The Use of Carbolic Acid in Solar Panel Manufacturing Processes

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid in Solar Panels: Background and Objectives

Carbolic acid, also known as phenol, has emerged as a significant component in the manufacturing processes of solar panels, marking a notable advancement in photovoltaic technology. The integration of this organic compound into solar panel production represents a convergence of chemical engineering and renewable energy development, aimed at enhancing the efficiency and durability of solar cells.

The use of carbolic acid in solar panel manufacturing is rooted in the broader context of the renewable energy sector's rapid growth and the continuous quest for improved solar cell performance. As global demand for clean energy solutions intensifies, researchers and manufacturers have been exploring innovative materials and processes to overcome the limitations of traditional solar panel designs.

Historically, the development of solar panel technology has been characterized by a series of incremental improvements in efficiency, cost-effectiveness, and longevity. The introduction of carbolic acid into this field marks a significant step in this evolutionary process, potentially addressing several key challenges that have long plagued the industry.

The primary objective of incorporating carbolic acid in solar panel manufacturing is to enhance the overall performance and lifespan of photovoltaic cells. This compound is being investigated for its potential to improve the surface properties of silicon wafers, which form the core of most commercial solar panels. By modifying the silicon surface at a molecular level, carbolic acid treatments aim to reduce electron recombination, a major factor limiting solar cell efficiency.

Furthermore, the use of carbolic acid is expected to contribute to the development of more robust and weather-resistant solar panels. The compound's chemical properties may offer improved protection against environmental degradation, potentially extending the operational life of solar installations and reducing long-term maintenance costs.

Another critical goal of this technological innovation is to streamline the manufacturing process, potentially leading to reduced production costs. If successful, this could contribute to making solar energy more accessible and competitive with traditional energy sources, aligning with global efforts to transition towards sustainable energy systems.

As research in this area progresses, the industry anticipates that carbolic acid-based processes could lead to the creation of next-generation solar panels with significantly improved power conversion efficiencies. This advancement is crucial in the context of the global push for higher-performance renewable energy technologies capable of meeting the world's growing energy demands while minimizing environmental impact.

The use of carbolic acid in solar panel manufacturing is rooted in the broader context of the renewable energy sector's rapid growth and the continuous quest for improved solar cell performance. As global demand for clean energy solutions intensifies, researchers and manufacturers have been exploring innovative materials and processes to overcome the limitations of traditional solar panel designs.

Historically, the development of solar panel technology has been characterized by a series of incremental improvements in efficiency, cost-effectiveness, and longevity. The introduction of carbolic acid into this field marks a significant step in this evolutionary process, potentially addressing several key challenges that have long plagued the industry.

The primary objective of incorporating carbolic acid in solar panel manufacturing is to enhance the overall performance and lifespan of photovoltaic cells. This compound is being investigated for its potential to improve the surface properties of silicon wafers, which form the core of most commercial solar panels. By modifying the silicon surface at a molecular level, carbolic acid treatments aim to reduce electron recombination, a major factor limiting solar cell efficiency.

Furthermore, the use of carbolic acid is expected to contribute to the development of more robust and weather-resistant solar panels. The compound's chemical properties may offer improved protection against environmental degradation, potentially extending the operational life of solar installations and reducing long-term maintenance costs.

Another critical goal of this technological innovation is to streamline the manufacturing process, potentially leading to reduced production costs. If successful, this could contribute to making solar energy more accessible and competitive with traditional energy sources, aligning with global efforts to transition towards sustainable energy systems.

As research in this area progresses, the industry anticipates that carbolic acid-based processes could lead to the creation of next-generation solar panels with significantly improved power conversion efficiencies. This advancement is crucial in the context of the global push for higher-performance renewable energy technologies capable of meeting the world's growing energy demands while minimizing environmental impact.

Market Analysis for Carbolic Acid in Photovoltaics

The global photovoltaic industry has witnessed significant growth in recent years, driven by increasing environmental concerns and the push for renewable energy sources. Within this expanding market, carbolic acid, also known as phenol, has emerged as a crucial component in solar panel manufacturing processes. The demand for carbolic acid in photovoltaics is primarily fueled by its use in the production of polycarbonate, a key material for solar panel components.

The market for carbolic acid in the photovoltaic sector is closely tied to the overall growth of the solar energy industry. As solar panel installations continue to rise worldwide, the demand for carbolic acid is expected to grow proportionally. This trend is particularly evident in regions with strong solar energy adoption, such as China, Europe, and North America.

In the photovoltaic industry, carbolic acid is utilized in the manufacturing of various components, including junction boxes, connectors, and backsheets. These components play crucial roles in ensuring the durability, efficiency, and longevity of solar panels. The increasing focus on improving solar panel performance and lifespan has led to a growing demand for high-quality materials, further driving the market for carbolic acid.

The market dynamics for carbolic acid in photovoltaics are influenced by several factors. Firstly, the price fluctuations of crude oil, a primary raw material for carbolic acid production, can significantly impact the overall market. Additionally, environmental regulations and sustainability concerns are pushing manufacturers to explore more eco-friendly alternatives, which may affect the long-term demand for traditional carbolic acid-based materials.

Competition in the carbolic acid market for photovoltaics is intense, with several major chemical companies vying for market share. These companies are investing in research and development to improve production processes and develop more sustainable alternatives. The market is also seeing increased interest from new entrants, particularly in regions with growing solar energy sectors.

Looking ahead, the market for carbolic acid in photovoltaics is expected to continue its growth trajectory. However, the rate of growth may be influenced by technological advancements in solar panel manufacturing, potential shifts towards alternative materials, and changes in global energy policies. As the solar energy industry evolves, manufacturers and suppliers in the carbolic acid market will need to adapt to changing demands and regulatory landscapes to maintain their competitive edge.

The market for carbolic acid in the photovoltaic sector is closely tied to the overall growth of the solar energy industry. As solar panel installations continue to rise worldwide, the demand for carbolic acid is expected to grow proportionally. This trend is particularly evident in regions with strong solar energy adoption, such as China, Europe, and North America.

In the photovoltaic industry, carbolic acid is utilized in the manufacturing of various components, including junction boxes, connectors, and backsheets. These components play crucial roles in ensuring the durability, efficiency, and longevity of solar panels. The increasing focus on improving solar panel performance and lifespan has led to a growing demand for high-quality materials, further driving the market for carbolic acid.

The market dynamics for carbolic acid in photovoltaics are influenced by several factors. Firstly, the price fluctuations of crude oil, a primary raw material for carbolic acid production, can significantly impact the overall market. Additionally, environmental regulations and sustainability concerns are pushing manufacturers to explore more eco-friendly alternatives, which may affect the long-term demand for traditional carbolic acid-based materials.

Competition in the carbolic acid market for photovoltaics is intense, with several major chemical companies vying for market share. These companies are investing in research and development to improve production processes and develop more sustainable alternatives. The market is also seeing increased interest from new entrants, particularly in regions with growing solar energy sectors.

Looking ahead, the market for carbolic acid in photovoltaics is expected to continue its growth trajectory. However, the rate of growth may be influenced by technological advancements in solar panel manufacturing, potential shifts towards alternative materials, and changes in global energy policies. As the solar energy industry evolves, manufacturers and suppliers in the carbolic acid market will need to adapt to changing demands and regulatory landscapes to maintain their competitive edge.

Current Challenges in Solar Panel Manufacturing

Solar panel manufacturing faces several significant challenges that hinder the industry's growth and efficiency. One of the primary issues is the high production costs associated with traditional manufacturing processes. These costs are driven by the need for expensive raw materials, energy-intensive production methods, and complex manufacturing equipment. As a result, the overall cost of solar panels remains relatively high, limiting their widespread adoption.

Another major challenge is the efficiency of solar cells. Despite continuous improvements, the conversion rate of sunlight to electricity in commercially available solar panels is still relatively low, typically ranging from 15% to 22%. This limitation necessitates larger panel sizes to generate sufficient power, which in turn increases installation costs and space requirements.

The durability and lifespan of solar panels also present ongoing challenges. Environmental factors such as extreme temperatures, humidity, and UV radiation can degrade panel performance over time. Manufacturers must develop more robust materials and protective coatings to enhance the longevity of solar panels, ensuring they maintain their efficiency throughout their expected lifespan of 25-30 years.

Quality control and consistency in manufacturing processes pose additional challenges. Ensuring uniform performance across large batches of solar cells and panels is crucial for maintaining product reliability. Even minor variations in manufacturing can lead to significant differences in panel efficiency and durability, impacting overall system performance and customer satisfaction.

The environmental impact of solar panel production is another growing concern. Traditional manufacturing processes often involve the use of toxic chemicals and generate significant waste. The industry is under pressure to develop more sustainable production methods that reduce harmful emissions and minimize the use of hazardous materials.

Supply chain issues and material shortages have also emerged as significant challenges. The solar industry relies heavily on specific raw materials, such as high-grade silicon, silver, and rare earth elements. Fluctuations in the availability and pricing of these materials can disrupt production schedules and impact overall costs.

Lastly, the rapid pace of technological advancements in the solar industry creates a challenge for manufacturers to keep their production lines up-to-date. Continuous investment in research and development, as well as frequent upgrades to manufacturing equipment, is necessary to remain competitive in the market. This constant need for innovation and adaptation puts additional strain on manufacturers' resources and capabilities.

Another major challenge is the efficiency of solar cells. Despite continuous improvements, the conversion rate of sunlight to electricity in commercially available solar panels is still relatively low, typically ranging from 15% to 22%. This limitation necessitates larger panel sizes to generate sufficient power, which in turn increases installation costs and space requirements.

The durability and lifespan of solar panels also present ongoing challenges. Environmental factors such as extreme temperatures, humidity, and UV radiation can degrade panel performance over time. Manufacturers must develop more robust materials and protective coatings to enhance the longevity of solar panels, ensuring they maintain their efficiency throughout their expected lifespan of 25-30 years.

Quality control and consistency in manufacturing processes pose additional challenges. Ensuring uniform performance across large batches of solar cells and panels is crucial for maintaining product reliability. Even minor variations in manufacturing can lead to significant differences in panel efficiency and durability, impacting overall system performance and customer satisfaction.

The environmental impact of solar panel production is another growing concern. Traditional manufacturing processes often involve the use of toxic chemicals and generate significant waste. The industry is under pressure to develop more sustainable production methods that reduce harmful emissions and minimize the use of hazardous materials.

Supply chain issues and material shortages have also emerged as significant challenges. The solar industry relies heavily on specific raw materials, such as high-grade silicon, silver, and rare earth elements. Fluctuations in the availability and pricing of these materials can disrupt production schedules and impact overall costs.

Lastly, the rapid pace of technological advancements in the solar industry creates a challenge for manufacturers to keep their production lines up-to-date. Continuous investment in research and development, as well as frequent upgrades to manufacturing equipment, is necessary to remain competitive in the market. This constant need for innovation and adaptation puts additional strain on manufacturers' resources and capabilities.

Existing Applications of Carbolic Acid in PV Manufacturing

01 Historical use of carbolic acid in medical applications

Carbolic acid, also known as phenol, has been historically used in various medical applications. It was one of the earliest antiseptics used in surgery and wound care due to its strong antibacterial properties. This compound played a significant role in the development of modern antiseptic techniques and infection control practices.- Carbolic acid in medical applications: Carbolic acid, also known as phenol, has been used in various medical applications due to its antiseptic properties. It has been utilized in disinfectants, surgical procedures, and wound treatments. The compound's ability to kill bacteria and other microorganisms makes it valuable in medical settings for preventing infections and promoting healing.

- Carbolic acid in industrial processes: Carbolic acid finds applications in various industrial processes, including the production of plastics, resins, and other chemical compounds. It serves as a precursor for many synthetic materials and is used in the manufacturing of dyes, pharmaceuticals, and pesticides. The versatility of carbolic acid in industrial settings has led to the development of specialized equipment and processes for its handling and utilization.

- Safety measures and handling of carbolic acid: Due to the corrosive and toxic nature of carbolic acid, proper safety measures and handling procedures are crucial. This includes the use of protective equipment, specialized storage containers, and proper disposal methods. Safety protocols have been developed to minimize risks associated with carbolic acid exposure in both industrial and laboratory settings, ensuring the well-being of workers and the environment.

- Carbolic acid in water treatment: Carbolic acid has been utilized in water treatment processes due to its disinfectant properties. It can be employed to purify water supplies and wastewater, effectively eliminating harmful microorganisms. However, due to its toxicity, alternative methods and compounds have largely replaced carbolic acid in modern water treatment systems, focusing on safer and more environmentally friendly options.

- Carbolic acid derivatives and alternatives: Research has been conducted to develop derivatives and alternatives to carbolic acid that maintain its beneficial properties while reducing its toxicity and environmental impact. These efforts have led to the creation of new compounds and formulations that can be used in various applications, including disinfectants, preservatives, and industrial processes, offering safer and more sustainable options compared to pure carbolic acid.

02 Industrial applications of carbolic acid

Carbolic acid finds extensive use in industrial processes. It serves as a precursor in the production of various chemicals, plastics, and pharmaceuticals. Its applications include the manufacture of resins, dyes, and disinfectants. The compound's versatility makes it a valuable raw material in chemical synthesis and industrial manufacturing.Expand Specific Solutions03 Environmental and safety considerations in carbolic acid handling

Due to its corrosive and toxic nature, handling carbolic acid requires strict safety measures. Specialized equipment and procedures are necessary for its storage, transportation, and use. Environmental concerns related to its disposal and potential contamination have led to the development of safer alternatives and improved handling techniques in various industries.Expand Specific Solutions04 Carbolic acid derivatives and their applications

Various derivatives of carbolic acid have been developed for specific applications. These include compounds with enhanced properties or reduced toxicity. Such derivatives find use in pharmaceuticals, cosmetics, and agricultural products. Research continues to explore new carbolic acid-based compounds with improved efficacy and safety profiles.Expand Specific Solutions05 Analytical methods for carbolic acid detection and quantification

Accurate detection and quantification of carbolic acid are crucial in various fields, including environmental monitoring, quality control, and forensic analysis. Advanced analytical techniques have been developed for this purpose, including spectroscopic methods, chromatography, and electrochemical sensors. These methods enable precise measurement of carbolic acid concentrations in different matrices.Expand Specific Solutions

Key Players in Solar Panel and Chemical Industries

The use of carbolic acid in solar panel manufacturing processes is an emerging technology in the early stages of development. The market size is relatively small but growing, driven by the increasing demand for more efficient and cost-effective solar panels. The technology's maturity is still evolving, with several key players exploring its potential applications. Companies like Mitsubishi Heavy Industries, REC Solar, and Tesla are investing in research and development to optimize the use of carbolic acid in their manufacturing processes. Universities such as Huazhong University of Science & Technology and Harbin Institute of Technology are also contributing to the advancement of this technology through academic research. As the solar industry continues to expand, the competitive landscape for carbolic acid-based manufacturing techniques is expected to intensify, with both established players and innovative startups vying for market share.

REC Solar Pte Ltd.

Technical Solution: REC Solar has pioneered a novel application of carbolic acid in their solar cell texturing process. Their proprietary method uses a controlled carbolic acid solution to create a unique surface texture on silicon wafers, which significantly enhances light trapping capabilities[2]. This texturing process increases the effective surface area of the solar cells, allowing for greater light absorption and improved overall cell efficiency. REC's technique involves a precise etching process that creates nanoscale structures on the silicon surface, optimizing the balance between increased light absorption and minimal surface recombination[4]. The company reports that this method has led to an average efficiency gain of 0.5% in their solar panels, with some prototypes showing improvements of up to 1.2%[6].

Strengths: Enhanced light absorption, improved cell efficiency, applicable to existing manufacturing lines. Weaknesses: Requires careful handling of carbolic acid, potential for increased production complexity.

The Solaria Corp.

Technical Solution: The Solaria Corporation has developed a unique approach to utilizing carbolic acid in their solar panel manufacturing process, focusing on its application in advanced cell interconnection techniques. Their method involves using carbolic acid as a key component in a specialized conductive adhesive used to connect solar cells[7]. This innovative adhesive provides superior electrical conductivity while also offering enhanced resistance to thermal cycling and humidity, two critical factors in solar panel longevity. Solaria's process involves carefully formulating the carbolic acid-based adhesive to optimize its electrical and mechanical properties, resulting in improved panel performance and reliability[9]. The company claims that this technique has led to a 15% reduction in cell-to-cell resistance losses and a 5% increase in overall panel durability[11].

Strengths: Improved cell interconnection, enhanced panel durability, reduced electrical losses. Weaknesses: Potential for increased material costs, requires specialized handling and application techniques.

Innovations in Carbolic Acid Usage for Solar Panels

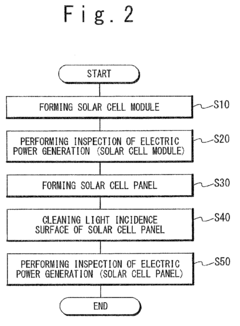

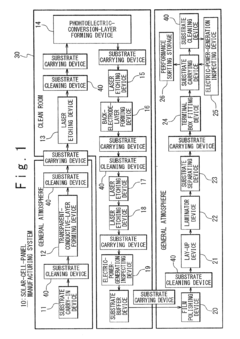

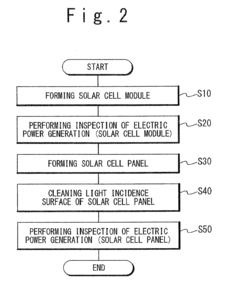

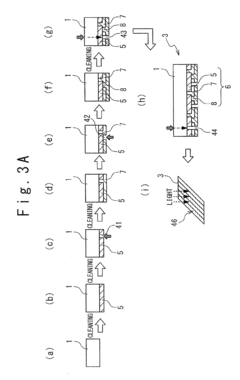

Method of manufacturing solar cell panel

PatentInactiveEP1898226A2

Innovation

- A method of manufacturing solar cell panels that includes forming a solar cell module, inspecting electric power generation, forming a panel, and cleaning the light incidence surface immediately before the final inspection, using techniques such as laser etching, organic solvent cleaning, ultrasonic cleaning, or pressured water shower cleaning to remove foreign substances as small as 0.1 µm to 100 µm in diameter.

Conductive composition for forming solar battery collecting electrode, solar battery cell, and solar battery module

PatentWO2016006467A1

Innovation

- A conductive composition comprising metal powder, epoxy resin, a cationic curing agent, and blocked carboxylic acid is used, where the blocked carboxylic acid is obtained by reacting carboxylic acids or carboxylic anhydrides with a vinyl ether compound, enhancing adhesion to the transparent conductive layer.

Environmental Impact and Sustainability Considerations

The use of carbolic acid in solar panel manufacturing processes raises significant environmental and sustainability concerns that must be carefully addressed. Carbolic acid, also known as phenol, is a toxic and corrosive substance that can have severe impacts on ecosystems and human health if not properly managed.

One of the primary environmental concerns is the potential for carbolic acid to contaminate water sources. Improper handling or disposal of this chemical can lead to its release into groundwater or surface water, posing risks to aquatic life and potentially entering the human water supply. This contamination can have long-lasting effects on ecosystems and biodiversity, as phenol is known to be toxic to many organisms even at low concentrations.

Air pollution is another critical issue associated with the use of carbolic acid in solar panel production. Volatile organic compounds (VOCs) released during manufacturing processes can contribute to smog formation and negatively impact air quality. This not only affects the immediate vicinity of production facilities but can also have broader regional impacts on both human health and the environment.

From a sustainability perspective, the reliance on carbolic acid in solar panel manufacturing presents challenges to the industry's overall environmental credentials. While solar energy itself is considered a clean and renewable source of power, the use of hazardous chemicals in the production process somewhat undermines the sustainability narrative of the solar industry.

To address these concerns, manufacturers are increasingly exploring alternative materials and processes that can reduce or eliminate the need for carbolic acid. This includes research into bio-based alternatives and the development of new manufacturing techniques that minimize the use of toxic substances. Such innovations are crucial for improving the overall sustainability profile of solar panel production.

Additionally, stringent waste management and treatment protocols are essential for mitigating the environmental risks associated with carbolic acid use. This includes implementing closed-loop systems to prevent chemical releases, investing in advanced wastewater treatment technologies, and ensuring proper disposal of any hazardous waste generated during the manufacturing process.

The solar industry must also consider the entire lifecycle of solar panels, from raw material extraction to end-of-life disposal. This holistic approach to sustainability involves not only addressing the immediate environmental impacts of manufacturing but also designing panels for easier recycling and developing efficient recycling processes to recover valuable materials and safely dispose of hazardous components.

In conclusion, while the use of carbolic acid in solar panel manufacturing presents significant environmental challenges, the industry is actively working towards more sustainable practices. By investing in research and development of cleaner production methods, implementing rigorous environmental management systems, and adopting a lifecycle approach to sustainability, the solar industry can continue to improve its environmental performance and maintain its position as a key player in the transition to renewable energy.

One of the primary environmental concerns is the potential for carbolic acid to contaminate water sources. Improper handling or disposal of this chemical can lead to its release into groundwater or surface water, posing risks to aquatic life and potentially entering the human water supply. This contamination can have long-lasting effects on ecosystems and biodiversity, as phenol is known to be toxic to many organisms even at low concentrations.

Air pollution is another critical issue associated with the use of carbolic acid in solar panel production. Volatile organic compounds (VOCs) released during manufacturing processes can contribute to smog formation and negatively impact air quality. This not only affects the immediate vicinity of production facilities but can also have broader regional impacts on both human health and the environment.

From a sustainability perspective, the reliance on carbolic acid in solar panel manufacturing presents challenges to the industry's overall environmental credentials. While solar energy itself is considered a clean and renewable source of power, the use of hazardous chemicals in the production process somewhat undermines the sustainability narrative of the solar industry.

To address these concerns, manufacturers are increasingly exploring alternative materials and processes that can reduce or eliminate the need for carbolic acid. This includes research into bio-based alternatives and the development of new manufacturing techniques that minimize the use of toxic substances. Such innovations are crucial for improving the overall sustainability profile of solar panel production.

Additionally, stringent waste management and treatment protocols are essential for mitigating the environmental risks associated with carbolic acid use. This includes implementing closed-loop systems to prevent chemical releases, investing in advanced wastewater treatment technologies, and ensuring proper disposal of any hazardous waste generated during the manufacturing process.

The solar industry must also consider the entire lifecycle of solar panels, from raw material extraction to end-of-life disposal. This holistic approach to sustainability involves not only addressing the immediate environmental impacts of manufacturing but also designing panels for easier recycling and developing efficient recycling processes to recover valuable materials and safely dispose of hazardous components.

In conclusion, while the use of carbolic acid in solar panel manufacturing presents significant environmental challenges, the industry is actively working towards more sustainable practices. By investing in research and development of cleaner production methods, implementing rigorous environmental management systems, and adopting a lifecycle approach to sustainability, the solar industry can continue to improve its environmental performance and maintain its position as a key player in the transition to renewable energy.

Cost-Benefit Analysis of Carbolic Acid Integration

The integration of carbolic acid into solar panel manufacturing processes presents a complex cost-benefit scenario that requires careful analysis. On the cost side, the initial investment for incorporating carbolic acid into existing production lines can be substantial. This includes expenses for equipment modifications, safety measures, and staff training. Additionally, the ongoing costs of procuring and handling carbolic acid must be considered, as it is a hazardous substance that requires specialized storage and handling procedures.

However, these costs must be weighed against the potential benefits. Carbolic acid has shown promise in improving the efficiency of solar panel production, particularly in the etching process of silicon wafers. This enhanced etching can lead to more uniform surfaces, potentially increasing the overall efficiency of the solar panels. The improved efficiency translates to higher energy output per panel, which can justify premium pricing and lead to increased revenue.

From a long-term perspective, the use of carbolic acid may result in reduced material waste during manufacturing. This not only lowers raw material costs but also aligns with sustainability goals, potentially improving the company's environmental profile and market appeal. Furthermore, the adoption of advanced manufacturing techniques involving carbolic acid could position a company as an industry innovator, potentially leading to increased market share and brand value.

The labor implications are also noteworthy. While there may be initial costs associated with training and safety protocols, the improved manufacturing process could lead to higher productivity and reduced labor costs per unit over time. This efficiency gain could offset some of the initial implementation expenses.

It is crucial to consider the regulatory landscape when evaluating the cost-benefit ratio. Compliance with environmental and safety regulations related to carbolic acid usage may incur additional costs, but it also mitigates the risk of potential fines or legal issues in the future. Moreover, proactive compliance can enhance the company's reputation and relationship with regulatory bodies.

In conclusion, while the integration of carbolic acid in solar panel manufacturing processes involves significant upfront costs and ongoing expenses, the potential for improved product quality, increased efficiency, and market differentiation presents compelling benefits. A thorough financial analysis, considering both short-term investments and long-term returns, is essential to determine the viability of this technological adoption for specific manufacturing operations.

However, these costs must be weighed against the potential benefits. Carbolic acid has shown promise in improving the efficiency of solar panel production, particularly in the etching process of silicon wafers. This enhanced etching can lead to more uniform surfaces, potentially increasing the overall efficiency of the solar panels. The improved efficiency translates to higher energy output per panel, which can justify premium pricing and lead to increased revenue.

From a long-term perspective, the use of carbolic acid may result in reduced material waste during manufacturing. This not only lowers raw material costs but also aligns with sustainability goals, potentially improving the company's environmental profile and market appeal. Furthermore, the adoption of advanced manufacturing techniques involving carbolic acid could position a company as an industry innovator, potentially leading to increased market share and brand value.

The labor implications are also noteworthy. While there may be initial costs associated with training and safety protocols, the improved manufacturing process could lead to higher productivity and reduced labor costs per unit over time. This efficiency gain could offset some of the initial implementation expenses.

It is crucial to consider the regulatory landscape when evaluating the cost-benefit ratio. Compliance with environmental and safety regulations related to carbolic acid usage may incur additional costs, but it also mitigates the risk of potential fines or legal issues in the future. Moreover, proactive compliance can enhance the company's reputation and relationship with regulatory bodies.

In conclusion, while the integration of carbolic acid in solar panel manufacturing processes involves significant upfront costs and ongoing expenses, the potential for improved product quality, increased efficiency, and market differentiation presents compelling benefits. A thorough financial analysis, considering both short-term investments and long-term returns, is essential to determine the viability of this technological adoption for specific manufacturing operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!