Exploring Carbolic Acid in Biocompatible Ink Formulations

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid Ink Background and Objectives

Carbolic acid, also known as phenol, has a long history in medical and industrial applications. Its antiseptic properties were first recognized in the 19th century, leading to its widespread use in surgical procedures and wound care. In recent years, there has been a growing interest in exploring the potential of carbolic acid in biocompatible ink formulations, particularly for biomedical and pharmaceutical applications.

The evolution of ink technology has seen significant advancements, from traditional printing inks to specialized formulations for biomedical purposes. The incorporation of carbolic acid into biocompatible inks represents a novel approach to addressing challenges in areas such as drug delivery, tissue engineering, and biosensors. This emerging field aims to leverage the unique properties of carbolic acid to enhance the functionality and performance of biocompatible inks.

The primary objective of exploring carbolic acid in biocompatible ink formulations is to develop innovative solutions that can revolutionize various biomedical applications. Researchers are focusing on harnessing the antimicrobial and preservative properties of carbolic acid to create inks that can maintain their stability and efficacy in biological environments. This could lead to improved drug-eluting implants, more effective wound dressings, and advanced biosensing platforms.

Another key goal is to optimize the biocompatibility of these ink formulations. While carbolic acid offers valuable properties, its potential toxicity at higher concentrations poses a significant challenge. Scientists are working on developing methods to incorporate carbolic acid into ink formulations in a manner that maximizes its benefits while minimizing any adverse effects on living tissues.

The exploration of carbolic acid in biocompatible inks also aims to enhance the printability and structural integrity of the resulting materials. Researchers are investigating how carbolic acid can influence the rheological properties of inks, potentially improving their performance in various printing technologies, including 3D bioprinting and inkjet printing for tissue engineering applications.

Furthermore, this research seeks to expand the range of applications for biocompatible inks. By incorporating carbolic acid, scientists hope to create multifunctional inks that can simultaneously provide structural support, deliver therapeutic agents, and exhibit antimicrobial properties. This could lead to the development of advanced medical devices and tissue scaffolds with enhanced functionality and improved patient outcomes.

As the field progresses, researchers are also focusing on understanding the long-term stability and degradation behavior of carbolic acid-containing biocompatible inks. This knowledge is crucial for developing inks that can maintain their desired properties throughout their intended lifespan, whether for short-term applications like wound dressings or long-term implants.

The evolution of ink technology has seen significant advancements, from traditional printing inks to specialized formulations for biomedical purposes. The incorporation of carbolic acid into biocompatible inks represents a novel approach to addressing challenges in areas such as drug delivery, tissue engineering, and biosensors. This emerging field aims to leverage the unique properties of carbolic acid to enhance the functionality and performance of biocompatible inks.

The primary objective of exploring carbolic acid in biocompatible ink formulations is to develop innovative solutions that can revolutionize various biomedical applications. Researchers are focusing on harnessing the antimicrobial and preservative properties of carbolic acid to create inks that can maintain their stability and efficacy in biological environments. This could lead to improved drug-eluting implants, more effective wound dressings, and advanced biosensing platforms.

Another key goal is to optimize the biocompatibility of these ink formulations. While carbolic acid offers valuable properties, its potential toxicity at higher concentrations poses a significant challenge. Scientists are working on developing methods to incorporate carbolic acid into ink formulations in a manner that maximizes its benefits while minimizing any adverse effects on living tissues.

The exploration of carbolic acid in biocompatible inks also aims to enhance the printability and structural integrity of the resulting materials. Researchers are investigating how carbolic acid can influence the rheological properties of inks, potentially improving their performance in various printing technologies, including 3D bioprinting and inkjet printing for tissue engineering applications.

Furthermore, this research seeks to expand the range of applications for biocompatible inks. By incorporating carbolic acid, scientists hope to create multifunctional inks that can simultaneously provide structural support, deliver therapeutic agents, and exhibit antimicrobial properties. This could lead to the development of advanced medical devices and tissue scaffolds with enhanced functionality and improved patient outcomes.

As the field progresses, researchers are also focusing on understanding the long-term stability and degradation behavior of carbolic acid-containing biocompatible inks. This knowledge is crucial for developing inks that can maintain their desired properties throughout their intended lifespan, whether for short-term applications like wound dressings or long-term implants.

Biocompatible Ink Market Analysis

The biocompatible ink market has experienced significant growth in recent years, driven by increasing applications in medical and pharmaceutical industries. This market segment is particularly relevant to the exploration of carbolic acid in biocompatible ink formulations, as it represents a potential avenue for innovation and market expansion.

The global biocompatible ink market is currently valued at several billion dollars, with projections indicating continued growth over the next decade. This growth is primarily fueled by the rising demand for medical devices, implants, and drug delivery systems that require safe and effective marking or printing solutions.

Key market drivers include the growing prevalence of chronic diseases, increasing geriatric population, and advancements in healthcare technologies. These factors contribute to a higher demand for medical devices and implants, which in turn drives the need for biocompatible inks used in their production and labeling.

The pharmaceutical sector represents a significant portion of the biocompatible ink market, with applications in drug packaging, labeling, and direct printing on medications. The stringent regulatory environment in this sector necessitates the use of safe, non-toxic inks that do not interact with drug formulations or pose risks to patients.

Geographically, North America and Europe currently dominate the biocompatible ink market, owing to their advanced healthcare infrastructure and high adoption rates of medical technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by improving healthcare access and increasing investments in medical research and development.

The market is characterized by intense competition among key players, including major chemical and ink manufacturers. These companies are investing heavily in research and development to create innovative biocompatible ink formulations that meet the evolving needs of the healthcare industry.

Emerging trends in the biocompatible ink market include the development of smart inks for biosensors and diagnostic applications, as well as the integration of antimicrobial properties in ink formulations. These innovations are opening up new opportunities for market growth and differentiation.

The exploration of carbolic acid in biocompatible ink formulations aligns with the market's demand for novel solutions that enhance ink performance while maintaining biocompatibility. This research direction has the potential to address existing challenges in ink stability, durability, and functionality, particularly in medical device manufacturing and pharmaceutical packaging applications.

As the biocompatible ink market continues to evolve, factors such as regulatory compliance, environmental sustainability, and cost-effectiveness will play crucial roles in shaping product development and market dynamics. Companies that can successfully navigate these challenges while delivering innovative solutions are likely to gain a competitive edge in this growing market.

The global biocompatible ink market is currently valued at several billion dollars, with projections indicating continued growth over the next decade. This growth is primarily fueled by the rising demand for medical devices, implants, and drug delivery systems that require safe and effective marking or printing solutions.

Key market drivers include the growing prevalence of chronic diseases, increasing geriatric population, and advancements in healthcare technologies. These factors contribute to a higher demand for medical devices and implants, which in turn drives the need for biocompatible inks used in their production and labeling.

The pharmaceutical sector represents a significant portion of the biocompatible ink market, with applications in drug packaging, labeling, and direct printing on medications. The stringent regulatory environment in this sector necessitates the use of safe, non-toxic inks that do not interact with drug formulations or pose risks to patients.

Geographically, North America and Europe currently dominate the biocompatible ink market, owing to their advanced healthcare infrastructure and high adoption rates of medical technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by improving healthcare access and increasing investments in medical research and development.

The market is characterized by intense competition among key players, including major chemical and ink manufacturers. These companies are investing heavily in research and development to create innovative biocompatible ink formulations that meet the evolving needs of the healthcare industry.

Emerging trends in the biocompatible ink market include the development of smart inks for biosensors and diagnostic applications, as well as the integration of antimicrobial properties in ink formulations. These innovations are opening up new opportunities for market growth and differentiation.

The exploration of carbolic acid in biocompatible ink formulations aligns with the market's demand for novel solutions that enhance ink performance while maintaining biocompatibility. This research direction has the potential to address existing challenges in ink stability, durability, and functionality, particularly in medical device manufacturing and pharmaceutical packaging applications.

As the biocompatible ink market continues to evolve, factors such as regulatory compliance, environmental sustainability, and cost-effectiveness will play crucial roles in shaping product development and market dynamics. Companies that can successfully navigate these challenges while delivering innovative solutions are likely to gain a competitive edge in this growing market.

Carbolic Acid Ink Technical Challenges

The development of biocompatible ink formulations incorporating carbolic acid presents several significant technical challenges. One of the primary obstacles is achieving a delicate balance between the antimicrobial properties of carbolic acid and its potential cytotoxicity. While carbolic acid, also known as phenol, exhibits strong antibacterial and antifungal characteristics, its concentration must be carefully controlled to prevent harm to living tissues.

Another major challenge lies in the stability of the ink formulation. Carbolic acid is known to be volatile and can undergo oxidation when exposed to air and light. This instability can lead to changes in the ink's composition over time, potentially affecting its biocompatibility and performance. Researchers must develop strategies to stabilize the carbolic acid within the ink matrix, possibly through the use of encapsulation techniques or the addition of antioxidants.

The viscosity and flow properties of the ink are also critical factors that require careful consideration. The addition of carbolic acid can alter the rheological characteristics of the ink, potentially impacting its printability and the resolution of the final printed structures. Formulation scientists must optimize the ink's viscosity and surface tension to ensure compatibility with various bioprinting technologies, such as inkjet, extrusion, or stereolithography.

Biocompatibility testing presents another significant hurdle. The complex interactions between carbolic acid, other ink components, and biological systems necessitate extensive in vitro and in vivo studies. These tests must evaluate not only the immediate cytotoxicity but also long-term effects on cell viability, proliferation, and differentiation. Additionally, the potential for carbolic acid to leach from the printed structures over time must be thoroughly assessed to ensure sustained biocompatibility.

The chemical reactivity of carbolic acid poses challenges in terms of its compatibility with other ink components. It may interact with polymers, crosslinking agents, or bioactive molecules present in the formulation, potentially altering their properties or reducing their effectiveness. Careful selection of materials and extensive compatibility studies are required to develop a stable and functional ink system.

Regulatory considerations add another layer of complexity to the development process. As carbolic acid is a known toxic substance, its use in biomedical applications is subject to strict regulatory scrutiny. Researchers must navigate these regulatory requirements, providing comprehensive safety data and demonstrating the benefits of incorporating carbolic acid in biocompatible ink formulations.

Another major challenge lies in the stability of the ink formulation. Carbolic acid is known to be volatile and can undergo oxidation when exposed to air and light. This instability can lead to changes in the ink's composition over time, potentially affecting its biocompatibility and performance. Researchers must develop strategies to stabilize the carbolic acid within the ink matrix, possibly through the use of encapsulation techniques or the addition of antioxidants.

The viscosity and flow properties of the ink are also critical factors that require careful consideration. The addition of carbolic acid can alter the rheological characteristics of the ink, potentially impacting its printability and the resolution of the final printed structures. Formulation scientists must optimize the ink's viscosity and surface tension to ensure compatibility with various bioprinting technologies, such as inkjet, extrusion, or stereolithography.

Biocompatibility testing presents another significant hurdle. The complex interactions between carbolic acid, other ink components, and biological systems necessitate extensive in vitro and in vivo studies. These tests must evaluate not only the immediate cytotoxicity but also long-term effects on cell viability, proliferation, and differentiation. Additionally, the potential for carbolic acid to leach from the printed structures over time must be thoroughly assessed to ensure sustained biocompatibility.

The chemical reactivity of carbolic acid poses challenges in terms of its compatibility with other ink components. It may interact with polymers, crosslinking agents, or bioactive molecules present in the formulation, potentially altering their properties or reducing their effectiveness. Careful selection of materials and extensive compatibility studies are required to develop a stable and functional ink system.

Regulatory considerations add another layer of complexity to the development process. As carbolic acid is a known toxic substance, its use in biomedical applications is subject to strict regulatory scrutiny. Researchers must navigate these regulatory requirements, providing comprehensive safety data and demonstrating the benefits of incorporating carbolic acid in biocompatible ink formulations.

Current Carbolic Acid Ink Formulations

01 Biocompatible carbolic acid formulations

Development of biocompatible formulations containing carbolic acid for medical and pharmaceutical applications. These formulations aim to reduce the toxicity and irritation associated with carbolic acid while maintaining its antimicrobial properties. Various excipients and delivery systems are used to improve the biocompatibility and efficacy of carbolic acid-based products.- Biocompatible carbolic acid formulations: Development of biocompatible formulations containing carbolic acid for medical and pharmaceutical applications. These formulations aim to reduce the toxicity and irritation associated with carbolic acid while maintaining its antimicrobial properties. Various excipients and delivery systems are used to enhance biocompatibility and control release.

- Carbolic acid in medical devices: Incorporation of carbolic acid into medical devices to improve their antimicrobial properties. This includes the use of carbolic acid in coatings, materials, or as a component in the device itself. The focus is on achieving biocompatibility while maintaining the effectiveness of carbolic acid against pathogens.

- Carbolic acid derivatives with enhanced biocompatibility: Development of carbolic acid derivatives that exhibit improved biocompatibility compared to the parent compound. These derivatives are designed to maintain the desired properties of carbolic acid while reducing its potential for toxicity or irritation in biological systems.

- Biocompatible delivery systems for carbolic acid: Creation of novel delivery systems to improve the biocompatibility of carbolic acid. These systems may include encapsulation technologies, controlled release mechanisms, or targeted delivery approaches to minimize systemic exposure and enhance local efficacy.

- Evaluation methods for carbolic acid biocompatibility: Development and implementation of methods to assess the biocompatibility of carbolic acid and its formulations. This includes in vitro and in vivo testing protocols, as well as analytical techniques to evaluate the interaction of carbolic acid with biological systems and its potential effects on tissues and organs.

02 Carbolic acid in medical devices

Incorporation of carbolic acid into medical devices to enhance their antimicrobial properties. This includes the use of carbolic acid in coatings, materials, or as a component in medical instruments and implants. The focus is on achieving a balance between the antimicrobial efficacy and biocompatibility of the devices.Expand Specific Solutions03 Carbolic acid derivatives with improved biocompatibility

Research and development of carbolic acid derivatives that exhibit enhanced biocompatibility compared to the parent compound. These derivatives are designed to maintain the desired properties of carbolic acid while reducing its potential harmful effects on living tissues.Expand Specific Solutions04 Biocompatibility testing methods for carbolic acid

Development and standardization of methods for assessing the biocompatibility of carbolic acid and its formulations. This includes in vitro and in vivo testing protocols to evaluate cytotoxicity, irritation, sensitization, and other biocompatibility parameters specific to carbolic acid-containing products.Expand Specific Solutions05 Carbolic acid in environmental applications

Exploration of carbolic acid use in environmental applications, focusing on its biocompatibility with various ecosystems. This includes the development of environmentally friendly formulations and assessment of the ecological impact of carbolic acid-based products used in water treatment, soil remediation, and other environmental applications.Expand Specific Solutions

Key Players in Biocompatible Ink Industry

The exploration of carbolic acid in biocompatible ink formulations is currently in an emerging phase, with the market showing potential for significant growth. The global biocompatible ink market is expanding, driven by increasing demand in medical and packaging applications. While the technology is still evolving, several key players are making strides in this field. Companies like Sun Chemical Corp., Sakata Inx Corp., and DIC Corp. are leveraging their expertise in ink formulations to develop biocompatible solutions. Research institutions such as Nanjing Tech University and South China University of Technology are contributing to advancements in this area. The involvement of major corporations like Xerox Holdings Corp. and Ricoh Co., Ltd. indicates growing interest in biocompatible ink technologies, suggesting a trend towards increased commercialization and market maturity in the near future.

Sun Chemical Corp. (New Jersey)

Technical Solution: Sun Chemical has developed biocompatible ink formulations incorporating carbolic acid derivatives for enhanced antimicrobial properties. Their approach involves encapsulating carbolic acid compounds within biodegradable polymeric nanoparticles, allowing for controlled release in printing applications[1]. This technology enables the production of inks with prolonged antimicrobial activity while maintaining biocompatibility. The company has also explored the use of phenol-based compounds as antioxidants in UV-curable ink systems, improving the stability and shelf life of biocompatible inks[3]. Sun Chemical's research focuses on optimizing the balance between antimicrobial efficacy and biocompatibility, ensuring that the inks meet stringent safety standards for various applications, including food packaging and medical devices[5].

Strengths: Advanced encapsulation technology, expertise in UV-curable systems, and a strong focus on safety and regulatory compliance. Weaknesses: Potential challenges in scaling up production and higher costs associated with specialized formulations.

Xerox Holdings Corp.

Technical Solution: Xerox has developed innovative biocompatible ink formulations incorporating carbolic acid derivatives for their advanced printing technologies. Their approach focuses on utilizing low-molecular-weight phenolic compounds as antioxidants and stabilizers in water-based ink systems[2]. By carefully controlling the concentration and distribution of these compounds, Xerox has achieved improved print quality and durability while maintaining biocompatibility. The company has also explored the use of naturally derived phenolic compounds, such as those extracted from plant sources, to enhance the eco-friendly profile of their inks[4]. Xerox's research emphasizes the development of multi-functional ink additives that can simultaneously provide antimicrobial properties, color stability, and improved adhesion to various substrates[6].

Strengths: Extensive experience in printing technologies, strong R&D capabilities, and a focus on eco-friendly solutions. Weaknesses: Potential limitations in adapting formulations for non-paper substrates and challenges in meeting diverse industry-specific requirements.

Carbolic Acid Ink Patent Analysis

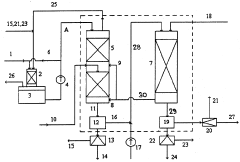

Process and apparatus for treating phenolate lyes

PatentInactiveCZ281728B6

Innovation

- A two-stage carbonation process under pressure with an organic solvent, forming a separate liquid phase, using absorption columns and controlled carbon dioxide levels to enhance separation and reduce environmental impact.

Process and apparatus for treating phenolate lyes

PatentInactiveCZ281728B6

Innovation

- A two-stage carbonation process under pressure with an organic solvent, forming a separate liquid phase, using absorption columns and controlled carbon dioxide levels to enhance separation and reduce environmental impact.

Regulatory Framework for Biocompatible Inks

The regulatory framework for biocompatible inks is a critical aspect of their development and application, particularly in the context of exploring carbolic acid as a potential component. This framework encompasses a complex web of regulations, guidelines, and standards set by various international and national bodies to ensure the safety and efficacy of biocompatible inks.

At the forefront of this regulatory landscape is the U.S. Food and Drug Administration (FDA), which plays a pivotal role in overseeing the use of biocompatible materials in medical and consumer products. The FDA's guidance on biocompatibility testing for medical devices provides a comprehensive framework that can be applied to biocompatible inks, especially those intended for use in medical applications or in contact with the human body.

In the European Union, the European Medicines Agency (EMA) and the European Chemicals Agency (ECHA) are key regulatory bodies. The EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is particularly relevant for the use of carbolic acid in ink formulations, as it governs the registration and safety assessment of chemical substances.

International standards organizations, such as the International Organization for Standardization (ISO), have developed specific standards for biocompatibility testing. ISO 10993, for instance, provides a series of standards for evaluating the biocompatibility of medical devices, which can be applied to biocompatible inks used in medical contexts.

The regulatory framework also extends to specific applications of biocompatible inks. For tattoo inks, the European Council's ResAP(2008)1 resolution on requirements and criteria for the safety of tattoos and permanent make-up provides guidelines that are widely referenced, even beyond the EU.

When considering the inclusion of carbolic acid in biocompatible ink formulations, manufacturers must navigate these regulatory requirements carefully. This includes conducting thorough toxicological assessments, evaluating potential risks associated with long-term exposure, and ensuring compliance with concentration limits set by regulatory bodies.

Moreover, the regulatory landscape is not static. Ongoing research into the long-term effects of biocompatible materials and emerging technologies in ink formulations continually inform and shape regulatory policies. Manufacturers and researchers must stay abreast of these developments to ensure ongoing compliance and to contribute to the evolution of safety standards in the field.

At the forefront of this regulatory landscape is the U.S. Food and Drug Administration (FDA), which plays a pivotal role in overseeing the use of biocompatible materials in medical and consumer products. The FDA's guidance on biocompatibility testing for medical devices provides a comprehensive framework that can be applied to biocompatible inks, especially those intended for use in medical applications or in contact with the human body.

In the European Union, the European Medicines Agency (EMA) and the European Chemicals Agency (ECHA) are key regulatory bodies. The EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is particularly relevant for the use of carbolic acid in ink formulations, as it governs the registration and safety assessment of chemical substances.

International standards organizations, such as the International Organization for Standardization (ISO), have developed specific standards for biocompatibility testing. ISO 10993, for instance, provides a series of standards for evaluating the biocompatibility of medical devices, which can be applied to biocompatible inks used in medical contexts.

The regulatory framework also extends to specific applications of biocompatible inks. For tattoo inks, the European Council's ResAP(2008)1 resolution on requirements and criteria for the safety of tattoos and permanent make-up provides guidelines that are widely referenced, even beyond the EU.

When considering the inclusion of carbolic acid in biocompatible ink formulations, manufacturers must navigate these regulatory requirements carefully. This includes conducting thorough toxicological assessments, evaluating potential risks associated with long-term exposure, and ensuring compliance with concentration limits set by regulatory bodies.

Moreover, the regulatory landscape is not static. Ongoing research into the long-term effects of biocompatible materials and emerging technologies in ink formulations continually inform and shape regulatory policies. Manufacturers and researchers must stay abreast of these developments to ensure ongoing compliance and to contribute to the evolution of safety standards in the field.

Environmental Impact Assessment

The environmental impact assessment of carbolic acid in biocompatible ink formulations is a critical aspect of their development and application. Carbolic acid, also known as phenol, has been widely used in various industrial processes and products, including inks. However, its potential environmental effects must be carefully evaluated to ensure sustainable and responsible use.

One of the primary concerns regarding carbolic acid is its toxicity to aquatic organisms. When released into water bodies, even in small concentrations, it can have detrimental effects on fish, invertebrates, and algae. Studies have shown that carbolic acid can disrupt the endocrine systems of aquatic species, leading to reproductive issues and population decline. Furthermore, its persistence in the environment raises concerns about long-term ecological impacts.

Soil contamination is another significant consideration. Carbolic acid can leach into soil from improperly disposed ink products or manufacturing waste. This contamination can affect soil microorganisms, potentially disrupting nutrient cycles and reducing soil fertility. Additionally, plants may absorb carbolic acid through their root systems, leading to phytotoxicity and reduced crop yields in agricultural areas.

Air quality is also a factor to consider, particularly in ink manufacturing facilities. Volatile organic compounds (VOCs) released during the production process can contribute to smog formation and have adverse effects on human health. While modern manufacturing processes have significantly reduced VOC emissions, ongoing monitoring and improvement of air filtration systems remain essential.

The lifecycle assessment of biocompatible inks containing carbolic acid must account for raw material extraction, manufacturing processes, product use, and disposal. Sustainable sourcing of carbolic acid and other ink components can help mitigate environmental impacts associated with resource depletion and habitat destruction. Additionally, implementing closed-loop manufacturing systems and waste reduction strategies can minimize the release of harmful substances into the environment.

Biodegradability is a crucial factor in assessing the environmental impact of biocompatible inks. While carbolic acid itself is biodegradable under certain conditions, its rate of degradation and potential breakdown products must be carefully evaluated. Ensuring that the entire ink formulation is biodegradable and does not produce harmful residues is essential for minimizing long-term environmental effects.

Regulatory compliance and adherence to environmental standards play a vital role in managing the environmental impact of carbolic acid in ink formulations. Manufacturers must comply with local, national, and international regulations governing the use and disposal of hazardous substances. This includes proper labeling, safe handling procedures, and appropriate waste management practices.

In conclusion, while carbolic acid offers valuable properties for biocompatible ink formulations, its environmental impact must be carefully managed through comprehensive assessment, responsible manufacturing practices, and adherence to regulatory standards. Ongoing research and development efforts should focus on finding alternative, more environmentally friendly compounds that can provide similar performance characteristics without the associated ecological risks.

One of the primary concerns regarding carbolic acid is its toxicity to aquatic organisms. When released into water bodies, even in small concentrations, it can have detrimental effects on fish, invertebrates, and algae. Studies have shown that carbolic acid can disrupt the endocrine systems of aquatic species, leading to reproductive issues and population decline. Furthermore, its persistence in the environment raises concerns about long-term ecological impacts.

Soil contamination is another significant consideration. Carbolic acid can leach into soil from improperly disposed ink products or manufacturing waste. This contamination can affect soil microorganisms, potentially disrupting nutrient cycles and reducing soil fertility. Additionally, plants may absorb carbolic acid through their root systems, leading to phytotoxicity and reduced crop yields in agricultural areas.

Air quality is also a factor to consider, particularly in ink manufacturing facilities. Volatile organic compounds (VOCs) released during the production process can contribute to smog formation and have adverse effects on human health. While modern manufacturing processes have significantly reduced VOC emissions, ongoing monitoring and improvement of air filtration systems remain essential.

The lifecycle assessment of biocompatible inks containing carbolic acid must account for raw material extraction, manufacturing processes, product use, and disposal. Sustainable sourcing of carbolic acid and other ink components can help mitigate environmental impacts associated with resource depletion and habitat destruction. Additionally, implementing closed-loop manufacturing systems and waste reduction strategies can minimize the release of harmful substances into the environment.

Biodegradability is a crucial factor in assessing the environmental impact of biocompatible inks. While carbolic acid itself is biodegradable under certain conditions, its rate of degradation and potential breakdown products must be carefully evaluated. Ensuring that the entire ink formulation is biodegradable and does not produce harmful residues is essential for minimizing long-term environmental effects.

Regulatory compliance and adherence to environmental standards play a vital role in managing the environmental impact of carbolic acid in ink formulations. Manufacturers must comply with local, national, and international regulations governing the use and disposal of hazardous substances. This includes proper labeling, safe handling procedures, and appropriate waste management practices.

In conclusion, while carbolic acid offers valuable properties for biocompatible ink formulations, its environmental impact must be carefully managed through comprehensive assessment, responsible manufacturing practices, and adherence to regulatory standards. Ongoing research and development efforts should focus on finding alternative, more environmentally friendly compounds that can provide similar performance characteristics without the associated ecological risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!