The Use of Carbolic Acid in Enhancing Biodegradable Packaging Solutions

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid in Packaging: Background and Objectives

Carbolic acid, also known as phenol, has emerged as a promising component in the development of enhanced biodegradable packaging solutions. This technological advancement is rooted in the growing global concern over plastic pollution and the urgent need for sustainable packaging alternatives. The evolution of biodegradable packaging has been driven by increasing environmental awareness and stringent regulations aimed at reducing plastic waste.

The use of carbolic acid in packaging represents a significant leap forward in the field of sustainable materials. Historically, biodegradable packaging has faced challenges in terms of durability, moisture resistance, and cost-effectiveness. The introduction of carbolic acid as a key ingredient aims to address these limitations and push the boundaries of what is possible in eco-friendly packaging solutions.

The primary objective of incorporating carbolic acid into biodegradable packaging is to enhance the material's properties while maintaining its environmentally friendly characteristics. Researchers and industry experts are exploring how carbolic acid can improve the mechanical strength, barrier properties, and overall performance of biodegradable packaging materials. This includes investigating its potential to extend shelf life, resist moisture, and withstand various environmental conditions without compromising biodegradability.

Another crucial goal is to develop packaging solutions that are economically viable and can be scaled up for mass production. The integration of carbolic acid is expected to contribute to the creation of cost-effective biodegradable packaging that can compete with traditional plastic alternatives in terms of both performance and price point. This is essential for widespread adoption across various industries, from food and beverage to consumer goods and electronics.

Furthermore, the research into carbolic acid-enhanced biodegradable packaging aligns with the broader trend of circular economy principles. The aim is to create packaging materials that not only decompose naturally but also contribute positively to the environment during their lifecycle. This includes exploring the potential for these materials to enrich soil quality or serve as nutrients for plants upon decomposition.

As we delve deeper into this technological frontier, it is crucial to consider the potential impacts on existing recycling systems and waste management infrastructure. The development of carbolic acid-enhanced biodegradable packaging must take into account the need for compatibility with current recycling processes or the establishment of new, specialized recycling streams.

In conclusion, the exploration of carbolic acid in enhancing biodegradable packaging solutions represents a significant step towards more sustainable and environmentally responsible packaging options. The technology aims to address key challenges in the field while opening up new possibilities for innovative, high-performance biodegradable materials that can meet the demands of modern consumers and industries.

The use of carbolic acid in packaging represents a significant leap forward in the field of sustainable materials. Historically, biodegradable packaging has faced challenges in terms of durability, moisture resistance, and cost-effectiveness. The introduction of carbolic acid as a key ingredient aims to address these limitations and push the boundaries of what is possible in eco-friendly packaging solutions.

The primary objective of incorporating carbolic acid into biodegradable packaging is to enhance the material's properties while maintaining its environmentally friendly characteristics. Researchers and industry experts are exploring how carbolic acid can improve the mechanical strength, barrier properties, and overall performance of biodegradable packaging materials. This includes investigating its potential to extend shelf life, resist moisture, and withstand various environmental conditions without compromising biodegradability.

Another crucial goal is to develop packaging solutions that are economically viable and can be scaled up for mass production. The integration of carbolic acid is expected to contribute to the creation of cost-effective biodegradable packaging that can compete with traditional plastic alternatives in terms of both performance and price point. This is essential for widespread adoption across various industries, from food and beverage to consumer goods and electronics.

Furthermore, the research into carbolic acid-enhanced biodegradable packaging aligns with the broader trend of circular economy principles. The aim is to create packaging materials that not only decompose naturally but also contribute positively to the environment during their lifecycle. This includes exploring the potential for these materials to enrich soil quality or serve as nutrients for plants upon decomposition.

As we delve deeper into this technological frontier, it is crucial to consider the potential impacts on existing recycling systems and waste management infrastructure. The development of carbolic acid-enhanced biodegradable packaging must take into account the need for compatibility with current recycling processes or the establishment of new, specialized recycling streams.

In conclusion, the exploration of carbolic acid in enhancing biodegradable packaging solutions represents a significant step towards more sustainable and environmentally responsible packaging options. The technology aims to address key challenges in the field while opening up new possibilities for innovative, high-performance biodegradable materials that can meet the demands of modern consumers and industries.

Market Analysis for Eco-Friendly Packaging Solutions

The market for eco-friendly packaging solutions has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations on plastic waste. The global biodegradable packaging market is projected to reach $21.7 billion by 2026, growing at a CAGR of 17.4% from 2021 to 2026. This surge in demand is primarily fueled by consumer preferences for sustainable products and corporate commitments to reduce environmental impact.

The food and beverage industry remains the largest consumer of biodegradable packaging, accounting for over 40% of the market share. This sector's dominance is attributed to the high volume of single-use packaging and growing concerns about food waste. Retail and consumer goods industries are also rapidly adopting eco-friendly packaging solutions, with many major brands pledging to transition to 100% recyclable, reusable, or compostable packaging by 2025.

Geographically, Europe leads the market for biodegradable packaging, followed closely by North America. These regions benefit from advanced waste management infrastructure and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India.

The market landscape is characterized by intense competition and innovation. Key players in the biodegradable packaging industry are investing heavily in research and development to improve material properties and reduce production costs. The integration of carbolic acid in biodegradable packaging solutions represents a promising avenue for enhancing the performance and durability of these materials.

Despite the positive growth trajectory, the eco-friendly packaging market faces several challenges. The higher cost of biodegradable materials compared to traditional plastics remains a significant barrier to widespread adoption. Additionally, the lack of standardized disposal and composting infrastructure in many regions hinders the effective end-of-life management of these products.

Consumer education and awareness also play a crucial role in market development. While there is a growing preference for sustainable packaging, many consumers are still unfamiliar with proper disposal methods for biodegradable materials. This knowledge gap can lead to improper disposal, negating the environmental benefits of these products.

In conclusion, the market for eco-friendly packaging solutions, particularly those incorporating innovative materials like carbolic acid-enhanced biodegradable plastics, presents substantial growth opportunities. As technology advances and economies of scale are achieved, the cost gap between traditional and biodegradable packaging is expected to narrow, further driving market expansion.

The food and beverage industry remains the largest consumer of biodegradable packaging, accounting for over 40% of the market share. This sector's dominance is attributed to the high volume of single-use packaging and growing concerns about food waste. Retail and consumer goods industries are also rapidly adopting eco-friendly packaging solutions, with many major brands pledging to transition to 100% recyclable, reusable, or compostable packaging by 2025.

Geographically, Europe leads the market for biodegradable packaging, followed closely by North America. These regions benefit from advanced waste management infrastructure and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India.

The market landscape is characterized by intense competition and innovation. Key players in the biodegradable packaging industry are investing heavily in research and development to improve material properties and reduce production costs. The integration of carbolic acid in biodegradable packaging solutions represents a promising avenue for enhancing the performance and durability of these materials.

Despite the positive growth trajectory, the eco-friendly packaging market faces several challenges. The higher cost of biodegradable materials compared to traditional plastics remains a significant barrier to widespread adoption. Additionally, the lack of standardized disposal and composting infrastructure in many regions hinders the effective end-of-life management of these products.

Consumer education and awareness also play a crucial role in market development. While there is a growing preference for sustainable packaging, many consumers are still unfamiliar with proper disposal methods for biodegradable materials. This knowledge gap can lead to improper disposal, negating the environmental benefits of these products.

In conclusion, the market for eco-friendly packaging solutions, particularly those incorporating innovative materials like carbolic acid-enhanced biodegradable plastics, presents substantial growth opportunities. As technology advances and economies of scale are achieved, the cost gap between traditional and biodegradable packaging is expected to narrow, further driving market expansion.

Current Challenges in Biodegradable Packaging Technology

The field of biodegradable packaging technology faces several significant challenges that hinder its widespread adoption and effectiveness. One of the primary obstacles is the limited range of suitable materials that can meet both biodegradability requirements and performance standards. Many existing biodegradable materials struggle to match the durability, barrier properties, and shelf life of conventional plastics, making them less attractive for certain applications.

Cost remains a major hurdle in the industry. Biodegradable packaging solutions are often more expensive to produce than their non-biodegradable counterparts, which can deter manufacturers and consumers from embracing these eco-friendly alternatives. The higher production costs are typically attributed to the specialized materials and processes required for biodegradable packaging.

Another significant challenge is the lack of standardization in biodegradability testing and certification. Different regions and organizations have varying standards for what qualifies as "biodegradable," leading to confusion in the market and potential greenwashing. This inconsistency makes it difficult for consumers to make informed choices and for manufacturers to ensure compliance across different markets.

The disposal infrastructure for biodegradable packaging is also underdeveloped in many areas. Without proper composting facilities or waste management systems capable of handling biodegradable materials, these products may end up in landfills where they cannot degrade as intended. This gap in infrastructure undermines the environmental benefits of biodegradable packaging.

Technical limitations in material properties present ongoing challenges. Many biodegradable materials are sensitive to moisture and temperature, which can affect their stability and shelf life. Improving the barrier properties of these materials without compromising their biodegradability is a complex task that researchers continue to grapple with.

The scalability of production processes for biodegradable packaging materials is another hurdle. Many innovative solutions developed in laboratories face difficulties when scaled up to industrial production levels, often due to technical complexities or economic feasibility issues.

Lastly, there is a need for more research into the long-term environmental impacts of biodegradable materials. While these materials are designed to break down more quickly than conventional plastics, concerns remain about potential microplastic formation and the effects of degradation byproducts on ecosystems.

Addressing these challenges requires a multifaceted approach involving continued research and development, policy support, infrastructure investment, and consumer education. As the industry evolves, overcoming these obstacles will be crucial for realizing the full potential of biodegradable packaging technology in reducing environmental impact and promoting sustainability.

Cost remains a major hurdle in the industry. Biodegradable packaging solutions are often more expensive to produce than their non-biodegradable counterparts, which can deter manufacturers and consumers from embracing these eco-friendly alternatives. The higher production costs are typically attributed to the specialized materials and processes required for biodegradable packaging.

Another significant challenge is the lack of standardization in biodegradability testing and certification. Different regions and organizations have varying standards for what qualifies as "biodegradable," leading to confusion in the market and potential greenwashing. This inconsistency makes it difficult for consumers to make informed choices and for manufacturers to ensure compliance across different markets.

The disposal infrastructure for biodegradable packaging is also underdeveloped in many areas. Without proper composting facilities or waste management systems capable of handling biodegradable materials, these products may end up in landfills where they cannot degrade as intended. This gap in infrastructure undermines the environmental benefits of biodegradable packaging.

Technical limitations in material properties present ongoing challenges. Many biodegradable materials are sensitive to moisture and temperature, which can affect their stability and shelf life. Improving the barrier properties of these materials without compromising their biodegradability is a complex task that researchers continue to grapple with.

The scalability of production processes for biodegradable packaging materials is another hurdle. Many innovative solutions developed in laboratories face difficulties when scaled up to industrial production levels, often due to technical complexities or economic feasibility issues.

Lastly, there is a need for more research into the long-term environmental impacts of biodegradable materials. While these materials are designed to break down more quickly than conventional plastics, concerns remain about potential microplastic formation and the effects of degradation byproducts on ecosystems.

Addressing these challenges requires a multifaceted approach involving continued research and development, policy support, infrastructure investment, and consumer education. As the industry evolves, overcoming these obstacles will be crucial for realizing the full potential of biodegradable packaging technology in reducing environmental impact and promoting sustainability.

Existing Carbolic Acid-Based Packaging Solutions

01 Biodegradability of carbolic acid in wastewater treatment

Carbolic acid, also known as phenol, can be biodegraded in wastewater treatment processes. Various microorganisms are capable of breaking down phenol compounds, making it possible to remove carbolic acid from industrial effluents through biological treatment methods. This biodegradation process is essential for reducing environmental pollution and ensuring compliance with discharge regulations.- Biodegradation of carbolic acid in wastewater treatment: Carbolic acid, also known as phenol, can be biodegraded in wastewater treatment processes. Various microorganisms are capable of breaking down phenol compounds, making it possible to remove carbolic acid from industrial effluents through biological treatment methods. This approach is environmentally friendly and cost-effective for managing phenol-containing waste streams.

- Use of advanced oxidation processes for carbolic acid degradation: Advanced oxidation processes (AOPs) can be employed to enhance the biodegradability of carbolic acid. These processes involve the generation of highly reactive hydroxyl radicals that can break down complex organic compounds like phenol into simpler, more biodegradable molecules. This pre-treatment can significantly improve the efficiency of subsequent biological treatment steps.

- Microbial strains for phenol biodegradation: Specific microbial strains have been identified and isolated for their ability to efficiently degrade carbolic acid. These microorganisms possess specialized enzyme systems that can metabolize phenol as a carbon source. The use of these strains in bioremediation processes can significantly enhance the biodegradability of carbolic acid in contaminated environments.

- Factors affecting carbolic acid biodegradability: Various factors influence the biodegradability of carbolic acid, including pH, temperature, oxygen availability, and the presence of other organic compounds. Optimizing these parameters can enhance the efficiency of biodegradation processes. Additionally, the initial concentration of carbolic acid can impact its biodegradability, with higher concentrations potentially inhibiting microbial growth and degradation rates.

- Enzymatic degradation of carbolic acid: Enzymes play a crucial role in the biodegradation of carbolic acid. Specific enzymes, such as phenol hydroxylase and catechol dioxygenases, are involved in the initial steps of phenol degradation. Understanding the enzymatic pathways and optimizing enzyme production in microbial systems can lead to more effective biodegradation strategies for carbolic acid and other phenolic compounds.

02 Use of advanced oxidation processes for carbolic acid degradation

Advanced oxidation processes can be employed to enhance the biodegradability of carbolic acid in water treatment systems. These processes typically involve the generation of highly reactive hydroxyl radicals, which can effectively break down recalcitrant organic compounds like carbolic acid into more biodegradable intermediates. This approach can be particularly useful for treating industrial wastewater containing high concentrations of phenolic compounds.Expand Specific Solutions03 Biodegradation of carbolic acid in soil environments

Carbolic acid can be biodegraded in soil environments through the action of various soil microorganisms. The biodegradation process in soil is influenced by factors such as soil type, pH, temperature, and the presence of other organic compounds. Understanding the biodegradation pathways of carbolic acid in soil is crucial for developing effective bioremediation strategies for contaminated sites.Expand Specific Solutions04 Enhancing carbolic acid biodegradability through chemical modifications

Chemical modifications can be applied to carbolic acid to enhance its biodegradability. These modifications may involve the addition of functional groups or the alteration of the molecular structure to make the compound more susceptible to microbial degradation. Such approaches can be valuable in situations where traditional biodegradation methods are less effective due to the recalcitrant nature of carbolic acid.Expand Specific Solutions05 Monitoring and assessment of carbolic acid biodegradation

Various analytical techniques and monitoring methods can be employed to assess the biodegradation of carbolic acid in different environmental matrices. These may include chromatographic methods, spectroscopic techniques, and biological assays. Accurate monitoring of carbolic acid biodegradation is essential for evaluating the effectiveness of treatment processes and ensuring compliance with environmental regulations.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The market for carbolic acid in biodegradable packaging is in its growth phase, driven by increasing environmental concerns and regulatory pressures. The global biodegradable packaging market is projected to reach $21.6 billion by 2025, with a CAGR of 17.4%. Technologically, the field is rapidly evolving, with companies like DSM IP Assets BV, BIOTEC, and Sulapac Oy leading innovation. These firms are developing advanced bio-based materials and sustainable packaging solutions, leveraging carbolic acid's properties. However, the technology is not yet fully mature, with challenges in scalability and cost-effectiveness. Companies such as Toray Industries and LANXESS are also contributing to the advancement of this technology, indicating a competitive and dynamic landscape.

BIOTEC Biologische Naturverpackungen GmbH & Co. KG

Technical Solution: BIOTEC has developed a range of biodegradable packaging solutions that incorporate carbolic acid derivatives to enhance biodegradability and material properties. Their technology focuses on starch-based bioplastics, which are modified with carbolic acid compounds to improve their resistance to moisture and extend shelf life while maintaining biodegradability[5]. BIOTEC's approach involves a proprietary compounding process that allows for the precise control of material properties, resulting in packaging solutions that can be tailored to specific product requirements. Their biodegradable packaging typically decomposes within 3-6 months in industrial composting facilities, leaving no harmful residues[6].

Strengths: Highly customizable material properties, rapid biodegradation in industrial composting. Weaknesses: May have limitations in high-moisture applications, potentially higher cost compared to conventional plastics.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed an innovative approach to enhancing biodegradable packaging solutions using carbolic acid derivatives. Their technology involves incorporating these compounds into their existing line of bio-based polymers, such as polylactic acid (PLA), to improve both biodegradability and material performance. Toray's process includes a proprietary blending technique that ensures uniform distribution of the carbolic acid derivatives throughout the polymer matrix, resulting in consistent biodegradation rates and improved mechanical properties[7]. The company has successfully applied this technology to various packaging applications, including food containers, beverage bottles, and flexible films. Toray's enhanced biodegradable packaging solutions typically achieve complete biodegradation within 6-18 months in industrial composting conditions, depending on the specific formulation[8].

Strengths: Improved mechanical properties compared to standard bioplastics, versatile application range. Weaknesses: May require specialized processing equipment, potentially higher raw material costs.

Innovative Carbolic Acid Formulations for Packaging

Phenol with color

PatentInactiveUS20110217242A1

Innovation

- Adding color to Phenol solutions to enhance visibility and identification during medical procedures.

Method for obtaining a thermoplastic biodegradable packaging material from plantain and/or banana peel and thermoplastic biodegradable packaging material obtained using same

PatentWO2025146515A1

Innovation

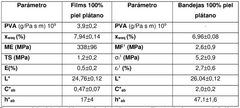

- A method involving drying, grinding, sieving, and thermoforming of banana or plantain peels, optionally combined with starch and a plasticizer, to create a biodegradable thermoplastic material with specific antioxidant and mechanical properties, including a phenol content of at least 5 mg gallic acid equivalent/g dry film and an EC50 concentration of at least 0.025 mg DPPH/mg dry film.

Environmental Impact Assessment

The incorporation of carbolic acid in biodegradable packaging solutions necessitates a comprehensive environmental impact assessment. This evaluation is crucial to understand the potential effects on ecosystems, human health, and overall environmental sustainability.

Carbolic acid, also known as phenol, is a organic compound with potential antimicrobial properties. When used in biodegradable packaging, it may enhance the material's resistance to microbial degradation, potentially extending shelf life. However, its environmental implications require careful consideration.

One primary concern is the potential leaching of carbolic acid into soil and water systems. As biodegradable packaging decomposes, there is a risk of releasing phenol compounds into the environment. This could lead to soil contamination and affect microbial communities essential for nutrient cycling and ecosystem health. Aquatic ecosystems may also be impacted if carbolic acid-containing packaging materials find their way into water bodies.

The toxicity of carbolic acid to various organisms is another critical factor. Studies have shown that phenol compounds can be harmful to aquatic life, even at low concentrations. This raises concerns about the potential bioaccumulation of these substances in food chains and their long-term effects on biodiversity.

Air quality is another aspect to consider. During the production and disposal of carbolic acid-enhanced packaging, there may be emissions of volatile organic compounds (VOCs). These emissions could contribute to air pollution and potentially affect local air quality, particularly in areas surrounding manufacturing facilities or waste management sites.

The lifecycle assessment of carbolic acid in biodegradable packaging is essential. This includes evaluating the environmental impacts from raw material extraction, manufacturing processes, transportation, use phase, and end-of-life disposal. The energy consumption and carbon footprint associated with incorporating carbolic acid into packaging materials must be weighed against potential benefits.

Waste management implications are also significant. While biodegradable packaging aims to reduce landfill waste, the addition of carbolic acid may alter decomposition rates and processes. This could affect the efficiency of composting facilities and the overall management of organic waste streams.

Human health considerations cannot be overlooked. The potential for carbolic acid to migrate from packaging into food products raises concerns about consumer safety. Rigorous testing and compliance with food safety regulations are imperative to ensure that the use of carbolic acid in packaging does not pose risks to human health.

In conclusion, while carbolic acid may offer benefits in enhancing biodegradable packaging solutions, its environmental impact must be thoroughly assessed. Balancing the potential advantages with ecological considerations is crucial for developing truly sustainable packaging alternatives. Further research and long-term studies are necessary to fully understand and mitigate any adverse environmental effects associated with this innovative approach to packaging.

Carbolic acid, also known as phenol, is a organic compound with potential antimicrobial properties. When used in biodegradable packaging, it may enhance the material's resistance to microbial degradation, potentially extending shelf life. However, its environmental implications require careful consideration.

One primary concern is the potential leaching of carbolic acid into soil and water systems. As biodegradable packaging decomposes, there is a risk of releasing phenol compounds into the environment. This could lead to soil contamination and affect microbial communities essential for nutrient cycling and ecosystem health. Aquatic ecosystems may also be impacted if carbolic acid-containing packaging materials find their way into water bodies.

The toxicity of carbolic acid to various organisms is another critical factor. Studies have shown that phenol compounds can be harmful to aquatic life, even at low concentrations. This raises concerns about the potential bioaccumulation of these substances in food chains and their long-term effects on biodiversity.

Air quality is another aspect to consider. During the production and disposal of carbolic acid-enhanced packaging, there may be emissions of volatile organic compounds (VOCs). These emissions could contribute to air pollution and potentially affect local air quality, particularly in areas surrounding manufacturing facilities or waste management sites.

The lifecycle assessment of carbolic acid in biodegradable packaging is essential. This includes evaluating the environmental impacts from raw material extraction, manufacturing processes, transportation, use phase, and end-of-life disposal. The energy consumption and carbon footprint associated with incorporating carbolic acid into packaging materials must be weighed against potential benefits.

Waste management implications are also significant. While biodegradable packaging aims to reduce landfill waste, the addition of carbolic acid may alter decomposition rates and processes. This could affect the efficiency of composting facilities and the overall management of organic waste streams.

Human health considerations cannot be overlooked. The potential for carbolic acid to migrate from packaging into food products raises concerns about consumer safety. Rigorous testing and compliance with food safety regulations are imperative to ensure that the use of carbolic acid in packaging does not pose risks to human health.

In conclusion, while carbolic acid may offer benefits in enhancing biodegradable packaging solutions, its environmental impact must be thoroughly assessed. Balancing the potential advantages with ecological considerations is crucial for developing truly sustainable packaging alternatives. Further research and long-term studies are necessary to fully understand and mitigate any adverse environmental effects associated with this innovative approach to packaging.

Regulatory Framework for Chemical Use in Packaging

The regulatory framework for chemical use in packaging is a critical aspect of the development and implementation of biodegradable packaging solutions, particularly when considering the use of carbolic acid. This framework encompasses a complex web of international, national, and local regulations that govern the use of chemicals in food contact materials and packaging.

At the international level, organizations such as the World Health Organization (WHO) and the Food and Agriculture Organization (FAO) provide guidelines and standards for chemical use in packaging. These guidelines often serve as a basis for national regulations and help ensure consistency in global trade practices.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating chemicals used in food packaging. The FDA's regulations, particularly those outlined in 21 CFR 175-178, provide detailed requirements for substances that can be used in food contact materials. For biodegradable packaging incorporating carbolic acid, manufacturers must demonstrate compliance with these regulations, including providing evidence of safety and efficacy.

The European Union has established a comprehensive regulatory framework through the European Food Safety Authority (EFSA) and the European Chemicals Agency (ECHA). The EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is particularly relevant, as it requires manufacturers to register and evaluate the safety of chemicals used in products, including packaging materials.

Many countries have adopted their own regulatory frameworks, often building upon or adapting international standards. For instance, Japan's Ministry of Health, Labour and Welfare has established specific regulations for food packaging materials, while China's GB standards provide guidelines for chemical use in packaging.

Environmental regulations also play a significant role in shaping the use of chemicals in biodegradable packaging. As sustainability becomes increasingly important, regulations are evolving to encourage the development of eco-friendly packaging solutions. This includes standards for biodegradability, compostability, and overall environmental impact.

Compliance with these diverse regulatory frameworks presents both challenges and opportunities for manufacturers developing biodegradable packaging solutions using carbolic acid. It necessitates rigorous testing, documentation, and often certification processes to ensure that products meet the required safety and environmental standards across different markets.

As the field of biodegradable packaging continues to evolve, regulatory frameworks are likely to adapt and expand. This may include the development of new standards specifically addressing novel biodegradable materials and the chemicals used in their production. Manufacturers and researchers must stay abreast of these regulatory changes to ensure continued compliance and market access for their innovative packaging solutions.

At the international level, organizations such as the World Health Organization (WHO) and the Food and Agriculture Organization (FAO) provide guidelines and standards for chemical use in packaging. These guidelines often serve as a basis for national regulations and help ensure consistency in global trade practices.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating chemicals used in food packaging. The FDA's regulations, particularly those outlined in 21 CFR 175-178, provide detailed requirements for substances that can be used in food contact materials. For biodegradable packaging incorporating carbolic acid, manufacturers must demonstrate compliance with these regulations, including providing evidence of safety and efficacy.

The European Union has established a comprehensive regulatory framework through the European Food Safety Authority (EFSA) and the European Chemicals Agency (ECHA). The EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is particularly relevant, as it requires manufacturers to register and evaluate the safety of chemicals used in products, including packaging materials.

Many countries have adopted their own regulatory frameworks, often building upon or adapting international standards. For instance, Japan's Ministry of Health, Labour and Welfare has established specific regulations for food packaging materials, while China's GB standards provide guidelines for chemical use in packaging.

Environmental regulations also play a significant role in shaping the use of chemicals in biodegradable packaging. As sustainability becomes increasingly important, regulations are evolving to encourage the development of eco-friendly packaging solutions. This includes standards for biodegradability, compostability, and overall environmental impact.

Compliance with these diverse regulatory frameworks presents both challenges and opportunities for manufacturers developing biodegradable packaging solutions using carbolic acid. It necessitates rigorous testing, documentation, and often certification processes to ensure that products meet the required safety and environmental standards across different markets.

As the field of biodegradable packaging continues to evolve, regulatory frameworks are likely to adapt and expand. This may include the development of new standards specifically addressing novel biodegradable materials and the chemicals used in their production. Manufacturers and researchers must stay abreast of these regulatory changes to ensure continued compliance and market access for their innovative packaging solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!