Developing Biodegradable Carbolic Acid-Based Plastics

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biodegradable Plastics Evolution and Objectives

The evolution of biodegradable plastics has been driven by the growing concern over environmental pollution caused by conventional petroleum-based plastics. The journey began in the 1980s with the development of starch-based biodegradable plastics, which marked the first significant step towards more sustainable alternatives. As research progressed, the focus shifted to developing plastics derived from renewable resources, such as polylactic acid (PLA) from corn starch and polyhydroxyalkanoates (PHAs) from bacterial fermentation.

The emergence of carbolic acid-based biodegradable plastics represents a new frontier in this field. Carbolic acid, also known as phenol, is a versatile organic compound that can be derived from both petrochemical and renewable sources. The development of biodegradable plastics using carbolic acid as a key component aims to combine the desirable properties of traditional plastics with enhanced biodegradability.

The primary objective of developing biodegradable carbolic acid-based plastics is to create materials that can maintain the performance characteristics of conventional plastics while significantly reducing their environmental impact. This includes achieving comparable mechanical strength, thermal stability, and processability, but with the added benefit of biodegrading within a reasonable timeframe when exposed to appropriate environmental conditions.

Another crucial goal is to establish a sustainable production process for these plastics. This involves optimizing the synthesis of carbolic acid from renewable sources, such as lignin or other plant-based materials, to reduce reliance on petroleum-derived feedstocks. Additionally, researchers aim to develop efficient polymerization techniques that can incorporate carbolic acid into biodegradable polymer structures without compromising their degradability.

The development of these plastics also seeks to address the end-of-life challenges associated with conventional plastics. By designing materials that can be broken down by natural processes, the aim is to mitigate the accumulation of plastic waste in landfills and oceans. This objective aligns with the broader goals of circular economy principles, where materials are designed to be reused, recycled, or safely returned to the environment.

Furthermore, the research in this field aims to expand the application range of biodegradable plastics. While early biodegradable plastics were limited in their use due to inferior properties compared to conventional plastics, the incorporation of carbolic acid offers the potential to create materials suitable for a wider array of applications, from packaging to more demanding industrial uses.

As the technology evolves, there is also a focus on understanding and optimizing the degradation mechanisms of these new plastics. This includes studying how they break down under various environmental conditions and ensuring that the degradation products are non-toxic and environmentally benign. The ultimate goal is to develop plastics that can offer a genuine solution to the global plastic waste problem while meeting the performance needs of modern society.

The emergence of carbolic acid-based biodegradable plastics represents a new frontier in this field. Carbolic acid, also known as phenol, is a versatile organic compound that can be derived from both petrochemical and renewable sources. The development of biodegradable plastics using carbolic acid as a key component aims to combine the desirable properties of traditional plastics with enhanced biodegradability.

The primary objective of developing biodegradable carbolic acid-based plastics is to create materials that can maintain the performance characteristics of conventional plastics while significantly reducing their environmental impact. This includes achieving comparable mechanical strength, thermal stability, and processability, but with the added benefit of biodegrading within a reasonable timeframe when exposed to appropriate environmental conditions.

Another crucial goal is to establish a sustainable production process for these plastics. This involves optimizing the synthesis of carbolic acid from renewable sources, such as lignin or other plant-based materials, to reduce reliance on petroleum-derived feedstocks. Additionally, researchers aim to develop efficient polymerization techniques that can incorporate carbolic acid into biodegradable polymer structures without compromising their degradability.

The development of these plastics also seeks to address the end-of-life challenges associated with conventional plastics. By designing materials that can be broken down by natural processes, the aim is to mitigate the accumulation of plastic waste in landfills and oceans. This objective aligns with the broader goals of circular economy principles, where materials are designed to be reused, recycled, or safely returned to the environment.

Furthermore, the research in this field aims to expand the application range of biodegradable plastics. While early biodegradable plastics were limited in their use due to inferior properties compared to conventional plastics, the incorporation of carbolic acid offers the potential to create materials suitable for a wider array of applications, from packaging to more demanding industrial uses.

As the technology evolves, there is also a focus on understanding and optimizing the degradation mechanisms of these new plastics. This includes studying how they break down under various environmental conditions and ensuring that the degradation products are non-toxic and environmentally benign. The ultimate goal is to develop plastics that can offer a genuine solution to the global plastic waste problem while meeting the performance needs of modern society.

Market Demand for Eco-Friendly Packaging Solutions

The demand for eco-friendly packaging solutions has surged in recent years, driven by increasing environmental awareness and regulatory pressures. Consumers are becoming more conscious of the environmental impact of their purchasing decisions, leading to a growing preference for sustainable packaging options. This shift in consumer behavior has created a significant market opportunity for biodegradable plastics, particularly those derived from renewable sources like carbolic acid.

The global market for biodegradable plastics is experiencing rapid growth, with projections indicating a compound annual growth rate (CAGR) of over 15% in the coming years. This growth is largely attributed to the rising demand for eco-friendly packaging in various industries, including food and beverage, personal care, and consumer goods. The food packaging sector, in particular, has shown a strong inclination towards biodegradable solutions due to concerns about plastic contamination in food products and the need for extended shelf life.

Governments worldwide are implementing stricter regulations on single-use plastics, further driving the demand for biodegradable alternatives. Several countries have introduced bans or taxes on conventional plastic bags and packaging materials, creating a favorable environment for the adoption of biodegradable plastics. This regulatory landscape is expected to continue evolving, providing additional impetus to the market for eco-friendly packaging solutions.

The retail sector has also played a significant role in boosting demand for biodegradable packaging. Major retailers and e-commerce platforms are increasingly adopting sustainable packaging practices to align with their corporate social responsibility goals and meet consumer expectations. This trend has created a ripple effect throughout the supply chain, encouraging manufacturers to develop and offer biodegradable packaging options.

Despite the growing demand, challenges remain in terms of cost competitiveness and performance characteristics of biodegradable plastics compared to traditional petroleum-based plastics. However, ongoing research and development efforts, including those focused on carbolic acid-based plastics, are addressing these challenges. Innovations in material science and production processes are gradually narrowing the gap in terms of cost and performance, making biodegradable plastics increasingly viable for widespread adoption.

The healthcare industry has also emerged as a potential growth area for biodegradable plastics, particularly in the wake of the global pandemic. The increased use of disposable medical equipment and personal protective gear has highlighted the need for more sustainable options in healthcare packaging and disposables. This presents an additional avenue for market expansion and innovation in biodegradable plastics technology.

The global market for biodegradable plastics is experiencing rapid growth, with projections indicating a compound annual growth rate (CAGR) of over 15% in the coming years. This growth is largely attributed to the rising demand for eco-friendly packaging in various industries, including food and beverage, personal care, and consumer goods. The food packaging sector, in particular, has shown a strong inclination towards biodegradable solutions due to concerns about plastic contamination in food products and the need for extended shelf life.

Governments worldwide are implementing stricter regulations on single-use plastics, further driving the demand for biodegradable alternatives. Several countries have introduced bans or taxes on conventional plastic bags and packaging materials, creating a favorable environment for the adoption of biodegradable plastics. This regulatory landscape is expected to continue evolving, providing additional impetus to the market for eco-friendly packaging solutions.

The retail sector has also played a significant role in boosting demand for biodegradable packaging. Major retailers and e-commerce platforms are increasingly adopting sustainable packaging practices to align with their corporate social responsibility goals and meet consumer expectations. This trend has created a ripple effect throughout the supply chain, encouraging manufacturers to develop and offer biodegradable packaging options.

Despite the growing demand, challenges remain in terms of cost competitiveness and performance characteristics of biodegradable plastics compared to traditional petroleum-based plastics. However, ongoing research and development efforts, including those focused on carbolic acid-based plastics, are addressing these challenges. Innovations in material science and production processes are gradually narrowing the gap in terms of cost and performance, making biodegradable plastics increasingly viable for widespread adoption.

The healthcare industry has also emerged as a potential growth area for biodegradable plastics, particularly in the wake of the global pandemic. The increased use of disposable medical equipment and personal protective gear has highlighted the need for more sustainable options in healthcare packaging and disposables. This presents an additional avenue for market expansion and innovation in biodegradable plastics technology.

Current Challenges in Carbolic Acid-Based Plastics

The development of biodegradable carbolic acid-based plastics faces several significant challenges that hinder widespread adoption and commercialization. One of the primary obstacles is the inherent instability of carbolic acid-based polymers. These materials tend to degrade prematurely, often before the end of their intended product lifecycle, leading to compromised structural integrity and functionality.

Another major challenge lies in achieving a balance between biodegradability and durability. While rapid biodegradation is desirable for environmental reasons, it often comes at the cost of reduced mechanical strength and thermal stability. This trade-off limits the application range of carbolic acid-based plastics, particularly in sectors requiring long-term durability or exposure to harsh environmental conditions.

The production process of these biodegradable plastics presents its own set of challenges. Current manufacturing methods are often energy-intensive and require the use of toxic solvents, which contradicts the eco-friendly nature of the end product. Scaling up production while maintaining consistent quality and properties across batches remains a significant hurdle for industrial-scale implementation.

Cost-effectiveness is another critical issue. The production of carbolic acid-based biodegradable plastics is generally more expensive than conventional petroleum-based plastics, making it difficult to compete in price-sensitive markets. This economic barrier slows down market penetration and limits widespread adoption by industries and consumers.

Furthermore, there are challenges related to the biodegradation process itself. The rate and extent of biodegradation can vary significantly depending on environmental conditions such as temperature, humidity, and microbial activity. Ensuring consistent and predictable biodegradation across different disposal scenarios is crucial for meeting regulatory standards and consumer expectations.

Regulatory hurdles also pose significant challenges. The lack of standardized testing methods and certification processes for biodegradable plastics creates uncertainty in the market. This regulatory ambiguity makes it difficult for manufacturers to make verifiable claims about their products' biodegradability and compostability.

Lastly, there are concerns about the potential environmental impact of degradation byproducts. As carbolic acid-based plastics break down, they may release compounds that could have unforeseen effects on ecosystems. Comprehensive studies on the long-term environmental impact of these materials are still limited, creating hesitation among environmentalists and policymakers.

Addressing these challenges requires a multidisciplinary approach, combining advances in polymer chemistry, materials science, and environmental engineering. Overcoming these hurdles is crucial for realizing the full potential of biodegradable carbolic acid-based plastics as a sustainable alternative to conventional plastics.

Another major challenge lies in achieving a balance between biodegradability and durability. While rapid biodegradation is desirable for environmental reasons, it often comes at the cost of reduced mechanical strength and thermal stability. This trade-off limits the application range of carbolic acid-based plastics, particularly in sectors requiring long-term durability or exposure to harsh environmental conditions.

The production process of these biodegradable plastics presents its own set of challenges. Current manufacturing methods are often energy-intensive and require the use of toxic solvents, which contradicts the eco-friendly nature of the end product. Scaling up production while maintaining consistent quality and properties across batches remains a significant hurdle for industrial-scale implementation.

Cost-effectiveness is another critical issue. The production of carbolic acid-based biodegradable plastics is generally more expensive than conventional petroleum-based plastics, making it difficult to compete in price-sensitive markets. This economic barrier slows down market penetration and limits widespread adoption by industries and consumers.

Furthermore, there are challenges related to the biodegradation process itself. The rate and extent of biodegradation can vary significantly depending on environmental conditions such as temperature, humidity, and microbial activity. Ensuring consistent and predictable biodegradation across different disposal scenarios is crucial for meeting regulatory standards and consumer expectations.

Regulatory hurdles also pose significant challenges. The lack of standardized testing methods and certification processes for biodegradable plastics creates uncertainty in the market. This regulatory ambiguity makes it difficult for manufacturers to make verifiable claims about their products' biodegradability and compostability.

Lastly, there are concerns about the potential environmental impact of degradation byproducts. As carbolic acid-based plastics break down, they may release compounds that could have unforeseen effects on ecosystems. Comprehensive studies on the long-term environmental impact of these materials are still limited, creating hesitation among environmentalists and policymakers.

Addressing these challenges requires a multidisciplinary approach, combining advances in polymer chemistry, materials science, and environmental engineering. Overcoming these hurdles is crucial for realizing the full potential of biodegradable carbolic acid-based plastics as a sustainable alternative to conventional plastics.

Existing Carbolic Acid-Based Plastic Solutions

01 Biodegradable carbolic acid-based plastic compositions

Development of plastic compositions incorporating carbolic acid derivatives that exhibit improved biodegradability. These compositions may include additives or modifications to enhance the breakdown of the plastic material in natural environments.- Biodegradable carbolic acid-based plastic compositions: Development of plastic compositions incorporating carbolic acid derivatives that exhibit improved biodegradability. These compositions may include additives or modifications to enhance the breakdown of the plastic in natural environments, addressing environmental concerns associated with traditional plastics.

- Carbolic acid-based plastic recycling methods: Innovative recycling techniques specifically designed for carbolic acid-based plastics. These methods aim to efficiently break down and repurpose these materials, reducing environmental impact and promoting circular economy principles in plastic waste management.

- Environmental impact assessment of carbolic acid plastics: Studies and methodologies for evaluating the environmental impact of carbolic acid-based plastics throughout their lifecycle. This includes assessing biodegradation rates, potential ecological effects, and comparing their performance to other plastic types in various environmental conditions.

- Modifications to enhance biodegradability of carbolic acid plastics: Techniques for modifying carbolic acid-based plastics to improve their biodegradability. This may involve incorporating biodegradable additives, altering the polymer structure, or developing new copolymers that maintain desired material properties while increasing susceptibility to natural breakdown processes.

- Applications of biodegradable carbolic acid-based plastics: Exploration of potential applications for biodegradable carbolic acid-based plastics in various industries. This includes developing products that leverage the unique properties of these materials while addressing environmental concerns, such as in packaging, agriculture, or medical devices.

02 Carbolic acid-based plastic recycling methods

Innovative recycling techniques specifically designed for carbolic acid-based plastics. These methods aim to efficiently break down and reprocess these materials, reducing environmental impact and promoting circular economy principles.Expand Specific Solutions03 Environmental impact assessment of carbolic acid plastics

Studies and methodologies for evaluating the environmental impact of carbolic acid-based plastics throughout their lifecycle. This includes assessing biodegradation rates, potential ecological effects, and comparison with alternative materials.Expand Specific Solutions04 Modification of carbolic acid plastics for enhanced biodegradability

Techniques for modifying the molecular structure or composition of carbolic acid-based plastics to improve their biodegradability. This may involve the incorporation of biodegradable additives or the development of new polymer blends.Expand Specific Solutions05 Biodegradation testing methods for carbolic acid-based plastics

Development and standardization of testing protocols to accurately assess the biodegradability of carbolic acid-based plastics. These methods aim to provide reliable data on degradation rates and environmental persistence under various conditions.Expand Specific Solutions

Key Players in Biodegradable Plastics Industry

The development of biodegradable carbolic acid-based plastics is in an emerging stage, with growing market potential driven by increasing environmental concerns. The global biodegradable plastics market is expanding rapidly, expected to reach $7.8 billion by 2025. While the technology is still evolving, several key players are making significant strides. Companies like Kaneka Corp., BioLogiQ, and Mitsui Chemicals are at the forefront, investing in R&D to improve material properties and scalability. Academic institutions such as Peking University and Clemson University are contributing to fundamental research, while organizations like the Industrial Technology Research Institute are bridging the gap between academia and industry. The competitive landscape is diverse, with both established chemical companies and innovative startups vying for market share in this promising field.

Kaneka Corp.

Technical Solution: Kaneka has developed a novel biodegradable plastic called PHBH (Poly(3-hydroxybutyrate-co-3-hydroxyhexanoate)), which is produced through microbial fermentation using plant oils as raw materials[1]. This material offers excellent biodegradability in various environments, including marine settings. Kaneka's PHBH technology involves optimizing the bacterial strain and fermentation process to achieve high yields and consistent quality. The company has also developed specialized compounding techniques to enhance the material's processability and mechanical properties, making it suitable for a wide range of applications, from packaging to agricultural films[2]. Kaneka's approach addresses the challenge of creating carbolic acid-based plastics by focusing on bio-based monomers that can be polymerized into biodegradable materials.

Strengths: Fully bio-based and biodegradable in various environments, including marine. Versatile material properties. Weaknesses: Higher production costs compared to conventional plastics. Limited production capacity.

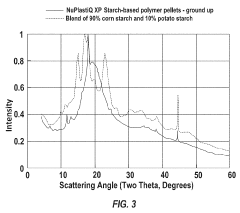

BioLogiQ, Inc.

Technical Solution: BioLogiQ has developed a proprietary technology called NuPlastiQ, which is a plant-based biopolymer that can be blended with traditional plastics to create biodegradable and compostable materials[3]. Their approach involves using a thermoplastic starch (TPS) derived from potato and cassava, which is then modified and compounded with other biodegradable polymers. This technology allows for the creation of blends that maintain the desired physical properties of traditional plastics while significantly reducing the carbon footprint and improving end-of-life biodegradability[4]. BioLogiQ's process includes optimizing the TPS formulation, developing compatibilizers for effective blending, and tailoring the material properties for specific applications such as films, rigid packaging, and injection molded products.

Strengths: Highly versatile, can be blended with various plastics. Reduces carbon footprint. Weaknesses: May not be suitable for all applications requiring high-performance plastics. Biodegradation rate depends on blending ratios.

Core Innovations in Biodegradable Polymer Science

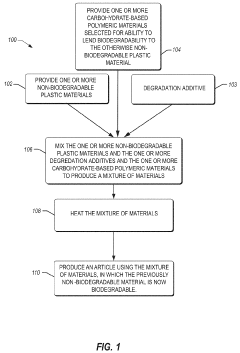

Addition of biodegradability lending additives to plastic materials

PatentActiveUS20190256681A1

Innovation

- Incorporating a carbohydrate-based polymeric material, NuPlastiQ, in combination with degradation additives, to enhance biodegradability of non-biodegradable plastics by promoting microbial action and complete conversion into natural elements in landfill, compost, or marine environments.

Biodegradable Polymers for Packaging Applications and Methods of Making the Same

PatentPendingUS20250197630A1

Innovation

- A biodegradable polymer composition is developed, comprising Polylactic Acid (PLA), Polyhydroxyalkanoates (PHA), Polyvinyl alcohol (PVOH), Polybutylene adipate terephthalate (PBAT), Polybutylene Succinate (PBS), starch, plasticizers, and fillers, which are blended and processed to achieve optimal mechanical strength, flexibility, and biodegradability for packaging applications.

Environmental Impact Assessment

The development of biodegradable carbolic acid-based plastics presents a significant opportunity to address environmental concerns associated with traditional plastic materials. This environmental impact assessment aims to evaluate the potential effects of these innovative plastics on ecosystems, waste management systems, and overall environmental sustainability.

One of the primary advantages of biodegradable carbolic acid-based plastics is their potential to reduce long-term plastic pollution. Unlike conventional plastics that persist in the environment for hundreds of years, these biodegradable alternatives are designed to break down into harmless components within a relatively short timeframe. This characteristic could significantly reduce the accumulation of plastic waste in landfills, oceans, and terrestrial ecosystems.

The biodegradation process of these plastics may contribute to reduced greenhouse gas emissions compared to traditional plastic waste management methods. As the materials decompose naturally, they avoid the need for energy-intensive recycling processes or incineration, which often release harmful pollutants into the atmosphere. However, it is crucial to consider the potential release of carbolic acid during degradation and its impact on soil and water ecosystems.

In terms of resource conservation, biodegradable carbolic acid-based plastics offer the potential to decrease reliance on fossil fuel-derived raw materials. By utilizing renewable resources in their production, these plastics could help mitigate the environmental impacts associated with petroleum extraction and processing. This shift towards more sustainable feedstocks aligns with global efforts to reduce carbon footprints and promote circular economy principles.

The introduction of these biodegradable plastics may also have positive implications for marine ecosystems. With millions of tons of plastic waste entering oceans annually, the ability of these materials to degrade in aquatic environments could help reduce the devastating effects of plastic pollution on marine life. However, thorough studies are needed to assess the potential impacts of degradation byproducts on marine organisms and food chains.

While the environmental benefits of biodegradable carbolic acid-based plastics are promising, it is essential to consider potential challenges and unintended consequences. The widespread adoption of these materials could lead to changes in consumer behavior, potentially resulting in increased littering due to misconceptions about biodegradability. Additionally, the integration of these new plastics into existing waste management systems may require adjustments to ensure proper handling and disposal.

In conclusion, the environmental impact assessment of biodegradable carbolic acid-based plastics reveals a complex interplay of potential benefits and challenges. While these materials offer promising solutions to plastic pollution and resource depletion, careful consideration must be given to their entire lifecycle, from production to disposal. Further research and long-term studies are necessary to fully understand and optimize the environmental performance of these innovative plastics.

One of the primary advantages of biodegradable carbolic acid-based plastics is their potential to reduce long-term plastic pollution. Unlike conventional plastics that persist in the environment for hundreds of years, these biodegradable alternatives are designed to break down into harmless components within a relatively short timeframe. This characteristic could significantly reduce the accumulation of plastic waste in landfills, oceans, and terrestrial ecosystems.

The biodegradation process of these plastics may contribute to reduced greenhouse gas emissions compared to traditional plastic waste management methods. As the materials decompose naturally, they avoid the need for energy-intensive recycling processes or incineration, which often release harmful pollutants into the atmosphere. However, it is crucial to consider the potential release of carbolic acid during degradation and its impact on soil and water ecosystems.

In terms of resource conservation, biodegradable carbolic acid-based plastics offer the potential to decrease reliance on fossil fuel-derived raw materials. By utilizing renewable resources in their production, these plastics could help mitigate the environmental impacts associated with petroleum extraction and processing. This shift towards more sustainable feedstocks aligns with global efforts to reduce carbon footprints and promote circular economy principles.

The introduction of these biodegradable plastics may also have positive implications for marine ecosystems. With millions of tons of plastic waste entering oceans annually, the ability of these materials to degrade in aquatic environments could help reduce the devastating effects of plastic pollution on marine life. However, thorough studies are needed to assess the potential impacts of degradation byproducts on marine organisms and food chains.

While the environmental benefits of biodegradable carbolic acid-based plastics are promising, it is essential to consider potential challenges and unintended consequences. The widespread adoption of these materials could lead to changes in consumer behavior, potentially resulting in increased littering due to misconceptions about biodegradability. Additionally, the integration of these new plastics into existing waste management systems may require adjustments to ensure proper handling and disposal.

In conclusion, the environmental impact assessment of biodegradable carbolic acid-based plastics reveals a complex interplay of potential benefits and challenges. While these materials offer promising solutions to plastic pollution and resource depletion, careful consideration must be given to their entire lifecycle, from production to disposal. Further research and long-term studies are necessary to fully understand and optimize the environmental performance of these innovative plastics.

Regulatory Framework for Biodegradable Materials

The regulatory framework for biodegradable materials plays a crucial role in the development and adoption of biodegradable carbolic acid-based plastics. As these innovative materials gain traction in various industries, governments and international organizations are establishing guidelines and standards to ensure their safety, efficacy, and environmental impact.

At the forefront of this regulatory landscape is the European Union (EU), which has implemented the EN 13432 standard for compostable and biodegradable packaging. This standard sets specific criteria for biodegradation, disintegration, and ecotoxicity, requiring materials to decompose within 12 weeks and leave no more than 10% of the original mass in 2mm-sized fragments. The EU has also introduced the Single-Use Plastics Directive, which promotes the use of biodegradable alternatives and sets targets for reducing plastic waste.

In the United States, the Federal Trade Commission (FTC) has established the Green Guides, which provide guidelines for environmental marketing claims, including those related to biodegradability. The American Society for Testing and Materials (ASTM) has developed several standards, such as ASTM D6400 for compostable plastics, which are widely recognized and adopted by manufacturers and regulators alike.

Japan has implemented the GreenPla certification system, managed by the Japan BioPlastics Association, which sets standards for biodegradable plastics and their appropriate disposal. This system has been instrumental in promoting the use of biodegradable materials in various applications.

International organizations like the International Organization for Standardization (ISO) have also contributed to the regulatory framework. ISO 17088 provides specifications for compostable plastics, while ISO 14851 and ISO 14852 outline methods for determining the aerobic biodegradability of plastic materials in an aqueous medium.

As the field of biodegradable carbolic acid-based plastics evolves, regulatory bodies are adapting their frameworks to address new challenges and opportunities. This includes considerations for marine biodegradability, as ocean plastic pollution remains a significant concern. The development of standards like ASTM D6691 for marine biodegradability testing reflects this growing focus.

Manufacturers and researchers working on biodegradable carbolic acid-based plastics must navigate this complex regulatory landscape to ensure compliance and market acceptance. This often involves extensive testing and certification processes to demonstrate that their materials meet the required standards for biodegradability, compostability, and environmental safety.

At the forefront of this regulatory landscape is the European Union (EU), which has implemented the EN 13432 standard for compostable and biodegradable packaging. This standard sets specific criteria for biodegradation, disintegration, and ecotoxicity, requiring materials to decompose within 12 weeks and leave no more than 10% of the original mass in 2mm-sized fragments. The EU has also introduced the Single-Use Plastics Directive, which promotes the use of biodegradable alternatives and sets targets for reducing plastic waste.

In the United States, the Federal Trade Commission (FTC) has established the Green Guides, which provide guidelines for environmental marketing claims, including those related to biodegradability. The American Society for Testing and Materials (ASTM) has developed several standards, such as ASTM D6400 for compostable plastics, which are widely recognized and adopted by manufacturers and regulators alike.

Japan has implemented the GreenPla certification system, managed by the Japan BioPlastics Association, which sets standards for biodegradable plastics and their appropriate disposal. This system has been instrumental in promoting the use of biodegradable materials in various applications.

International organizations like the International Organization for Standardization (ISO) have also contributed to the regulatory framework. ISO 17088 provides specifications for compostable plastics, while ISO 14851 and ISO 14852 outline methods for determining the aerobic biodegradability of plastic materials in an aqueous medium.

As the field of biodegradable carbolic acid-based plastics evolves, regulatory bodies are adapting their frameworks to address new challenges and opportunities. This includes considerations for marine biodegradability, as ocean plastic pollution remains a significant concern. The development of standards like ASTM D6691 for marine biodegradability testing reflects this growing focus.

Manufacturers and researchers working on biodegradable carbolic acid-based plastics must navigate this complex regulatory landscape to ensure compliance and market acceptance. This often involves extensive testing and certification processes to demonstrate that their materials meet the required standards for biodegradability, compostability, and environmental safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!