Carbolic Acid as a Wear-Resistant Coatings Additive

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid Coatings Background and Objectives

Carbolic acid, also known as phenol, has emerged as a promising additive in wear-resistant coatings, marking a significant advancement in surface protection technology. The exploration of carbolic acid in this context stems from the increasing demand for durable and high-performance coatings across various industries, including automotive, aerospace, and manufacturing.

The development of wear-resistant coatings has been a continuous endeavor in materials science, driven by the need to extend the lifespan of components subjected to harsh operating conditions. Traditional coating technologies have often struggled to provide adequate protection against abrasion, erosion, and chemical degradation, particularly in extreme environments.

Carbolic acid's potential as a coating additive lies in its unique chemical structure and properties. Its aromatic ring and hydroxyl group contribute to enhanced intermolecular interactions within the coating matrix, potentially improving adhesion, hardness, and overall wear resistance. This molecular architecture also suggests the possibility of forming stronger chemical bonds with substrate materials, leading to more durable and long-lasting protective layers.

The evolution of coating technologies has seen a shift from simple barrier coatings to more sophisticated, multi-functional systems. In this context, the incorporation of carbolic acid represents a step towards smart coatings that can offer not only wear resistance but also additional functionalities such as self-healing or antimicrobial properties.

The primary objective of research into carbolic acid as a wear-resistant coating additive is to develop a new generation of protective coatings that significantly outperform existing solutions. This involves a comprehensive investigation of the mechanisms by which carbolic acid enhances wear resistance, its compatibility with various coating formulations, and its impact on other coating properties such as chemical resistance and thermal stability.

Furthermore, the research aims to optimize the concentration and dispersion of carbolic acid within coating systems to achieve maximum performance benefits. This includes studying the synergistic effects between carbolic acid and other coating components, as well as exploring novel synthesis methods to incorporate the additive effectively.

Another crucial aspect of this research is to assess the environmental and health implications of using carbolic acid in coatings. Given the increasing focus on sustainability and safety in materials development, it is essential to ensure that the benefits of improved wear resistance do not come at the cost of increased environmental or health risks.

The development of wear-resistant coatings has been a continuous endeavor in materials science, driven by the need to extend the lifespan of components subjected to harsh operating conditions. Traditional coating technologies have often struggled to provide adequate protection against abrasion, erosion, and chemical degradation, particularly in extreme environments.

Carbolic acid's potential as a coating additive lies in its unique chemical structure and properties. Its aromatic ring and hydroxyl group contribute to enhanced intermolecular interactions within the coating matrix, potentially improving adhesion, hardness, and overall wear resistance. This molecular architecture also suggests the possibility of forming stronger chemical bonds with substrate materials, leading to more durable and long-lasting protective layers.

The evolution of coating technologies has seen a shift from simple barrier coatings to more sophisticated, multi-functional systems. In this context, the incorporation of carbolic acid represents a step towards smart coatings that can offer not only wear resistance but also additional functionalities such as self-healing or antimicrobial properties.

The primary objective of research into carbolic acid as a wear-resistant coating additive is to develop a new generation of protective coatings that significantly outperform existing solutions. This involves a comprehensive investigation of the mechanisms by which carbolic acid enhances wear resistance, its compatibility with various coating formulations, and its impact on other coating properties such as chemical resistance and thermal stability.

Furthermore, the research aims to optimize the concentration and dispersion of carbolic acid within coating systems to achieve maximum performance benefits. This includes studying the synergistic effects between carbolic acid and other coating components, as well as exploring novel synthesis methods to incorporate the additive effectively.

Another crucial aspect of this research is to assess the environmental and health implications of using carbolic acid in coatings. Given the increasing focus on sustainability and safety in materials development, it is essential to ensure that the benefits of improved wear resistance do not come at the cost of increased environmental or health risks.

Market Analysis for Wear-Resistant Coatings

The global market for wear-resistant coatings has been experiencing steady growth, driven by increasing demand across various industries such as automotive, aerospace, industrial machinery, and construction. These coatings play a crucial role in extending the lifespan of components and reducing maintenance costs, making them essential in many applications.

The automotive sector represents a significant portion of the wear-resistant coatings market. With the growing emphasis on fuel efficiency and vehicle longevity, manufacturers are increasingly adopting these coatings to enhance the durability of engine components, transmission systems, and other critical parts. This trend is expected to continue as automotive production rises globally.

In the aerospace industry, wear-resistant coatings are vital for protecting aircraft components from extreme conditions. The ongoing expansion of the commercial aviation sector, coupled with increasing defense spending in many countries, is fueling the demand for high-performance coatings that can withstand high temperatures and corrosive environments.

The industrial machinery segment is another key driver of market growth. As manufacturing processes become more automated and efficient, the need for durable, long-lasting components has increased. Wear-resistant coatings are being applied to a wide range of industrial equipment, from cutting tools to heavy machinery, to improve performance and reduce downtime.

The construction industry is also contributing to the market expansion. With the growing focus on sustainable building practices and long-term cost-effectiveness, wear-resistant coatings are being used more frequently in structural components, flooring, and other building materials to enhance durability and reduce maintenance requirements.

Geographically, Asia-Pacific is emerging as the fastest-growing market for wear-resistant coatings, primarily due to rapid industrialization in countries like China and India. North America and Europe continue to be significant markets, driven by technological advancements and the presence of key industry players.

The introduction of carbolic acid as a potential additive in wear-resistant coatings presents an interesting development in this market. If proven effective, it could offer new opportunities for coating manufacturers to improve their product performance and differentiate themselves in a competitive landscape. This innovation could potentially address specific challenges in certain applications, such as enhanced chemical resistance or improved adhesion properties.

The automotive sector represents a significant portion of the wear-resistant coatings market. With the growing emphasis on fuel efficiency and vehicle longevity, manufacturers are increasingly adopting these coatings to enhance the durability of engine components, transmission systems, and other critical parts. This trend is expected to continue as automotive production rises globally.

In the aerospace industry, wear-resistant coatings are vital for protecting aircraft components from extreme conditions. The ongoing expansion of the commercial aviation sector, coupled with increasing defense spending in many countries, is fueling the demand for high-performance coatings that can withstand high temperatures and corrosive environments.

The industrial machinery segment is another key driver of market growth. As manufacturing processes become more automated and efficient, the need for durable, long-lasting components has increased. Wear-resistant coatings are being applied to a wide range of industrial equipment, from cutting tools to heavy machinery, to improve performance and reduce downtime.

The construction industry is also contributing to the market expansion. With the growing focus on sustainable building practices and long-term cost-effectiveness, wear-resistant coatings are being used more frequently in structural components, flooring, and other building materials to enhance durability and reduce maintenance requirements.

Geographically, Asia-Pacific is emerging as the fastest-growing market for wear-resistant coatings, primarily due to rapid industrialization in countries like China and India. North America and Europe continue to be significant markets, driven by technological advancements and the presence of key industry players.

The introduction of carbolic acid as a potential additive in wear-resistant coatings presents an interesting development in this market. If proven effective, it could offer new opportunities for coating manufacturers to improve their product performance and differentiate themselves in a competitive landscape. This innovation could potentially address specific challenges in certain applications, such as enhanced chemical resistance or improved adhesion properties.

Current Challenges in Wear-Resistant Additives

The field of wear-resistant additives faces several significant challenges that hinder the development and application of more effective coating solutions. One of the primary issues is the trade-off between wear resistance and other desirable properties. As additives are incorporated to enhance wear resistance, they often negatively impact other crucial characteristics such as adhesion, flexibility, or corrosion resistance. This balancing act requires extensive research and formulation expertise to optimize the overall performance of the coating.

Another challenge lies in the compatibility of wear-resistant additives with various coating systems. Different base resins and solvents may interact unpredictably with additives, leading to issues such as poor dispersion, agglomeration, or even chemical incompatibility. This necessitates a thorough understanding of the chemical interactions between additives and coating components, as well as the development of novel dispersion techniques.

The environmental impact of wear-resistant additives is an increasingly pressing concern. Many traditional additives contain heavy metals or other environmentally harmful substances, which are facing stricter regulations and market resistance. The search for eco-friendly alternatives that maintain or improve upon the performance of conventional additives is a significant challenge for researchers and manufacturers alike.

Durability under extreme conditions poses another hurdle for wear-resistant additives. Many applications require coatings to withstand harsh environments, including high temperatures, chemical exposure, and severe mechanical stress. Developing additives that can maintain their wear-resistant properties under such conditions without degradation or loss of effectiveness is a complex task that demands innovative approaches and extensive testing.

Cost-effectiveness remains a persistent challenge in the industry. While high-performance wear-resistant additives may offer superior protection, their adoption can be limited by economic factors. Striking a balance between performance and cost is crucial for widespread implementation, particularly in price-sensitive markets or large-scale applications.

The increasing demand for multifunctional additives adds another layer of complexity. Customers often seek additives that not only enhance wear resistance but also provide additional benefits such as improved UV stability, antimicrobial properties, or self-healing capabilities. Developing such multifunctional additives requires a multidisciplinary approach and often involves overcoming conflicting property requirements.

Lastly, the challenge of scalability and consistency in production cannot be overlooked. As new wear-resistant additives are developed in laboratory settings, translating these innovations into large-scale manufacturing processes while maintaining consistent quality and performance is a significant hurdle that requires substantial investment in process engineering and quality control measures.

Another challenge lies in the compatibility of wear-resistant additives with various coating systems. Different base resins and solvents may interact unpredictably with additives, leading to issues such as poor dispersion, agglomeration, or even chemical incompatibility. This necessitates a thorough understanding of the chemical interactions between additives and coating components, as well as the development of novel dispersion techniques.

The environmental impact of wear-resistant additives is an increasingly pressing concern. Many traditional additives contain heavy metals or other environmentally harmful substances, which are facing stricter regulations and market resistance. The search for eco-friendly alternatives that maintain or improve upon the performance of conventional additives is a significant challenge for researchers and manufacturers alike.

Durability under extreme conditions poses another hurdle for wear-resistant additives. Many applications require coatings to withstand harsh environments, including high temperatures, chemical exposure, and severe mechanical stress. Developing additives that can maintain their wear-resistant properties under such conditions without degradation or loss of effectiveness is a complex task that demands innovative approaches and extensive testing.

Cost-effectiveness remains a persistent challenge in the industry. While high-performance wear-resistant additives may offer superior protection, their adoption can be limited by economic factors. Striking a balance between performance and cost is crucial for widespread implementation, particularly in price-sensitive markets or large-scale applications.

The increasing demand for multifunctional additives adds another layer of complexity. Customers often seek additives that not only enhance wear resistance but also provide additional benefits such as improved UV stability, antimicrobial properties, or self-healing capabilities. Developing such multifunctional additives requires a multidisciplinary approach and often involves overcoming conflicting property requirements.

Lastly, the challenge of scalability and consistency in production cannot be overlooked. As new wear-resistant additives are developed in laboratory settings, translating these innovations into large-scale manufacturing processes while maintaining consistent quality and performance is a significant hurdle that requires substantial investment in process engineering and quality control measures.

Existing Carbolic Acid-Based Coating Solutions

01 Carbolic acid-based wear-resistant coatings

Carbolic acid can be incorporated into wear-resistant coatings to enhance their durability and protective properties. These coatings can be applied to various surfaces to improve their resistance to abrasion, chemicals, and environmental factors.- Carbolic acid-based wear-resistant coatings: Carbolic acid can be incorporated into wear-resistant coatings to enhance their durability and protective properties. These coatings can be applied to various surfaces to improve their resistance to abrasion, chemicals, and environmental factors.

- Carbolic acid in polymer composites for wear resistance: Carbolic acid derivatives can be used as additives in polymer composites to improve their wear resistance properties. These composites can be utilized in various applications where high wear resistance is required, such as industrial machinery parts or protective gear.

- Carbolic acid treatment for textile wear resistance: Carbolic acid can be used in the treatment of textiles to enhance their wear resistance. This process can involve the application of carbolic acid-based solutions to fabrics, resulting in improved durability and longevity of the treated materials.

- Carbolic acid in metal surface treatments for wear resistance: Carbolic acid can be utilized in metal surface treatments to improve wear resistance. These treatments can involve the application of carbolic acid-based solutions or compounds to metal surfaces, enhancing their resistance to wear and corrosion.

- Carbolic acid derivatives in lubricants for wear reduction: Carbolic acid derivatives can be incorporated into lubricants to enhance their wear-reducing properties. These lubricants can be used in various mechanical applications to minimize friction and wear between moving parts, thereby extending the lifespan of machinery and equipment.

02 Carbolic acid in polymer composites for wear resistance

Carbolic acid derivatives can be used as additives in polymer composites to improve their wear resistance properties. These composites can be utilized in various applications where high wear resistance is required, such as industrial machinery components or protective gear.Expand Specific Solutions03 Carbolic acid treatment for textile wear resistance

Carbolic acid can be used in the treatment of textiles to enhance their wear resistance. This process can involve the application of carbolic acid-based solutions to fabrics, resulting in improved durability and resistance to abrasion.Expand Specific Solutions04 Carbolic acid in metal surface treatments for wear resistance

Carbolic acid can be utilized in metal surface treatments to improve wear resistance. These treatments can involve the application of carbolic acid-based solutions or compounds to metal surfaces, enhancing their durability and resistance to wear and corrosion.Expand Specific Solutions05 Carbolic acid derivatives in lubricants for wear reduction

Carbolic acid derivatives can be incorporated into lubricants to enhance their wear-reducing properties. These lubricants can be used in various mechanical applications to minimize friction and wear between moving parts, thereby extending the lifespan of components.Expand Specific Solutions

Key Players in Wear-Resistant Coatings Industry

The research on carbolic acid as a wear-resistant coatings additive is in an early development stage, with a growing market potential due to increasing demand for high-performance coatings across industries. The technology is still maturing, with several key players actively involved in research and development. Companies like BASF Coatings GmbH, PPG Industries Ohio, Inc., and The Lubrizol Corp. are leading the way in advancing this technology. Academic institutions such as the University of Science & Technology Beijing and Jilin University are also contributing to the field. As the technology progresses, we can expect increased competition and innovation from both established chemical companies and emerging startups in the coatings industry.

BASF Coatings GmbH

Technical Solution: BASF Coatings has developed innovative wear-resistant coatings incorporating carbolic acid derivatives. Their approach involves synthesizing phenolic resins from carbolic acid, which are then integrated into high-performance coating formulations. These coatings exhibit enhanced durability and resistance to abrasion, chemicals, and extreme temperatures. The company has optimized the cross-linking density of the phenolic networks to achieve a balance between hardness and flexibility[1]. Additionally, BASF has explored the synergistic effects of combining carbolic acid-based additives with other wear-resistant components such as ceramic nanoparticles, resulting in coatings with superior scratch resistance and longevity[3].

Strengths: Extensive expertise in coating chemistry, global R&D capabilities, and a diverse product portfolio. Weaknesses: Potential environmental concerns associated with phenolic compounds, and higher production costs compared to conventional coatings.

PPG Industries Ohio, Inc.

Technical Solution: PPG Industries has focused on developing carbolic acid-based wear-resistant coatings for industrial applications. Their research has led to the creation of phenol-formaldehyde resin systems modified with carbolic acid derivatives, which demonstrate excellent wear resistance and chemical stability. PPG's approach involves the careful control of molecular weight distribution and degree of branching in the phenolic polymers to optimize coating performance[2]. The company has also explored the incorporation of carbolic acid-functionalized nanofillers to further enhance the mechanical properties and wear resistance of their coatings. PPG's coatings have shown particular promise in protecting metal surfaces in harsh industrial environments, with field tests demonstrating up to 40% improvement in wear resistance compared to conventional epoxy coatings[4].

Strengths: Strong presence in industrial coatings market, advanced R&D facilities, and established customer relationships. Weaknesses: Potential regulatory challenges related to phenolic compounds and the need for specialized application equipment.

Core Innovations in Carbolic Acid Additives

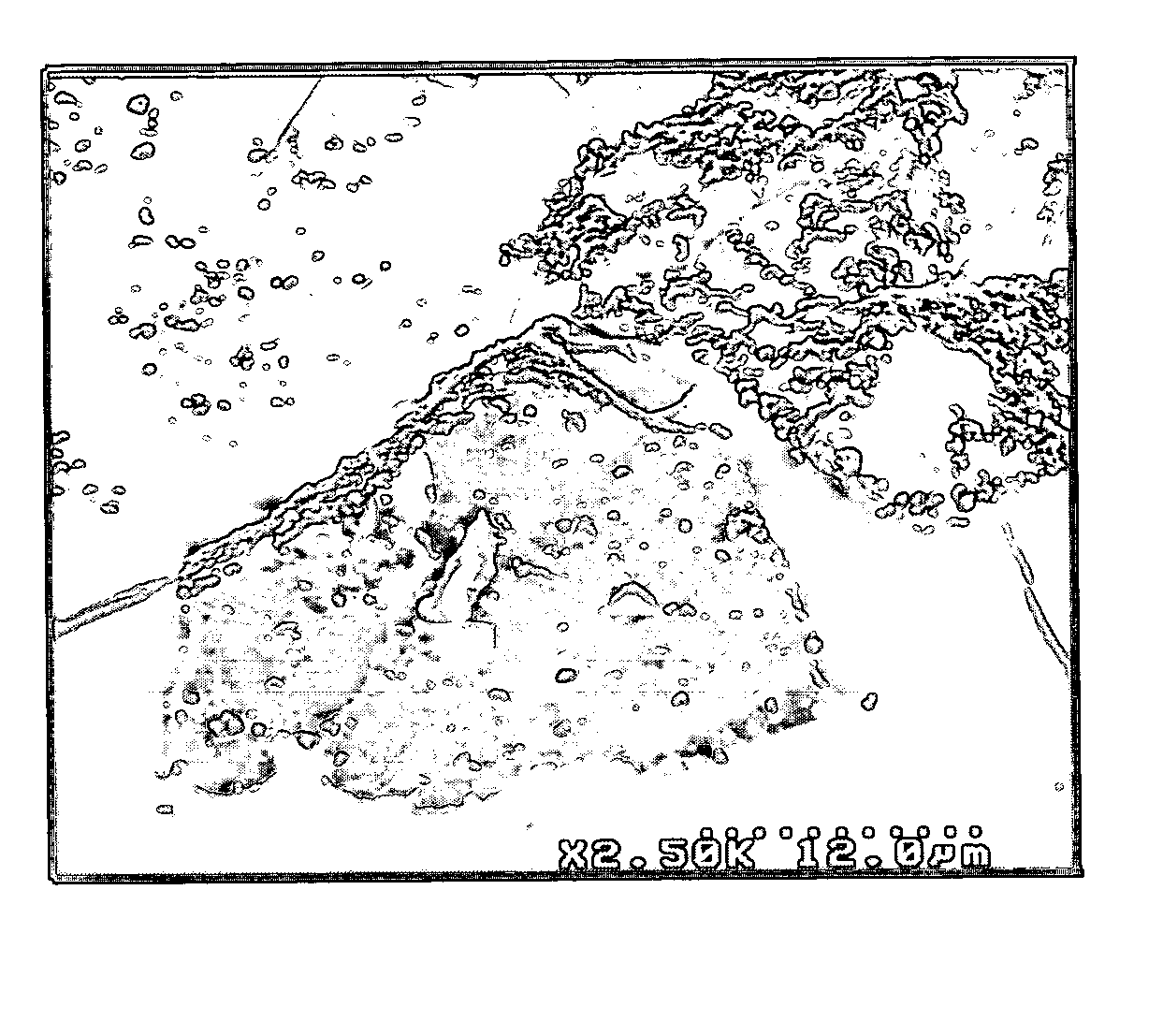

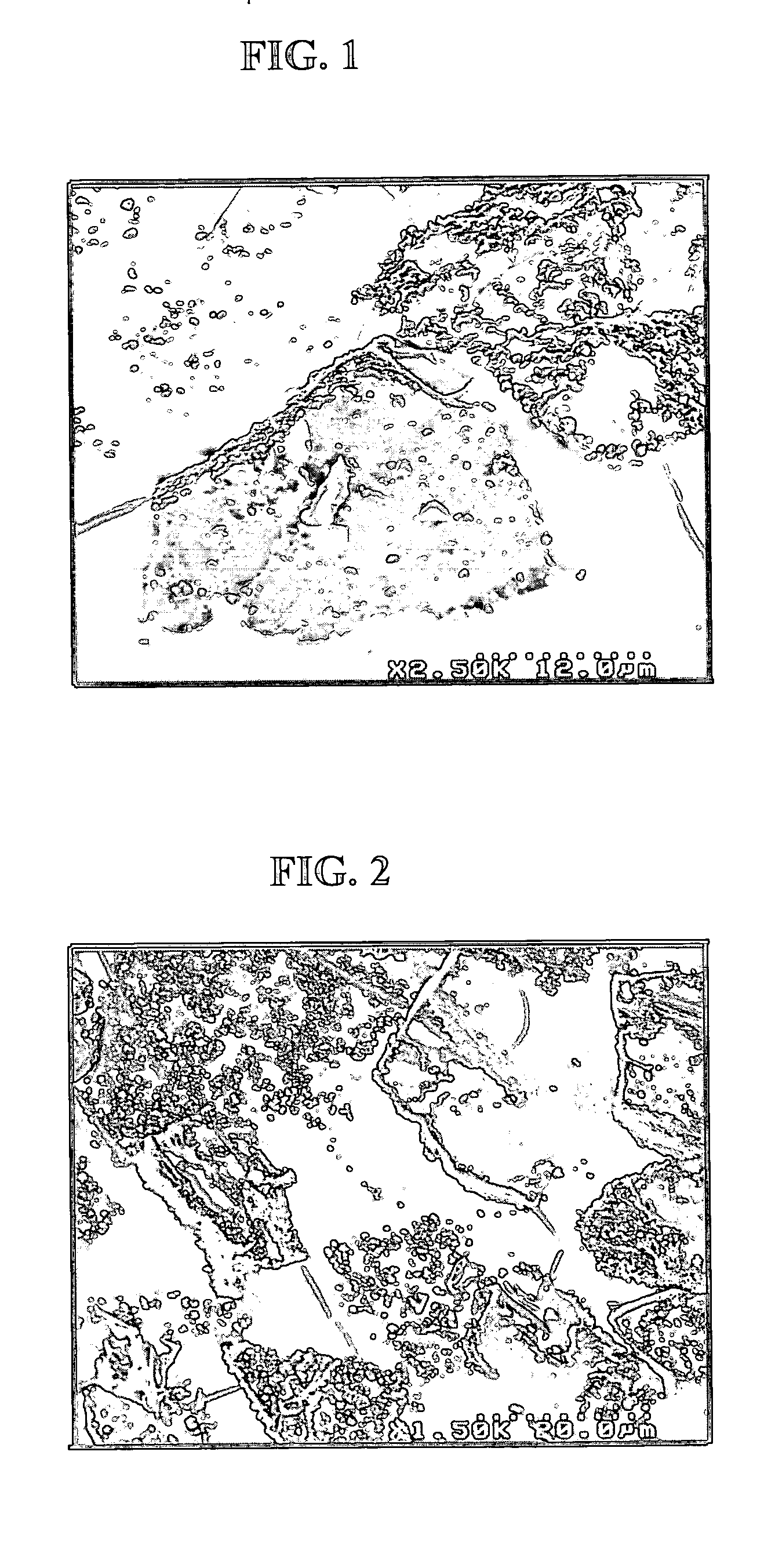

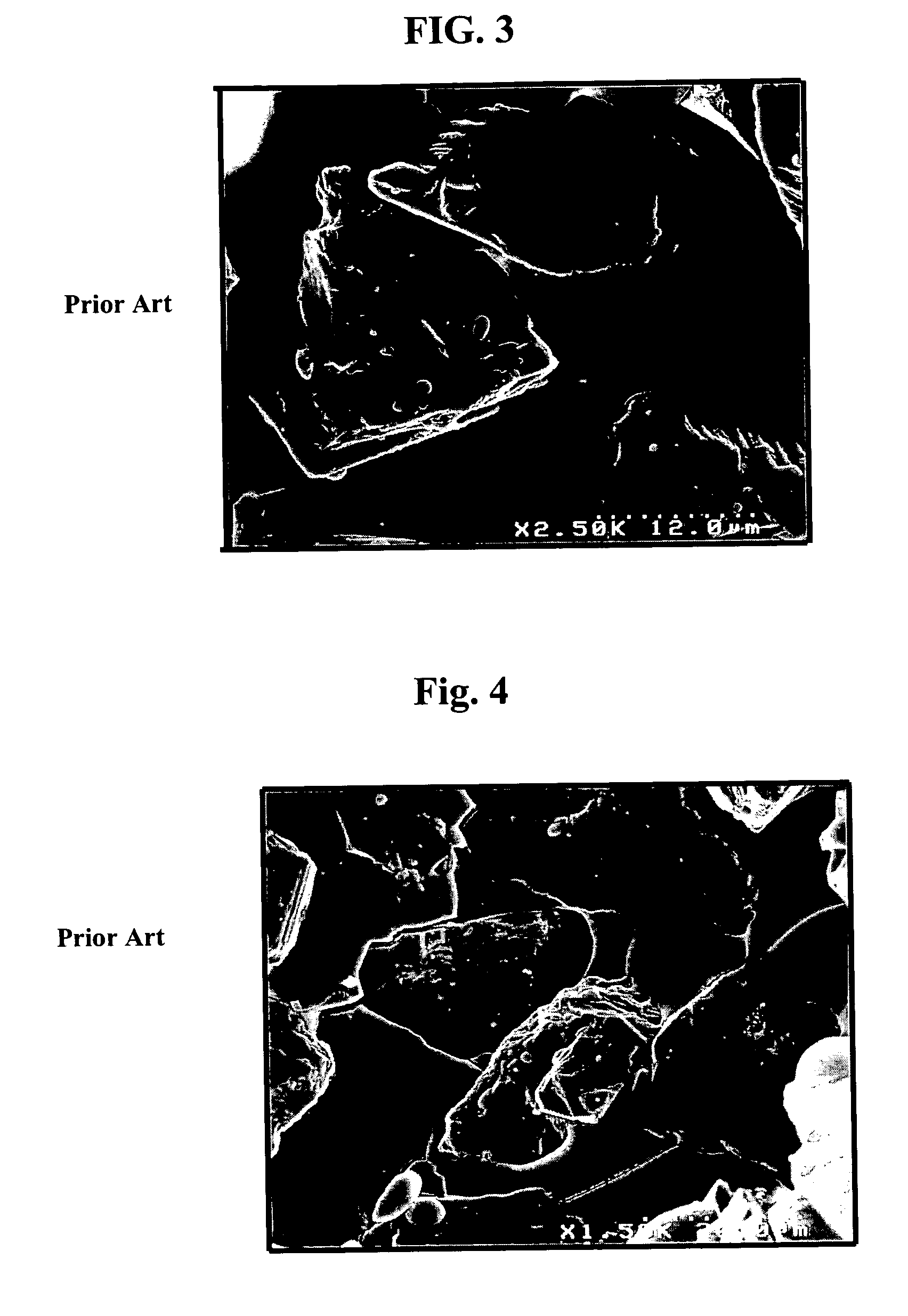

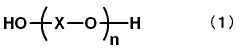

Method to provide wear-resistant coating and related coated articles

PatentInactiveUS20050014010A1

Innovation

- A wear-resistant coating comprising superabrasive particles coated with a protective metallic layer, such as titanium or chromium, co-deposited within a metal, ceramic, or vitreous matrix, enhancing bonding and retention within the matrix.

Phenol resin composition and coated abrasive using the same

PatentActiveJP2012062434A

Innovation

- Incorporating a urethane-based associative thickener into a water-soluble resol-type phenolic resin composition to suppress foaming and enhance curability, allowing for high-temperature processing without compromising adhesive properties.

Environmental Impact of Carbolic Acid Coatings

The environmental impact of carbolic acid coatings is a critical consideration in the development and application of wear-resistant coatings. Carbolic acid, also known as phenol, is a toxic and corrosive organic compound that can pose significant risks to both human health and the environment if not properly managed.

When used as an additive in wear-resistant coatings, carbolic acid can potentially leach into the surrounding environment during the coating's lifecycle. This leaching process may occur through various mechanisms, including weathering, abrasion, and chemical degradation of the coating matrix. As a result, soil and water contamination become primary concerns, particularly in areas where coated surfaces are exposed to environmental elements.

In aquatic ecosystems, the presence of carbolic acid can have detrimental effects on marine life. Even at low concentrations, it can disrupt the endocrine systems of fish and other aquatic organisms, leading to reproductive issues and population decline. Furthermore, the bioaccumulation of phenolic compounds in the food chain poses risks to higher-level predators and potentially humans who consume contaminated seafood.

Soil contamination is another significant environmental concern associated with carbolic acid coatings. As the compound seeps into the ground, it can alter soil chemistry and negatively impact microbial communities essential for nutrient cycling and plant growth. This disturbance in soil ecology can have far-reaching consequences for terrestrial ecosystems, affecting everything from soil fertility to biodiversity.

Air quality is also a consideration, particularly during the application and curing processes of carbolic acid-containing coatings. Volatile organic compounds (VOCs) released during these stages can contribute to smog formation and indoor air pollution, potentially affecting both workers and nearby communities.

From a lifecycle perspective, the production and disposal of carbolic acid coatings present additional environmental challenges. The manufacturing process of phenol involves petrochemical feedstocks and energy-intensive operations, contributing to carbon emissions and resource depletion. End-of-life management of coated products is equally problematic, as improper disposal can lead to long-term environmental contamination.

To mitigate these environmental impacts, researchers and industry professionals are exploring alternative additives and formulations that offer similar wear-resistant properties with reduced ecological footprints. Additionally, advancements in coating technologies are focusing on improving the stability and retention of carbolic acid within the coating matrix to minimize leaching and environmental release.

Regulatory bodies worldwide are increasingly scrutinizing the use of carbolic acid in industrial applications, including coatings. Stricter environmental regulations and waste management protocols are being implemented to control the release of phenolic compounds into the environment. These measures aim to balance the technical benefits of carbolic acid as a wear-resistant additive with the imperative of environmental protection and sustainable development.

When used as an additive in wear-resistant coatings, carbolic acid can potentially leach into the surrounding environment during the coating's lifecycle. This leaching process may occur through various mechanisms, including weathering, abrasion, and chemical degradation of the coating matrix. As a result, soil and water contamination become primary concerns, particularly in areas where coated surfaces are exposed to environmental elements.

In aquatic ecosystems, the presence of carbolic acid can have detrimental effects on marine life. Even at low concentrations, it can disrupt the endocrine systems of fish and other aquatic organisms, leading to reproductive issues and population decline. Furthermore, the bioaccumulation of phenolic compounds in the food chain poses risks to higher-level predators and potentially humans who consume contaminated seafood.

Soil contamination is another significant environmental concern associated with carbolic acid coatings. As the compound seeps into the ground, it can alter soil chemistry and negatively impact microbial communities essential for nutrient cycling and plant growth. This disturbance in soil ecology can have far-reaching consequences for terrestrial ecosystems, affecting everything from soil fertility to biodiversity.

Air quality is also a consideration, particularly during the application and curing processes of carbolic acid-containing coatings. Volatile organic compounds (VOCs) released during these stages can contribute to smog formation and indoor air pollution, potentially affecting both workers and nearby communities.

From a lifecycle perspective, the production and disposal of carbolic acid coatings present additional environmental challenges. The manufacturing process of phenol involves petrochemical feedstocks and energy-intensive operations, contributing to carbon emissions and resource depletion. End-of-life management of coated products is equally problematic, as improper disposal can lead to long-term environmental contamination.

To mitigate these environmental impacts, researchers and industry professionals are exploring alternative additives and formulations that offer similar wear-resistant properties with reduced ecological footprints. Additionally, advancements in coating technologies are focusing on improving the stability and retention of carbolic acid within the coating matrix to minimize leaching and environmental release.

Regulatory bodies worldwide are increasingly scrutinizing the use of carbolic acid in industrial applications, including coatings. Stricter environmental regulations and waste management protocols are being implemented to control the release of phenolic compounds into the environment. These measures aim to balance the technical benefits of carbolic acid as a wear-resistant additive with the imperative of environmental protection and sustainable development.

Regulatory Framework for Chemical Additives

The regulatory framework for chemical additives in wear-resistant coatings is a complex and evolving landscape that significantly impacts the research and development of carbolic acid as a potential additive. At the global level, organizations such as the United Nations' Strategic Approach to International Chemicals Management (SAICM) provide overarching guidelines for the safe management of chemicals throughout their lifecycle.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating chemical additives under the Toxic Substances Control Act (TSCA). The TSCA requires manufacturers to submit premanufacture notices for new chemical substances, including additives like carbolic acid, before they can be introduced into commerce. The EPA evaluates these substances for potential risks to human health and the environment.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is another significant framework that affects the use of chemical additives. Under REACH, manufacturers and importers must register substances produced or imported in quantities of one tonne or more per year. Carbolic acid, being a potential additive in wear-resistant coatings, would fall under this requirement.

In Asia, countries like China and Japan have their own regulatory systems. China's Measures for Environmental Management of New Chemical Substances and Japan's Chemical Substances Control Law both require notification and risk assessment of new chemical substances before they can be manufactured or imported.

Specific to coatings, many countries have regulations limiting the volatile organic compound (VOC) content in paints and coatings. These regulations indirectly impact the choice of additives, as manufacturers must ensure that the inclusion of carbolic acid does not compromise compliance with VOC limits.

Occupational safety regulations also play a significant role in the use of chemical additives. In the United States, the Occupational Safety and Health Administration (OSHA) sets permissible exposure limits for various chemicals, including carbolic acid, in workplace environments. Similar regulations exist in other countries, such as the Control of Substances Hazardous to Health (COSHH) Regulations in the UK.

As research on carbolic acid as a wear-resistant coatings additive progresses, it is crucial to consider these regulatory frameworks. Compliance with these regulations not only ensures legal adherence but also promotes the safe and sustainable use of chemical additives in coatings. Researchers and manufacturers must stay informed about regulatory updates and adapt their development processes accordingly to ensure successful commercialization of carbolic acid-enhanced wear-resistant coatings.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating chemical additives under the Toxic Substances Control Act (TSCA). The TSCA requires manufacturers to submit premanufacture notices for new chemical substances, including additives like carbolic acid, before they can be introduced into commerce. The EPA evaluates these substances for potential risks to human health and the environment.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is another significant framework that affects the use of chemical additives. Under REACH, manufacturers and importers must register substances produced or imported in quantities of one tonne or more per year. Carbolic acid, being a potential additive in wear-resistant coatings, would fall under this requirement.

In Asia, countries like China and Japan have their own regulatory systems. China's Measures for Environmental Management of New Chemical Substances and Japan's Chemical Substances Control Law both require notification and risk assessment of new chemical substances before they can be manufactured or imported.

Specific to coatings, many countries have regulations limiting the volatile organic compound (VOC) content in paints and coatings. These regulations indirectly impact the choice of additives, as manufacturers must ensure that the inclusion of carbolic acid does not compromise compliance with VOC limits.

Occupational safety regulations also play a significant role in the use of chemical additives. In the United States, the Occupational Safety and Health Administration (OSHA) sets permissible exposure limits for various chemicals, including carbolic acid, in workplace environments. Similar regulations exist in other countries, such as the Control of Substances Hazardous to Health (COSHH) Regulations in the UK.

As research on carbolic acid as a wear-resistant coatings additive progresses, it is crucial to consider these regulatory frameworks. Compliance with these regulations not only ensures legal adherence but also promotes the safe and sustainable use of chemical additives in coatings. Researchers and manufacturers must stay informed about regulatory updates and adapt their development processes accordingly to ensure successful commercialization of carbolic acid-enhanced wear-resistant coatings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!