How Carbolic Acid Enhances Electrically Conductive Paint Development

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid in Conductive Paint: Background

Carbolic acid, also known as phenol, has emerged as a significant component in the development of electrically conductive paints. This organic compound, with its unique chemical properties, has opened new avenues for enhancing the conductivity and performance of these specialized coatings. The journey of carbolic acid in conductive paint technology began in the early 2000s when researchers started exploring alternative additives to improve the electrical properties of paint formulations.

The primary motivation behind incorporating carbolic acid into conductive paint stems from the growing demand for efficient and cost-effective conductive coatings across various industries. Traditional conductive paints often relied heavily on metallic particles, which posed challenges in terms of cost, weight, and processability. Carbolic acid, with its ability to form conductive polymers, presented a promising solution to these limitations.

Initially, the integration of carbolic acid into conductive paint formulations was met with skepticism due to concerns about its toxicity and potential environmental impact. However, advancements in chemical engineering and safety protocols have significantly mitigated these concerns, paving the way for its widespread adoption in the field.

The evolution of carbolic acid's role in conductive paint development has been marked by several key milestones. Early experiments focused on understanding the interaction between carbolic acid and other paint components, particularly binders and solvents. Researchers discovered that under specific conditions, carbolic acid could form conductive networks within the paint matrix, enhancing its overall electrical properties.

As the technology progressed, scientists began exploring various derivatives and modifications of carbolic acid to further optimize its performance in conductive paints. This led to the development of novel phenolic compounds tailored specifically for paint applications, offering improved conductivity, durability, and ease of application.

The integration of carbolic acid in conductive paint formulations has revolutionized several industries. In the automotive sector, these paints have found applications in electromagnetic shielding and anti-static coatings. The electronics industry has benefited from carbolic acid-enhanced paints for printed circuit boards and conductive adhesives. Additionally, the aerospace and defense sectors have shown increasing interest in these advanced coatings for their potential in radar-absorbing materials and lightning protection systems.

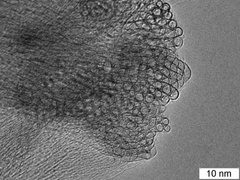

Recent years have seen a surge in research focusing on the synergistic effects of combining carbolic acid with other conductive materials, such as carbon nanotubes and graphene. These hybrid formulations promise to push the boundaries of conductive paint performance, offering unprecedented levels of conductivity and versatility.

The primary motivation behind incorporating carbolic acid into conductive paint stems from the growing demand for efficient and cost-effective conductive coatings across various industries. Traditional conductive paints often relied heavily on metallic particles, which posed challenges in terms of cost, weight, and processability. Carbolic acid, with its ability to form conductive polymers, presented a promising solution to these limitations.

Initially, the integration of carbolic acid into conductive paint formulations was met with skepticism due to concerns about its toxicity and potential environmental impact. However, advancements in chemical engineering and safety protocols have significantly mitigated these concerns, paving the way for its widespread adoption in the field.

The evolution of carbolic acid's role in conductive paint development has been marked by several key milestones. Early experiments focused on understanding the interaction between carbolic acid and other paint components, particularly binders and solvents. Researchers discovered that under specific conditions, carbolic acid could form conductive networks within the paint matrix, enhancing its overall electrical properties.

As the technology progressed, scientists began exploring various derivatives and modifications of carbolic acid to further optimize its performance in conductive paints. This led to the development of novel phenolic compounds tailored specifically for paint applications, offering improved conductivity, durability, and ease of application.

The integration of carbolic acid in conductive paint formulations has revolutionized several industries. In the automotive sector, these paints have found applications in electromagnetic shielding and anti-static coatings. The electronics industry has benefited from carbolic acid-enhanced paints for printed circuit boards and conductive adhesives. Additionally, the aerospace and defense sectors have shown increasing interest in these advanced coatings for their potential in radar-absorbing materials and lightning protection systems.

Recent years have seen a surge in research focusing on the synergistic effects of combining carbolic acid with other conductive materials, such as carbon nanotubes and graphene. These hybrid formulations promise to push the boundaries of conductive paint performance, offering unprecedented levels of conductivity and versatility.

Market Analysis for Conductive Coatings

The global market for electrically conductive coatings has been experiencing significant growth, driven by the increasing demand for electronic devices, automotive applications, and industrial equipment. This market segment is expected to continue its upward trajectory due to the rising need for electromagnetic interference (EMI) shielding and static discharge protection in various industries.

The incorporation of carbolic acid in conductive paint development represents a novel approach that could potentially address some of the existing challenges in the market. Carbolic acid, also known as phenol, has properties that may enhance the conductivity and adhesion of conductive coatings, potentially leading to improved performance and durability.

In the electronics sector, conductive coatings are extensively used for EMI shielding in smartphones, tablets, and other consumer electronics. The automotive industry is another major consumer, utilizing these coatings for anti-static applications and EMI protection in vehicle electronics. With the increasing electrification of vehicles and the advent of autonomous driving technologies, the demand for high-performance conductive coatings is expected to surge.

The aerospace and defense sectors also contribute significantly to the market demand, requiring conductive coatings for radar absorption, antenna systems, and protection against electromagnetic pulses. Additionally, the growing adoption of Internet of Things (IoT) devices across various industries is creating new opportunities for conductive coating applications.

Geographically, Asia-Pacific dominates the conductive coatings market, with China and Japan being the major contributors. This is primarily due to the region's strong presence in electronics manufacturing and automotive production. North America and Europe follow, driven by technological advancements and stringent regulations regarding EMI shielding and static discharge protection.

The market is characterized by intense competition among key players, including PPG Industries, Henkel, and Akzo Nobel. These companies are investing heavily in research and development to improve the performance of their conductive coatings and expand their product portfolios. The potential integration of carbolic acid in conductive paint formulations could provide a competitive edge to manufacturers who successfully implement this innovation.

However, challenges such as environmental regulations and the high cost of raw materials continue to impact the market. The development of eco-friendly conductive coatings and the exploration of cost-effective production methods are becoming increasingly important for market players to maintain their competitive positions and meet evolving customer demands.

The incorporation of carbolic acid in conductive paint development represents a novel approach that could potentially address some of the existing challenges in the market. Carbolic acid, also known as phenol, has properties that may enhance the conductivity and adhesion of conductive coatings, potentially leading to improved performance and durability.

In the electronics sector, conductive coatings are extensively used for EMI shielding in smartphones, tablets, and other consumer electronics. The automotive industry is another major consumer, utilizing these coatings for anti-static applications and EMI protection in vehicle electronics. With the increasing electrification of vehicles and the advent of autonomous driving technologies, the demand for high-performance conductive coatings is expected to surge.

The aerospace and defense sectors also contribute significantly to the market demand, requiring conductive coatings for radar absorption, antenna systems, and protection against electromagnetic pulses. Additionally, the growing adoption of Internet of Things (IoT) devices across various industries is creating new opportunities for conductive coating applications.

Geographically, Asia-Pacific dominates the conductive coatings market, with China and Japan being the major contributors. This is primarily due to the region's strong presence in electronics manufacturing and automotive production. North America and Europe follow, driven by technological advancements and stringent regulations regarding EMI shielding and static discharge protection.

The market is characterized by intense competition among key players, including PPG Industries, Henkel, and Akzo Nobel. These companies are investing heavily in research and development to improve the performance of their conductive coatings and expand their product portfolios. The potential integration of carbolic acid in conductive paint formulations could provide a competitive edge to manufacturers who successfully implement this innovation.

However, challenges such as environmental regulations and the high cost of raw materials continue to impact the market. The development of eco-friendly conductive coatings and the exploration of cost-effective production methods are becoming increasingly important for market players to maintain their competitive positions and meet evolving customer demands.

Technical Challenges in Conductive Paint Development

The development of electrically conductive paint faces several significant technical challenges that researchers and manufacturers must overcome to enhance its performance and applicability. One of the primary obstacles is achieving a balance between conductivity and adhesion. As the concentration of conductive particles increases to improve conductivity, the paint's adhesive properties often deteriorate, leading to poor durability and potential flaking or peeling.

Another major challenge lies in the uniform dispersion of conductive particles within the paint matrix. Achieving homogeneous distribution is crucial for consistent electrical conductivity across the painted surface. However, conductive particles tend to agglomerate due to their surface properties, resulting in uneven conductivity and potential "hot spots" or "dead zones" in the painted layer.

The stability of conductive paints over time presents another significant hurdle. Environmental factors such as temperature fluctuations, humidity, and UV exposure can degrade the paint's conductive properties, reducing its long-term effectiveness. Developing formulations that maintain conductivity under various environmental conditions remains a key focus area for researchers.

Compatibility with different substrate materials poses an additional challenge. Conductive paints must adhere well to a wide range of surfaces, including metals, plastics, and composites, while maintaining their electrical properties. This requires careful consideration of the paint's chemical composition and its interaction with various substrate materials.

The incorporation of carbolic acid into electrically conductive paint formulations introduces its own set of challenges. While carbolic acid can potentially enhance certain properties of the paint, such as its antimicrobial characteristics or its ability to form stronger bonds with certain substrates, it also raises concerns about toxicity and environmental impact. Researchers must carefully balance the benefits of carbolic acid with its potential drawbacks, ensuring that the final product meets safety and environmental regulations.

Furthermore, the scalability of production processes for conductive paints incorporating carbolic acid presents technical difficulties. Ensuring consistent quality and performance across large-scale manufacturing batches requires precise control over mixing, curing, and application processes. This becomes even more complex when dealing with the potentially corrosive nature of carbolic acid and its interactions with other paint components.

Another major challenge lies in the uniform dispersion of conductive particles within the paint matrix. Achieving homogeneous distribution is crucial for consistent electrical conductivity across the painted surface. However, conductive particles tend to agglomerate due to their surface properties, resulting in uneven conductivity and potential "hot spots" or "dead zones" in the painted layer.

The stability of conductive paints over time presents another significant hurdle. Environmental factors such as temperature fluctuations, humidity, and UV exposure can degrade the paint's conductive properties, reducing its long-term effectiveness. Developing formulations that maintain conductivity under various environmental conditions remains a key focus area for researchers.

Compatibility with different substrate materials poses an additional challenge. Conductive paints must adhere well to a wide range of surfaces, including metals, plastics, and composites, while maintaining their electrical properties. This requires careful consideration of the paint's chemical composition and its interaction with various substrate materials.

The incorporation of carbolic acid into electrically conductive paint formulations introduces its own set of challenges. While carbolic acid can potentially enhance certain properties of the paint, such as its antimicrobial characteristics or its ability to form stronger bonds with certain substrates, it also raises concerns about toxicity and environmental impact. Researchers must carefully balance the benefits of carbolic acid with its potential drawbacks, ensuring that the final product meets safety and environmental regulations.

Furthermore, the scalability of production processes for conductive paints incorporating carbolic acid presents technical difficulties. Ensuring consistent quality and performance across large-scale manufacturing batches requires precise control over mixing, curing, and application processes. This becomes even more complex when dealing with the potentially corrosive nature of carbolic acid and its interactions with other paint components.

Current Carbolic Acid Integration Methods

01 Conductive fillers for electrically conductive paint

Electrically conductive paints often incorporate conductive fillers such as carbon black, graphite, metal particles, or conductive polymers to achieve desired electrical conductivity. The type and concentration of these fillers can be adjusted to control the paint's conductivity and other properties.- Conductive fillers for electrically conductive paint: Electrically conductive paints often incorporate conductive fillers such as metal particles, carbon black, or graphene to enhance electrical conductivity. These fillers create a network within the paint matrix, allowing for the flow of electricity. The type and concentration of conductive fillers can be adjusted to achieve desired conductivity levels.

- Polymer binders for conductive paint formulations: The choice of polymer binder in electrically conductive paint formulations is crucial for balancing conductivity and adhesion properties. Specialized polymers can be used to ensure proper dispersion of conductive fillers while maintaining paint integrity. Some formulations may use conductive polymers themselves to enhance overall conductivity.

- Nanostructured materials for improved conductivity: Incorporating nanostructured materials such as carbon nanotubes or metal nanowires can significantly enhance the electrical conductivity of paints. These materials offer high aspect ratios and can form efficient conductive networks at lower concentrations compared to traditional fillers, potentially improving both conductivity and mechanical properties.

- Surface treatment and dispersion techniques: Proper dispersion of conductive fillers is essential for achieving uniform conductivity in paints. Surface treatment of fillers and advanced dispersion techniques can improve filler distribution and prevent agglomeration, leading to enhanced electrical properties and paint performance.

- Measurement and control of paint conductivity: Accurate measurement and control of electrical conductivity in conductive paints are crucial for quality assurance and application-specific performance. Various methods and devices have been developed to assess and monitor conductivity during paint formulation and application processes, ensuring consistent electrical properties in the final product.

02 Polymer matrix for conductive paint formulations

The choice of polymer matrix in electrically conductive paint formulations is crucial for balancing conductivity, adhesion, and durability. Various polymers such as acrylics, epoxies, or polyurethanes can be used, each offering different properties and compatibility with conductive fillers.Expand Specific Solutions03 Nanoparticle-based conductive paints

Incorporating conductive nanoparticles, such as carbon nanotubes or metal nanowires, into paint formulations can significantly enhance electrical conductivity while maintaining transparency and flexibility. These nanoparticle-based paints offer unique properties for specialized applications.Expand Specific Solutions04 Measurement and control of paint conductivity

Techniques for measuring and controlling the electrical conductivity of conductive paints are essential for quality control and performance optimization. This includes methods for in-situ conductivity measurements and adjusting formulations to achieve target conductivity levels.Expand Specific Solutions05 Application methods for conductive paints

The application method of electrically conductive paints can significantly affect their final conductivity and performance. Techniques such as spray coating, screen printing, or brush application may be optimized for different paint formulations and substrate materials to ensure uniform conductivity.Expand Specific Solutions

Key Players in Conductive Coating Industry

The development of electrically conductive paint enhanced by carbolic acid is in its early stages, with the market showing significant growth potential. The global conductive paint market is expected to expand rapidly due to increasing applications in electronics, automotive, and aerospace industries. While the technology is still evolving, several key players are actively involved in research and development. Companies like BASF Coatings GmbH, Kansai Paint Co., Ltd., and Nippon Paint Co., Ltd. are leveraging their expertise in coatings to advance this technology. Emerging players such as Cabot Corp. and Lamberti SpA are also contributing to innovation in conductive materials. As the technology matures, we can expect increased competition and further advancements in performance and application range.

Kansai Paint Co., Ltd.

Technical Solution: Kansai Paint has developed an innovative approach to enhancing electrically conductive paint using carbolic acid. Their method involves the creation of a novel binder system that incorporates carbolic acid derivatives, which act as both conductivity enhancers and cross-linking agents. This dual functionality improves the paint's electrical properties while maintaining excellent adhesion and durability[13]. Kansai's research has demonstrated that this technology can achieve conductivity levels comparable to traditional metal-filled paints while using significantly less conductive filler material, resulting in lighter and more cost-effective coatings[14]. The company has also focused on developing water-based formulations using this technology, addressing environmental concerns and expanding the application range to include sensitive electronic components. These paints have shown particular promise in the automotive sector for applications such as electromagnetic interference (EMI) shielding and electrostatic discharge (ESD) protection[15].

Strengths: Reduced filler content leading to lighter and more cost-effective coatings, environmentally friendly water-based options available. Weaknesses: Potential limitations in achieving ultra-high conductivity levels, may require specific application conditions for optimal performance.

BASF Coatings GmbH

Technical Solution: BASF Coatings GmbH has developed a novel approach to enhance electrically conductive paint using carbolic acid as a key component. Their method involves incorporating carbolic acid derivatives into conductive polymer matrices, which significantly improves the paint's electrical conductivity and adhesion properties. The company has optimized the formulation to achieve a balance between conductivity and durability, utilizing carbolic acid's ability to form strong intermolecular bonds[1]. This technology has been successfully applied in automotive coatings, where it provides improved electromagnetic shielding and anti-static properties[2]. BASF's research has also focused on the synergistic effects of carbolic acid with other conductive fillers, such as carbon nanotubes and graphene, to further enhance the paint's performance[3].

Strengths: Superior conductivity and adhesion, versatile application in automotive and industrial sectors. Weaknesses: Potential environmental concerns due to carbolic acid use, higher production costs compared to standard conductive paints.

Innovations in Carbolic Acid-Enhanced Conductivity

Electrically conductive covering paint

PatentWO1999023178A1

Innovation

- Development of polymer-based paints with added conductive additives such as carbon blacks, metal powders, and semiconductor-doped TiO2, which form a network of conductive paths to allow charge dissipation, eliminating the need for a conductive primer and enhancing mechanical, optical, and corrosion protection properties.

Priming composition for creating a light electrically conductive priming coating

PatentWO2022115004A1

Innovation

- A primer composition containing single-walled and/or double-walled carbon nanotubes at concentrations between 0.005% and 0.1% wt., with a degree of grinding no more than 20 microns, combined with a non-Newtonian pseudoplastic rheology and high concentrations of white pigment, to achieve a light-colored, electrically conductive coating with a surface resistance below 10^9 Ohms/square and a light reflectance value of at least 60%.

Environmental Impact of Carbolic Acid Usage

The use of carbolic acid in the development of electrically conductive paint raises significant environmental concerns that warrant careful consideration. Carbolic acid, also known as phenol, is a toxic and corrosive substance that can have detrimental effects on ecosystems and human health if not properly managed. When used in paint formulations, there is a risk of environmental contamination through various pathways, including air emissions during production and application, as well as leaching from painted surfaces over time.

One of the primary environmental impacts of carbolic acid usage in conductive paint is its potential to contaminate water sources. If improperly disposed of or if the paint degrades, carbolic acid can leach into groundwater and surface water, posing risks to aquatic life and potentially entering the human water supply. Even at low concentrations, phenol can be harmful to fish and other aquatic organisms, disrupting ecosystems and biodiversity.

Air pollution is another significant concern associated with carbolic acid in paint production. During the manufacturing process and paint application, volatile organic compounds (VOCs) containing phenol can be released into the atmosphere. These emissions contribute to smog formation and can have adverse effects on air quality, particularly in urban areas where paint usage is more concentrated.

The persistence of carbolic acid in the environment is a long-term issue. Unlike some other chemicals that break down relatively quickly, phenol can remain in soil and sediments for extended periods, potentially accumulating over time. This persistence increases the likelihood of ongoing environmental exposure and makes remediation efforts more challenging and costly.

Furthermore, the production of carbolic acid itself has environmental implications. The industrial processes used to synthesize phenol often involve the use of fossil fuels and generate significant amounts of greenhouse gases, contributing to climate change. Additionally, the transportation and storage of carbolic acid present risks of accidental spills or releases, which can have immediate and severe impacts on local environments.

To mitigate these environmental risks, stringent regulations and best practices must be implemented throughout the lifecycle of electrically conductive paint containing carbolic acid. This includes proper handling and disposal protocols, emission control technologies in production facilities, and the development of more environmentally friendly alternatives. Research into bio-based phenols or other less toxic conductive additives could provide more sustainable options for the industry.

In conclusion, while carbolic acid may enhance the performance of electrically conductive paint, its environmental impact is a critical factor that must be carefully balanced against its technical benefits. As the industry moves towards more sustainable practices, finding ways to reduce or eliminate the use of carbolic acid in paint formulations will be essential for minimizing environmental harm and ensuring long-term ecological sustainability.

One of the primary environmental impacts of carbolic acid usage in conductive paint is its potential to contaminate water sources. If improperly disposed of or if the paint degrades, carbolic acid can leach into groundwater and surface water, posing risks to aquatic life and potentially entering the human water supply. Even at low concentrations, phenol can be harmful to fish and other aquatic organisms, disrupting ecosystems and biodiversity.

Air pollution is another significant concern associated with carbolic acid in paint production. During the manufacturing process and paint application, volatile organic compounds (VOCs) containing phenol can be released into the atmosphere. These emissions contribute to smog formation and can have adverse effects on air quality, particularly in urban areas where paint usage is more concentrated.

The persistence of carbolic acid in the environment is a long-term issue. Unlike some other chemicals that break down relatively quickly, phenol can remain in soil and sediments for extended periods, potentially accumulating over time. This persistence increases the likelihood of ongoing environmental exposure and makes remediation efforts more challenging and costly.

Furthermore, the production of carbolic acid itself has environmental implications. The industrial processes used to synthesize phenol often involve the use of fossil fuels and generate significant amounts of greenhouse gases, contributing to climate change. Additionally, the transportation and storage of carbolic acid present risks of accidental spills or releases, which can have immediate and severe impacts on local environments.

To mitigate these environmental risks, stringent regulations and best practices must be implemented throughout the lifecycle of electrically conductive paint containing carbolic acid. This includes proper handling and disposal protocols, emission control technologies in production facilities, and the development of more environmentally friendly alternatives. Research into bio-based phenols or other less toxic conductive additives could provide more sustainable options for the industry.

In conclusion, while carbolic acid may enhance the performance of electrically conductive paint, its environmental impact is a critical factor that must be carefully balanced against its technical benefits. As the industry moves towards more sustainable practices, finding ways to reduce or eliminate the use of carbolic acid in paint formulations will be essential for minimizing environmental harm and ensuring long-term ecological sustainability.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for electrically conductive paint enhanced with carbolic acid are crucial factors in determining the commercial viability and widespread adoption of this technology. As production scales up, maintaining consistent quality and performance becomes increasingly challenging. The integration of carbolic acid into the paint formulation requires precise control over mixing processes and environmental conditions to ensure uniform distribution and optimal conductivity.

One key consideration is the development of robust manufacturing protocols that can accommodate large-scale production while preserving the paint's electrical properties. This involves designing specialized mixing equipment capable of handling the corrosive nature of carbolic acid and ensuring thorough dispersion throughout the paint matrix. Additionally, the manufacturing process must account for potential variations in raw material quality and implement stringent quality control measures to maintain consistent conductivity across batches.

The selection of appropriate materials for manufacturing equipment is critical due to the corrosive nature of carbolic acid. Stainless steel or specialized polymer-lined vessels may be necessary to prevent degradation and contamination during production. Furthermore, the manufacturing facility must be equipped with adequate ventilation and safety systems to manage the potential health hazards associated with carbolic acid exposure.

Scaling up production also necessitates the optimization of curing and drying processes to achieve the desired conductivity in the final product. This may involve the use of controlled environment chambers or specialized drying techniques to ensure uniform evaporation of solvents and proper integration of the carbolic acid into the paint structure. The development of in-line testing methods to verify conductivity during production is essential for maintaining quality control at scale.

Supply chain management becomes increasingly complex as production volumes grow. Securing a stable and cost-effective supply of high-quality carbolic acid and other raw materials is crucial for consistent manufacturing. Establishing partnerships with reliable suppliers and potentially exploring vertical integration options may be necessary to ensure a steady supply of critical components.

Environmental considerations and regulatory compliance must also be addressed in the scaling process. The use of carbolic acid may require additional waste management protocols and emission control systems to meet environmental regulations. Developing eco-friendly alternatives or recycling processes for waste materials could contribute to the sustainability of large-scale production.

As production scales up, cost optimization becomes a critical factor in maintaining competitiveness. This may involve exploring automation opportunities, implementing lean manufacturing principles, and continuously refining the formulation to reduce material costs without compromising performance. The ability to achieve economies of scale while maintaining product quality will be essential for the long-term success of carbolic acid-enhanced electrically conductive paint in the market.

One key consideration is the development of robust manufacturing protocols that can accommodate large-scale production while preserving the paint's electrical properties. This involves designing specialized mixing equipment capable of handling the corrosive nature of carbolic acid and ensuring thorough dispersion throughout the paint matrix. Additionally, the manufacturing process must account for potential variations in raw material quality and implement stringent quality control measures to maintain consistent conductivity across batches.

The selection of appropriate materials for manufacturing equipment is critical due to the corrosive nature of carbolic acid. Stainless steel or specialized polymer-lined vessels may be necessary to prevent degradation and contamination during production. Furthermore, the manufacturing facility must be equipped with adequate ventilation and safety systems to manage the potential health hazards associated with carbolic acid exposure.

Scaling up production also necessitates the optimization of curing and drying processes to achieve the desired conductivity in the final product. This may involve the use of controlled environment chambers or specialized drying techniques to ensure uniform evaporation of solvents and proper integration of the carbolic acid into the paint structure. The development of in-line testing methods to verify conductivity during production is essential for maintaining quality control at scale.

Supply chain management becomes increasingly complex as production volumes grow. Securing a stable and cost-effective supply of high-quality carbolic acid and other raw materials is crucial for consistent manufacturing. Establishing partnerships with reliable suppliers and potentially exploring vertical integration options may be necessary to ensure a steady supply of critical components.

Environmental considerations and regulatory compliance must also be addressed in the scaling process. The use of carbolic acid may require additional waste management protocols and emission control systems to meet environmental regulations. Developing eco-friendly alternatives or recycling processes for waste materials could contribute to the sustainability of large-scale production.

As production scales up, cost optimization becomes a critical factor in maintaining competitiveness. This may involve exploring automation opportunities, implementing lean manufacturing principles, and continuously refining the formulation to reduce material costs without compromising performance. The ability to achieve economies of scale while maintaining product quality will be essential for the long-term success of carbolic acid-enhanced electrically conductive paint in the market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!