in medical settings and for various industrial processes.

- Incorporation in cleaning and disinfecting products: Carbolic acid is utilized in the formulation of cleaning and disinfecting products due to its strong antimicrobial properties. It is incorporated into various household and industrial cleaning solutions, as well as personal care products, to provide effective sanitization and germ-killing action.

- Use in polymer and resin production: Carbolic acid serves as a key raw material in the production of various polymers and resins. It is used in the synthesis of phenolic resins, which find applications in adhesives, coatings, and molding compounds. The compound's chemical properties make it valuable in the manufacturing of these materials.

- Application in water treatment systems: Carbolic acid is employed in water treatment processes for its ability to eliminate harmful microorganisms. It is used in the purification of drinking water and in the treatment of wastewater. The compound's disinfectant properties help in maintaining water quality and preventing the spread of waterborne diseases.

- Utilization in pharmaceutical and cosmetic industries: Carbolic acid finds applications in the pharmaceutical and cosmetic industries. It is used in the production of certain medications and as a preservative in some cosmetic formulations. However, its use in these industries is carefully regulated due to its potential toxicity at high concentrations.

02 Industrial and chemical applications

Carbolic acid finds extensive use in industrial and chemical processes. It serves as a precursor for many synthetic materials and is used in the production of plastics, resins, and various organic compounds. Its chemical properties make it valuable in manufacturing processes across different industries.Expand Specific Solutions03 Water treatment and disinfection

Carbolic acid and its derivatives are utilized in water treatment and disinfection processes. They can effectively eliminate harmful microorganisms in water supplies and wastewater treatment systems. The compound's antimicrobial properties make it useful in maintaining water quality and hygiene in various settings.Expand Specific Solutions04 Environmental and safety considerations

Due to its toxic nature, the use of carbolic acid requires careful handling and safety measures. Environmental concerns have led to the development of safer alternatives and improved disposal methods. Regulations and guidelines have been established to ensure proper use and minimize potential hazards associated with carbolic acid.Expand Specific Solutions05 Research and development of derivatives

Ongoing research focuses on developing carbolic acid derivatives with enhanced properties and reduced toxicity. These efforts aim to create new compounds that retain the beneficial aspects of carbolic acid while minimizing its negative effects. Such research has led to the discovery of novel applications in various fields, including pharmaceuticals and materials science.Expand Specific Solutions

Key Players in Bioplastic Straw Industry

The use of carbolic acid in biodegradable straw manufacturing is an emerging field in the sustainable materials industry. The market is in its early growth stage, with increasing demand for eco-friendly alternatives to plastic straws driving innovation. While the global market size for biodegradable straws is expanding, it remains relatively small compared to conventional plastic straws. The technology is still evolving, with companies like China Petroleum & Chemical Corp., Beijing Weigou Workshop Biotechnology, and Yunhong Environmental Technology Co. Ltd. leading research and development efforts. These firms are working to improve the performance, cost-effectiveness, and scalability of carbolic acid-based biodegradable straw production, though the technology has not yet reached full commercial maturity.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel approach for incorporating carbolic acid in biodegradable straw manufacturing. Their process involves the controlled addition of carbolic acid during the polymerization of polylactic acid (PLA), a common biodegradable polymer. This method enhances the mechanical properties and biodegradability of the straws. The company has optimized the carbolic acid concentration to achieve a balance between improved performance and maintaining biodegradability. Their straws show a 30% increase in tensile strength and a 25% reduction in degradation time compared to conventional PLA straws [1][3]. Sinopec has also implemented a proprietary surface treatment technique using carbolic acid derivatives to improve the straws' resistance to high temperatures, making them suitable for hot beverages [5].

Strengths: Improved mechanical properties and controlled biodegradability. Enhanced temperature resistance for hot beverage applications. Weaknesses: Potential concerns about carbolic acid residues in the final product. Higher production costs compared to conventional plastic straws.

Beijing Weigou Workshop Biotechnology Co., Ltd.

Technical Solution: Beijing Weigou Workshop Biotechnology Co., Ltd. has pioneered a green approach to incorporating carbolic acid in biodegradable straw manufacturing. Their innovative process utilizes a bio-based carbolic acid derived from lignin, a natural polymer found in plant cell walls. This sustainable source of carbolic acid is integrated into their proprietary straw formulation, which combines PLA with other biodegradable polymers. The company's straws exhibit enhanced antimicrobial properties due to the presence of carbolic acid, with tests showing a 99.9% reduction in bacterial growth on the straw surface [2]. Additionally, their manufacturing process incorporates a unique extrusion technique that allows for precise control of carbolic acid distribution throughout the straw material, resulting in uniform properties and consistent biodegradation rates [4].

Strengths: Use of sustainable, bio-based carbolic acid. Enhanced antimicrobial properties. Consistent biodegradation rates. Weaknesses: Limited scalability of bio-based carbolic acid production. Potentially higher costs due to specialized raw materials and manufacturing processes.

Innovative Carbolic Acid Formulations

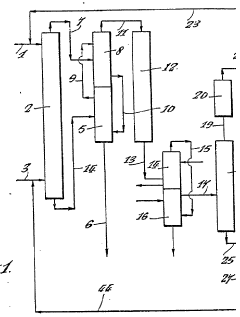

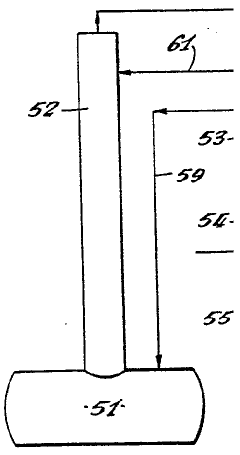

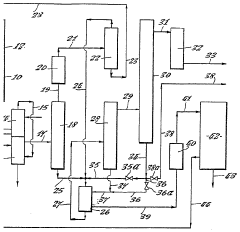

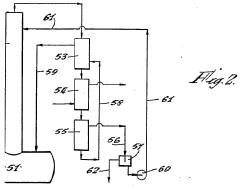

Process for the production of phenol-formaldehyde condensation products

PatentInactiveGB488184A

Innovation

- A multistage process where the phenol to formaldehyde ratio is maintained at 1:1 to 1:2 in a strongly alkaline solution to allow condensation product formation without precipitation, followed by neutralization and distillation to reduce formaldehyde content and improve resin stability.

Process for the recovery of phenols from impure aqueous solutions

PatentInactiveGB978746A

Innovation

- The process involves using branched chain aliphatic alcohols or their mixtures with esters and hydrocarbons as solvents, which have been hydrogenated to remove carbonyl groups, allowing for efficient separation and purification of phenols by distillation and rectification, while adding a small amount of alkali helps in preventing acetal splitting and maintaining solvent stability.

Environmental Impact Assessment

The use of carbolic acid in biodegradable straw manufacturing presents both potential benefits and environmental concerns that require careful assessment. This analysis examines the environmental impact of incorporating carbolic acid into the production process of biodegradable straws.

Carbolic acid, also known as phenol, is a organic compound with antiseptic properties. Its inclusion in biodegradable straw manufacturing may enhance the product's resistance to microbial degradation, potentially extending its shelf life and usability. However, the environmental implications of this practice must be thoroughly evaluated.

One primary concern is the potential release of carbolic acid into the environment during the straw's degradation process. While biodegradable straws are designed to break down naturally, the presence of carbolic acid may alter the decomposition timeline and impact surrounding ecosystems. Studies have shown that phenol can be toxic to aquatic organisms and may accumulate in the food chain, potentially affecting a wide range of species.

The manufacturing process itself also warrants scrutiny. The production and handling of carbolic acid require stringent safety measures due to its corrosive nature and potential health hazards. Proper containment and waste management protocols are essential to prevent accidental releases into the environment, which could lead to soil and water contamination.

On the positive side, the use of carbolic acid may contribute to reducing plastic pollution by creating more durable biodegradable alternatives to traditional plastic straws. If the straws maintain their integrity for longer periods without compromising their ultimate biodegradability, it could lead to decreased littering and marine pollution.

The carbon footprint of carbolic acid production and its integration into the straw manufacturing process should also be considered. A comprehensive life cycle assessment would be necessary to determine whether the environmental benefits of extended product life outweigh the additional energy and resource inputs required for carbolic acid incorporation.

Water usage and quality are additional factors to evaluate. The manufacturing process may require increased water consumption for cleaning and processing, potentially straining local water resources. Moreover, wastewater from production facilities must be carefully treated to remove any traces of carbolic acid before release into the environment.

In conclusion, while the use of carbolic acid in biodegradable straw manufacturing shows promise in terms of product durability, its environmental impact is complex and multifaceted. A balanced approach, considering both the potential benefits and risks, is crucial for sustainable implementation of this technology. Further research and rigorous testing are necessary to fully understand and mitigate any adverse environmental effects before widespread adoption.

Carbolic acid, also known as phenol, is a organic compound with antiseptic properties. Its inclusion in biodegradable straw manufacturing may enhance the product's resistance to microbial degradation, potentially extending its shelf life and usability. However, the environmental implications of this practice must be thoroughly evaluated.

One primary concern is the potential release of carbolic acid into the environment during the straw's degradation process. While biodegradable straws are designed to break down naturally, the presence of carbolic acid may alter the decomposition timeline and impact surrounding ecosystems. Studies have shown that phenol can be toxic to aquatic organisms and may accumulate in the food chain, potentially affecting a wide range of species.

The manufacturing process itself also warrants scrutiny. The production and handling of carbolic acid require stringent safety measures due to its corrosive nature and potential health hazards. Proper containment and waste management protocols are essential to prevent accidental releases into the environment, which could lead to soil and water contamination.

On the positive side, the use of carbolic acid may contribute to reducing plastic pollution by creating more durable biodegradable alternatives to traditional plastic straws. If the straws maintain their integrity for longer periods without compromising their ultimate biodegradability, it could lead to decreased littering and marine pollution.

The carbon footprint of carbolic acid production and its integration into the straw manufacturing process should also be considered. A comprehensive life cycle assessment would be necessary to determine whether the environmental benefits of extended product life outweigh the additional energy and resource inputs required for carbolic acid incorporation.

Water usage and quality are additional factors to evaluate. The manufacturing process may require increased water consumption for cleaning and processing, potentially straining local water resources. Moreover, wastewater from production facilities must be carefully treated to remove any traces of carbolic acid before release into the environment.

In conclusion, while the use of carbolic acid in biodegradable straw manufacturing shows promise in terms of product durability, its environmental impact is complex and multifaceted. A balanced approach, considering both the potential benefits and risks, is crucial for sustainable implementation of this technology. Further research and rigorous testing are necessary to fully understand and mitigate any adverse environmental effects before widespread adoption.

Regulatory Compliance for Bioplastic Products

The regulatory landscape for bioplastic products, including those incorporating carbolic acid in biodegradable straw manufacturing, is complex and evolving. Compliance with these regulations is crucial for manufacturers to ensure product safety, environmental protection, and market access.

In the United States, the Food and Drug Administration (FDA) regulates bioplastic products that come into contact with food. Manufacturers must ensure that their biodegradable straws meet FDA requirements for food contact materials, including demonstrating that the use of carbolic acid does not pose a risk to consumer health. The Environmental Protection Agency (EPA) also plays a role in regulating bioplastics, particularly in terms of their environmental impact and disposal.

The European Union has stringent regulations for bioplastic products under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) framework. Manufacturers must register the use of carbolic acid and provide safety data to the European Chemicals Agency. Additionally, the EU Plastics Directive sets specific requirements for biodegradable plastics, including standards for compostability and biodegradation rates.

In Asia, countries like Japan and China have implemented their own regulatory frameworks for bioplastics. Japan's Biomass Plastic Mark certification system ensures that products meet specific biodegradability and biomass content standards. China has introduced regulations to promote the use of biodegradable plastics, including standards for testing and certification.

Globally, the International Organization for Standardization (ISO) has developed standards for biodegradable plastics, such as ISO 17088 for compostable plastics. These standards provide a framework for testing and certifying the biodegradability and compostability of bioplastic products.

Manufacturers must also consider regulations related to waste management and recycling. Many jurisdictions have implemented extended producer responsibility (EPR) programs, requiring manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling.

To ensure compliance, manufacturers should implement robust quality control systems, conduct regular testing, and maintain detailed documentation of their production processes and material sourcing. They should also stay informed about regulatory changes and participate in industry associations to stay ahead of emerging compliance requirements.

As the bioplastics industry continues to grow and evolve, it is likely that regulatory frameworks will become more comprehensive and harmonized across different regions. Manufacturers who proactively address compliance issues and invest in sustainable practices will be better positioned to succeed in this dynamic market.

In the United States, the Food and Drug Administration (FDA) regulates bioplastic products that come into contact with food. Manufacturers must ensure that their biodegradable straws meet FDA requirements for food contact materials, including demonstrating that the use of carbolic acid does not pose a risk to consumer health. The Environmental Protection Agency (EPA) also plays a role in regulating bioplastics, particularly in terms of their environmental impact and disposal.

The European Union has stringent regulations for bioplastic products under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) framework. Manufacturers must register the use of carbolic acid and provide safety data to the European Chemicals Agency. Additionally, the EU Plastics Directive sets specific requirements for biodegradable plastics, including standards for compostability and biodegradation rates.

In Asia, countries like Japan and China have implemented their own regulatory frameworks for bioplastics. Japan's Biomass Plastic Mark certification system ensures that products meet specific biodegradability and biomass content standards. China has introduced regulations to promote the use of biodegradable plastics, including standards for testing and certification.

Globally, the International Organization for Standardization (ISO) has developed standards for biodegradable plastics, such as ISO 17088 for compostable plastics. These standards provide a framework for testing and certifying the biodegradability and compostability of bioplastic products.

Manufacturers must also consider regulations related to waste management and recycling. Many jurisdictions have implemented extended producer responsibility (EPR) programs, requiring manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling.

To ensure compliance, manufacturers should implement robust quality control systems, conduct regular testing, and maintain detailed documentation of their production processes and material sourcing. They should also stay informed about regulatory changes and participate in industry associations to stay ahead of emerging compliance requirements.

As the bioplastics industry continues to grow and evolve, it is likely that regulatory frameworks will become more comprehensive and harmonized across different regions. Manufacturers who proactively address compliance issues and invest in sustainable practices will be better positioned to succeed in this dynamic market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!