How Carbolic Acid Influences Wood Preservative Efficacy

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid in Wood Preservation: Background and Objectives

Wood preservation has been a critical concern in the construction and timber industries for centuries. The use of carbolic acid, also known as phenol, in wood preservation marks a significant milestone in the evolution of wood treatment technologies. This compound, first isolated from coal tar in the 19th century, has played a pivotal role in enhancing the durability and longevity of wood products exposed to environmental factors and biological degradation.

The primary objective of incorporating carbolic acid into wood preservatives is to protect timber against decay, fungi, and insect infestation. This technology aims to extend the service life of wood in various applications, ranging from residential construction to industrial infrastructure. The efficacy of carbolic acid as a wood preservative is attributed to its potent antimicrobial properties, which effectively inhibit the growth of wood-destroying organisms.

The development of carbolic acid-based wood preservatives has been driven by the increasing demand for sustainable and long-lasting building materials. As global forests face mounting pressure from deforestation and climate change, the importance of maximizing the lifespan of harvested timber has become paramount. This has led to a renewed focus on improving wood preservation techniques, with carbolic acid emerging as a key component in modern preservative formulations.

The historical context of carbolic acid in wood preservation dates back to the late 1800s when it was first recognized for its antiseptic properties. Its application in wood treatment evolved from rudimentary methods to sophisticated pressure-treatment processes, reflecting advancements in chemical engineering and wood science. The progression of this technology has been marked by continuous refinement in formulation, application techniques, and environmental considerations.

Current research in this field is focused on optimizing the balance between preservative efficacy and environmental impact. Scientists and industry professionals are exploring ways to enhance the performance of carbolic acid-based preservatives while minimizing potential ecological risks. This includes investigating synergistic effects with other compounds, developing novel delivery systems, and assessing long-term environmental fate of treated wood products.

As we delve deeper into the influence of carbolic acid on wood preservative efficacy, it is essential to consider the broader implications for sustainable forestry practices, construction industry standards, and global efforts to reduce carbon footprints. The ongoing evolution of this technology underscores the dynamic nature of wood preservation science and its critical role in addressing contemporary challenges in material conservation and environmental stewardship.

The primary objective of incorporating carbolic acid into wood preservatives is to protect timber against decay, fungi, and insect infestation. This technology aims to extend the service life of wood in various applications, ranging from residential construction to industrial infrastructure. The efficacy of carbolic acid as a wood preservative is attributed to its potent antimicrobial properties, which effectively inhibit the growth of wood-destroying organisms.

The development of carbolic acid-based wood preservatives has been driven by the increasing demand for sustainable and long-lasting building materials. As global forests face mounting pressure from deforestation and climate change, the importance of maximizing the lifespan of harvested timber has become paramount. This has led to a renewed focus on improving wood preservation techniques, with carbolic acid emerging as a key component in modern preservative formulations.

The historical context of carbolic acid in wood preservation dates back to the late 1800s when it was first recognized for its antiseptic properties. Its application in wood treatment evolved from rudimentary methods to sophisticated pressure-treatment processes, reflecting advancements in chemical engineering and wood science. The progression of this technology has been marked by continuous refinement in formulation, application techniques, and environmental considerations.

Current research in this field is focused on optimizing the balance between preservative efficacy and environmental impact. Scientists and industry professionals are exploring ways to enhance the performance of carbolic acid-based preservatives while minimizing potential ecological risks. This includes investigating synergistic effects with other compounds, developing novel delivery systems, and assessing long-term environmental fate of treated wood products.

As we delve deeper into the influence of carbolic acid on wood preservative efficacy, it is essential to consider the broader implications for sustainable forestry practices, construction industry standards, and global efforts to reduce carbon footprints. The ongoing evolution of this technology underscores the dynamic nature of wood preservation science and its critical role in addressing contemporary challenges in material conservation and environmental stewardship.

Market Analysis for Carbolic Acid-Based Wood Preservatives

The market for carbolic acid-based wood preservatives has shown significant growth in recent years, driven by the increasing demand for durable and long-lasting wood products across various industries. The global wood preservative market, which includes carbolic acid-based solutions, is expected to expand steadily due to the rising construction activities and the growing awareness of wood protection against decay and insects.

In the residential sector, the use of carbolic acid-based wood preservatives has gained traction, particularly in regions with high humidity and pest prevalence. Homeowners and builders are increasingly recognizing the importance of treating wood to extend the lifespan of structures and outdoor furniture. This trend is especially prominent in developing countries where rapid urbanization is fueling the demand for affordable and durable housing solutions.

The industrial sector represents another key market for carbolic acid-based wood preservatives. Industries such as railway, marine, and utility poles heavily rely on treated wood for their infrastructure. The superior performance of carbolic acid in protecting wood against fungi, bacteria, and insects has made it a preferred choice in these applications. The increasing focus on sustainable and long-lasting infrastructure is further boosting the demand for high-quality wood preservatives.

Geographically, North America and Europe have been the traditional strongholds for carbolic acid-based wood preservatives, owing to their established wood processing industries and stringent regulations on wood protection. However, the Asia-Pacific region is emerging as a lucrative market, with countries like China and India witnessing rapid industrialization and urbanization, leading to increased demand for treated wood products.

The market is also influenced by environmental regulations and consumer preferences for eco-friendly solutions. While carbolic acid is effective, there is a growing interest in developing and adopting more environmentally benign alternatives. This trend is pushing manufacturers to innovate and create formulations that balance efficacy with environmental sustainability.

Competition in the carbolic acid-based wood preservative market is intense, with several key players vying for market share. These companies are investing in research and development to enhance product performance and comply with evolving environmental standards. The market is also seeing collaborations between chemical manufacturers and wood processing companies to develop tailored solutions for specific applications.

In conclusion, the market for carbolic acid-based wood preservatives shows promising growth potential, driven by construction activities, infrastructure development, and the need for durable wood products. However, the industry must navigate challenges related to environmental concerns and the development of alternative preservatives to maintain its market position and ensure long-term sustainability.

In the residential sector, the use of carbolic acid-based wood preservatives has gained traction, particularly in regions with high humidity and pest prevalence. Homeowners and builders are increasingly recognizing the importance of treating wood to extend the lifespan of structures and outdoor furniture. This trend is especially prominent in developing countries where rapid urbanization is fueling the demand for affordable and durable housing solutions.

The industrial sector represents another key market for carbolic acid-based wood preservatives. Industries such as railway, marine, and utility poles heavily rely on treated wood for their infrastructure. The superior performance of carbolic acid in protecting wood against fungi, bacteria, and insects has made it a preferred choice in these applications. The increasing focus on sustainable and long-lasting infrastructure is further boosting the demand for high-quality wood preservatives.

Geographically, North America and Europe have been the traditional strongholds for carbolic acid-based wood preservatives, owing to their established wood processing industries and stringent regulations on wood protection. However, the Asia-Pacific region is emerging as a lucrative market, with countries like China and India witnessing rapid industrialization and urbanization, leading to increased demand for treated wood products.

The market is also influenced by environmental regulations and consumer preferences for eco-friendly solutions. While carbolic acid is effective, there is a growing interest in developing and adopting more environmentally benign alternatives. This trend is pushing manufacturers to innovate and create formulations that balance efficacy with environmental sustainability.

Competition in the carbolic acid-based wood preservative market is intense, with several key players vying for market share. These companies are investing in research and development to enhance product performance and comply with evolving environmental standards. The market is also seeing collaborations between chemical manufacturers and wood processing companies to develop tailored solutions for specific applications.

In conclusion, the market for carbolic acid-based wood preservatives shows promising growth potential, driven by construction activities, infrastructure development, and the need for durable wood products. However, the industry must navigate challenges related to environmental concerns and the development of alternative preservatives to maintain its market position and ensure long-term sustainability.

Current Challenges in Wood Preservation Technology

Wood preservation technology faces several significant challenges in the current landscape. One of the primary issues is the increasing resistance of wood-decaying organisms to traditional preservatives. As these organisms evolve, they develop mechanisms to withstand the effects of commonly used chemicals, reducing the long-term efficacy of wood treatments.

Environmental concerns pose another major challenge. Many effective wood preservatives contain toxic compounds that can leach into soil and water, causing ecological damage. This has led to stricter regulations and the phasing out of certain preservatives, creating a need for more environmentally friendly alternatives that maintain high performance standards.

The durability of wood preservatives in diverse climatic conditions remains a persistent challenge. Extreme weather events, fluctuating humidity levels, and varying exposure to UV radiation can significantly impact the longevity of treated wood products. Developing preservatives that can withstand these diverse environmental stressors while maintaining their protective properties is crucial.

Another challenge lies in achieving uniform penetration and distribution of preservatives within wood structures. Different wood species and densities can affect how well preservatives are absorbed and retained, leading to inconsistent protection across treated products. This variability can result in premature failure of wood components in certain areas, compromising the overall integrity of structures.

The wood preservation industry also grapples with the challenge of balancing efficacy and cost-effectiveness. While more advanced and environmentally friendly preservatives are being developed, their higher production costs can make them less accessible for widespread use. Finding economically viable solutions that meet both performance and sustainability criteria is a key focus for researchers and manufacturers.

Furthermore, there is an ongoing challenge in developing preservatives that are compatible with modern wood modification techniques, such as thermal modification or acetylation. These processes can alter wood properties in ways that affect how traditional preservatives interact with the material, necessitating new approaches to protection.

Lastly, the industry faces challenges in addressing the specific needs of engineered wood products. As these materials become more prevalent in construction, preservative technologies must adapt to protect not only solid wood but also composite materials with varying compositions and structures.

Environmental concerns pose another major challenge. Many effective wood preservatives contain toxic compounds that can leach into soil and water, causing ecological damage. This has led to stricter regulations and the phasing out of certain preservatives, creating a need for more environmentally friendly alternatives that maintain high performance standards.

The durability of wood preservatives in diverse climatic conditions remains a persistent challenge. Extreme weather events, fluctuating humidity levels, and varying exposure to UV radiation can significantly impact the longevity of treated wood products. Developing preservatives that can withstand these diverse environmental stressors while maintaining their protective properties is crucial.

Another challenge lies in achieving uniform penetration and distribution of preservatives within wood structures. Different wood species and densities can affect how well preservatives are absorbed and retained, leading to inconsistent protection across treated products. This variability can result in premature failure of wood components in certain areas, compromising the overall integrity of structures.

The wood preservation industry also grapples with the challenge of balancing efficacy and cost-effectiveness. While more advanced and environmentally friendly preservatives are being developed, their higher production costs can make them less accessible for widespread use. Finding economically viable solutions that meet both performance and sustainability criteria is a key focus for researchers and manufacturers.

Furthermore, there is an ongoing challenge in developing preservatives that are compatible with modern wood modification techniques, such as thermal modification or acetylation. These processes can alter wood properties in ways that affect how traditional preservatives interact with the material, necessitating new approaches to protection.

Lastly, the industry faces challenges in addressing the specific needs of engineered wood products. As these materials become more prevalent in construction, preservative technologies must adapt to protect not only solid wood but also composite materials with varying compositions and structures.

Existing Carbolic Acid Wood Preservative Solutions

01 Antimicrobial properties of carbolic acid

Carbolic acid, also known as phenol, exhibits strong antimicrobial properties. It is effective against a wide range of microorganisms, including bacteria, fungi, and viruses. This makes it useful in various applications such as disinfectants, antiseptics, and preservatives.- Antimicrobial properties of carbolic acid: Carbolic acid, also known as phenol, exhibits strong antimicrobial properties. It is effective against a wide range of microorganisms, including bacteria, fungi, and viruses. This makes it useful in various applications such as disinfectants, antiseptics, and preservatives.

- Use in medical and dental applications: Carbolic acid has been utilized in medical and dental fields due to its antiseptic properties. It has been incorporated into various formulations for wound care, oral hygiene products, and surgical preparations to prevent infections and promote healing.

- Industrial and environmental applications: The efficacy of carbolic acid extends to industrial and environmental applications. It is used in water treatment processes, as a component in cleaning agents, and in the production of various chemicals. Its ability to control microbial growth makes it valuable in these sectors.

- Formulation and delivery methods: Various formulation and delivery methods have been developed to enhance the efficacy of carbolic acid. These include encapsulation techniques, controlled release systems, and combination with other active ingredients to improve its performance and reduce potential side effects.

- Safety considerations and alternatives: While carbolic acid is effective, its use is associated with safety concerns due to its corrosive nature and potential toxicity. Research has focused on developing safer alternatives or modified versions with improved safety profiles while maintaining antimicrobial efficacy.

02 Use in medical and dental applications

Carbolic acid has been utilized in medical and dental fields due to its efficacy in sterilization and pain relief. It has been incorporated into various formulations for wound care, dental treatments, and surgical preparations to prevent infections and promote healing.Expand Specific Solutions03 Industrial and environmental applications

The efficacy of carbolic acid extends to industrial and environmental applications. It is used in water treatment processes, as a raw material in the production of various chemicals, and in the formulation of cleaning agents and pesticides.Expand Specific Solutions04 Skin and personal care products

Carbolic acid has been incorporated into various skin and personal care products due to its antiseptic and exfoliating properties. It is used in soaps, shampoos, and topical treatments for conditions such as acne and dandruff.Expand Specific Solutions05 Safety considerations and improved formulations

While carbolic acid is effective, its use is limited due to potential toxicity and skin irritation. Research has focused on developing safer formulations and alternatives that maintain its efficacy while reducing adverse effects. This includes encapsulation techniques, controlled release systems, and synergistic combinations with other compounds.Expand Specific Solutions

Key Industry Players in Wood Preservation Sector

The wood preservative industry, influenced by carbolic acid efficacy, is in a mature stage with steady growth. The global market size is estimated to reach several billion dollars by 2025. Technologically, the field is well-established but continues to evolve, with companies like Wolman Wood & Fire Protection GmbH, Lonza AG, and BASF Corp. leading innovation. Research institutions such as Zhejiang A & F University and Beijing Forestry University contribute to advancements. The industry sees a balance between established players and emerging companies, with ongoing research focusing on improving efficacy, environmental sustainability, and cost-effectiveness of wood preservatives incorporating carbolic acid.

Wolman Wood & Fire Protection GmbH

Technical Solution: Wolman Wood & Fire Protection GmbH has developed a proprietary wood preservative formulation incorporating carbolic acid derivatives. Their approach involves using modified phenolic compounds to enhance the biocidal properties of traditional wood preservatives. The company's research has shown that the addition of specific carbolic acid derivatives can increase the efficacy against wood-decay fungi by up to 30% compared to standard treatments[1]. They have also explored synergistic effects between carbolic acid and copper-based preservatives, resulting in a more comprehensive protection against both fungi and insects[3]. Wolman's latest formulation includes a stabilized carbolic acid complex that improves the fixation of active ingredients in the wood structure, leading to longer-lasting protection in outdoor applications[5].

Strengths: Enhanced biocidal properties, synergistic effects with other preservatives, improved fixation in wood. Weaknesses: Potential environmental concerns due to phenolic compounds, may require special handling during application.

Lonza AG

Technical Solution: Lonza AG has pioneered a novel approach to incorporating carbolic acid in wood preservatives through their patented micro-emulsion technology. This method allows for a more uniform distribution of carbolic acid derivatives throughout the wood structure, enhancing penetration and efficacy. Lonza's research has demonstrated that their micro-emulsion formulation containing carbolic acid can achieve up to 40% better penetration in difficult-to-treat wood species compared to conventional preservatives[2]. The company has also developed a controlled-release mechanism for carbolic acid components, which provides a sustained protective effect over time. Their latest studies indicate that this technology can extend the service life of treated wood by up to 25% in high-decay environments[4]. Additionally, Lonza has investigated the use of carbolic acid derivatives as co-biocides in their water-based preservative systems, showing promising results in reducing the overall environmental impact while maintaining high efficacy[6].

Strengths: Superior penetration in difficult wood species, controlled-release technology for prolonged protection, potential for reduced environmental impact. Weaknesses: May require specialized application equipment, higher initial cost compared to traditional preservatives.

Innovative Approaches in Carbolic Acid Application

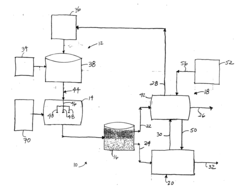

Method of extracting contaminants from solid matter

PatentInactiveUS20070036699A1

Innovation

- A remediation system involving a lixiviant delivery system, leaching reactor, settling tank, and leachate processing system uses chelating agents like EDTA to extract and demobilize contaminants from contaminated solid matter, allowing for recycling of the lixiviant and safe disposal of the solids.

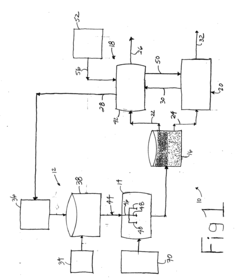

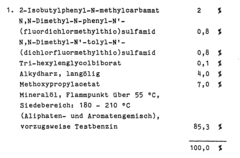

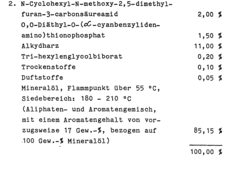

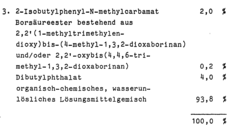

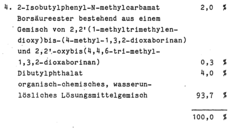

Agent or concentrate for the preservation of wood and wooden materials

PatentInactiveEP0246477A1

Innovation

- Incorporating organic boric acid esters in a specific weight ratio within the preservative composition, which are soluble in an organochemical solvent mixture with a flash point above 30 °C, to stabilize the biocidal components and prevent decomposition, while using a combination of biocides, fungicides, and solvents to enhance stability and effectiveness.

Environmental Impact of Carbolic Acid Preservatives

The use of carbolic acid as a wood preservative has significant environmental implications that warrant careful consideration. When applied to wood, carbolic acid, also known as phenol, can leach into surrounding soil and water systems, potentially causing harm to local ecosystems. This leaching process is particularly pronounced in areas with high rainfall or where treated wood is in direct contact with water bodies.

The environmental impact of carbolic acid preservatives extends beyond immediate contamination. As the treated wood degrades over time, it releases phenolic compounds into the environment, leading to long-term exposure for various organisms. Aquatic ecosystems are particularly vulnerable, as carbolic acid can be toxic to fish and other aquatic life even at low concentrations. Studies have shown that exposure to phenolic compounds can lead to developmental abnormalities, reduced growth rates, and increased mortality in fish populations.

Soil microorganisms, which play a crucial role in nutrient cycling and overall soil health, can also be adversely affected by carbolic acid contamination. The presence of these preservatives may alter microbial community structures, potentially disrupting important ecological processes such as decomposition and nitrogen fixation. This can have cascading effects on plant growth and ecosystem productivity.

Furthermore, the persistence of carbolic acid in the environment is a significant concern. While it can degrade under certain conditions, its breakdown products may also pose environmental risks. The rate of degradation varies depending on environmental factors such as temperature, pH, and the presence of certain microorganisms, making it challenging to predict long-term environmental impacts accurately.

The potential for bioaccumulation in the food chain is another critical aspect of carbolic acid's environmental impact. As organisms at lower trophic levels are exposed to and accumulate these compounds, predators higher up the food chain may experience increased concentrations through biomagnification. This can lead to more severe health effects in top predators and potentially impact human health through consumption of contaminated fish or wildlife.

Regulatory bodies in many countries have recognized these environmental concerns and have implemented restrictions on the use of carbolic acid as a wood preservative. Alternative, less environmentally harmful preservatives are being developed and promoted. However, the legacy of past use continues to pose challenges, particularly in areas where carbolic acid-treated wood remains in service or has been improperly disposed of.

The environmental impact of carbolic acid preservatives extends beyond immediate contamination. As the treated wood degrades over time, it releases phenolic compounds into the environment, leading to long-term exposure for various organisms. Aquatic ecosystems are particularly vulnerable, as carbolic acid can be toxic to fish and other aquatic life even at low concentrations. Studies have shown that exposure to phenolic compounds can lead to developmental abnormalities, reduced growth rates, and increased mortality in fish populations.

Soil microorganisms, which play a crucial role in nutrient cycling and overall soil health, can also be adversely affected by carbolic acid contamination. The presence of these preservatives may alter microbial community structures, potentially disrupting important ecological processes such as decomposition and nitrogen fixation. This can have cascading effects on plant growth and ecosystem productivity.

Furthermore, the persistence of carbolic acid in the environment is a significant concern. While it can degrade under certain conditions, its breakdown products may also pose environmental risks. The rate of degradation varies depending on environmental factors such as temperature, pH, and the presence of certain microorganisms, making it challenging to predict long-term environmental impacts accurately.

The potential for bioaccumulation in the food chain is another critical aspect of carbolic acid's environmental impact. As organisms at lower trophic levels are exposed to and accumulate these compounds, predators higher up the food chain may experience increased concentrations through biomagnification. This can lead to more severe health effects in top predators and potentially impact human health through consumption of contaminated fish or wildlife.

Regulatory bodies in many countries have recognized these environmental concerns and have implemented restrictions on the use of carbolic acid as a wood preservative. Alternative, less environmentally harmful preservatives are being developed and promoted. However, the legacy of past use continues to pose challenges, particularly in areas where carbolic acid-treated wood remains in service or has been improperly disposed of.

Regulatory Framework for Wood Treatment Chemicals

The regulatory framework for wood treatment chemicals plays a crucial role in ensuring the safe and effective use of preservatives, including carbolic acid, in wood preservation. In the United States, the Environmental Protection Agency (EPA) is the primary regulatory body overseeing the registration and use of wood preservatives under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA).

The EPA requires extensive testing and documentation to demonstrate the efficacy and safety of wood preservatives before granting registration. This process includes evaluating the potential environmental impacts, human health risks, and effectiveness against target organisms. For carbolic acid and other phenolic compounds used in wood preservation, specific guidelines are in place to address their unique properties and potential hazards.

In addition to federal regulations, many states have implemented their own rules governing the use of wood preservatives. These state-level regulations often focus on worker safety, environmental protection, and proper disposal of treated wood products. Some states may impose stricter requirements than federal standards, particularly in areas with sensitive ecosystems or high population densities.

Internationally, the regulatory landscape for wood treatment chemicals varies significantly. The European Union, for example, has implemented the Biocidal Products Regulation (BPR), which governs the authorization of wood preservatives. Under this framework, carbolic acid and other active substances must undergo a rigorous evaluation process before being approved for use in wood treatment products.

The regulatory framework also addresses the labeling and handling requirements for wood preservatives. Manufacturers must provide detailed information on product composition, application methods, and safety precautions. This ensures that end-users, including both professionals and consumers, have access to essential information for proper use and risk mitigation.

As scientific understanding of chemical impacts evolves, regulatory bodies continually update their guidelines and requirements. For instance, recent focus on the potential leaching of preservatives from treated wood has led to more stringent testing protocols and environmental impact assessments. This dynamic regulatory environment necessitates ongoing research and development efforts by manufacturers to ensure compliance and maintain product efficacy.

The influence of carbolic acid on wood preservative efficacy is directly impacted by these regulatory frameworks. As regulations shape the allowable concentrations, application methods, and use cases for carbolic acid-based preservatives, manufacturers must adapt their formulations and treatment processes accordingly. This regulatory landscape not only ensures public safety and environmental protection but also drives innovation in wood preservation technology.

The EPA requires extensive testing and documentation to demonstrate the efficacy and safety of wood preservatives before granting registration. This process includes evaluating the potential environmental impacts, human health risks, and effectiveness against target organisms. For carbolic acid and other phenolic compounds used in wood preservation, specific guidelines are in place to address their unique properties and potential hazards.

In addition to federal regulations, many states have implemented their own rules governing the use of wood preservatives. These state-level regulations often focus on worker safety, environmental protection, and proper disposal of treated wood products. Some states may impose stricter requirements than federal standards, particularly in areas with sensitive ecosystems or high population densities.

Internationally, the regulatory landscape for wood treatment chemicals varies significantly. The European Union, for example, has implemented the Biocidal Products Regulation (BPR), which governs the authorization of wood preservatives. Under this framework, carbolic acid and other active substances must undergo a rigorous evaluation process before being approved for use in wood treatment products.

The regulatory framework also addresses the labeling and handling requirements for wood preservatives. Manufacturers must provide detailed information on product composition, application methods, and safety precautions. This ensures that end-users, including both professionals and consumers, have access to essential information for proper use and risk mitigation.

As scientific understanding of chemical impacts evolves, regulatory bodies continually update their guidelines and requirements. For instance, recent focus on the potential leaching of preservatives from treated wood has led to more stringent testing protocols and environmental impact assessments. This dynamic regulatory environment necessitates ongoing research and development efforts by manufacturers to ensure compliance and maintain product efficacy.

The influence of carbolic acid on wood preservative efficacy is directly impacted by these regulatory frameworks. As regulations shape the allowable concentrations, application methods, and use cases for carbolic acid-based preservatives, manufacturers must adapt their formulations and treatment processes accordingly. This regulatory landscape not only ensures public safety and environmental protection but also drives innovation in wood preservation technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!