Carbolic Acid and Its Contribution to Hybrid Composite Materials

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid Overview

Carbolic acid, also known as phenol, is a versatile organic compound with the molecular formula C6H5OH. It consists of a hydroxyl group (-OH) bonded to a phenyl ring, giving it unique chemical properties that have made it valuable in various industrial applications. Discovered in the 19th century, carbolic acid has played a significant role in the development of modern chemistry and materials science.

The compound's structure allows it to participate in a wide range of chemical reactions, making it an essential precursor in the synthesis of numerous organic compounds. Its ability to form strong hydrogen bonds and engage in electrophilic aromatic substitution reactions contributes to its reactivity and usefulness in various chemical processes.

In the context of hybrid composite materials, carbolic acid serves as a crucial building block for the production of phenolic resins. These resins are widely used as binders and matrix materials in composite structures due to their excellent thermal stability, fire resistance, and mechanical properties. The phenolic groups in carbolic acid enable the formation of cross-linked polymer networks, which are essential for the high-performance characteristics of these composites.

The contribution of carbolic acid to hybrid composite materials extends beyond its role in phenolic resins. It is also utilized in the synthesis of other polymers and additives that enhance the properties of composite materials. For instance, carbolic acid derivatives are employed in the production of flame retardants, which are crucial for improving the fire resistance of composites used in aerospace and automotive applications.

Furthermore, carbolic acid plays a role in the surface treatment of reinforcing fibers used in hybrid composites. Its ability to modify surface chemistry can improve the interfacial adhesion between the matrix and reinforcing elements, leading to enhanced mechanical properties and durability of the composite material.

The industrial production of carbolic acid primarily relies on the cumene process, which involves the oxidation of cumene to form phenol and acetone. This process has been optimized over the years to meet the growing demand for carbolic acid in various sectors, including the composite materials industry.

As research in hybrid composite materials continues to advance, the role of carbolic acid is likely to evolve. Scientists and engineers are exploring new ways to leverage its chemical properties to develop novel composite formulations with improved performance characteristics. This ongoing research underscores the enduring importance of carbolic acid in the field of materials science and its potential to contribute to future innovations in hybrid composite materials.

The compound's structure allows it to participate in a wide range of chemical reactions, making it an essential precursor in the synthesis of numerous organic compounds. Its ability to form strong hydrogen bonds and engage in electrophilic aromatic substitution reactions contributes to its reactivity and usefulness in various chemical processes.

In the context of hybrid composite materials, carbolic acid serves as a crucial building block for the production of phenolic resins. These resins are widely used as binders and matrix materials in composite structures due to their excellent thermal stability, fire resistance, and mechanical properties. The phenolic groups in carbolic acid enable the formation of cross-linked polymer networks, which are essential for the high-performance characteristics of these composites.

The contribution of carbolic acid to hybrid composite materials extends beyond its role in phenolic resins. It is also utilized in the synthesis of other polymers and additives that enhance the properties of composite materials. For instance, carbolic acid derivatives are employed in the production of flame retardants, which are crucial for improving the fire resistance of composites used in aerospace and automotive applications.

Furthermore, carbolic acid plays a role in the surface treatment of reinforcing fibers used in hybrid composites. Its ability to modify surface chemistry can improve the interfacial adhesion between the matrix and reinforcing elements, leading to enhanced mechanical properties and durability of the composite material.

The industrial production of carbolic acid primarily relies on the cumene process, which involves the oxidation of cumene to form phenol and acetone. This process has been optimized over the years to meet the growing demand for carbolic acid in various sectors, including the composite materials industry.

As research in hybrid composite materials continues to advance, the role of carbolic acid is likely to evolve. Scientists and engineers are exploring new ways to leverage its chemical properties to develop novel composite formulations with improved performance characteristics. This ongoing research underscores the enduring importance of carbolic acid in the field of materials science and its potential to contribute to future innovations in hybrid composite materials.

Market Demand Analysis

The market demand for carbolic acid and its applications in hybrid composite materials has been steadily growing in recent years. This growth is primarily driven by the increasing need for high-performance materials in various industries, including aerospace, automotive, construction, and electronics. Carbolic acid, also known as phenol, plays a crucial role in the production of phenolic resins, which are essential components in many hybrid composite materials.

In the aerospace sector, there is a rising demand for lightweight yet strong materials that can withstand extreme conditions. Hybrid composites incorporating carbolic acid-based resins offer excellent thermal stability, fire resistance, and mechanical properties, making them ideal for aircraft interiors and structural components. The automotive industry is also showing increased interest in these materials due to their potential to reduce vehicle weight while maintaining safety standards and improving fuel efficiency.

The construction industry is another significant market for carbolic acid-based hybrid composites. These materials are being increasingly used in building facades, insulation, and fire-resistant panels due to their durability, weather resistance, and thermal insulation properties. As sustainable construction practices gain traction, the demand for eco-friendly composite materials is expected to further boost the market for carbolic acid-based products.

In the electronics sector, the miniaturization trend and the need for heat-resistant materials in circuit boards and electronic components are driving the demand for phenolic resins and related hybrid composites. The growing adoption of 5G technology and the expansion of data centers are also contributing to the increased use of these materials in telecommunications infrastructure.

The global phenolic resin market, which is closely tied to carbolic acid consumption, is projected to experience significant growth in the coming years. This growth is attributed to the expanding applications of hybrid composite materials across various end-use industries. Additionally, the increasing focus on research and development to enhance the properties of these materials and explore new applications is expected to create further market opportunities.

However, it is important to note that the market demand for carbolic acid and its derivatives in hybrid composites is not without challenges. Environmental concerns and stringent regulations regarding the production and use of phenol-based materials may impact market growth in some regions. Furthermore, the volatility of raw material prices and the availability of alternative materials could influence market dynamics.

Despite these challenges, the overall market outlook for carbolic acid in hybrid composite materials remains positive. The unique combination of properties offered by these materials, coupled with ongoing technological advancements and the push for more sustainable solutions, is likely to drive continued growth in demand across multiple industries.

In the aerospace sector, there is a rising demand for lightweight yet strong materials that can withstand extreme conditions. Hybrid composites incorporating carbolic acid-based resins offer excellent thermal stability, fire resistance, and mechanical properties, making them ideal for aircraft interiors and structural components. The automotive industry is also showing increased interest in these materials due to their potential to reduce vehicle weight while maintaining safety standards and improving fuel efficiency.

The construction industry is another significant market for carbolic acid-based hybrid composites. These materials are being increasingly used in building facades, insulation, and fire-resistant panels due to their durability, weather resistance, and thermal insulation properties. As sustainable construction practices gain traction, the demand for eco-friendly composite materials is expected to further boost the market for carbolic acid-based products.

In the electronics sector, the miniaturization trend and the need for heat-resistant materials in circuit boards and electronic components are driving the demand for phenolic resins and related hybrid composites. The growing adoption of 5G technology and the expansion of data centers are also contributing to the increased use of these materials in telecommunications infrastructure.

The global phenolic resin market, which is closely tied to carbolic acid consumption, is projected to experience significant growth in the coming years. This growth is attributed to the expanding applications of hybrid composite materials across various end-use industries. Additionally, the increasing focus on research and development to enhance the properties of these materials and explore new applications is expected to create further market opportunities.

However, it is important to note that the market demand for carbolic acid and its derivatives in hybrid composites is not without challenges. Environmental concerns and stringent regulations regarding the production and use of phenol-based materials may impact market growth in some regions. Furthermore, the volatility of raw material prices and the availability of alternative materials could influence market dynamics.

Despite these challenges, the overall market outlook for carbolic acid in hybrid composite materials remains positive. The unique combination of properties offered by these materials, coupled with ongoing technological advancements and the push for more sustainable solutions, is likely to drive continued growth in demand across multiple industries.

Current Challenges

The integration of carbolic acid into hybrid composite materials presents several significant challenges that researchers and manufacturers are currently grappling with. One of the primary obstacles is the inherent reactivity of carbolic acid, which can lead to undesired chemical interactions with other components of the composite matrix. This reactivity can potentially compromise the structural integrity and long-term stability of the resulting materials, necessitating careful consideration of compatibility and potential degradation pathways.

Another critical challenge lies in achieving uniform dispersion of carbolic acid within the composite matrix. The tendency of carbolic acid to form aggregates or clusters can result in heterogeneous distribution, leading to inconsistent material properties and reduced overall performance. Developing effective dispersion techniques that maintain the acid's beneficial properties while ensuring even distribution throughout the composite remains a key area of focus for researchers in this field.

The impact of carbolic acid on the mechanical properties of hybrid composites is also a subject of ongoing investigation. While the acid can potentially enhance certain characteristics, such as thermal stability or flame retardancy, it may simultaneously affect other crucial properties like tensile strength, flexural modulus, or impact resistance. Striking the right balance to optimize overall material performance without sacrificing essential mechanical attributes poses a significant challenge for materials scientists and engineers.

Environmental and health concerns associated with carbolic acid usage in composite materials represent another hurdle. The potential for leaching or off-gassing of the acid during the material's lifecycle raises questions about long-term environmental impact and potential health risks to end-users. Developing effective encapsulation or binding methods to mitigate these risks without compromising the acid's functional benefits is an area of active research and development.

Scalability and cost-effectiveness in manufacturing processes incorporating carbolic acid into hybrid composites present additional challenges. The need for specialized equipment, handling procedures, and safety measures to work with carbolic acid can increase production costs and complexity. Finding economically viable methods for large-scale production while maintaining consistent quality and performance standards is crucial for the widespread adoption of these advanced materials in various industries.

Lastly, the regulatory landscape surrounding the use of carbolic acid in composite materials is evolving, with potential implications for product development and market entry. Navigating the complex web of safety regulations, material certifications, and environmental standards across different regions and applications adds another layer of complexity to the development and commercialization of carbolic acid-enhanced hybrid composites.

Another critical challenge lies in achieving uniform dispersion of carbolic acid within the composite matrix. The tendency of carbolic acid to form aggregates or clusters can result in heterogeneous distribution, leading to inconsistent material properties and reduced overall performance. Developing effective dispersion techniques that maintain the acid's beneficial properties while ensuring even distribution throughout the composite remains a key area of focus for researchers in this field.

The impact of carbolic acid on the mechanical properties of hybrid composites is also a subject of ongoing investigation. While the acid can potentially enhance certain characteristics, such as thermal stability or flame retardancy, it may simultaneously affect other crucial properties like tensile strength, flexural modulus, or impact resistance. Striking the right balance to optimize overall material performance without sacrificing essential mechanical attributes poses a significant challenge for materials scientists and engineers.

Environmental and health concerns associated with carbolic acid usage in composite materials represent another hurdle. The potential for leaching or off-gassing of the acid during the material's lifecycle raises questions about long-term environmental impact and potential health risks to end-users. Developing effective encapsulation or binding methods to mitigate these risks without compromising the acid's functional benefits is an area of active research and development.

Scalability and cost-effectiveness in manufacturing processes incorporating carbolic acid into hybrid composites present additional challenges. The need for specialized equipment, handling procedures, and safety measures to work with carbolic acid can increase production costs and complexity. Finding economically viable methods for large-scale production while maintaining consistent quality and performance standards is crucial for the widespread adoption of these advanced materials in various industries.

Lastly, the regulatory landscape surrounding the use of carbolic acid in composite materials is evolving, with potential implications for product development and market entry. Navigating the complex web of safety regulations, material certifications, and environmental standards across different regions and applications adds another layer of complexity to the development and commercialization of carbolic acid-enhanced hybrid composites.

Existing Applications

01 Carbolic acid in medical applications

Carbolic acid, also known as phenol, has been used in various medical applications due to its antiseptic properties. It has been utilized in disinfectants, surgical procedures, and wound treatments. The compound's ability to kill bacteria and other microorganisms makes it valuable in medical settings for preventing infections and promoting healing.- Historical use of carbolic acid in medical applications: Carbolic acid, also known as phenol, has a long history of use in medical and pharmaceutical applications. It was widely used as an antiseptic and disinfectant in the late 19th and early 20th centuries. Its properties made it valuable for wound treatment and surgical procedures, although its use has since been largely replaced by safer alternatives.

- Carbolic acid in industrial processes: Carbolic acid finds applications in various industrial processes. It is used in the production of plastics, resins, and other synthetic materials. Its chemical properties make it useful in manufacturing processes, particularly in the creation of phenolic compounds and derivatives used in different industries.

- Environmental and waste treatment applications: Carbolic acid and its derivatives are utilized in environmental and waste treatment applications. They can be employed in water purification processes, sewage treatment, and as components in certain types of filters or treatment systems designed to remove contaminants from water or air.

- Safety considerations and handling of carbolic acid: Due to its corrosive and toxic nature, special safety measures are required when handling carbolic acid. This includes the use of protective equipment, proper storage methods, and specific handling procedures to minimize risks associated with exposure or accidental release. Safety guidelines and regulations have been developed for its use in industrial and laboratory settings.

- Modern alternatives and substitutes for carbolic acid: With increased awareness of the health and environmental risks associated with carbolic acid, research has focused on developing safer alternatives and substitutes. These include less toxic antiseptics, environmentally friendly industrial chemicals, and alternative compounds that can perform similar functions in various applications while minimizing potential hazards.

02 Carbolic acid in industrial processes

Carbolic acid finds applications in various industrial processes, including the production of plastics, resins, and other chemical compounds. It serves as a precursor for many synthetic materials and is used in the manufacturing of dyes, pharmaceuticals, and pesticides. The versatility of carbolic acid in industrial settings has led to the development of specialized equipment and processes for its handling and utilization.Expand Specific Solutions03 Safety measures and handling of carbolic acid

Due to the corrosive and toxic nature of carbolic acid, proper safety measures and handling procedures are crucial. This includes the use of specialized containers, protective equipment, and storage facilities designed to prevent leaks, spills, and exposure. Safety protocols often involve proper ventilation, emergency response plans, and regular training for personnel working with the compound.Expand Specific Solutions04 Environmental impact and waste management

The use and disposal of carbolic acid have significant environmental implications. Proper waste management techniques are essential to prevent contamination of soil and water sources. This includes the development of treatment methods for carbolic acid-containing waste, recycling processes, and the implementation of environmentally friendly alternatives where possible.Expand Specific Solutions05 Carbolic acid derivatives and modifications

Research and development efforts have focused on creating derivatives and modifications of carbolic acid to enhance its properties or reduce its negative effects. These modifications aim to improve the compound's effectiveness in various applications while minimizing its toxicity and environmental impact. Such innovations have led to the development of new materials and processes across multiple industries.Expand Specific Solutions

Key Industry Players

The carbolic acid and hybrid composite materials market is in a growth phase, driven by increasing demand in various industries. The market size is expanding, with significant potential in sectors like automotive, construction, and electronics. Technological maturity varies, with established players like BASF Corp. and LG Chem Ltd. leading in innovation. Emerging companies such as Kingfa Sci. & Tech. Co., Ltd. and Midwest Industrial Supply, Inc. are focusing on niche applications and eco-friendly solutions. The competitive landscape is diverse, with traditional chemical giants competing alongside specialized materials manufacturers, creating a dynamic environment for technological advancements and market expansion.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has made significant contributions to hybrid composite materials using carbolic acid derivatives. Their research focuses on developing high-performance composites for oil and gas applications, utilizing phenol-formaldehyde resins modified with carbolic acid to enhance chemical resistance and thermal stability[10]. Sinopec's approach involves a proprietary curing process that optimizes the cross-linking density of the phenolic network, resulting in composites with improved mechanical properties and resistance to harsh environments[11]. The company has also developed novel carbolic acid-based coupling agents to enhance the interfacial adhesion between inorganic fillers and organic matrices, leading to composites with superior strength and durability[12].

Strengths: Extensive experience in petrochemical industry, access to raw materials, and strong R&D capabilities. Weaknesses: Potential limitations in applications outside the oil and gas sector and challenges in meeting stringent environmental regulations.

Eastman Chemical Co.

Technical Solution: Eastman Chemical Co. has developed innovative hybrid composite materials incorporating carbolic acid-based compounds. Their approach focuses on utilizing specialty phenolic resins derived from carbolic acid to enhance the performance of thermoplastic composites[13]. Eastman's technology involves a proprietary compatibilization process that improves the miscibility between the phenolic components and various thermoplastic matrices, resulting in composites with enhanced thermal stability, chemical resistance, and mechanical properties[14]. The company has also developed a range of carbolic acid-based additives that can be used to tailor the properties of composites for specific applications, such as improved flame retardancy or impact resistance[15]. Eastman's research extends to the development of bio-based phenolic compounds derived from renewable resources, aligning with the growing demand for sustainable materials.

Strengths: Strong expertise in specialty chemicals, diverse product portfolio, and focus on sustainability. Weaknesses: Potential higher costs compared to conventional composites and challenges in scaling up production for certain applications.

Core Innovations

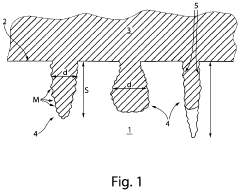

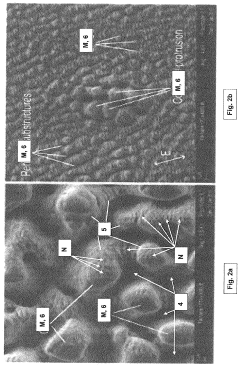

Hybrid composite material between a metal surface and a polymeric material surface and process for producing the hybrid composite material

PatentInactiveUS20220347938A1

Innovation

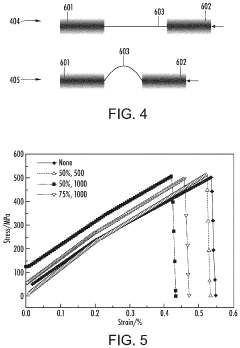

- The introduction of nanostructures on microstructured metal surfaces, created using short or ultra-short pulse laser radiation, enhances adhesion forces and covalent bonding between the metal and polymeric surfaces, significantly improving joint strength by increasing the surface area and specific adhesion, without the need for additives or intermediate layers.

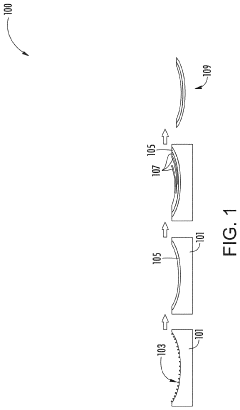

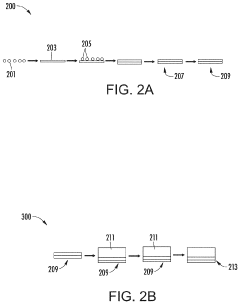

Hybrid multifunctional composite material and method of making the same

PatentActiveUS11505502B2

Innovation

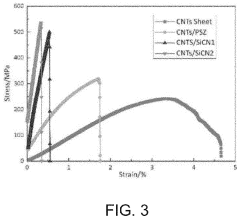

- A hybrid composite material is formed by integrating a flexible ceramic composite with a carbon fiber reinforced polymer, using non-woven carbon nanotube tissues as a transition layer, which enhances mechanical properties, thermal conductivity, and electromagnetic interference shielding capabilities.

Environmental Impact

The environmental impact of carbolic acid and its use in hybrid composite materials is a critical consideration in the development and application of these advanced materials. Carbolic acid, also known as phenol, is a key component in the production of various resins and polymers used in hybrid composites. While these materials offer significant advantages in terms of strength, durability, and versatility, their environmental footprint must be carefully evaluated.

The production of carbolic acid primarily relies on petrochemical processes, which contribute to greenhouse gas emissions and resource depletion. The extraction and refining of fossil fuels used as raw materials for carbolic acid synthesis have substantial environmental implications, including air and water pollution, as well as habitat disruption. Additionally, the manufacturing process itself involves energy-intensive steps and potentially hazardous chemical reactions, further adding to the environmental burden.

In the context of hybrid composite materials, the incorporation of carbolic acid-based resins can lead to improved material properties but may also present challenges in terms of end-of-life management. The complex nature of these composites often makes recycling difficult, potentially resulting in increased waste generation and landfill usage. However, ongoing research is exploring innovative recycling techniques and the development of more environmentally friendly alternatives to traditional carbolic acid-based resins.

The use phase of hybrid composite materials containing carbolic acid derivatives generally demonstrates positive environmental attributes. These materials often contribute to weight reduction in various applications, such as automotive and aerospace industries, leading to improved fuel efficiency and reduced emissions during the product's lifetime. Furthermore, the enhanced durability and corrosion resistance of these composites can extend product lifespans, potentially offsetting some of the environmental impacts associated with their production.

Efforts to mitigate the environmental impact of carbolic acid in hybrid composites are focusing on several key areas. These include the development of bio-based alternatives to petrochemical-derived carbolic acid, optimization of production processes to reduce energy consumption and emissions, and the implementation of closed-loop recycling systems for composite materials. Additionally, research into green chemistry principles is driving the creation of less toxic and more environmentally benign substitutes for traditional phenolic resins.

As regulations and consumer awareness regarding environmental sustainability continue to evolve, the industry is increasingly prioritizing the development of eco-friendly hybrid composite materials. This shift is driving innovation in material science and manufacturing processes, aiming to balance the exceptional performance characteristics of carbolic acid-based composites with reduced environmental impact throughout their lifecycle.

The production of carbolic acid primarily relies on petrochemical processes, which contribute to greenhouse gas emissions and resource depletion. The extraction and refining of fossil fuels used as raw materials for carbolic acid synthesis have substantial environmental implications, including air and water pollution, as well as habitat disruption. Additionally, the manufacturing process itself involves energy-intensive steps and potentially hazardous chemical reactions, further adding to the environmental burden.

In the context of hybrid composite materials, the incorporation of carbolic acid-based resins can lead to improved material properties but may also present challenges in terms of end-of-life management. The complex nature of these composites often makes recycling difficult, potentially resulting in increased waste generation and landfill usage. However, ongoing research is exploring innovative recycling techniques and the development of more environmentally friendly alternatives to traditional carbolic acid-based resins.

The use phase of hybrid composite materials containing carbolic acid derivatives generally demonstrates positive environmental attributes. These materials often contribute to weight reduction in various applications, such as automotive and aerospace industries, leading to improved fuel efficiency and reduced emissions during the product's lifetime. Furthermore, the enhanced durability and corrosion resistance of these composites can extend product lifespans, potentially offsetting some of the environmental impacts associated with their production.

Efforts to mitigate the environmental impact of carbolic acid in hybrid composites are focusing on several key areas. These include the development of bio-based alternatives to petrochemical-derived carbolic acid, optimization of production processes to reduce energy consumption and emissions, and the implementation of closed-loop recycling systems for composite materials. Additionally, research into green chemistry principles is driving the creation of less toxic and more environmentally benign substitutes for traditional phenolic resins.

As regulations and consumer awareness regarding environmental sustainability continue to evolve, the industry is increasingly prioritizing the development of eco-friendly hybrid composite materials. This shift is driving innovation in material science and manufacturing processes, aiming to balance the exceptional performance characteristics of carbolic acid-based composites with reduced environmental impact throughout their lifecycle.

Regulatory Compliance

The regulatory landscape surrounding carbolic acid and its use in hybrid composite materials is complex and multifaceted. Compliance with various regulations is crucial for manufacturers, researchers, and end-users involved in the development and application of these materials. The primary regulatory bodies overseeing the use of carbolic acid in composite materials include the Environmental Protection Agency (EPA), the Occupational Safety and Health Administration (OSHA), and the European Chemicals Agency (ECHA).

In the United States, the EPA regulates carbolic acid under the Toxic Substances Control Act (TSCA). Manufacturers and importers must comply with reporting, record-keeping, and testing requirements. The EPA also sets guidelines for the safe handling, storage, and disposal of carbolic acid and its derivatives. OSHA, on the other hand, focuses on workplace safety and has established permissible exposure limits (PELs) for carbolic acid to protect workers from potential health hazards.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation governs the use of carbolic acid. Companies must register substances manufactured or imported in quantities over one tonne per year and provide safety data sheets. The Classification, Labeling, and Packaging (CLP) regulation also applies, requiring proper labeling and packaging of carbolic acid and its mixtures.

For hybrid composite materials containing carbolic acid, additional regulations may come into play depending on the specific application. For instance, in the aerospace industry, materials must meet stringent safety and performance standards set by agencies such as the Federal Aviation Administration (FAA) or the European Aviation Safety Agency (EASA). In the automotive sector, regulations like the End-of-Life Vehicles (ELV) Directive in the EU impact the use of certain chemicals in vehicle components.

Compliance with these regulations often requires extensive testing and documentation. Manufacturers must conduct toxicity assessments, environmental impact studies, and performance evaluations to ensure their products meet regulatory standards. This process can be time-consuming and costly, potentially impacting the development and commercialization of new hybrid composite materials.

As environmental concerns grow, regulations are becoming increasingly stringent. There is a trend towards promoting the use of safer alternatives and encouraging the development of more sustainable materials. This regulatory pressure may drive innovation in the field of hybrid composites, pushing researchers to explore new formulations that maintain or improve performance while reducing environmental impact.

In the United States, the EPA regulates carbolic acid under the Toxic Substances Control Act (TSCA). Manufacturers and importers must comply with reporting, record-keeping, and testing requirements. The EPA also sets guidelines for the safe handling, storage, and disposal of carbolic acid and its derivatives. OSHA, on the other hand, focuses on workplace safety and has established permissible exposure limits (PELs) for carbolic acid to protect workers from potential health hazards.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation governs the use of carbolic acid. Companies must register substances manufactured or imported in quantities over one tonne per year and provide safety data sheets. The Classification, Labeling, and Packaging (CLP) regulation also applies, requiring proper labeling and packaging of carbolic acid and its mixtures.

For hybrid composite materials containing carbolic acid, additional regulations may come into play depending on the specific application. For instance, in the aerospace industry, materials must meet stringent safety and performance standards set by agencies such as the Federal Aviation Administration (FAA) or the European Aviation Safety Agency (EASA). In the automotive sector, regulations like the End-of-Life Vehicles (ELV) Directive in the EU impact the use of certain chemicals in vehicle components.

Compliance with these regulations often requires extensive testing and documentation. Manufacturers must conduct toxicity assessments, environmental impact studies, and performance evaluations to ensure their products meet regulatory standards. This process can be time-consuming and costly, potentially impacting the development and commercialization of new hybrid composite materials.

As environmental concerns grow, regulations are becoming increasingly stringent. There is a trend towards promoting the use of safer alternatives and encouraging the development of more sustainable materials. This regulatory pressure may drive innovation in the field of hybrid composites, pushing researchers to explore new formulations that maintain or improve performance while reducing environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!