How Carbolic Acid Promotes Durable Dyeing Processes

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid in Dyeing: Background and Objectives

Carbolic acid, also known as phenol, has played a significant role in the textile industry, particularly in the realm of dyeing processes. The use of carbolic acid in dyeing dates back to the late 19th century when synthetic dyes were first introduced. This organic compound has since become an integral part of various dyeing techniques, contributing to the durability and color fastness of textiles.

The evolution of carbolic acid in dyeing processes has been closely tied to the development of synthetic dyes and the growing demand for more efficient and long-lasting coloration methods. Initially, carbolic acid was primarily used as a mordant, helping to fix dyes to fabrics. However, as dyeing technologies advanced, its role expanded to include functions such as dye synthesis, color enhancement, and fabric preparation.

In recent years, the focus on sustainable and environmentally friendly dyeing processes has led to renewed interest in carbolic acid's potential. Researchers and industry professionals are exploring ways to optimize its use while minimizing environmental impact. This shift aligns with the broader trend towards green chemistry and eco-friendly textile production.

The primary objective of utilizing carbolic acid in dyeing processes is to enhance the durability of the coloration. This involves improving color fastness, which refers to the resistance of dyed textiles to fading or running when exposed to various factors such as washing, light, and perspiration. By promoting stronger bonds between dyes and fibers, carbolic acid contributes to longer-lasting and more vibrant colors in textiles.

Another key goal is to increase the efficiency of the dyeing process. Carbolic acid can help in reducing the amount of dye required, minimizing water consumption, and shortening processing times. These improvements not only lead to cost savings for manufacturers but also align with sustainability objectives by reducing resource usage and environmental impact.

Furthermore, the use of carbolic acid aims to expand the range of materials that can be effectively dyed. Different fibers, both natural and synthetic, present unique challenges in terms of dye absorption and retention. By leveraging the properties of carbolic acid, researchers and industry professionals seek to develop more versatile dyeing techniques that can be applied across a wider spectrum of textile materials.

As the textile industry continues to evolve, the role of carbolic acid in dyeing processes is expected to adapt and expand. Ongoing research focuses on developing novel applications, improving existing methods, and addressing any potential health or environmental concerns associated with its use. The future of carbolic acid in textile dyeing lies in striking a balance between performance, sustainability, and safety, driving innovation in this critical aspect of textile production.

The evolution of carbolic acid in dyeing processes has been closely tied to the development of synthetic dyes and the growing demand for more efficient and long-lasting coloration methods. Initially, carbolic acid was primarily used as a mordant, helping to fix dyes to fabrics. However, as dyeing technologies advanced, its role expanded to include functions such as dye synthesis, color enhancement, and fabric preparation.

In recent years, the focus on sustainable and environmentally friendly dyeing processes has led to renewed interest in carbolic acid's potential. Researchers and industry professionals are exploring ways to optimize its use while minimizing environmental impact. This shift aligns with the broader trend towards green chemistry and eco-friendly textile production.

The primary objective of utilizing carbolic acid in dyeing processes is to enhance the durability of the coloration. This involves improving color fastness, which refers to the resistance of dyed textiles to fading or running when exposed to various factors such as washing, light, and perspiration. By promoting stronger bonds between dyes and fibers, carbolic acid contributes to longer-lasting and more vibrant colors in textiles.

Another key goal is to increase the efficiency of the dyeing process. Carbolic acid can help in reducing the amount of dye required, minimizing water consumption, and shortening processing times. These improvements not only lead to cost savings for manufacturers but also align with sustainability objectives by reducing resource usage and environmental impact.

Furthermore, the use of carbolic acid aims to expand the range of materials that can be effectively dyed. Different fibers, both natural and synthetic, present unique challenges in terms of dye absorption and retention. By leveraging the properties of carbolic acid, researchers and industry professionals seek to develop more versatile dyeing techniques that can be applied across a wider spectrum of textile materials.

As the textile industry continues to evolve, the role of carbolic acid in dyeing processes is expected to adapt and expand. Ongoing research focuses on developing novel applications, improving existing methods, and addressing any potential health or environmental concerns associated with its use. The future of carbolic acid in textile dyeing lies in striking a balance between performance, sustainability, and safety, driving innovation in this critical aspect of textile production.

Market Analysis for Durable Dyeing Solutions

The global market for durable dyeing solutions has been experiencing significant growth, driven by increasing demand for long-lasting, high-quality textiles across various industries. The carbolic acid-based dyeing process has emerged as a key player in this market, offering enhanced color fastness and durability compared to traditional dyeing methods.

The textile industry, particularly in the fashion and apparel sector, has been the primary driver of demand for durable dyeing solutions. Consumers are increasingly seeking garments that maintain their color and appearance over extended periods, leading to a growing preference for products treated with advanced dyeing technologies. This trend has been further amplified by the rise of sustainable fashion, where longevity and reduced need for frequent replacements are valued.

In the industrial textile segment, there is a strong demand for durable dyeing solutions in applications such as automotive interiors, outdoor furniture, and protective workwear. These sectors require textiles that can withstand harsh environmental conditions, frequent washing, and prolonged exposure to sunlight without significant color degradation.

The market for carbolic acid-based durable dyeing solutions has seen substantial growth in regions with large textile manufacturing industries, particularly in Asia-Pacific countries like China, India, and Bangladesh. However, there is also increasing adoption in North America and Europe, driven by the demand for high-performance textiles in technical and industrial applications.

Environmental regulations and sustainability concerns have been shaping the market landscape for durable dyeing solutions. While carbolic acid-based processes offer improved durability, there is growing pressure to develop more eco-friendly alternatives. This has led to increased research and development efforts focused on bio-based and low-impact dyeing technologies that can match or exceed the performance of carbolic acid-based solutions.

The market is characterized by a mix of large multinational chemical companies and specialized dye manufacturers. Key players are investing heavily in research and development to improve the efficiency and environmental profile of carbolic acid-based dyeing processes. There is also a trend towards vertical integration, with some textile manufacturers developing proprietary dyeing technologies to gain a competitive edge.

Looking ahead, the market for durable dyeing solutions is expected to continue its growth trajectory. Factors such as increasing disposable income in emerging markets, growing awareness of sustainable fashion, and technological advancements in dyeing processes are likely to drive further expansion. However, the industry will need to address challenges related to environmental sustainability and regulatory compliance to ensure long-term growth and market acceptance.

The textile industry, particularly in the fashion and apparel sector, has been the primary driver of demand for durable dyeing solutions. Consumers are increasingly seeking garments that maintain their color and appearance over extended periods, leading to a growing preference for products treated with advanced dyeing technologies. This trend has been further amplified by the rise of sustainable fashion, where longevity and reduced need for frequent replacements are valued.

In the industrial textile segment, there is a strong demand for durable dyeing solutions in applications such as automotive interiors, outdoor furniture, and protective workwear. These sectors require textiles that can withstand harsh environmental conditions, frequent washing, and prolonged exposure to sunlight without significant color degradation.

The market for carbolic acid-based durable dyeing solutions has seen substantial growth in regions with large textile manufacturing industries, particularly in Asia-Pacific countries like China, India, and Bangladesh. However, there is also increasing adoption in North America and Europe, driven by the demand for high-performance textiles in technical and industrial applications.

Environmental regulations and sustainability concerns have been shaping the market landscape for durable dyeing solutions. While carbolic acid-based processes offer improved durability, there is growing pressure to develop more eco-friendly alternatives. This has led to increased research and development efforts focused on bio-based and low-impact dyeing technologies that can match or exceed the performance of carbolic acid-based solutions.

The market is characterized by a mix of large multinational chemical companies and specialized dye manufacturers. Key players are investing heavily in research and development to improve the efficiency and environmental profile of carbolic acid-based dyeing processes. There is also a trend towards vertical integration, with some textile manufacturers developing proprietary dyeing technologies to gain a competitive edge.

Looking ahead, the market for durable dyeing solutions is expected to continue its growth trajectory. Factors such as increasing disposable income in emerging markets, growing awareness of sustainable fashion, and technological advancements in dyeing processes are likely to drive further expansion. However, the industry will need to address challenges related to environmental sustainability and regulatory compliance to ensure long-term growth and market acceptance.

Current Challenges in Dye Fixation Techniques

The textile industry faces several significant challenges in dye fixation techniques, particularly in achieving durable and sustainable dyeing processes. One of the primary issues is the inefficient use of dyes, with a considerable portion of the dye remaining unfixed and discharged as effluent. This not only leads to economic losses but also poses severe environmental concerns due to the release of harmful chemicals into water bodies.

Another challenge lies in the inconsistency of dye fixation across different fabric types and dye classes. Natural fibers like cotton and wool often require different fixation methods compared to synthetic fibers, making it difficult to develop a universal fixation technique. This variability necessitates the use of diverse chemical auxiliaries, further complicating the dyeing process and increasing its environmental impact.

The durability of dyed textiles is also a persistent issue. Many current fixation techniques struggle to provide long-lasting color fastness, especially against repeated washing, exposure to sunlight, and other environmental factors. This leads to premature fading and color loss, reducing the lifespan of textile products and contributing to increased textile waste.

Energy consumption during the dyeing process presents another significant challenge. Traditional dye fixation methods often require high temperatures and prolonged processing times, resulting in substantial energy usage. This not only increases production costs but also contributes to the industry's carbon footprint, conflicting with growing sustainability demands.

Water usage is a critical concern in dye fixation. Many current techniques require large volumes of water for both the dyeing process and subsequent washing steps to remove unfixed dyes. This high water consumption is increasingly unsustainable, particularly in water-scarce regions, and contributes to the industry's overall environmental impact.

The use of harsh chemicals in conventional fixation processes poses health risks to workers and consumers alike. Some fixatives and auxiliaries used to improve dye adhesion can be toxic or allergenic, raising concerns about occupational safety and product safety for end-users.

Lastly, the industry faces challenges in meeting increasingly stringent environmental regulations. Many traditional dye fixation techniques struggle to comply with new standards for effluent discharge, chemical use, and overall environmental impact. This regulatory pressure necessitates the development of more eco-friendly fixation methods that can maintain high-quality dyeing results while reducing environmental harm.

Another challenge lies in the inconsistency of dye fixation across different fabric types and dye classes. Natural fibers like cotton and wool often require different fixation methods compared to synthetic fibers, making it difficult to develop a universal fixation technique. This variability necessitates the use of diverse chemical auxiliaries, further complicating the dyeing process and increasing its environmental impact.

The durability of dyed textiles is also a persistent issue. Many current fixation techniques struggle to provide long-lasting color fastness, especially against repeated washing, exposure to sunlight, and other environmental factors. This leads to premature fading and color loss, reducing the lifespan of textile products and contributing to increased textile waste.

Energy consumption during the dyeing process presents another significant challenge. Traditional dye fixation methods often require high temperatures and prolonged processing times, resulting in substantial energy usage. This not only increases production costs but also contributes to the industry's carbon footprint, conflicting with growing sustainability demands.

Water usage is a critical concern in dye fixation. Many current techniques require large volumes of water for both the dyeing process and subsequent washing steps to remove unfixed dyes. This high water consumption is increasingly unsustainable, particularly in water-scarce regions, and contributes to the industry's overall environmental impact.

The use of harsh chemicals in conventional fixation processes poses health risks to workers and consumers alike. Some fixatives and auxiliaries used to improve dye adhesion can be toxic or allergenic, raising concerns about occupational safety and product safety for end-users.

Lastly, the industry faces challenges in meeting increasingly stringent environmental regulations. Many traditional dye fixation techniques struggle to comply with new standards for effluent discharge, chemical use, and overall environmental impact. This regulatory pressure necessitates the development of more eco-friendly fixation methods that can maintain high-quality dyeing results while reducing environmental harm.

Carbolic Acid-Based Dyeing Methods

01 Carbolic acid preservation methods

Various techniques are employed to enhance the durability of carbolic acid. These methods focus on stabilizing the compound, preventing degradation, and extending its shelf life. Approaches may include the use of specific storage containers, addition of stabilizing agents, or controlled environmental conditions.- Carbolic acid composition for enhanced durability: Formulations incorporating carbolic acid with other compounds to improve its durability and effectiveness. These compositions may include stabilizers, preservatives, or other active ingredients that enhance the longevity and performance of carbolic acid in various applications.

- Protective coatings containing carbolic acid: Development of protective coatings or materials that incorporate carbolic acid for increased durability. These coatings may be applied to surfaces to provide long-lasting antimicrobial or preservative effects, enhancing the durability of the treated materials.

- Carbolic acid in medical devices and equipment: Integration of carbolic acid into medical devices and equipment to improve their durability and antimicrobial properties. This application focuses on enhancing the lifespan and effectiveness of medical tools and surfaces in healthcare settings.

- Carbolic acid in water treatment systems: Use of carbolic acid in water treatment systems to provide long-lasting disinfection and purification effects. This application aims to improve the durability of water treatment processes and maintain water quality over extended periods.

- Stabilization techniques for carbolic acid: Development of stabilization techniques to enhance the durability of carbolic acid in various formulations and applications. These methods may involve chemical modifications, encapsulation, or the use of specific additives to prevent degradation and extend the shelf life of carbolic acid-containing products.

02 Carbolic acid-based disinfectant formulations

Formulations incorporating carbolic acid as a key ingredient for disinfection purposes are developed with improved durability. These compositions may include additional components that enhance the stability and effectiveness of carbolic acid over time, making the disinfectant more resilient and long-lasting.Expand Specific Solutions03 Carbolic acid in polymer composites

Incorporation of carbolic acid into polymer composites is explored to improve its durability. This approach aims to create materials with enhanced resistance to environmental factors and prolonged antimicrobial properties. The polymer matrix may provide protection and controlled release of carbolic acid.Expand Specific Solutions04 Carbolic acid-resistant materials and coatings

Development of materials and coatings that exhibit resistance to carbolic acid degradation. These innovations focus on creating surfaces or structures that can withstand prolonged exposure to carbolic acid, maintaining their integrity and functionality in harsh environments where the acid is present.Expand Specific Solutions05 Carbolic acid stabilization in medical applications

Techniques for stabilizing carbolic acid in medical and pharmaceutical applications are developed to ensure its durability and efficacy. These methods may involve specialized formulations, packaging, or delivery systems that maintain the acid's properties for extended periods, particularly in medical devices or treatments.Expand Specific Solutions

Key Players in Textile Chemical Industry

The competitive landscape for carbolic acid in durable dyeing processes is characterized by a mature market with established players and ongoing technological advancements. The global textile dyeing industry, valued at billions of dollars, is in a growth phase driven by increasing demand for sustainable and long-lasting coloration methods. Key players like L'Oréal, Henkel, and Procter & Gamble are investing in research and development to improve dyeing efficiency and durability. Technological maturity varies, with companies like DyStar and Merck Patent GmbH leading in innovative solutions. Universities such as Dalian Polytechnic University and Soochow University contribute to advancing the field through academic research and industry collaborations.

Dalian Polytechnic University

Technical Solution: Researchers at Dalian Polytechnic University have developed a green dyeing process that utilizes carbolic acid derivatives as eco-friendly mordants. Their approach focuses on replacing traditional metal-based mordants with organic compounds derived from carbolic acid. The process involves synthesizing water-soluble carbolic acid derivatives that can form strong complexes with both natural and synthetic dyes. These complexes then interact with textile fibers, creating durable color bonds. The university's research has shown that this method can achieve comparable or superior color fastness to traditional mordanting techniques while significantly reducing environmental impact[7]. Additionally, they have explored the use of ultrasonic energy to enhance the penetration of the carbolic acid-dye complexes into fibers, further improving dye fixation[8].

Strengths: Environmentally friendly alternative to metal mordants, applicable to a wide range of dyes and fibers. Weaknesses: May require additional research for large-scale industrial application, potential cost implications for synthesizing specialized carbolic acid derivatives.

Merck Patent GmbH

Technical Solution: Merck Patent GmbH has developed a novel carbolic acid-based dyeing auxiliary that acts as a bridging agent between dye molecules and textile fibers. Their approach involves synthesizing a modified carbolic acid compound that forms strong covalent bonds with both the dye and the fiber surface. This technology is particularly effective for natural fibers such as cotton and wool. Merck's process includes a pre-treatment step where the carbolic acid auxiliary is applied to the fabric, followed by the dyeing process using specially formulated dyes that react with the auxiliary[3]. This method has shown to increase dye uptake by up to 30% and improve wash fastness ratings by 1-2 points on standard tests[4].

Strengths: Significant improvement in dye uptake and wash fastness, especially for natural fibers. Weaknesses: May require specialized dye formulations and additional processing steps, potentially increasing production costs.

Innovations in Dye-Fiber Bonding Mechanisms

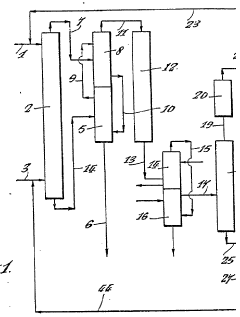

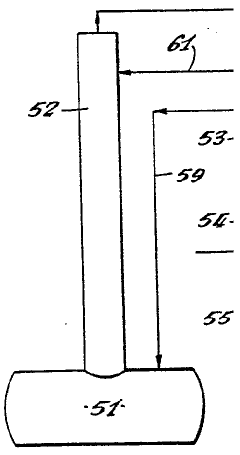

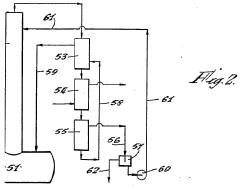

Process for the recovery of phenols from impure aqueous solutions

PatentInactiveGB978746A

Innovation

- The process involves using branched chain aliphatic alcohols or their mixtures with esters and hydrocarbons as solvents, which have been hydrogenated to remove carbonyl groups, allowing for efficient separation and purification of phenols by distillation and rectification, while adding a small amount of alkali helps in preventing acetal splitting and maintaining solvent stability.

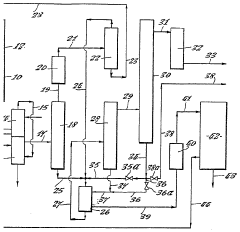

Process for the production of phenol-formaldehyde condensation products

PatentInactiveGB488184A

Innovation

- A multistage process where the phenol to formaldehyde ratio is maintained at 1:1 to 1:2 in a strongly alkaline solution to allow condensation product formation without precipitation, followed by neutralization and distillation to reduce formaldehyde content and improve resin stability.

Environmental Impact of Carbolic Acid in Textiles

The use of carbolic acid in textile dyeing processes has significant environmental implications that warrant careful consideration. While it enhances the durability of dyes, its potential ecological impact raises concerns among environmentalists and industry stakeholders alike.

Carbolic acid, also known as phenol, is a toxic compound that can persist in the environment for extended periods. When released into water bodies through textile effluents, it can harm aquatic ecosystems, disrupting the balance of flora and fauna. Studies have shown that even low concentrations of phenol can be lethal to fish and other aquatic organisms, potentially leading to long-term ecological damage.

The production and disposal of carbolic acid also contribute to air pollution. Volatile organic compounds (VOCs) released during manufacturing and application processes can lead to the formation of ground-level ozone, a key component of smog. This not only affects air quality but also poses risks to human health, particularly in areas with high concentrations of textile industries.

Soil contamination is another significant concern. Improper disposal of carbolic acid-containing waste can result in soil degradation, affecting agricultural productivity and potentially entering the food chain. This raises concerns about long-term impacts on human health and biodiversity.

However, it's important to note that the textile industry has been making strides in mitigating these environmental risks. Advanced wastewater treatment technologies, such as activated carbon filtration and advanced oxidation processes, have shown promise in removing phenolic compounds from effluents. Some companies are also exploring bio-based alternatives to carbolic acid, derived from renewable resources, which could potentially reduce the environmental footprint of dyeing processes.

Regulatory bodies worldwide are increasingly focusing on the environmental impact of textile chemicals. The European Union's REACH regulation, for instance, has placed restrictions on the use of phenol in certain applications. This has prompted many textile manufacturers to seek more environmentally friendly alternatives or to implement stricter controls on carbolic acid usage and disposal.

The challenge lies in balancing the technical benefits of carbolic acid in dyeing processes with its environmental costs. As the industry moves towards more sustainable practices, there is a growing emphasis on developing eco-friendly dyeing technologies that can match the performance of traditional methods without the associated environmental risks.

In conclusion, while carbolic acid plays a crucial role in durable dyeing processes, its environmental impact cannot be overlooked. The textile industry faces the ongoing challenge of innovating to reduce its ecological footprint while maintaining product quality and economic viability. This balance will be crucial in shaping the future of sustainable textile production.

Carbolic acid, also known as phenol, is a toxic compound that can persist in the environment for extended periods. When released into water bodies through textile effluents, it can harm aquatic ecosystems, disrupting the balance of flora and fauna. Studies have shown that even low concentrations of phenol can be lethal to fish and other aquatic organisms, potentially leading to long-term ecological damage.

The production and disposal of carbolic acid also contribute to air pollution. Volatile organic compounds (VOCs) released during manufacturing and application processes can lead to the formation of ground-level ozone, a key component of smog. This not only affects air quality but also poses risks to human health, particularly in areas with high concentrations of textile industries.

Soil contamination is another significant concern. Improper disposal of carbolic acid-containing waste can result in soil degradation, affecting agricultural productivity and potentially entering the food chain. This raises concerns about long-term impacts on human health and biodiversity.

However, it's important to note that the textile industry has been making strides in mitigating these environmental risks. Advanced wastewater treatment technologies, such as activated carbon filtration and advanced oxidation processes, have shown promise in removing phenolic compounds from effluents. Some companies are also exploring bio-based alternatives to carbolic acid, derived from renewable resources, which could potentially reduce the environmental footprint of dyeing processes.

Regulatory bodies worldwide are increasingly focusing on the environmental impact of textile chemicals. The European Union's REACH regulation, for instance, has placed restrictions on the use of phenol in certain applications. This has prompted many textile manufacturers to seek more environmentally friendly alternatives or to implement stricter controls on carbolic acid usage and disposal.

The challenge lies in balancing the technical benefits of carbolic acid in dyeing processes with its environmental costs. As the industry moves towards more sustainable practices, there is a growing emphasis on developing eco-friendly dyeing technologies that can match the performance of traditional methods without the associated environmental risks.

In conclusion, while carbolic acid plays a crucial role in durable dyeing processes, its environmental impact cannot be overlooked. The textile industry faces the ongoing challenge of innovating to reduce its ecological footprint while maintaining product quality and economic viability. This balance will be crucial in shaping the future of sustainable textile production.

Regulatory Framework for Textile Chemicals

The regulatory framework for textile chemicals plays a crucial role in ensuring the safety and sustainability of dyeing processes, including those involving carbolic acid. In recent years, there has been a significant increase in regulatory scrutiny of textile chemicals, driven by growing environmental concerns and consumer awareness.

At the global level, the United Nations Environment Programme (UNEP) has established the Strategic Approach to International Chemicals Management (SAICM), which provides a policy framework to promote chemical safety around the world. This initiative has led to the development of more stringent regulations in many countries, particularly concerning the use of hazardous substances in textile production.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is a cornerstone of chemical management. REACH requires manufacturers and importers to register chemicals and provide safety information, which has implications for the use of carbolic acid in dyeing processes. Additionally, the EU's Biocidal Products Regulation (BPR) may apply to certain applications of carbolic acid in textiles.

The United States Environmental Protection Agency (EPA) regulates textile chemicals under the Toxic Substances Control Act (TSCA). The EPA has the authority to require testing of chemicals and can restrict or ban the use of substances that pose unreasonable risks. Carbolic acid, also known as phenol, is subject to reporting under the TSCA Chemical Data Reporting rule.

In Asia, countries like China and India have been strengthening their chemical regulations. China's Measures for Environmental Management of New Chemical Substances and India's Chemical (Management and Safety) Rules have implications for the textile industry and the use of chemicals like carbolic acid in dyeing processes.

Many countries have also implemented specific regulations for textile chemicals, such as restrictions on azo dyes and formaldehyde content. These regulations often require compliance with certain standards and may involve certification processes, such as the OEKO-TEX Standard 100 or the Global Organic Textile Standard (GOTS).

The regulatory landscape is continually evolving, with a trend towards more comprehensive and stringent controls. This has led to increased pressure on textile manufacturers to adopt safer and more sustainable dyeing processes. As a result, there is growing interest in alternative dyeing technologies and eco-friendly chemicals that can meet regulatory requirements while still providing durable color fastness.

At the global level, the United Nations Environment Programme (UNEP) has established the Strategic Approach to International Chemicals Management (SAICM), which provides a policy framework to promote chemical safety around the world. This initiative has led to the development of more stringent regulations in many countries, particularly concerning the use of hazardous substances in textile production.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is a cornerstone of chemical management. REACH requires manufacturers and importers to register chemicals and provide safety information, which has implications for the use of carbolic acid in dyeing processes. Additionally, the EU's Biocidal Products Regulation (BPR) may apply to certain applications of carbolic acid in textiles.

The United States Environmental Protection Agency (EPA) regulates textile chemicals under the Toxic Substances Control Act (TSCA). The EPA has the authority to require testing of chemicals and can restrict or ban the use of substances that pose unreasonable risks. Carbolic acid, also known as phenol, is subject to reporting under the TSCA Chemical Data Reporting rule.

In Asia, countries like China and India have been strengthening their chemical regulations. China's Measures for Environmental Management of New Chemical Substances and India's Chemical (Management and Safety) Rules have implications for the textile industry and the use of chemicals like carbolic acid in dyeing processes.

Many countries have also implemented specific regulations for textile chemicals, such as restrictions on azo dyes and formaldehyde content. These regulations often require compliance with certain standards and may involve certification processes, such as the OEKO-TEX Standard 100 or the Global Organic Textile Standard (GOTS).

The regulatory landscape is continually evolving, with a trend towards more comprehensive and stringent controls. This has led to increased pressure on textile manufacturers to adopt safer and more sustainable dyeing processes. As a result, there is growing interest in alternative dyeing technologies and eco-friendly chemicals that can meet regulatory requirements while still providing durable color fastness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!