Carbolic Acid Utilization in Petrochemical Byproduct Refinement

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid Overview and Refinement Goals

Carbolic acid, also known as phenol, is a crucial compound in the petrochemical industry, serving as both a valuable product and a significant byproduct in various processes. Its history dates back to the 19th century when it was first isolated from coal tar. Since then, carbolic acid has become an essential component in the production of numerous industrial and consumer goods, including plastics, pharmaceuticals, and disinfectants.

The evolution of carbolic acid utilization has been closely tied to the development of the petrochemical industry. As refining processes became more sophisticated, the need for efficient carbolic acid management and refinement grew. This led to continuous improvements in extraction, purification, and conversion technologies, aimed at maximizing the value of this versatile compound.

In recent years, the focus has shifted towards sustainable and environmentally friendly approaches to carbolic acid utilization. This trend is driven by increasing environmental regulations and the industry's commitment to reducing its carbon footprint. As a result, new technologies are being developed to enhance the efficiency of carbolic acid recovery from petrochemical byproducts and to explore novel applications that align with circular economy principles.

The primary goals of carbolic acid refinement in the petrochemical industry are multifaceted. First and foremost is the optimization of extraction and purification processes to increase yield and quality. This involves developing advanced separation techniques and improving the efficiency of existing methods to minimize energy consumption and reduce waste.

Another critical objective is the exploration of new catalytic processes that can convert carbolic acid into higher-value products. This not only increases the economic viability of byproduct refinement but also opens up new market opportunities for petrochemical companies.

Furthermore, there is a growing emphasis on integrating carbolic acid refinement into broader waste management strategies. This includes developing closed-loop systems that can recycle and reuse carbolic acid within the production process, thereby reducing the overall environmental impact of petrochemical operations.

As the industry moves forward, the goals of carbolic acid refinement are increasingly aligned with broader sustainability objectives. This includes research into bio-based alternatives and the development of green chemistry approaches that can reduce the reliance on fossil fuel-derived carbolic acid. By setting these ambitious goals, the petrochemical industry aims to transform carbolic acid from a challenging byproduct into a valuable resource that contributes to both economic growth and environmental stewardship.

The evolution of carbolic acid utilization has been closely tied to the development of the petrochemical industry. As refining processes became more sophisticated, the need for efficient carbolic acid management and refinement grew. This led to continuous improvements in extraction, purification, and conversion technologies, aimed at maximizing the value of this versatile compound.

In recent years, the focus has shifted towards sustainable and environmentally friendly approaches to carbolic acid utilization. This trend is driven by increasing environmental regulations and the industry's commitment to reducing its carbon footprint. As a result, new technologies are being developed to enhance the efficiency of carbolic acid recovery from petrochemical byproducts and to explore novel applications that align with circular economy principles.

The primary goals of carbolic acid refinement in the petrochemical industry are multifaceted. First and foremost is the optimization of extraction and purification processes to increase yield and quality. This involves developing advanced separation techniques and improving the efficiency of existing methods to minimize energy consumption and reduce waste.

Another critical objective is the exploration of new catalytic processes that can convert carbolic acid into higher-value products. This not only increases the economic viability of byproduct refinement but also opens up new market opportunities for petrochemical companies.

Furthermore, there is a growing emphasis on integrating carbolic acid refinement into broader waste management strategies. This includes developing closed-loop systems that can recycle and reuse carbolic acid within the production process, thereby reducing the overall environmental impact of petrochemical operations.

As the industry moves forward, the goals of carbolic acid refinement are increasingly aligned with broader sustainability objectives. This includes research into bio-based alternatives and the development of green chemistry approaches that can reduce the reliance on fossil fuel-derived carbolic acid. By setting these ambitious goals, the petrochemical industry aims to transform carbolic acid from a challenging byproduct into a valuable resource that contributes to both economic growth and environmental stewardship.

Petrochemical Market Demand Analysis

The petrochemical industry's demand for carbolic acid, also known as phenol, has been steadily increasing due to its versatile applications in various downstream sectors. The global phenol market size was valued at approximately 11.5 million tons in 2020, with projections indicating a compound annual growth rate (CAGR) of 3.5% from 2021 to 2028. This growth is primarily driven by the rising demand for phenol derivatives in the production of bisphenol-A (BPA), phenolic resins, and caprolactam.

The automotive and construction industries are major consumers of phenol-derived products, particularly in the form of polycarbonates and epoxy resins. The increasing use of lightweight materials in automotive manufacturing to improve fuel efficiency has boosted the demand for polycarbonates, which are produced using BPA derived from phenol. Similarly, the construction sector's growth, especially in emerging economies, has led to higher consumption of phenolic resins in insulation materials and adhesives.

In the petrochemical byproduct refinement context, the utilization of carbolic acid presents significant opportunities for value addition. As refineries seek to maximize the efficiency of their operations and reduce waste, the extraction and purification of phenol from various byproduct streams have become increasingly important. This trend aligns with the industry's focus on circular economy principles and sustainable resource management.

The Asia-Pacific region dominates the global phenol market, accounting for over 50% of the total demand. China, in particular, has emerged as both a major producer and consumer of phenol, driven by its robust manufacturing sector and growing domestic consumption. The region's rapid industrialization and urbanization continue to fuel the demand for phenol-based products across various end-use industries.

Environmental regulations and sustainability concerns are shaping the market dynamics for carbolic acid utilization. Stricter emissions controls and waste management policies are encouraging refineries to invest in advanced technologies for byproduct recovery and utilization. This regulatory landscape is expected to drive innovation in phenol extraction and purification processes, potentially opening new avenues for market growth.

The pharmaceutical and healthcare sectors represent emerging opportunities for carbolic acid utilization. Phenol's antiseptic properties make it valuable in the production of disinfectants and medical devices. The ongoing global health concerns have further highlighted the importance of these applications, potentially leading to increased demand in the coming years.

The automotive and construction industries are major consumers of phenol-derived products, particularly in the form of polycarbonates and epoxy resins. The increasing use of lightweight materials in automotive manufacturing to improve fuel efficiency has boosted the demand for polycarbonates, which are produced using BPA derived from phenol. Similarly, the construction sector's growth, especially in emerging economies, has led to higher consumption of phenolic resins in insulation materials and adhesives.

In the petrochemical byproduct refinement context, the utilization of carbolic acid presents significant opportunities for value addition. As refineries seek to maximize the efficiency of their operations and reduce waste, the extraction and purification of phenol from various byproduct streams have become increasingly important. This trend aligns with the industry's focus on circular economy principles and sustainable resource management.

The Asia-Pacific region dominates the global phenol market, accounting for over 50% of the total demand. China, in particular, has emerged as both a major producer and consumer of phenol, driven by its robust manufacturing sector and growing domestic consumption. The region's rapid industrialization and urbanization continue to fuel the demand for phenol-based products across various end-use industries.

Environmental regulations and sustainability concerns are shaping the market dynamics for carbolic acid utilization. Stricter emissions controls and waste management policies are encouraging refineries to invest in advanced technologies for byproduct recovery and utilization. This regulatory landscape is expected to drive innovation in phenol extraction and purification processes, potentially opening new avenues for market growth.

The pharmaceutical and healthcare sectors represent emerging opportunities for carbolic acid utilization. Phenol's antiseptic properties make it valuable in the production of disinfectants and medical devices. The ongoing global health concerns have further highlighted the importance of these applications, potentially leading to increased demand in the coming years.

Current Challenges in Carbolic Acid Utilization

Despite the widespread use of carbolic acid (phenol) in petrochemical industries, several challenges persist in its utilization, particularly in the refinement of petrochemical byproducts. These challenges stem from both technical and environmental considerations, impacting the efficiency and sustainability of carbolic acid applications.

One of the primary technical challenges is the high energy requirement for carbolic acid extraction and purification processes. The conventional methods often involve energy-intensive distillation and crystallization steps, which significantly increase operational costs and carbon footprint. This energy inefficiency not only affects the economic viability of carbolic acid utilization but also contradicts the growing emphasis on sustainable industrial practices.

The corrosive nature of carbolic acid poses another significant challenge, particularly in terms of equipment durability and maintenance. Specialized materials and coatings are required to withstand the corrosive effects, leading to increased capital and maintenance costs. This corrosivity also raises safety concerns, necessitating stringent handling protocols and protective measures for workers involved in carbolic acid processing.

Environmental concerns present a substantial challenge in carbolic acid utilization. The compound is known for its toxicity and potential environmental hazards if not properly managed. Stringent regulations on emissions and waste disposal have necessitated the development of more sophisticated treatment and containment systems, adding complexity and cost to carbolic acid processing operations.

The variability in feedstock quality presents an ongoing challenge in carbolic acid refinement. Petrochemical byproducts often contain a mix of impurities that can interfere with the extraction and purification of carbolic acid. This variability necessitates adaptive processing techniques and robust quality control measures, which can be technically challenging and resource-intensive to implement consistently.

Another significant challenge lies in the optimization of reaction conditions for carbolic acid production and utilization. Achieving high yields and selectivity while minimizing unwanted side reactions remains a complex task. This challenge is particularly pronounced in the development of new catalytic systems and reaction pathways aimed at improving efficiency and reducing environmental impact.

The recovery and recycling of carbolic acid from waste streams pose additional technical challenges. Efficient separation technologies are needed to recover carbolic acid from dilute aqueous solutions or complex mixtures, a process that is often hindered by the presence of other organic compounds with similar properties.

Lastly, the development of alternative, more sustainable routes for carbolic acid production and utilization faces significant hurdles. While bio-based production methods show promise, scaling these processes to industrial levels while maintaining economic viability remains a challenge. The integration of these novel approaches into existing petrochemical infrastructure also presents technical and logistical difficulties that need to be addressed.

One of the primary technical challenges is the high energy requirement for carbolic acid extraction and purification processes. The conventional methods often involve energy-intensive distillation and crystallization steps, which significantly increase operational costs and carbon footprint. This energy inefficiency not only affects the economic viability of carbolic acid utilization but also contradicts the growing emphasis on sustainable industrial practices.

The corrosive nature of carbolic acid poses another significant challenge, particularly in terms of equipment durability and maintenance. Specialized materials and coatings are required to withstand the corrosive effects, leading to increased capital and maintenance costs. This corrosivity also raises safety concerns, necessitating stringent handling protocols and protective measures for workers involved in carbolic acid processing.

Environmental concerns present a substantial challenge in carbolic acid utilization. The compound is known for its toxicity and potential environmental hazards if not properly managed. Stringent regulations on emissions and waste disposal have necessitated the development of more sophisticated treatment and containment systems, adding complexity and cost to carbolic acid processing operations.

The variability in feedstock quality presents an ongoing challenge in carbolic acid refinement. Petrochemical byproducts often contain a mix of impurities that can interfere with the extraction and purification of carbolic acid. This variability necessitates adaptive processing techniques and robust quality control measures, which can be technically challenging and resource-intensive to implement consistently.

Another significant challenge lies in the optimization of reaction conditions for carbolic acid production and utilization. Achieving high yields and selectivity while minimizing unwanted side reactions remains a complex task. This challenge is particularly pronounced in the development of new catalytic systems and reaction pathways aimed at improving efficiency and reducing environmental impact.

The recovery and recycling of carbolic acid from waste streams pose additional technical challenges. Efficient separation technologies are needed to recover carbolic acid from dilute aqueous solutions or complex mixtures, a process that is often hindered by the presence of other organic compounds with similar properties.

Lastly, the development of alternative, more sustainable routes for carbolic acid production and utilization faces significant hurdles. While bio-based production methods show promise, scaling these processes to industrial levels while maintaining economic viability remains a challenge. The integration of these novel approaches into existing petrochemical infrastructure also presents technical and logistical difficulties that need to be addressed.

Existing Carbolic Acid Refinement Solutions

01 Historical use of carbolic acid in medical applications

Carbolic acid, also known as phenol, has a long history of use in medical applications. It was widely used as an antiseptic and disinfectant in the late 19th and early 20th centuries. This compound played a significant role in the development of modern surgical techniques and hygiene practices.- Carbolic acid in medical applications: Carbolic acid, also known as phenol, has been used in various medical applications due to its antiseptic properties. It has been utilized in disinfectants, surgical procedures, and wound treatments. The compound's ability to kill bacteria and fungi makes it valuable in medical settings for sterilization and infection prevention.

- Carbolic acid in industrial processes: Carbolic acid finds applications in various industrial processes, including the production of plastics, resins, and other chemical compounds. It serves as a precursor in the synthesis of many organic substances and is used in the manufacturing of dyes, pharmaceuticals, and pesticides.

- Carbolic acid in water treatment: Carbolic acid has been employed in water treatment processes due to its disinfectant properties. It can be used to purify water by eliminating harmful microorganisms. However, its use in water treatment has become less common due to environmental and health concerns, with safer alternatives being preferred in modern applications.

- Safety measures and handling of carbolic acid: Due to its corrosive and toxic nature, special safety measures are required when handling carbolic acid. This includes the use of protective equipment, proper storage facilities, and specific disposal methods. Safety protocols and regulations have been developed to minimize risks associated with its use in various industries and applications.

- Environmental impact and alternatives to carbolic acid: Concerns about the environmental impact of carbolic acid have led to research into safer alternatives and more sustainable practices. Efforts have been made to develop less toxic substitutes for various applications, including disinfectants and industrial processes. This has resulted in the gradual phasing out of carbolic acid in certain sectors and increased focus on eco-friendly alternatives.

02 Carbolic acid in industrial processes

Carbolic acid is utilized in various industrial processes, particularly in the production of plastics, resins, and other synthetic materials. It serves as a precursor for many chemical compounds and is an important raw material in the chemical industry.Expand Specific Solutions03 Environmental and safety concerns related to carbolic acid

Due to its toxic nature, the use of carbolic acid has raised environmental and safety concerns. This has led to the development of safer alternatives and improved handling methods. Proper disposal and treatment of carbolic acid waste are crucial to prevent environmental contamination.Expand Specific Solutions04 Carbolic acid derivatives in pharmaceutical applications

Derivatives of carbolic acid have found applications in the pharmaceutical industry. These compounds are used in the synthesis of various drugs and medicinal products. Research continues to explore new potential uses of carbolic acid derivatives in drug development.Expand Specific Solutions05 Analytical methods for carbolic acid detection and quantification

Various analytical methods have been developed for the detection and quantification of carbolic acid in different matrices. These techniques are important for quality control in industrial processes, environmental monitoring, and ensuring safety in workplaces where carbolic acid is used.Expand Specific Solutions

Key Players in Petrochemical Byproduct Industry

The carbolic acid utilization in petrochemical byproduct refinement sector is in a mature stage, with a significant global market size driven by the petrochemical industry's growth. Technologically, it's well-established, with major players like China Petroleum & Chemical Corp., PetroChina, and BASF leading innovation. These companies, along with LG Chem and Eastman Chemical, have developed advanced processes for efficient carbolic acid utilization, focusing on improving yield and reducing environmental impact. The competitive landscape is characterized by ongoing R&D efforts to enhance process efficiency and develop novel applications, with emerging players like Dorf Ketal Chemicals and SK Innovation contributing to technological advancements in this field.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach for carbolic acid utilization in petrochemical byproduct refinement. Their process involves catalytic oxidation of phenol to produce high-value chemicals like hydroquinone and catechol[1]. The company has implemented a closed-loop system that recycles carbolic acid, reducing waste and improving overall efficiency. Sinopec's method incorporates advanced catalysts and optimized reaction conditions to achieve higher yields and selectivity[2]. They have also integrated this process with their existing refinery operations, allowing for seamless integration and reduced operational costs[3].

Strengths: Integrated approach with existing operations, high efficiency, and reduced waste. Weaknesses: Potential high initial investment costs and reliance on specific catalysts.

BASF Corp.

Technical Solution: BASF Corp. has developed a novel approach to carbolic acid utilization focusing on sustainable production of high-value aromatics. Their process involves a combination of oxidative decarboxylation and selective hydrogenation to convert carbolic acid into benzene and other aromatic compounds[4]. BASF's technology utilizes a proprietary catalyst system that enhances selectivity and reduces energy consumption. The company has also implemented advanced process control systems to optimize reaction conditions in real-time, improving yield and product quality[5]. Additionally, BASF has integrated this technology with their bio-based feedstock initiatives, allowing for the production of renewable aromatics from bio-derived carbolic acid[6].

Strengths: High selectivity, energy-efficient process, and integration with renewable feedstocks. Weaknesses: Complexity of the process and potential sensitivity to feedstock quality.

Innovative Carbolic Acid Utilization Techniques

Synthetic caustic composition

PatentActiveUS20210276877A1

Innovation

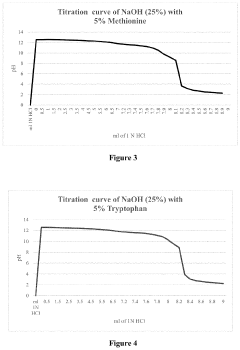

- A novel caustic composition comprising a caustic component, such as potassium hydroxide or sodium hydroxide, combined with an amino acid additive that provides an extended, linear buffering effect and lowers the freeze point, along with water, to enhance dermal protection and improve handling safety.

Method for one-pot co-production of caproic acid and hydrogen

PatentPendingEP3581659A1

Innovation

- A one-step bioprocess in a single bioreactor that utilizes microbial consortia to convert organic biomass into caproic acid and hydrogen, where lactic acid acts as an in-situ electron donor, operating under specific conditions to inhibit methane formation and optimize caproic acid and hydrogen production.

Environmental Impact Assessment

The utilization of carbolic acid in petrochemical byproduct refinement presents significant environmental considerations that require thorough assessment. The process of refining and utilizing carbolic acid, also known as phenol, can have both positive and negative impacts on the environment.

One of the primary environmental benefits of carbolic acid utilization is the reduction of waste in petrochemical processes. By refining and repurposing this byproduct, industries can minimize the amount of potentially harmful substances released into the environment. This approach aligns with circular economy principles, promoting resource efficiency and waste reduction.

However, the production and handling of carbolic acid pose potential risks to ecosystems and human health. Phenol is known to be toxic to aquatic life and can persist in the environment for extended periods. Accidental releases or improper disposal of carbolic acid can lead to soil and water contamination, affecting local flora and fauna.

Air quality is another crucial factor to consider. The refining process may release volatile organic compounds (VOCs) and other air pollutants. These emissions can contribute to smog formation and have adverse effects on respiratory health in surrounding communities. Implementing advanced air pollution control technologies is essential to mitigate these impacts.

Water usage and wastewater management are critical aspects of the environmental impact assessment. The refinement process typically requires significant amounts of water, potentially straining local water resources. Additionally, the wastewater generated may contain phenol and other contaminants, necessitating robust treatment systems to prevent water pollution.

Energy consumption and associated greenhouse gas emissions must also be evaluated. The refinement and utilization processes often require substantial energy inputs, contributing to the overall carbon footprint of the operation. Implementing energy-efficient technologies and exploring renewable energy sources can help mitigate these impacts.

Biodiversity protection is another key consideration. Industrial facilities involved in carbolic acid refinement may impact local ecosystems through habitat disruption or potential chemical exposure. Comprehensive environmental management plans should include measures to protect and preserve biodiversity in the surrounding areas.

Long-term environmental monitoring is crucial to assess the cumulative impacts of carbolic acid utilization. This includes regular soil, water, and air quality testing, as well as ecological surveys to detect any changes in local ecosystems over time. Such monitoring programs can help identify and address potential environmental issues proactively.

In conclusion, while the utilization of carbolic acid in petrochemical byproduct refinement offers opportunities for waste reduction and resource efficiency, it also presents significant environmental challenges. A comprehensive environmental impact assessment is essential to identify, evaluate, and mitigate potential risks, ensuring that the benefits of this process are realized without compromising environmental integrity.

One of the primary environmental benefits of carbolic acid utilization is the reduction of waste in petrochemical processes. By refining and repurposing this byproduct, industries can minimize the amount of potentially harmful substances released into the environment. This approach aligns with circular economy principles, promoting resource efficiency and waste reduction.

However, the production and handling of carbolic acid pose potential risks to ecosystems and human health. Phenol is known to be toxic to aquatic life and can persist in the environment for extended periods. Accidental releases or improper disposal of carbolic acid can lead to soil and water contamination, affecting local flora and fauna.

Air quality is another crucial factor to consider. The refining process may release volatile organic compounds (VOCs) and other air pollutants. These emissions can contribute to smog formation and have adverse effects on respiratory health in surrounding communities. Implementing advanced air pollution control technologies is essential to mitigate these impacts.

Water usage and wastewater management are critical aspects of the environmental impact assessment. The refinement process typically requires significant amounts of water, potentially straining local water resources. Additionally, the wastewater generated may contain phenol and other contaminants, necessitating robust treatment systems to prevent water pollution.

Energy consumption and associated greenhouse gas emissions must also be evaluated. The refinement and utilization processes often require substantial energy inputs, contributing to the overall carbon footprint of the operation. Implementing energy-efficient technologies and exploring renewable energy sources can help mitigate these impacts.

Biodiversity protection is another key consideration. Industrial facilities involved in carbolic acid refinement may impact local ecosystems through habitat disruption or potential chemical exposure. Comprehensive environmental management plans should include measures to protect and preserve biodiversity in the surrounding areas.

Long-term environmental monitoring is crucial to assess the cumulative impacts of carbolic acid utilization. This includes regular soil, water, and air quality testing, as well as ecological surveys to detect any changes in local ecosystems over time. Such monitoring programs can help identify and address potential environmental issues proactively.

In conclusion, while the utilization of carbolic acid in petrochemical byproduct refinement offers opportunities for waste reduction and resource efficiency, it also presents significant environmental challenges. A comprehensive environmental impact assessment is essential to identify, evaluate, and mitigate potential risks, ensuring that the benefits of this process are realized without compromising environmental integrity.

Regulatory Framework for Petrochemical Byproducts

The regulatory framework for petrochemical byproducts, including carbolic acid utilization, is a complex and evolving landscape that significantly impacts the industry's operations and innovation potential. At the global level, organizations such as the United Nations Environment Programme (UNEP) and the Organisation for Economic Co-operation and Development (OECD) provide guidelines and recommendations for the safe management and disposal of petrochemical byproducts.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating petrochemical byproducts under various acts, including the Resource Conservation and Recovery Act (RCRA) and the Toxic Substances Control Act (TSCA). These regulations establish stringent requirements for handling, storage, transportation, and disposal of hazardous materials, including carbolic acid and other petrochemical byproducts.

The European Union has implemented the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation, which aims to improve the protection of human health and the environment from risks posed by chemicals. This regulation directly affects the petrochemical industry, including the management and utilization of byproducts like carbolic acid.

Many countries have adopted their own regulatory frameworks, often inspired by or aligned with international standards. For instance, China's Measures for Environmental Management of New Chemical Substances and Japan's Chemical Substances Control Law both address the management of petrochemical byproducts.

Specific to carbolic acid utilization, regulations often focus on its classification as a hazardous substance and the associated handling requirements. This includes guidelines for personal protective equipment, storage conditions, and disposal methods. Additionally, regulations may address the permissible levels of carbolic acid in various products and environmental media.

The regulatory landscape also encompasses emissions standards and waste management practices. Many jurisdictions have implemented strict limits on the release of petrochemical byproducts into the environment, necessitating advanced treatment and disposal technologies.

As sustainability becomes an increasingly important focus, regulations are evolving to encourage the circular economy and promote the utilization of byproducts. This shift is driving innovation in carbolic acid utilization, as companies seek to comply with regulations while maximizing resource efficiency.

Compliance with these diverse regulatory frameworks presents both challenges and opportunities for the petrochemical industry. While adherence to regulations can be resource-intensive, it also drives technological advancements and promotes safer, more sustainable practices in carbolic acid utilization and overall petrochemical byproduct refinement.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating petrochemical byproducts under various acts, including the Resource Conservation and Recovery Act (RCRA) and the Toxic Substances Control Act (TSCA). These regulations establish stringent requirements for handling, storage, transportation, and disposal of hazardous materials, including carbolic acid and other petrochemical byproducts.

The European Union has implemented the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation, which aims to improve the protection of human health and the environment from risks posed by chemicals. This regulation directly affects the petrochemical industry, including the management and utilization of byproducts like carbolic acid.

Many countries have adopted their own regulatory frameworks, often inspired by or aligned with international standards. For instance, China's Measures for Environmental Management of New Chemical Substances and Japan's Chemical Substances Control Law both address the management of petrochemical byproducts.

Specific to carbolic acid utilization, regulations often focus on its classification as a hazardous substance and the associated handling requirements. This includes guidelines for personal protective equipment, storage conditions, and disposal methods. Additionally, regulations may address the permissible levels of carbolic acid in various products and environmental media.

The regulatory landscape also encompasses emissions standards and waste management practices. Many jurisdictions have implemented strict limits on the release of petrochemical byproducts into the environment, necessitating advanced treatment and disposal technologies.

As sustainability becomes an increasingly important focus, regulations are evolving to encourage the circular economy and promote the utilization of byproducts. This shift is driving innovation in carbolic acid utilization, as companies seek to comply with regulations while maximizing resource efficiency.

Compliance with these diverse regulatory frameworks presents both challenges and opportunities for the petrochemical industry. While adherence to regulations can be resource-intensive, it also drives technological advancements and promotes safer, more sustainable practices in carbolic acid utilization and overall petrochemical byproduct refinement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!