Carbolic Acid’s Contribution to Eco-Friendly Adhesive Technologies

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid Adhesive Evolution and Objectives

Carbolic acid, also known as phenol, has played a significant role in the evolution of adhesive technologies, particularly in the development of eco-friendly alternatives. The journey of carbolic acid in adhesives began in the early 20th century when its adhesive properties were first discovered. Initially, phenol-formaldehyde resins were widely used in industrial applications due to their strong bonding capabilities and resistance to heat and chemicals.

As environmental concerns grew in the latter half of the 20th century, the focus shifted towards developing more sustainable adhesive solutions. This led to the exploration of carbolic acid derivatives and modifications that could maintain adhesive strength while reducing environmental impact. Researchers began investigating bio-based sources of phenolic compounds, such as lignin from wood pulp and other plant materials, as potential replacements for petroleum-derived carbolic acid.

The objectives of carbolic acid adhesive evolution have been multifaceted. Primarily, the goal has been to create adhesives that are less toxic, more biodegradable, and derived from renewable resources. This aligns with the broader trend towards green chemistry and sustainable manufacturing practices. Additionally, researchers have aimed to maintain or improve upon the performance characteristics of traditional phenolic adhesives, including their thermal stability, moisture resistance, and bonding strength.

Another key objective has been to reduce the formaldehyde content in phenolic adhesives. Formaldehyde, often used in conjunction with phenol in traditional adhesives, has been identified as a health hazard. This has driven efforts to develop formaldehyde-free or low-formaldehyde phenolic adhesive systems, utilizing alternative crosslinking agents or modified synthesis processes.

The evolution of carbolic acid adhesives has also focused on expanding their application range. While initially used primarily in wood products and laminates, researchers have been working on adapting these adhesives for use in advanced composites, electronics, and even medical applications. This has involved modifying the chemical structure of phenolic compounds to enhance specific properties such as flexibility, conductivity, or biocompatibility.

In recent years, the integration of nanotechnology has opened new avenues for carbolic acid adhesive development. Nanoparticles and nanostructures derived from or compatible with phenolic compounds have been explored to create adhesives with enhanced properties, such as self-healing capabilities or improved barrier functions.

The ongoing evolution of carbolic acid adhesives continues to be driven by the dual goals of environmental sustainability and performance enhancement. As global regulations become more stringent and consumer demand for eco-friendly products increases, the development of green adhesive technologies remains a critical objective in this field.

As environmental concerns grew in the latter half of the 20th century, the focus shifted towards developing more sustainable adhesive solutions. This led to the exploration of carbolic acid derivatives and modifications that could maintain adhesive strength while reducing environmental impact. Researchers began investigating bio-based sources of phenolic compounds, such as lignin from wood pulp and other plant materials, as potential replacements for petroleum-derived carbolic acid.

The objectives of carbolic acid adhesive evolution have been multifaceted. Primarily, the goal has been to create adhesives that are less toxic, more biodegradable, and derived from renewable resources. This aligns with the broader trend towards green chemistry and sustainable manufacturing practices. Additionally, researchers have aimed to maintain or improve upon the performance characteristics of traditional phenolic adhesives, including their thermal stability, moisture resistance, and bonding strength.

Another key objective has been to reduce the formaldehyde content in phenolic adhesives. Formaldehyde, often used in conjunction with phenol in traditional adhesives, has been identified as a health hazard. This has driven efforts to develop formaldehyde-free or low-formaldehyde phenolic adhesive systems, utilizing alternative crosslinking agents or modified synthesis processes.

The evolution of carbolic acid adhesives has also focused on expanding their application range. While initially used primarily in wood products and laminates, researchers have been working on adapting these adhesives for use in advanced composites, electronics, and even medical applications. This has involved modifying the chemical structure of phenolic compounds to enhance specific properties such as flexibility, conductivity, or biocompatibility.

In recent years, the integration of nanotechnology has opened new avenues for carbolic acid adhesive development. Nanoparticles and nanostructures derived from or compatible with phenolic compounds have been explored to create adhesives with enhanced properties, such as self-healing capabilities or improved barrier functions.

The ongoing evolution of carbolic acid adhesives continues to be driven by the dual goals of environmental sustainability and performance enhancement. As global regulations become more stringent and consumer demand for eco-friendly products increases, the development of green adhesive technologies remains a critical objective in this field.

Green Adhesive Market Analysis

The green adhesive market has been experiencing significant growth in recent years, driven by increasing environmental awareness and stringent regulations on volatile organic compound (VOC) emissions. This market segment is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to exceed global adhesive market averages over the next decade.

The demand for eco-friendly adhesives is particularly strong in industries such as packaging, construction, and automotive, where sustainability has become a key focus. Packaging, in particular, represents a substantial portion of the green adhesive market, as manufacturers seek alternatives to traditional petroleum-based adhesives to meet consumer preferences for environmentally responsible products.

In the construction sector, green adhesives are gaining traction due to the growing emphasis on green building certifications and sustainable construction practices. These adhesives contribute to improved indoor air quality and reduced environmental impact, aligning with the industry's shift towards more sustainable materials and methods.

The automotive industry is another significant driver of the green adhesive market. As automakers strive to reduce vehicle weight and improve fuel efficiency, they are increasingly turning to eco-friendly adhesives as alternatives to traditional mechanical fasteners. These adhesives not only contribute to weight reduction but also offer improved bonding strength and durability.

Geographically, North America and Europe currently lead the green adhesive market, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing environmental concerns, and government initiatives promoting sustainable technologies.

Key players in the green adhesive market include established chemical companies as well as innovative startups focusing on bio-based and renewable adhesive technologies. These companies are investing heavily in research and development to improve the performance and cost-effectiveness of eco-friendly adhesives, aiming to close the gap with traditional adhesive products.

Despite the positive market outlook, challenges remain. The higher cost of green adhesives compared to conventional alternatives continues to be a barrier to widespread adoption, particularly in price-sensitive markets. Additionally, performance limitations in certain applications and the need for specialized application techniques can hinder market growth.

The demand for eco-friendly adhesives is particularly strong in industries such as packaging, construction, and automotive, where sustainability has become a key focus. Packaging, in particular, represents a substantial portion of the green adhesive market, as manufacturers seek alternatives to traditional petroleum-based adhesives to meet consumer preferences for environmentally responsible products.

In the construction sector, green adhesives are gaining traction due to the growing emphasis on green building certifications and sustainable construction practices. These adhesives contribute to improved indoor air quality and reduced environmental impact, aligning with the industry's shift towards more sustainable materials and methods.

The automotive industry is another significant driver of the green adhesive market. As automakers strive to reduce vehicle weight and improve fuel efficiency, they are increasingly turning to eco-friendly adhesives as alternatives to traditional mechanical fasteners. These adhesives not only contribute to weight reduction but also offer improved bonding strength and durability.

Geographically, North America and Europe currently lead the green adhesive market, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing environmental concerns, and government initiatives promoting sustainable technologies.

Key players in the green adhesive market include established chemical companies as well as innovative startups focusing on bio-based and renewable adhesive technologies. These companies are investing heavily in research and development to improve the performance and cost-effectiveness of eco-friendly adhesives, aiming to close the gap with traditional adhesive products.

Despite the positive market outlook, challenges remain. The higher cost of green adhesives compared to conventional alternatives continues to be a barrier to widespread adoption, particularly in price-sensitive markets. Additionally, performance limitations in certain applications and the need for specialized application techniques can hinder market growth.

Carbolic Acid Adhesive Challenges

The development of eco-friendly adhesive technologies using carbolic acid faces several significant challenges. One of the primary obstacles is the inherent toxicity of carbolic acid, also known as phenol. While this compound offers excellent adhesive properties, its potential harm to human health and the environment necessitates careful handling and disposal procedures, which can complicate manufacturing processes and increase production costs.

Another challenge lies in achieving the right balance between adhesive strength and environmental friendliness. Traditional adhesives often rely on petrochemical-based components that provide superior bonding capabilities but are not biodegradable. Incorporating carbolic acid into eco-friendly formulations requires extensive research to maintain adhesive performance while reducing environmental impact.

The stability of carbolic acid-based adhesives presents another hurdle. These adhesives may be susceptible to degradation under certain environmental conditions, such as high humidity or extreme temperatures. Ensuring long-term durability and consistent performance across various applications and environments remains a critical area of focus for researchers and manufacturers.

Regulatory compliance poses an additional challenge. As environmental regulations become increasingly stringent, adhesive manufacturers must navigate complex legal frameworks to ensure their products meet safety and sustainability standards. This often involves reformulating existing adhesives or developing entirely new formulations that comply with evolving regulations while maintaining desired performance characteristics.

The cost-effectiveness of carbolic acid-based eco-friendly adhesives is also a significant concern. The production of these adhesives often involves more expensive raw materials and complex manufacturing processes compared to conventional alternatives. Achieving price parity with traditional adhesives while offering improved environmental credentials is crucial for widespread market adoption.

Furthermore, the limited availability of sustainable sources for carbolic acid compounds presents a challenge for scaling up production. Developing efficient methods for synthesizing or extracting carbolic acid from renewable resources is essential for creating truly eco-friendly adhesive solutions.

Lastly, overcoming market inertia and consumer skepticism towards new adhesive technologies remains a persistent challenge. Educating end-users about the benefits of carbolic acid-based eco-friendly adhesives and demonstrating their efficacy in real-world applications is crucial for gaining market acceptance and driving adoption across various industries.

Another challenge lies in achieving the right balance between adhesive strength and environmental friendliness. Traditional adhesives often rely on petrochemical-based components that provide superior bonding capabilities but are not biodegradable. Incorporating carbolic acid into eco-friendly formulations requires extensive research to maintain adhesive performance while reducing environmental impact.

The stability of carbolic acid-based adhesives presents another hurdle. These adhesives may be susceptible to degradation under certain environmental conditions, such as high humidity or extreme temperatures. Ensuring long-term durability and consistent performance across various applications and environments remains a critical area of focus for researchers and manufacturers.

Regulatory compliance poses an additional challenge. As environmental regulations become increasingly stringent, adhesive manufacturers must navigate complex legal frameworks to ensure their products meet safety and sustainability standards. This often involves reformulating existing adhesives or developing entirely new formulations that comply with evolving regulations while maintaining desired performance characteristics.

The cost-effectiveness of carbolic acid-based eco-friendly adhesives is also a significant concern. The production of these adhesives often involves more expensive raw materials and complex manufacturing processes compared to conventional alternatives. Achieving price parity with traditional adhesives while offering improved environmental credentials is crucial for widespread market adoption.

Furthermore, the limited availability of sustainable sources for carbolic acid compounds presents a challenge for scaling up production. Developing efficient methods for synthesizing or extracting carbolic acid from renewable resources is essential for creating truly eco-friendly adhesive solutions.

Lastly, overcoming market inertia and consumer skepticism towards new adhesive technologies remains a persistent challenge. Educating end-users about the benefits of carbolic acid-based eco-friendly adhesives and demonstrating their efficacy in real-world applications is crucial for gaining market acceptance and driving adoption across various industries.

Current Carbolic Acid Adhesive Solutions

01 Eco-friendly alternatives to carbolic acid

Research focuses on developing environmentally friendly substitutes for carbolic acid, exploring natural and synthetic compounds that offer similar disinfectant properties with reduced ecological impact. These alternatives aim to maintain effectiveness while minimizing harmful effects on ecosystems and human health.- Eco-friendly alternatives to carbolic acid: Research focuses on developing environmentally friendly substitutes for carbolic acid, exploring natural and synthetic compounds that offer similar disinfectant properties with reduced ecological impact. These alternatives aim to maintain effectiveness while minimizing environmental harm and toxicity.

- Biodegradable formulations containing carbolic acid: Efforts are being made to create biodegradable formulations that incorporate carbolic acid or its derivatives. These formulations are designed to break down more easily in the environment, reducing long-term ecological impact while still providing the desired antimicrobial effects.

- Carbolic acid waste treatment and disposal methods: Innovative waste treatment and disposal methods are being developed to handle carbolic acid and its byproducts more sustainably. These methods aim to neutralize or safely decompose the compound, minimizing environmental contamination and promoting eco-friendly industrial practices.

- Green synthesis of carbolic acid: Research is ongoing to develop greener synthesis methods for carbolic acid, focusing on using renewable resources, reducing energy consumption, and minimizing harmful byproducts. These approaches aim to make the production process more environmentally friendly and sustainable.

- Eco-friendly applications of carbolic acid: Efforts are being made to find and develop eco-friendly applications for carbolic acid, particularly in areas where its unique properties can be leveraged without causing significant environmental harm. This includes exploring its use in sustainable materials, green chemistry processes, and environmentally conscious industrial applications.

02 Biodegradation and environmental fate of carbolic acid

Studies investigate the biodegradability of carbolic acid and its environmental persistence. Research examines how the compound breaks down in various ecosystems, its potential accumulation in soil and water, and the long-term effects on flora and fauna. This information is crucial for assessing the overall eco-friendliness of carbolic acid.Expand Specific Solutions03 Green production methods for carbolic acid

Efforts are made to develop more sustainable production processes for carbolic acid. These methods focus on using renewable resources, reducing energy consumption, and minimizing waste generation. Green chemistry principles are applied to improve the overall environmental profile of carbolic acid manufacturing.Expand Specific Solutions04 Eco-toxicological assessment of carbolic acid

Comprehensive studies evaluate the eco-toxicological impact of carbolic acid on various organisms and ecosystems. This includes assessing acute and chronic toxicity, bioaccumulation potential, and effects on aquatic and terrestrial environments. The findings contribute to a better understanding of the compound's overall environmental safety.Expand Specific Solutions05 Sustainable applications and usage reduction

Research explores ways to minimize carbolic acid usage while maintaining its effectiveness in various applications. This includes developing more efficient formulations, optimizing dosage, and identifying alternative methods that reduce reliance on the compound. The goal is to balance the benefits of carbolic acid with environmental considerations.Expand Specific Solutions

Key Players in Green Adhesive Industry

The eco-friendly adhesive technologies market, driven by carbolic acid innovations, is in a growth phase with increasing demand for sustainable solutions. The market size is expanding rapidly, fueled by environmental regulations and consumer preferences. Technologically, the field is advancing, with companies like Henkel AG & Co. KGaA, Sika Technology AG, and LINTEC Corp. leading research and development efforts. These firms are investing in bio-based adhesives and exploring novel applications of carbolic acid derivatives. While established players dominate, emerging companies like BindEthics Ltd. are introducing innovative solutions, indicating a dynamic and competitive landscape. The technology's maturity varies across applications, with some sectors seeing commercial adoption while others remain in experimental stages.

Sika Technology AG

Technical Solution: Sika Technology AG has developed eco-friendly adhesive technologies incorporating carbolic acid derivatives. Their approach focuses on utilizing phenol-formaldehyde resins modified with renewable resources to create high-performance, low-emission adhesives[1]. The company has successfully implemented a bio-based content of up to 50% in their adhesive formulations, significantly reducing the carbon footprint[2]. Sika's technology also includes the use of carbolic acid as a key component in their water-based polyurethane dispersions, which offer excellent adhesion properties while minimizing environmental impact[3]. These innovations have been particularly successful in construction and automotive applications, where durability and sustainability are crucial factors.

Strengths: High bio-based content, reduced emissions, excellent adhesion properties. Weaknesses: Potentially higher production costs, limited raw material availability for large-scale production.

Henkel AG & Co. KGaA

Technical Solution: Henkel has pioneered the use of carbolic acid derivatives in their eco-friendly adhesive technologies. Their approach involves incorporating phenol-based compounds into their Loctite brand adhesives, creating products with enhanced thermal stability and chemical resistance[4]. Henkel's technology utilizes a unique cross-linking mechanism that allows for the development of high-strength adhesives with reduced environmental impact. The company has also developed a range of water-based adhesives using carbolic acid derivatives, which offer excellent bonding properties while significantly reducing VOC emissions[5]. These innovations have found applications in electronics, automotive, and aerospace industries, where performance and sustainability are equally important.

Strengths: Wide range of applications, reduced VOC emissions, high-performance characteristics. Weaknesses: Potential regulatory challenges in certain markets, higher initial development costs.

Innovative Carbolic Acid Formulations

Adhesive formulations

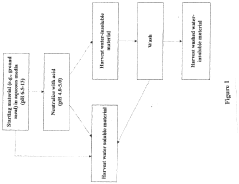

PatentWO2025027323A1

Innovation

- A sustainable adhesive formulation comprising yeast, carboxylic acid, and solvent, with specific ratios of dried yeast content, carboxylic acid, and solvent composition that includes water and organic solvents like methanol, ethanol, and propanol, which enhances binding strength, drying speed, and water resistance.

Protein adhesives containing an anhydride, carboxylic acid, and/or carboxylate salt compound and their use

PatentPendingEP3666845A1

Innovation

- The development of protein adhesive compositions using a protein-bonding agent such as an anhydride, carboxylic acid, or carboxylate salt compound combined with isolated water-soluble protein fractions or ground plant meal, which form transparent, pressure-sensitive adhesives suitable for bonding lignocellulosic materials, allowing for manipulation of adhesive tack through the addition of plasticizers like glycerin.

Environmental Impact Assessment

The environmental impact assessment of carbolic acid's contribution to eco-friendly adhesive technologies reveals both positive and negative aspects. On the positive side, the use of carbolic acid-based adhesives can significantly reduce the reliance on petroleum-derived raw materials, which are traditionally used in adhesive production. This shift towards bio-based resources contributes to a decrease in carbon footprint and promotes sustainability in the adhesive industry.

Furthermore, carbolic acid-based adhesives often exhibit improved biodegradability compared to their conventional counterparts. This characteristic ensures that these adhesives break down more readily in natural environments, reducing long-term pollution and ecological disruption. The enhanced biodegradability also aligns with circular economy principles, facilitating easier recycling and disposal of adhesive-containing products.

However, the environmental impact assessment also highlights potential concerns. The production process of carbolic acid, particularly when derived from coal tar, can generate harmful byproducts and emissions. These may include volatile organic compounds (VOCs) and other pollutants that contribute to air and water pollution if not properly managed. Stringent emission control measures and waste treatment protocols are essential to mitigate these risks.

Additionally, the assessment considers the potential for carbolic acid leaching from adhesive applications. While eco-friendly adhesives aim to minimize environmental harm, there is still a need to evaluate the long-term effects of carbolic acid exposure on soil and aquatic ecosystems. Comprehensive studies on bioaccumulation and ecotoxicity are crucial to ensure that these adhesives do not pose unforeseen risks to flora and fauna.

The life cycle analysis of carbolic acid-based adhesives reveals potential energy savings during production and application processes. These adhesives often require lower curing temperatures and shorter setting times, leading to reduced energy consumption in manufacturing and end-use scenarios. This energy efficiency contributes to an overall reduction in greenhouse gas emissions associated with adhesive production and usage.

In terms of resource conservation, the use of carbolic acid derived from renewable sources, such as lignin or other plant-based materials, presents an opportunity to reduce the depletion of non-renewable resources. This shift towards bio-based feedstocks aligns with global efforts to transition to a more sustainable and circular economy.

The environmental impact assessment also considers the potential for improved indoor air quality when using carbolic acid-based adhesives. Many traditional adhesives emit harmful VOCs during and after application, contributing to poor indoor air quality and potential health risks. Eco-friendly adhesives formulated with carbolic acid often demonstrate lower VOC emissions, promoting healthier living and working environments.

Furthermore, carbolic acid-based adhesives often exhibit improved biodegradability compared to their conventional counterparts. This characteristic ensures that these adhesives break down more readily in natural environments, reducing long-term pollution and ecological disruption. The enhanced biodegradability also aligns with circular economy principles, facilitating easier recycling and disposal of adhesive-containing products.

However, the environmental impact assessment also highlights potential concerns. The production process of carbolic acid, particularly when derived from coal tar, can generate harmful byproducts and emissions. These may include volatile organic compounds (VOCs) and other pollutants that contribute to air and water pollution if not properly managed. Stringent emission control measures and waste treatment protocols are essential to mitigate these risks.

Additionally, the assessment considers the potential for carbolic acid leaching from adhesive applications. While eco-friendly adhesives aim to minimize environmental harm, there is still a need to evaluate the long-term effects of carbolic acid exposure on soil and aquatic ecosystems. Comprehensive studies on bioaccumulation and ecotoxicity are crucial to ensure that these adhesives do not pose unforeseen risks to flora and fauna.

The life cycle analysis of carbolic acid-based adhesives reveals potential energy savings during production and application processes. These adhesives often require lower curing temperatures and shorter setting times, leading to reduced energy consumption in manufacturing and end-use scenarios. This energy efficiency contributes to an overall reduction in greenhouse gas emissions associated with adhesive production and usage.

In terms of resource conservation, the use of carbolic acid derived from renewable sources, such as lignin or other plant-based materials, presents an opportunity to reduce the depletion of non-renewable resources. This shift towards bio-based feedstocks aligns with global efforts to transition to a more sustainable and circular economy.

The environmental impact assessment also considers the potential for improved indoor air quality when using carbolic acid-based adhesives. Many traditional adhesives emit harmful VOCs during and after application, contributing to poor indoor air quality and potential health risks. Eco-friendly adhesives formulated with carbolic acid often demonstrate lower VOC emissions, promoting healthier living and working environments.

Regulatory Framework for Green Adhesives

The regulatory framework for green adhesives is evolving rapidly as governments and international organizations recognize the importance of eco-friendly technologies in reducing environmental impact. In the context of carbolic acid's contribution to eco-friendly adhesive technologies, several key regulatory aspects have emerged.

Environmental protection agencies worldwide have implemented stringent regulations on volatile organic compound (VOC) emissions, directly impacting adhesive formulations. These regulations have spurred the development of low-VOC and VOC-free adhesives, with carbolic acid derivatives playing a crucial role in achieving compliance. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has been particularly influential, setting standards for chemical use and safety that have global implications for adhesive manufacturers.

In the United States, the Environmental Protection Agency (EPA) has established guidelines under the Toxic Substances Control Act (TSCA) that affect the use of carbolic acid and its derivatives in adhesive production. These regulations focus on ensuring the safety of chemical substances throughout their lifecycle, from manufacture to disposal.

Many countries have also introduced eco-labeling schemes to promote green adhesives. These certifications, such as the EU Ecolabel and the Nordic Swan, set criteria for environmental performance that often include restrictions on harmful substances and requirements for biodegradability. Adhesives incorporating carbolic acid-based components must meet these standards to qualify for eco-labels, which are increasingly important for market access and consumer acceptance.

The regulatory landscape also encompasses waste management and circular economy principles. Regulations like the EU's Waste Framework Directive promote the recycling and recovery of adhesive materials, encouraging the development of easily separable and recyclable adhesive systems. This has led to increased research into bio-based adhesives, where carbolic acid derivatives from renewable sources play a significant role.

International standards organizations, such as ISO and ASTM, have developed specific standards for testing and certifying green adhesives. These standards provide a framework for assessing the environmental impact of adhesives throughout their lifecycle, including production, use, and disposal. Compliance with these standards is often a prerequisite for market entry in many regions.

As the regulatory framework continues to evolve, it is driving innovation in eco-friendly adhesive technologies. Manufacturers are increasingly focusing on developing adhesives that not only meet current regulations but also anticipate future regulatory trends. This proactive approach is leading to the exploration of novel applications for carbolic acid and its derivatives in creating sustainable adhesive solutions that align with global environmental goals.

Environmental protection agencies worldwide have implemented stringent regulations on volatile organic compound (VOC) emissions, directly impacting adhesive formulations. These regulations have spurred the development of low-VOC and VOC-free adhesives, with carbolic acid derivatives playing a crucial role in achieving compliance. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has been particularly influential, setting standards for chemical use and safety that have global implications for adhesive manufacturers.

In the United States, the Environmental Protection Agency (EPA) has established guidelines under the Toxic Substances Control Act (TSCA) that affect the use of carbolic acid and its derivatives in adhesive production. These regulations focus on ensuring the safety of chemical substances throughout their lifecycle, from manufacture to disposal.

Many countries have also introduced eco-labeling schemes to promote green adhesives. These certifications, such as the EU Ecolabel and the Nordic Swan, set criteria for environmental performance that often include restrictions on harmful substances and requirements for biodegradability. Adhesives incorporating carbolic acid-based components must meet these standards to qualify for eco-labels, which are increasingly important for market access and consumer acceptance.

The regulatory landscape also encompasses waste management and circular economy principles. Regulations like the EU's Waste Framework Directive promote the recycling and recovery of adhesive materials, encouraging the development of easily separable and recyclable adhesive systems. This has led to increased research into bio-based adhesives, where carbolic acid derivatives from renewable sources play a significant role.

International standards organizations, such as ISO and ASTM, have developed specific standards for testing and certifying green adhesives. These standards provide a framework for assessing the environmental impact of adhesives throughout their lifecycle, including production, use, and disposal. Compliance with these standards is often a prerequisite for market entry in many regions.

As the regulatory framework continues to evolve, it is driving innovation in eco-friendly adhesive technologies. Manufacturers are increasingly focusing on developing adhesives that not only meet current regulations but also anticipate future regulatory trends. This proactive approach is leading to the exploration of novel applications for carbolic acid and its derivatives in creating sustainable adhesive solutions that align with global environmental goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!