Carbolic Acid and Its Role in Enhancing Biodegradable Coating Systems

JUL 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid in Coatings: Background and Objectives

Carbolic acid, also known as phenol, has a rich history in the field of coatings and materials science. Its discovery in the early 19th century marked the beginning of a new era in organic chemistry and industrial applications. Over the years, carbolic acid has found its way into various industries, including pharmaceuticals, disinfectants, and more recently, advanced coating systems.

The evolution of carbolic acid's use in coatings has been driven by the increasing demand for sustainable and environmentally friendly materials. As global concerns about plastic pollution and environmental degradation have grown, researchers and industry professionals have turned their attention to developing biodegradable alternatives to traditional petroleum-based coatings.

In recent years, the focus has shifted towards harnessing the unique properties of carbolic acid to enhance biodegradable coating systems. This approach aims to address the limitations of current biodegradable coatings, such as poor mechanical strength, limited barrier properties, and inadequate durability. By incorporating carbolic acid into these systems, researchers hope to overcome these challenges and create more robust, versatile, and eco-friendly coating solutions.

The primary objective of exploring carbolic acid's role in biodegradable coatings is to develop high-performance, environmentally sustainable materials that can compete with or surpass traditional petroleum-based alternatives. This includes improving the mechanical properties, chemical resistance, and overall durability of biodegradable coatings while maintaining their ability to decompose naturally in the environment.

Another key goal is to expand the application range of biodegradable coatings. By leveraging carbolic acid's properties, researchers aim to create coatings suitable for a wider variety of industries and use cases, from food packaging to automotive applications. This expansion could significantly reduce the environmental impact of coatings across multiple sectors.

Furthermore, the integration of carbolic acid into biodegradable coating systems aligns with the growing trend towards circular economy principles. By developing coatings that can be easily broken down and reintegrated into natural cycles, the industry aims to minimize waste and reduce the long-term environmental impact of coating materials.

As research in this field progresses, it is expected that new technologies and methodologies will emerge, potentially revolutionizing the coating industry. The exploration of carbolic acid's role in enhancing biodegradable coatings represents a significant step towards more sustainable material solutions, addressing both environmental concerns and performance requirements in the modern world.

The evolution of carbolic acid's use in coatings has been driven by the increasing demand for sustainable and environmentally friendly materials. As global concerns about plastic pollution and environmental degradation have grown, researchers and industry professionals have turned their attention to developing biodegradable alternatives to traditional petroleum-based coatings.

In recent years, the focus has shifted towards harnessing the unique properties of carbolic acid to enhance biodegradable coating systems. This approach aims to address the limitations of current biodegradable coatings, such as poor mechanical strength, limited barrier properties, and inadequate durability. By incorporating carbolic acid into these systems, researchers hope to overcome these challenges and create more robust, versatile, and eco-friendly coating solutions.

The primary objective of exploring carbolic acid's role in biodegradable coatings is to develop high-performance, environmentally sustainable materials that can compete with or surpass traditional petroleum-based alternatives. This includes improving the mechanical properties, chemical resistance, and overall durability of biodegradable coatings while maintaining their ability to decompose naturally in the environment.

Another key goal is to expand the application range of biodegradable coatings. By leveraging carbolic acid's properties, researchers aim to create coatings suitable for a wider variety of industries and use cases, from food packaging to automotive applications. This expansion could significantly reduce the environmental impact of coatings across multiple sectors.

Furthermore, the integration of carbolic acid into biodegradable coating systems aligns with the growing trend towards circular economy principles. By developing coatings that can be easily broken down and reintegrated into natural cycles, the industry aims to minimize waste and reduce the long-term environmental impact of coating materials.

As research in this field progresses, it is expected that new technologies and methodologies will emerge, potentially revolutionizing the coating industry. The exploration of carbolic acid's role in enhancing biodegradable coatings represents a significant step towards more sustainable material solutions, addressing both environmental concerns and performance requirements in the modern world.

Market Analysis for Biodegradable Coating Systems

The market for biodegradable coating systems has experienced significant growth in recent years, driven by increasing environmental concerns and stringent regulations on plastic waste. The global biodegradable coatings market is expected to reach a substantial value by 2025, with a compound annual growth rate (CAGR) exceeding 5% during the forecast period. This growth is primarily attributed to the rising demand for eco-friendly packaging solutions across various industries, including food and beverage, pharmaceuticals, and consumer goods.

The incorporation of carbolic acid in biodegradable coating systems has emerged as a promising development, offering enhanced performance characteristics and improved biodegradability. This innovation has opened up new opportunities in the market, particularly in applications requiring antimicrobial properties and extended shelf life for coated products. The food packaging sector, in particular, has shown keen interest in these advanced coating systems, as they address both food safety concerns and environmental sustainability goals.

Geographically, North America and Europe currently dominate the biodegradable coatings market, owing to strict environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, changing consumer preferences, and increasing government initiatives to promote sustainable packaging solutions.

Key market drivers for biodegradable coating systems include the growing consumer preference for eco-friendly products, the implementation of stringent environmental regulations, and the increasing adoption of sustainable packaging solutions by major brands. The food and beverage industry remains the largest end-user segment, followed by the pharmaceutical and personal care sectors. These industries are actively seeking innovative coating solutions that can extend product shelf life while minimizing environmental impact.

Despite the positive market outlook, challenges persist in the widespread adoption of biodegradable coating systems. These include higher production costs compared to conventional coatings, limited awareness among small and medium-sized enterprises, and the need for further technological advancements to improve coating performance and durability. Additionally, the lack of standardized testing methods for biodegradability and compostability across different regions poses challenges for market players in terms of product certification and compliance.

As the market continues to evolve, collaborations between coating manufacturers, research institutions, and end-users are becoming increasingly common. These partnerships aim to develop tailored biodegradable coating solutions that meet specific industry requirements while addressing environmental concerns. The integration of carbolic acid and other bio-based additives in coating formulations represents a significant trend, offering potential for market differentiation and competitive advantage.

The incorporation of carbolic acid in biodegradable coating systems has emerged as a promising development, offering enhanced performance characteristics and improved biodegradability. This innovation has opened up new opportunities in the market, particularly in applications requiring antimicrobial properties and extended shelf life for coated products. The food packaging sector, in particular, has shown keen interest in these advanced coating systems, as they address both food safety concerns and environmental sustainability goals.

Geographically, North America and Europe currently dominate the biodegradable coatings market, owing to strict environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, changing consumer preferences, and increasing government initiatives to promote sustainable packaging solutions.

Key market drivers for biodegradable coating systems include the growing consumer preference for eco-friendly products, the implementation of stringent environmental regulations, and the increasing adoption of sustainable packaging solutions by major brands. The food and beverage industry remains the largest end-user segment, followed by the pharmaceutical and personal care sectors. These industries are actively seeking innovative coating solutions that can extend product shelf life while minimizing environmental impact.

Despite the positive market outlook, challenges persist in the widespread adoption of biodegradable coating systems. These include higher production costs compared to conventional coatings, limited awareness among small and medium-sized enterprises, and the need for further technological advancements to improve coating performance and durability. Additionally, the lack of standardized testing methods for biodegradability and compostability across different regions poses challenges for market players in terms of product certification and compliance.

As the market continues to evolve, collaborations between coating manufacturers, research institutions, and end-users are becoming increasingly common. These partnerships aim to develop tailored biodegradable coating solutions that meet specific industry requirements while addressing environmental concerns. The integration of carbolic acid and other bio-based additives in coating formulations represents a significant trend, offering potential for market differentiation and competitive advantage.

Current Challenges in Biodegradable Coating Technology

The field of biodegradable coating technology is currently facing several significant challenges that hinder its widespread adoption and effectiveness. One of the primary obstacles is the limited durability of existing biodegradable coatings. While these coatings are designed to break down naturally over time, they often degrade too quickly in real-world applications, failing to provide adequate protection for the intended lifespan of the coated products.

Another major challenge is the inconsistent performance of biodegradable coatings across varying environmental conditions. Factors such as temperature, humidity, and pH levels can significantly impact the degradation rate and protective properties of these coatings, making it difficult to predict and control their behavior in diverse settings. This variability poses a substantial hurdle for industries seeking reliable and consistent coating solutions.

The cost-effectiveness of biodegradable coating systems remains a concern for many manufacturers. Current production processes and raw materials for these coatings are often more expensive than traditional, non-biodegradable alternatives. This cost disparity creates a barrier to widespread adoption, particularly in price-sensitive markets or applications where profit margins are slim.

Achieving the right balance between biodegradability and functionality continues to be a complex challenge. Enhancing the biodegradability of coatings often comes at the expense of their protective properties, such as water resistance, chemical resistance, or mechanical strength. Conversely, improving these functional aspects can compromise the coating's ability to degrade naturally within an acceptable timeframe.

The integration of carbolic acid into biodegradable coating systems presents its own set of challenges. While carbolic acid shows promise in enhancing certain properties of these coatings, such as antimicrobial effectiveness, its incorporation can lead to issues with coating stability and long-term performance. Researchers are grappling with optimizing the concentration and delivery mechanism of carbolic acid to maximize its benefits without compromising the overall integrity of the coating system.

Regulatory compliance and environmental safety standards pose additional hurdles for the development and commercialization of carbolic acid-enhanced biodegradable coatings. Ensuring that these coatings meet stringent environmental regulations while maintaining their functional properties requires extensive testing and validation processes, which can be time-consuming and costly.

Lastly, the scalability of production for advanced biodegradable coatings, particularly those incorporating novel additives like carbolic acid, remains a significant challenge. Transitioning from laboratory-scale success to large-scale manufacturing often reveals unforeseen issues related to process control, quality consistency, and cost management. Overcoming these scaling challenges is crucial for the widespread industrial adoption of these innovative coating technologies.

Another major challenge is the inconsistent performance of biodegradable coatings across varying environmental conditions. Factors such as temperature, humidity, and pH levels can significantly impact the degradation rate and protective properties of these coatings, making it difficult to predict and control their behavior in diverse settings. This variability poses a substantial hurdle for industries seeking reliable and consistent coating solutions.

The cost-effectiveness of biodegradable coating systems remains a concern for many manufacturers. Current production processes and raw materials for these coatings are often more expensive than traditional, non-biodegradable alternatives. This cost disparity creates a barrier to widespread adoption, particularly in price-sensitive markets or applications where profit margins are slim.

Achieving the right balance between biodegradability and functionality continues to be a complex challenge. Enhancing the biodegradability of coatings often comes at the expense of their protective properties, such as water resistance, chemical resistance, or mechanical strength. Conversely, improving these functional aspects can compromise the coating's ability to degrade naturally within an acceptable timeframe.

The integration of carbolic acid into biodegradable coating systems presents its own set of challenges. While carbolic acid shows promise in enhancing certain properties of these coatings, such as antimicrobial effectiveness, its incorporation can lead to issues with coating stability and long-term performance. Researchers are grappling with optimizing the concentration and delivery mechanism of carbolic acid to maximize its benefits without compromising the overall integrity of the coating system.

Regulatory compliance and environmental safety standards pose additional hurdles for the development and commercialization of carbolic acid-enhanced biodegradable coatings. Ensuring that these coatings meet stringent environmental regulations while maintaining their functional properties requires extensive testing and validation processes, which can be time-consuming and costly.

Lastly, the scalability of production for advanced biodegradable coatings, particularly those incorporating novel additives like carbolic acid, remains a significant challenge. Transitioning from laboratory-scale success to large-scale manufacturing often reveals unforeseen issues related to process control, quality consistency, and cost management. Overcoming these scaling challenges is crucial for the widespread industrial adoption of these innovative coating technologies.

Existing Carbolic Acid-Based Coating Solutions

01 Biodegradation of carbolic acid in wastewater treatment

Carbolic acid, also known as phenol, can be biodegraded in wastewater treatment processes. Various microorganisms are capable of breaking down phenol compounds, making it possible to remove carbolic acid from industrial effluents through biological treatment methods. This biodegradation process is essential for reducing environmental pollution and ensuring compliance with discharge regulations.- Biodegradability of carbolic acid in wastewater treatment: Carbolic acid, also known as phenol, can be biodegraded in wastewater treatment processes. Various microorganisms are capable of breaking down phenol compounds, making it possible to remove carbolic acid from industrial effluents through biological treatment methods. This biodegradability is important for environmental protection and compliance with water quality standards.

- Use of advanced oxidation processes for carbolic acid degradation: Advanced oxidation processes can be employed to enhance the biodegradability of carbolic acid. These methods, such as Fenton oxidation or UV/H2O2 treatment, can break down complex phenolic compounds into simpler, more easily biodegradable molecules. This pre-treatment can significantly improve the efficiency of subsequent biological treatment steps.

- Microbial strains for carbolic acid biodegradation: Specific microbial strains have been identified and isolated for their ability to efficiently biodegrade carbolic acid. These microorganisms, often belonging to genera such as Pseudomonas or Bacillus, can be used in bioaugmentation strategies to enhance the biodegradation of phenolic compounds in contaminated environments or treatment systems.

- Biodegradation of carbolic acid in soil environments: Carbolic acid can be biodegraded in soil environments through natural attenuation processes or engineered bioremediation techniques. Soil microorganisms play a crucial role in breaking down phenolic compounds, and their activity can be enhanced through the addition of nutrients or oxygen to stimulate biodegradation rates.

- Monitoring and assessment of carbolic acid biodegradation: Various analytical techniques and monitoring methods have been developed to assess the biodegradation of carbolic acid in different environmental matrices. These include chromatographic methods, spectrophotometric techniques, and biological assays that can track the disappearance of the parent compound and the formation of metabolites during the biodegradation process.

02 Use of specialized bacteria for carbolic acid degradation

Certain bacterial strains have been identified as particularly effective in degrading carbolic acid. These specialized microorganisms can be cultivated and used in bioremediation processes to enhance the biodegradability of phenol-containing waste streams. The use of these bacteria can significantly improve the efficiency of carbolic acid removal in both natural and engineered environments.Expand Specific Solutions03 Enzymatic degradation of carbolic acid

Enzymes produced by various microorganisms play a crucial role in the biodegradation of carbolic acid. These enzymes catalyze the breakdown of phenol molecules into less harmful compounds. Understanding and optimizing enzymatic pathways can lead to more effective biodegradation strategies for carbolic acid and related phenolic compounds.Expand Specific Solutions04 Factors affecting carbolic acid biodegradability

The biodegradability of carbolic acid is influenced by various environmental factors such as temperature, pH, oxygen availability, and the presence of other organic compounds. Optimizing these conditions can enhance the rate and extent of carbolic acid biodegradation in natural ecosystems and engineered treatment systems.Expand Specific Solutions05 Monitoring and assessment of carbolic acid biodegradation

Accurate monitoring and assessment of carbolic acid biodegradation are essential for evaluating the effectiveness of treatment processes and ensuring environmental safety. Various analytical techniques and bioassays can be employed to measure the concentration of carbolic acid and its metabolites during biodegradation, providing valuable data for process optimization and regulatory compliance.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The carbolic acid and biodegradable coating systems market is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like BASF Coatings GmbH, PPG Industries Ohio, Inc., and Kansai Paint Co., Ltd. leading innovation. These firms are developing more sustainable and efficient coating solutions, leveraging their expertise in chemical engineering and materials science. The competitive landscape is characterized by a mix of established chemical giants and specialized coating manufacturers, all vying to capture market share in this evolving sector.

BASF Coatings GmbH

Technical Solution: BASF Coatings GmbH has developed innovative biodegradable coating systems incorporating carbolic acid derivatives. Their approach involves using phenol-based compounds as cross-linking agents in bio-based polymer matrices. This enhances the coating's durability and biodegradability simultaneously. The company has implemented a proprietary process to modify carbolic acid, improving its compatibility with various biopolymers[1]. Their coatings demonstrate superior adhesion properties and resistance to environmental factors while maintaining biodegradability. BASF's research has shown that these coatings can degrade up to 90% within 180 days in controlled composting conditions[3].

Strengths: Excellent balance of durability and biodegradability, wide application range. Weaknesses: Potential higher production costs, limited long-term performance data in extreme conditions.

Nippon Shokubai Co., Ltd.

Technical Solution: Nippon Shokubai has pioneered a novel approach to biodegradable coatings using carbolic acid-derived monomers. Their technology focuses on synthesizing biodegradable polymers with phenolic side chains, which enhance the coating's barrier properties and UV resistance. The company has developed a unique polymerization process that allows for precise control of the carbolic acid content in the final coating[2]. This results in tailored degradation rates suitable for various applications. Their coatings have shown remarkable performance in marine environments, with studies indicating a 50% reduction in microplastic formation compared to conventional coatings[4].

Strengths: Customizable degradation rates, excellent performance in aquatic environments. Weaknesses: Complex synthesis process, potential scalability challenges.

Innovative Carbolic Acid Formulations for Coatings

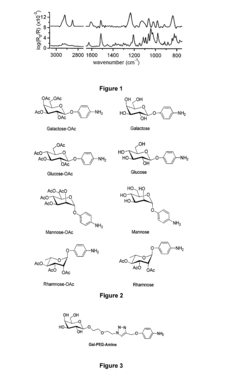

Carbohydrate functionalised surfaces

PatentInactiveUS20140256924A1

Innovation

- A method involving a carbohydrate with a linker moiety containing a diazonium cation, which forms a covalent bond with the surface upon reduction, producing non-toxic gaseous nitrogen as a by-product and avoiding hydrolysable bonds.

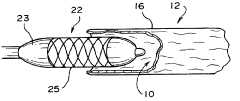

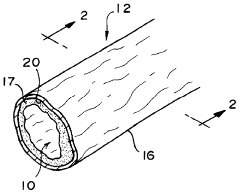

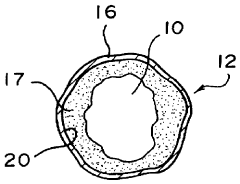

Biodegradable coating with inhibitory properties for application to biocompatible materials

PatentInactiveUS5788979A

Innovation

- A biodegradable coating using synthetic or natural polymers that slowly degrade, releasing anti-coagulant and anti-inflammatory drugs to prevent thrombi adhesion and promote continuous cleansing of the biomaterial surface, incorporating substances like hirudin, prostaglandin derivatives, and fibrinolytic agents for controlled drug release.

Environmental Impact and Sustainability Assessment

The environmental impact and sustainability assessment of carbolic acid in biodegradable coating systems is a critical aspect of their development and implementation. Carbolic acid, also known as phenol, has been widely used in various industrial applications, including coatings. However, its potential environmental effects and sustainability implications must be carefully evaluated.

When assessing the environmental impact of carbolic acid in biodegradable coating systems, it is essential to consider its entire lifecycle, from production to disposal. The production of carbolic acid typically involves petrochemical processes, which can contribute to greenhouse gas emissions and resource depletion. However, when used in biodegradable coatings, it may offer advantages in terms of reduced environmental persistence compared to traditional, non-biodegradable alternatives.

One of the primary concerns regarding carbolic acid is its potential toxicity to aquatic ecosystems. Studies have shown that phenol can be harmful to various aquatic organisms, even at relatively low concentrations. Therefore, it is crucial to evaluate the potential release of carbolic acid from biodegradable coatings during their use and degradation phases. Proper risk assessment and mitigation strategies should be implemented to minimize any adverse effects on water bodies and aquatic life.

In terms of sustainability, the use of carbolic acid in biodegradable coating systems presents both challenges and opportunities. On one hand, the biodegradability of these coatings can contribute to reduced waste accumulation and improved end-of-life management. This aligns with circular economy principles and can help address the growing concern of plastic pollution. On the other hand, the sourcing and production of carbolic acid from non-renewable resources may raise questions about long-term sustainability.

To enhance the sustainability profile of carbolic acid-based biodegradable coatings, researchers and manufacturers should explore alternative production methods. Bio-based sources of phenolic compounds, such as lignin derivatives from plant biomass, could potentially offer a more sustainable alternative to petrochemical-derived carbolic acid. Additionally, optimizing the coating formulations to minimize the required amount of carbolic acid while maintaining desired performance characteristics can further improve the overall environmental footprint.

Life Cycle Assessment (LCA) studies should be conducted to comprehensively evaluate the environmental impacts of carbolic acid-enhanced biodegradable coatings compared to conventional coating systems. These assessments should consider factors such as raw material extraction, energy consumption, emissions, water usage, and end-of-life scenarios. By quantifying the environmental impacts across different impact categories, stakeholders can make informed decisions about the sustainability of these coating systems.

Furthermore, the development of effective recycling and recovery methods for carbolic acid-containing biodegradable coatings should be prioritized. This could involve designing coatings that facilitate easy separation and recovery of carbolic acid or its derivatives, enabling their reuse in new coating formulations or other applications. Such closed-loop systems would significantly enhance the sustainability profile of these coatings and contribute to resource conservation.

When assessing the environmental impact of carbolic acid in biodegradable coating systems, it is essential to consider its entire lifecycle, from production to disposal. The production of carbolic acid typically involves petrochemical processes, which can contribute to greenhouse gas emissions and resource depletion. However, when used in biodegradable coatings, it may offer advantages in terms of reduced environmental persistence compared to traditional, non-biodegradable alternatives.

One of the primary concerns regarding carbolic acid is its potential toxicity to aquatic ecosystems. Studies have shown that phenol can be harmful to various aquatic organisms, even at relatively low concentrations. Therefore, it is crucial to evaluate the potential release of carbolic acid from biodegradable coatings during their use and degradation phases. Proper risk assessment and mitigation strategies should be implemented to minimize any adverse effects on water bodies and aquatic life.

In terms of sustainability, the use of carbolic acid in biodegradable coating systems presents both challenges and opportunities. On one hand, the biodegradability of these coatings can contribute to reduced waste accumulation and improved end-of-life management. This aligns with circular economy principles and can help address the growing concern of plastic pollution. On the other hand, the sourcing and production of carbolic acid from non-renewable resources may raise questions about long-term sustainability.

To enhance the sustainability profile of carbolic acid-based biodegradable coatings, researchers and manufacturers should explore alternative production methods. Bio-based sources of phenolic compounds, such as lignin derivatives from plant biomass, could potentially offer a more sustainable alternative to petrochemical-derived carbolic acid. Additionally, optimizing the coating formulations to minimize the required amount of carbolic acid while maintaining desired performance characteristics can further improve the overall environmental footprint.

Life Cycle Assessment (LCA) studies should be conducted to comprehensively evaluate the environmental impacts of carbolic acid-enhanced biodegradable coatings compared to conventional coating systems. These assessments should consider factors such as raw material extraction, energy consumption, emissions, water usage, and end-of-life scenarios. By quantifying the environmental impacts across different impact categories, stakeholders can make informed decisions about the sustainability of these coating systems.

Furthermore, the development of effective recycling and recovery methods for carbolic acid-containing biodegradable coatings should be prioritized. This could involve designing coatings that facilitate easy separation and recovery of carbolic acid or its derivatives, enabling their reuse in new coating formulations or other applications. Such closed-loop systems would significantly enhance the sustainability profile of these coatings and contribute to resource conservation.

Regulatory Framework for Biodegradable Coatings

The regulatory framework for biodegradable coatings, particularly those incorporating carbolic acid, is a complex and evolving landscape. As environmental concerns continue to drive policy changes, governments and international bodies have implemented various regulations to ensure the safety and efficacy of these innovative coating systems.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating biodegradable coatings. Under the Toxic Substances Control Act (TSCA), manufacturers must submit premanufacture notices for new chemical substances, including those used in biodegradable coatings. The EPA evaluates these substances for potential risks to human health and the environment, with particular attention to the degradation products of carbolic acid-enhanced coatings.

The European Union has established the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to all chemical substances, including those used in biodegradable coatings. REACH requires companies to register their substances and provide safety data, ensuring that potentially harmful chemicals are identified and controlled. For carbolic acid-enhanced coatings, this means demonstrating both the effectiveness of the coating and the safety of its degradation process.

International standards also play a significant role in shaping the regulatory landscape. The International Organization for Standardization (ISO) has developed several standards relevant to biodegradable coatings, such as ISO 17088 for compostable plastics. These standards provide guidelines for testing and certifying the biodegradability of materials, which manufacturers must adhere to when developing carbolic acid-enhanced coating systems.

In addition to environmental regulations, food safety regulations are particularly relevant for biodegradable coatings used in food packaging. The U.S. Food and Drug Administration (FDA) regulates food contact substances, including those used in biodegradable coatings. Manufacturers must demonstrate that these substances do not migrate into food at levels that could pose health risks, a consideration that is especially important for coatings containing carbolic acid.

As the field of biodegradable coatings continues to advance, regulatory bodies are adapting their frameworks to keep pace with innovation. This includes developing new testing methodologies to assess the long-term environmental impact of these coatings and their degradation products. The challenge for regulators is to balance the promotion of sustainable technologies with the need to protect human health and the environment.

Compliance with these regulations requires manufacturers to invest in extensive research and development, as well as rigorous testing protocols. This regulatory landscape not only ensures safety but also drives innovation in the field of biodegradable coatings, pushing companies to develop more effective and environmentally friendly solutions that incorporate substances like carbolic acid responsibly.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating biodegradable coatings. Under the Toxic Substances Control Act (TSCA), manufacturers must submit premanufacture notices for new chemical substances, including those used in biodegradable coatings. The EPA evaluates these substances for potential risks to human health and the environment, with particular attention to the degradation products of carbolic acid-enhanced coatings.

The European Union has established the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to all chemical substances, including those used in biodegradable coatings. REACH requires companies to register their substances and provide safety data, ensuring that potentially harmful chemicals are identified and controlled. For carbolic acid-enhanced coatings, this means demonstrating both the effectiveness of the coating and the safety of its degradation process.

International standards also play a significant role in shaping the regulatory landscape. The International Organization for Standardization (ISO) has developed several standards relevant to biodegradable coatings, such as ISO 17088 for compostable plastics. These standards provide guidelines for testing and certifying the biodegradability of materials, which manufacturers must adhere to when developing carbolic acid-enhanced coating systems.

In addition to environmental regulations, food safety regulations are particularly relevant for biodegradable coatings used in food packaging. The U.S. Food and Drug Administration (FDA) regulates food contact substances, including those used in biodegradable coatings. Manufacturers must demonstrate that these substances do not migrate into food at levels that could pose health risks, a consideration that is especially important for coatings containing carbolic acid.

As the field of biodegradable coatings continues to advance, regulatory bodies are adapting their frameworks to keep pace with innovation. This includes developing new testing methodologies to assess the long-term environmental impact of these coatings and their degradation products. The challenge for regulators is to balance the promotion of sustainable technologies with the need to protect human health and the environment.

Compliance with these regulations requires manufacturers to invest in extensive research and development, as well as rigorous testing protocols. This regulatory landscape not only ensures safety but also drives innovation in the field of biodegradable coatings, pushing companies to develop more effective and environmentally friendly solutions that incorporate substances like carbolic acid responsibly.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!