Carbolic Acid: A Catalyst in Polyurethane Foam Production

JUL 22, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid in PU Foam: Background and Objectives

Carbolic acid, also known as phenol, has played a significant role in the development of polyurethane (PU) foam production since its inception. The journey of carbolic acid in this field began in the early 20th century when the potential of polyurethane chemistry was first discovered. Initially, the focus was on understanding the basic reactions between isocyanates and polyols, which form the foundation of polyurethane synthesis.

As the industry evolved, researchers and manufacturers recognized the catalytic properties of carbolic acid in accelerating these reactions. This discovery marked a turning point in PU foam production, enabling faster curing times and improved foam quality. The ability of carbolic acid to influence the reaction kinetics opened up new possibilities for tailoring foam properties to meet specific application requirements.

Throughout the decades, the role of carbolic acid in PU foam production has expanded beyond its catalytic function. Its impact on foam cell structure, dimensional stability, and overall performance characteristics has been extensively studied and optimized. This continuous refinement has led to the development of a wide range of PU foam products, from flexible cushioning materials to rigid insulation panels.

The objectives of incorporating carbolic acid in PU foam production have evolved in response to changing market demands and environmental considerations. Initially, the primary goal was to enhance production efficiency and reduce costs. However, as sustainability became a key focus in the chemical industry, objectives shifted towards developing more environmentally friendly formulations and processes.

Current research aims to leverage the properties of carbolic acid to create PU foams with improved fire resistance, enhanced biodegradability, and reduced volatile organic compound (VOC) emissions. These objectives align with global efforts to produce safer and more sustainable materials for various applications, including construction, automotive, and consumer goods industries.

Furthermore, the integration of carbolic acid in PU foam production has spurred innovation in related fields, such as the development of bio-based alternatives and the exploration of novel catalytic systems. This cross-pollination of ideas has contributed to the broader advancement of polymer science and materials engineering.

As we look to the future, the role of carbolic acid in PU foam production continues to evolve. Researchers are exploring its potential in creating smart foams with self-healing properties, temperature-responsive characteristics, and enhanced recyclability. These ambitious objectives reflect the industry's commitment to pushing the boundaries of material science and addressing the complex challenges of the 21st century.

As the industry evolved, researchers and manufacturers recognized the catalytic properties of carbolic acid in accelerating these reactions. This discovery marked a turning point in PU foam production, enabling faster curing times and improved foam quality. The ability of carbolic acid to influence the reaction kinetics opened up new possibilities for tailoring foam properties to meet specific application requirements.

Throughout the decades, the role of carbolic acid in PU foam production has expanded beyond its catalytic function. Its impact on foam cell structure, dimensional stability, and overall performance characteristics has been extensively studied and optimized. This continuous refinement has led to the development of a wide range of PU foam products, from flexible cushioning materials to rigid insulation panels.

The objectives of incorporating carbolic acid in PU foam production have evolved in response to changing market demands and environmental considerations. Initially, the primary goal was to enhance production efficiency and reduce costs. However, as sustainability became a key focus in the chemical industry, objectives shifted towards developing more environmentally friendly formulations and processes.

Current research aims to leverage the properties of carbolic acid to create PU foams with improved fire resistance, enhanced biodegradability, and reduced volatile organic compound (VOC) emissions. These objectives align with global efforts to produce safer and more sustainable materials for various applications, including construction, automotive, and consumer goods industries.

Furthermore, the integration of carbolic acid in PU foam production has spurred innovation in related fields, such as the development of bio-based alternatives and the exploration of novel catalytic systems. This cross-pollination of ideas has contributed to the broader advancement of polymer science and materials engineering.

As we look to the future, the role of carbolic acid in PU foam production continues to evolve. Researchers are exploring its potential in creating smart foams with self-healing properties, temperature-responsive characteristics, and enhanced recyclability. These ambitious objectives reflect the industry's commitment to pushing the boundaries of material science and addressing the complex challenges of the 21st century.

Market Analysis for Carbolic Acid Catalyzed PU Foams

The market for carbolic acid catalyzed polyurethane (PU) foams has shown significant growth in recent years, driven by increasing demand across various industries. The global PU foam market, valued at approximately $50 billion in 2020, is projected to reach $80 billion by 2025, with a compound annual growth rate (CAGR) of around 8%.

Carbolic acid, also known as phenol, plays a crucial role as a catalyst in PU foam production, enhancing the reaction rate and improving the overall quality of the final product. The use of carbolic acid as a catalyst has gained traction due to its ability to produce foams with superior mechanical properties, thermal stability, and fire resistance.

The construction industry remains the largest consumer of carbolic acid catalyzed PU foams, accounting for nearly 40% of the market share. The growing demand for energy-efficient buildings and stringent building codes have fueled the adoption of PU foams as insulation materials. Additionally, the automotive sector has emerged as a significant market for these foams, driven by the need for lightweight materials to improve fuel efficiency and reduce emissions.

Geographically, Asia-Pacific dominates the market, with China and India leading the growth. The region's rapid industrialization, urbanization, and increasing disposable income have contributed to the rising demand for PU foams in various applications. North America and Europe follow closely, with mature markets focusing on technological advancements and sustainable solutions.

The market for carbolic acid catalyzed PU foams faces challenges related to environmental concerns and regulatory pressures. Stricter regulations on volatile organic compound (VOC) emissions and the push for more sustainable materials have led to increased research and development efforts in bio-based alternatives and recycling technologies.

Despite these challenges, the market outlook remains positive. Innovations in foam formulations, such as low-density and high-performance variants, are opening up new application areas. The growing emphasis on circular economy principles is also driving the development of recyclable and biodegradable PU foams, creating opportunities for market expansion and differentiation.

Carbolic acid, also known as phenol, plays a crucial role as a catalyst in PU foam production, enhancing the reaction rate and improving the overall quality of the final product. The use of carbolic acid as a catalyst has gained traction due to its ability to produce foams with superior mechanical properties, thermal stability, and fire resistance.

The construction industry remains the largest consumer of carbolic acid catalyzed PU foams, accounting for nearly 40% of the market share. The growing demand for energy-efficient buildings and stringent building codes have fueled the adoption of PU foams as insulation materials. Additionally, the automotive sector has emerged as a significant market for these foams, driven by the need for lightweight materials to improve fuel efficiency and reduce emissions.

Geographically, Asia-Pacific dominates the market, with China and India leading the growth. The region's rapid industrialization, urbanization, and increasing disposable income have contributed to the rising demand for PU foams in various applications. North America and Europe follow closely, with mature markets focusing on technological advancements and sustainable solutions.

The market for carbolic acid catalyzed PU foams faces challenges related to environmental concerns and regulatory pressures. Stricter regulations on volatile organic compound (VOC) emissions and the push for more sustainable materials have led to increased research and development efforts in bio-based alternatives and recycling technologies.

Despite these challenges, the market outlook remains positive. Innovations in foam formulations, such as low-density and high-performance variants, are opening up new application areas. The growing emphasis on circular economy principles is also driving the development of recyclable and biodegradable PU foams, creating opportunities for market expansion and differentiation.

Technical Challenges in Carbolic Acid Catalysis

The utilization of carbolic acid as a catalyst in polyurethane foam production presents several significant technical challenges that researchers and manufacturers must address. One of the primary issues is the corrosive nature of carbolic acid, which can lead to equipment degradation and potential safety hazards in production environments. This necessitates the use of specialized, acid-resistant materials for storage, handling, and processing equipment, increasing production costs and complexity.

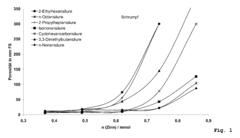

Another challenge lies in controlling the reaction kinetics when using carbolic acid as a catalyst. The acid's strong catalytic activity can result in rapid and exothermic reactions, making it difficult to maintain precise control over foam formation and properties. This can lead to inconsistencies in foam quality, density, and cellular structure, potentially affecting the final product's performance characteristics.

The environmental and health concerns associated with carbolic acid usage pose additional technical hurdles. Stringent regulations regarding emissions and worker exposure require sophisticated containment and ventilation systems, as well as robust personal protective equipment protocols. Developing effective methods for neutralizing and disposing of carbolic acid waste streams is also a critical challenge, as improper handling can lead to environmental contamination.

Furthermore, achieving optimal catalyst dispersion throughout the polyurethane mixture presents technical difficulties. Uneven distribution of carbolic acid can result in localized areas of accelerated reaction, leading to defects in the foam structure. Researchers must develop advanced mixing technologies and formulation strategies to ensure uniform catalyst distribution and consistent foam properties.

The sensitivity of carbolic acid to moisture and temperature fluctuations during storage and handling introduces additional complexities. Maintaining the catalyst's efficacy over time and preventing unwanted side reactions or degradation requires precise environmental control systems and storage protocols. This challenge is particularly pronounced in large-scale industrial applications where significant quantities of carbolic acid must be managed.

Lastly, the interaction between carbolic acid and other components in the polyurethane formulation, such as polyols, isocyanates, and additives, presents ongoing research challenges. Understanding and optimizing these complex chemical interactions is crucial for developing high-performance foam products with specific properties tailored to various applications. This requires extensive experimentation and analytical techniques to elucidate reaction mechanisms and structure-property relationships in carbolic acid-catalyzed polyurethane systems.

Another challenge lies in controlling the reaction kinetics when using carbolic acid as a catalyst. The acid's strong catalytic activity can result in rapid and exothermic reactions, making it difficult to maintain precise control over foam formation and properties. This can lead to inconsistencies in foam quality, density, and cellular structure, potentially affecting the final product's performance characteristics.

The environmental and health concerns associated with carbolic acid usage pose additional technical hurdles. Stringent regulations regarding emissions and worker exposure require sophisticated containment and ventilation systems, as well as robust personal protective equipment protocols. Developing effective methods for neutralizing and disposing of carbolic acid waste streams is also a critical challenge, as improper handling can lead to environmental contamination.

Furthermore, achieving optimal catalyst dispersion throughout the polyurethane mixture presents technical difficulties. Uneven distribution of carbolic acid can result in localized areas of accelerated reaction, leading to defects in the foam structure. Researchers must develop advanced mixing technologies and formulation strategies to ensure uniform catalyst distribution and consistent foam properties.

The sensitivity of carbolic acid to moisture and temperature fluctuations during storage and handling introduces additional complexities. Maintaining the catalyst's efficacy over time and preventing unwanted side reactions or degradation requires precise environmental control systems and storage protocols. This challenge is particularly pronounced in large-scale industrial applications where significant quantities of carbolic acid must be managed.

Lastly, the interaction between carbolic acid and other components in the polyurethane formulation, such as polyols, isocyanates, and additives, presents ongoing research challenges. Understanding and optimizing these complex chemical interactions is crucial for developing high-performance foam products with specific properties tailored to various applications. This requires extensive experimentation and analytical techniques to elucidate reaction mechanisms and structure-property relationships in carbolic acid-catalyzed polyurethane systems.

Current Carbolic Acid Catalysis Methods

01 Carbolic acid in medical applications

Carbolic acid, also known as phenol, has been used in various medical applications due to its antiseptic properties. It has been utilized in disinfectants, wound treatments, and surgical procedures to prevent infections. The use of carbolic acid in medical settings has evolved over time, with improvements in formulations and application methods to enhance its effectiveness and safety.- Historical use of carbolic acid in medical applications: Carbolic acid, also known as phenol, has been historically used in various medical applications. It was one of the earliest antiseptics used in surgery and wound care due to its strong antibacterial properties. This compound played a significant role in the development of modern antiseptic techniques in the late 19th and early 20th centuries.

- Carbolic acid in industrial cleaning and disinfection: Carbolic acid is utilized in industrial cleaning and disinfection processes. It is effective against a wide range of microorganisms, making it suitable for use in various settings such as hospitals, laboratories, and manufacturing facilities. Specialized equipment and formulations have been developed to safely handle and apply carbolic acid for these purposes.

- Carbolic acid derivatives in pharmaceutical compositions: Derivatives of carbolic acid are used in pharmaceutical compositions for various therapeutic applications. These compounds may exhibit improved efficacy or reduced side effects compared to the parent compound. Research continues to explore new carbolic acid derivatives and their potential medicinal uses.

- Environmental and safety considerations for carbolic acid use: Due to its toxic nature, the use of carbolic acid requires careful handling and disposal procedures. Specialized equipment and safety measures have been developed to minimize environmental impact and protect workers. This includes containment systems, personal protective equipment, and waste treatment processes specifically designed for carbolic acid and related compounds.

- Carbolic acid in polymer and material science applications: Carbolic acid and its derivatives play a role in polymer and material science applications. They can be used as precursors or additives in the synthesis of various polymers and materials with specific properties. This includes applications in adhesives, coatings, and specialty plastics where the unique chemical structure of carbolic acid contributes to desired material characteristics.

02 Carbolic acid in industrial processes

Carbolic acid finds applications in various industrial processes, including the production of plastics, resins, and other chemical compounds. It serves as a precursor or intermediate in the synthesis of numerous products. Industrial uses of carbolic acid often involve specialized equipment and processes to handle its corrosive nature and ensure worker safety.Expand Specific Solutions03 Carbolic acid in water treatment

Carbolic acid has been employed in water treatment processes, particularly for its ability to eliminate harmful microorganisms. It can be used in the disinfection of water supplies and wastewater treatment. However, due to its toxicity, alternative methods and compounds have largely replaced carbolic acid in modern water treatment systems.Expand Specific Solutions04 Safety measures and handling of carbolic acid

Given the corrosive and toxic nature of carbolic acid, proper safety measures and handling procedures are crucial. This includes the use of protective equipment, specialized storage containers, and proper disposal methods. Safety protocols have been developed to minimize risks associated with carbolic acid exposure in both industrial and laboratory settings.Expand Specific Solutions05 Carbolic acid derivatives and alternatives

Research has been conducted to develop derivatives of carbolic acid with improved properties or to find alternative compounds that can replace it in various applications. These efforts aim to maintain the beneficial properties of carbolic acid while reducing its toxicity and environmental impact. Some alternatives have been successfully implemented in industries where carbolic acid was traditionally used.Expand Specific Solutions

Key Players in Carbolic Acid and PU Foam Industry

The carbolic acid catalyst market for polyurethane foam production is in a growth phase, driven by increasing demand for polyurethane foams across various industries. The global market size is expanding, with key players like BASF, Dow, and Evonik Industries leading technological advancements. These companies, along with others such as Air Products & Chemicals and Momentive Performance Materials, are investing in R&D to improve catalyst efficiency and environmental sustainability. The technology is relatively mature, but ongoing innovations focus on enhancing performance, reducing environmental impact, and meeting stringent regulatory requirements. Emerging players from Asia, particularly China, are also making significant contributions to market growth and technological progress.

Air Products & Chemicals, Inc.

Technical Solution: Air Products has innovated a carbolic acid-based catalyst system for polyurethane foam production that emphasizes process efficiency and foam quality. Their approach involves a micro-emulsion technique to disperse the carbolic acid catalyst effectively throughout the reaction mixture[4]. This results in a more homogeneous foam structure and improved mechanical properties[8]. Air Products' technology also incorporates a novel heat management system that optimizes the exothermic reaction profile, allowing for better control of foam rise and cell structure[10]. Additionally, they have developed a proprietary additive package that works synergistically with the carbolic acid catalyst to enhance flame retardancy and reduce smoke generation in the final foam product[12].

Strengths: Improved foam homogeneity, enhanced process control, and advanced flame retardant properties. Weaknesses: Potential increased complexity in formulation and possible limitations in certain foam densities.

Evonik Operations GmbH

Technical Solution: Evonik has developed an advanced carbolic acid catalyst system for polyurethane foam production that focuses on versatility and customization. Their approach utilizes a modular catalyst package where carbolic acid is combined with various co-catalysts and additives to tailor foam properties for specific applications[5]. This system allows for fine-tuning of reaction kinetics, enabling the production of foams with a wide range of densities and hardness levels[9]. Evonik's technology also incorporates a novel encapsulation method for the carbolic acid catalyst, which provides controlled release during the foaming process and improves the overall stability of the foam system[11]. Furthermore, they have integrated a real-time monitoring system that adjusts catalyst activity based on reaction parameters, ensuring consistent foam quality across different production batches[13].

Strengths: High versatility in foam properties, improved process consistency, and adaptability to various applications. Weaknesses: Potential complexity in formulation optimization and possible higher initial investment costs.

Innovations in Carbolic Acid Catalytic Mechanisms

Use of metallic salts of a carboxylic acid in the production of polyurethane systems

PatentInactiveEP2289960A1

Innovation

- The use of metal salts of carboxylic acids like n-octanoic acid and 3,5,5-trimethylhexanoic acid, which do not have exclusive ethyl or n-propyl branching, as catalysts in polyurethane systems to produce foams with improved safety and broader processing ranges without compromising physical properties.

Catalyst for production of polyurethane

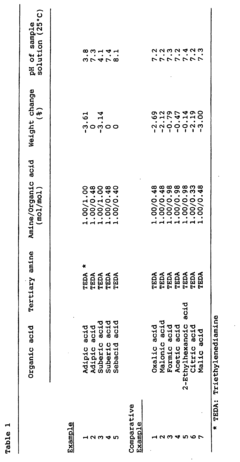

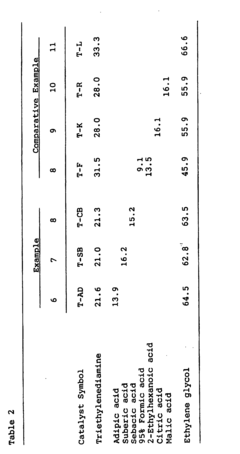

PatentInactiveEP0989146B1

Innovation

- A catalyst mixture of specific tertiary amines and saturated dicarboxylic acids, adjusted to a pH of 7.0 or higher, providing delayed activity and reduced corrosiveness, allowing for controlled polyurethane production with improved mold filling and productivity.

Environmental Impact of Carbolic Acid in PU Production

The use of carbolic acid (phenol) as a catalyst in polyurethane foam production has significant environmental implications. While it enhances the efficiency of the manufacturing process, its potential impact on ecosystems and human health cannot be overlooked.

Carbolic acid is known for its toxicity and corrosive properties. When released into the environment, it can contaminate soil and water sources, posing risks to aquatic life and terrestrial organisms. The compound's persistence in the environment is a concern, as it does not readily biodegrade, leading to potential long-term ecological effects.

In aquatic environments, carbolic acid can disrupt the balance of ecosystems by affecting the growth and reproduction of various species. Fish and other aquatic organisms may experience acute or chronic toxicity, depending on exposure levels. This can lead to population declines and alterations in food web dynamics.

Atmospheric emissions during polyurethane foam production can contribute to air pollution. Carbolic acid vapors can react with other pollutants, potentially forming secondary air contaminants. These emissions may contribute to the formation of photochemical smog and have adverse effects on air quality in surrounding areas.

The production process itself presents occupational health risks for workers in polyurethane manufacturing facilities. Exposure to carbolic acid can cause severe skin burns, respiratory irritation, and other health issues. Proper safety measures and protective equipment are crucial to mitigate these risks.

Waste management is another critical environmental concern. Improper disposal of carbolic acid-containing waste can lead to soil and groundwater contamination. This necessitates stringent protocols for handling, storage, and disposal of waste materials generated during the production process.

Efforts to reduce the environmental impact of carbolic acid in polyurethane foam production have led to the development of alternative catalysts and production methods. Green chemistry initiatives are exploring bio-based catalysts and environmentally friendly production processes to minimize the use of harmful substances like carbolic acid.

Regulatory bodies worldwide have implemented strict guidelines for the use and disposal of carbolic acid in industrial processes. These regulations aim to minimize environmental release and protect ecosystems and human health. Compliance with these standards is essential for sustainable polyurethane foam production.

As the industry moves towards more sustainable practices, there is a growing emphasis on life cycle assessments of polyurethane products. These assessments consider the environmental impact from raw material extraction through production, use, and disposal, providing a comprehensive view of the ecological footprint associated with carbolic acid use in polyurethane foam manufacturing.

Carbolic acid is known for its toxicity and corrosive properties. When released into the environment, it can contaminate soil and water sources, posing risks to aquatic life and terrestrial organisms. The compound's persistence in the environment is a concern, as it does not readily biodegrade, leading to potential long-term ecological effects.

In aquatic environments, carbolic acid can disrupt the balance of ecosystems by affecting the growth and reproduction of various species. Fish and other aquatic organisms may experience acute or chronic toxicity, depending on exposure levels. This can lead to population declines and alterations in food web dynamics.

Atmospheric emissions during polyurethane foam production can contribute to air pollution. Carbolic acid vapors can react with other pollutants, potentially forming secondary air contaminants. These emissions may contribute to the formation of photochemical smog and have adverse effects on air quality in surrounding areas.

The production process itself presents occupational health risks for workers in polyurethane manufacturing facilities. Exposure to carbolic acid can cause severe skin burns, respiratory irritation, and other health issues. Proper safety measures and protective equipment are crucial to mitigate these risks.

Waste management is another critical environmental concern. Improper disposal of carbolic acid-containing waste can lead to soil and groundwater contamination. This necessitates stringent protocols for handling, storage, and disposal of waste materials generated during the production process.

Efforts to reduce the environmental impact of carbolic acid in polyurethane foam production have led to the development of alternative catalysts and production methods. Green chemistry initiatives are exploring bio-based catalysts and environmentally friendly production processes to minimize the use of harmful substances like carbolic acid.

Regulatory bodies worldwide have implemented strict guidelines for the use and disposal of carbolic acid in industrial processes. These regulations aim to minimize environmental release and protect ecosystems and human health. Compliance with these standards is essential for sustainable polyurethane foam production.

As the industry moves towards more sustainable practices, there is a growing emphasis on life cycle assessments of polyurethane products. These assessments consider the environmental impact from raw material extraction through production, use, and disposal, providing a comprehensive view of the ecological footprint associated with carbolic acid use in polyurethane foam manufacturing.

Safety Regulations for Carbolic Acid Use in Industry

The use of carbolic acid (phenol) in polyurethane foam production necessitates stringent safety regulations to protect workers and the environment. Occupational Safety and Health Administration (OSHA) guidelines mandate comprehensive hazard communication programs, including proper labeling, safety data sheets, and employee training on the risks associated with carbolic acid exposure. Personal protective equipment (PPE) is crucial, with requirements for chemical-resistant gloves, goggles, face shields, and impervious clothing to prevent skin and eye contact.

Ventilation systems are essential in industrial settings using carbolic acid. Local exhaust ventilation must be installed to capture and remove vapors at the source, while general ventilation should maintain air quality throughout the facility. Regular air monitoring is required to ensure exposure levels remain below permissible limits set by regulatory agencies.

Emergency response protocols are a critical component of safety regulations. Facilities must have readily accessible eyewash stations and safety showers for immediate decontamination in case of accidental exposure. Spill containment and cleanup procedures should be well-documented and practiced regularly by trained personnel.

Storage and handling regulations for carbolic acid are equally important. The chemical must be stored in tightly sealed containers in cool, well-ventilated areas away from incompatible materials. Transfer and handling operations should be conducted in designated areas with proper containment measures to prevent spills and leaks.

Environmental protection regulations address the potential ecological impact of carbolic acid. Wastewater treatment systems must be in place to neutralize and remove phenol before discharge. Proper disposal of carbolic acid waste is regulated under the Resource Conservation and Recovery Act (RCRA), requiring specialized handling and documentation.

Transportation of carbolic acid is subject to Department of Transportation (DOT) regulations. Proper packaging, labeling, and documentation are essential for safe transport. Drivers must be trained in handling hazardous materials and equipped with appropriate emergency response information.

Regular safety audits and compliance inspections are mandated to ensure ongoing adherence to these regulations. Companies must maintain detailed records of training, incidents, and corrective actions. Continuous improvement of safety protocols is expected, with periodic reviews and updates to reflect new research findings and regulatory changes in the field of carbolic acid handling and polyurethane foam production.

Ventilation systems are essential in industrial settings using carbolic acid. Local exhaust ventilation must be installed to capture and remove vapors at the source, while general ventilation should maintain air quality throughout the facility. Regular air monitoring is required to ensure exposure levels remain below permissible limits set by regulatory agencies.

Emergency response protocols are a critical component of safety regulations. Facilities must have readily accessible eyewash stations and safety showers for immediate decontamination in case of accidental exposure. Spill containment and cleanup procedures should be well-documented and practiced regularly by trained personnel.

Storage and handling regulations for carbolic acid are equally important. The chemical must be stored in tightly sealed containers in cool, well-ventilated areas away from incompatible materials. Transfer and handling operations should be conducted in designated areas with proper containment measures to prevent spills and leaks.

Environmental protection regulations address the potential ecological impact of carbolic acid. Wastewater treatment systems must be in place to neutralize and remove phenol before discharge. Proper disposal of carbolic acid waste is regulated under the Resource Conservation and Recovery Act (RCRA), requiring specialized handling and documentation.

Transportation of carbolic acid is subject to Department of Transportation (DOT) regulations. Proper packaging, labeling, and documentation are essential for safe transport. Drivers must be trained in handling hazardous materials and equipped with appropriate emergency response information.

Regular safety audits and compliance inspections are mandated to ensure ongoing adherence to these regulations. Companies must maintain detailed records of training, incidents, and corrective actions. Continuous improvement of safety protocols is expected, with periodic reviews and updates to reflect new research findings and regulatory changes in the field of carbolic acid handling and polyurethane foam production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!