Analyzing the Role of Magnesium Nitrate in Bio-Inspired Designs

AUG 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Nitrate in Bio-Inspired Design: Background and Objectives

Magnesium nitrate has emerged as a fascinating compound in the realm of bio-inspired design, drawing significant attention from researchers and engineers alike. This inorganic salt, with its unique properties and versatile applications, has become a focal point in the development of innovative materials and systems that mimic natural processes and structures.

The journey of magnesium nitrate in bio-inspired design can be traced back to the early 21st century when scientists began to explore its potential in various fields. Initially, it was primarily used in agriculture as a fertilizer due to its high magnesium and nitrogen content. However, as research progressed, its applications expanded into more sophisticated areas of materials science and engineering.

One of the key drivers behind the increased interest in magnesium nitrate is its ability to form complex structures at the molecular level. This property has been particularly valuable in the development of biomimetic materials, which aim to replicate the intricate designs found in nature. Researchers have discovered that magnesium nitrate can be used to create self-assembling structures that mimic the hierarchical organization of biological systems, opening up new possibilities in fields such as tissue engineering and drug delivery.

The evolution of magnesium nitrate's role in bio-inspired design has been closely linked to advancements in nanotechnology and materials science. As our understanding of these fields has grown, so too has our ability to manipulate magnesium nitrate at the nanoscale, leading to the creation of novel materials with enhanced properties and functionalities.

In recent years, the focus has shifted towards exploring the potential of magnesium nitrate in energy-related applications. Its unique chemical properties make it an attractive candidate for use in thermal energy storage systems, phase change materials, and even in the development of next-generation batteries. These applications align with the growing global emphasis on sustainable and efficient energy solutions, further driving research and development in this area.

The objectives of current research on magnesium nitrate in bio-inspired design are multifaceted. Scientists aim to deepen our understanding of its fundamental properties and behavior under various conditions, with the goal of expanding its applications across different industries. There is a particular focus on developing environmentally friendly and sustainable materials that can address pressing global challenges, such as climate change and resource scarcity.

Another key objective is to improve the scalability and cost-effectiveness of magnesium nitrate-based technologies. While many promising applications have been demonstrated in laboratory settings, translating these innovations into commercially viable products remains a significant challenge. Researchers are working to optimize production processes and enhance the stability and performance of magnesium nitrate-based materials in real-world conditions.

As we look to the future, the role of magnesium nitrate in bio-inspired design is expected to continue evolving. With ongoing advancements in characterization techniques and computational modeling, researchers are poised to unlock even more potential applications for this versatile compound, paving the way for a new generation of bio-inspired technologies that could revolutionize various aspects of our lives.

The journey of magnesium nitrate in bio-inspired design can be traced back to the early 21st century when scientists began to explore its potential in various fields. Initially, it was primarily used in agriculture as a fertilizer due to its high magnesium and nitrogen content. However, as research progressed, its applications expanded into more sophisticated areas of materials science and engineering.

One of the key drivers behind the increased interest in magnesium nitrate is its ability to form complex structures at the molecular level. This property has been particularly valuable in the development of biomimetic materials, which aim to replicate the intricate designs found in nature. Researchers have discovered that magnesium nitrate can be used to create self-assembling structures that mimic the hierarchical organization of biological systems, opening up new possibilities in fields such as tissue engineering and drug delivery.

The evolution of magnesium nitrate's role in bio-inspired design has been closely linked to advancements in nanotechnology and materials science. As our understanding of these fields has grown, so too has our ability to manipulate magnesium nitrate at the nanoscale, leading to the creation of novel materials with enhanced properties and functionalities.

In recent years, the focus has shifted towards exploring the potential of magnesium nitrate in energy-related applications. Its unique chemical properties make it an attractive candidate for use in thermal energy storage systems, phase change materials, and even in the development of next-generation batteries. These applications align with the growing global emphasis on sustainable and efficient energy solutions, further driving research and development in this area.

The objectives of current research on magnesium nitrate in bio-inspired design are multifaceted. Scientists aim to deepen our understanding of its fundamental properties and behavior under various conditions, with the goal of expanding its applications across different industries. There is a particular focus on developing environmentally friendly and sustainable materials that can address pressing global challenges, such as climate change and resource scarcity.

Another key objective is to improve the scalability and cost-effectiveness of magnesium nitrate-based technologies. While many promising applications have been demonstrated in laboratory settings, translating these innovations into commercially viable products remains a significant challenge. Researchers are working to optimize production processes and enhance the stability and performance of magnesium nitrate-based materials in real-world conditions.

As we look to the future, the role of magnesium nitrate in bio-inspired design is expected to continue evolving. With ongoing advancements in characterization techniques and computational modeling, researchers are poised to unlock even more potential applications for this versatile compound, paving the way for a new generation of bio-inspired technologies that could revolutionize various aspects of our lives.

Market Analysis for Bio-Inspired Materials

The market for bio-inspired materials has been experiencing significant growth in recent years, driven by increasing demand for sustainable and high-performance solutions across various industries. Bio-inspired materials, which draw inspiration from nature's designs and processes, offer unique properties that can address many challenges faced by traditional materials.

In the context of magnesium nitrate's role in bio-inspired designs, the market potential is particularly promising. Magnesium nitrate, a versatile compound, has found applications in several bio-inspired material developments, contributing to the overall market expansion. The global bio-inspired materials market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years.

Key industries driving the demand for bio-inspired materials include aerospace, automotive, construction, healthcare, and consumer goods. In the aerospace sector, bio-inspired materials incorporating magnesium nitrate have shown potential in developing lightweight yet strong structures, mimicking natural designs found in bird bones or insect exoskeletons. The automotive industry is exploring these materials for improving fuel efficiency and reducing environmental impact.

The construction sector has shown interest in bio-inspired materials for their potential to create more resilient and energy-efficient buildings. Magnesium nitrate's role in developing self-healing concrete and other smart building materials has garnered attention from industry players and researchers alike.

In healthcare, bio-inspired materials are revolutionizing drug delivery systems, tissue engineering, and medical implants. Magnesium nitrate's biocompatibility and its ability to enhance certain material properties make it a valuable component in developing advanced biomaterials for medical applications.

The consumer goods sector is also embracing bio-inspired materials, particularly in packaging and textiles. Sustainable packaging solutions inspired by natural structures and incorporating magnesium nitrate-based compounds are gaining traction as companies strive to reduce their environmental footprint.

Market trends indicate a growing preference for multifunctional bio-inspired materials that can address multiple challenges simultaneously. This trend aligns well with the versatility of magnesium nitrate in various bio-inspired designs. Additionally, there is an increasing focus on scalable production methods to bring bio-inspired materials from laboratory concepts to commercial viability.

As sustainability becomes a key driver in material selection across industries, bio-inspired materials are well-positioned to capture a larger market share. The role of magnesium nitrate in enhancing the performance and functionality of these materials is expected to contribute significantly to market growth and innovation in the coming years.

In the context of magnesium nitrate's role in bio-inspired designs, the market potential is particularly promising. Magnesium nitrate, a versatile compound, has found applications in several bio-inspired material developments, contributing to the overall market expansion. The global bio-inspired materials market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years.

Key industries driving the demand for bio-inspired materials include aerospace, automotive, construction, healthcare, and consumer goods. In the aerospace sector, bio-inspired materials incorporating magnesium nitrate have shown potential in developing lightweight yet strong structures, mimicking natural designs found in bird bones or insect exoskeletons. The automotive industry is exploring these materials for improving fuel efficiency and reducing environmental impact.

The construction sector has shown interest in bio-inspired materials for their potential to create more resilient and energy-efficient buildings. Magnesium nitrate's role in developing self-healing concrete and other smart building materials has garnered attention from industry players and researchers alike.

In healthcare, bio-inspired materials are revolutionizing drug delivery systems, tissue engineering, and medical implants. Magnesium nitrate's biocompatibility and its ability to enhance certain material properties make it a valuable component in developing advanced biomaterials for medical applications.

The consumer goods sector is also embracing bio-inspired materials, particularly in packaging and textiles. Sustainable packaging solutions inspired by natural structures and incorporating magnesium nitrate-based compounds are gaining traction as companies strive to reduce their environmental footprint.

Market trends indicate a growing preference for multifunctional bio-inspired materials that can address multiple challenges simultaneously. This trend aligns well with the versatility of magnesium nitrate in various bio-inspired designs. Additionally, there is an increasing focus on scalable production methods to bring bio-inspired materials from laboratory concepts to commercial viability.

As sustainability becomes a key driver in material selection across industries, bio-inspired materials are well-positioned to capture a larger market share. The role of magnesium nitrate in enhancing the performance and functionality of these materials is expected to contribute significantly to market growth and innovation in the coming years.

Current State and Challenges in Magnesium Nitrate Applications

Magnesium nitrate has gained significant attention in bio-inspired designs due to its unique properties and versatile applications. Currently, this compound is widely used in various fields, including agriculture, materials science, and environmental engineering. In agriculture, magnesium nitrate serves as an essential fertilizer, providing both magnesium and nitrogen to plants, thereby enhancing crop yield and quality. Its high solubility in water makes it an ideal choice for hydroponic systems and foliar applications.

In materials science, magnesium nitrate plays a crucial role in the development of advanced materials with enhanced properties. It is extensively used in the synthesis of magnesium oxide nanoparticles, which find applications in catalysis, adsorption, and as a reinforcing agent in composite materials. The compound's ability to form stable hydrates has also led to its use in phase change materials for thermal energy storage systems.

Environmental engineering has seen a surge in the application of magnesium nitrate for wastewater treatment and air pollution control. Its effectiveness in removing phosphates from water bodies has made it a valuable tool in combating eutrophication. Additionally, magnesium nitrate is employed in selective catalytic reduction systems to reduce nitrogen oxide emissions from industrial processes and vehicles.

Despite these advancements, several challenges persist in the widespread adoption and optimization of magnesium nitrate in bio-inspired designs. One of the primary concerns is the potential environmental impact of excessive use, particularly in agricultural settings. Over-application can lead to soil salinization and nutrient imbalances, affecting long-term soil health and ecosystem stability.

Another significant challenge lies in the energy-intensive production process of magnesium nitrate. Current manufacturing methods often rely on fossil fuels, contributing to greenhouse gas emissions. Developing more sustainable and eco-friendly production techniques remains a priority for researchers and industry professionals.

The hygroscopic nature of magnesium nitrate poses storage and handling challenges, especially in humid environments. This property can lead to caking and reduced shelf life, necessitating specialized storage solutions and careful handling procedures. Addressing these issues is crucial for improving the compound's practicality in various applications.

In the realm of materials science, controlling the morphology and size distribution of magnesium nitrate-derived nanoparticles remains a challenge. Achieving consistent and tailored properties is essential for optimizing performance in specific applications. Researchers are actively exploring novel synthesis methods and surface modification techniques to overcome these limitations.

As bio-inspired designs continue to evolve, integrating magnesium nitrate into complex systems while maintaining its beneficial properties presents ongoing challenges. Interdisciplinary collaboration between materials scientists, biologists, and engineers is essential to unlock the full potential of this compound in mimicking natural processes and creating innovative solutions.

In materials science, magnesium nitrate plays a crucial role in the development of advanced materials with enhanced properties. It is extensively used in the synthesis of magnesium oxide nanoparticles, which find applications in catalysis, adsorption, and as a reinforcing agent in composite materials. The compound's ability to form stable hydrates has also led to its use in phase change materials for thermal energy storage systems.

Environmental engineering has seen a surge in the application of magnesium nitrate for wastewater treatment and air pollution control. Its effectiveness in removing phosphates from water bodies has made it a valuable tool in combating eutrophication. Additionally, magnesium nitrate is employed in selective catalytic reduction systems to reduce nitrogen oxide emissions from industrial processes and vehicles.

Despite these advancements, several challenges persist in the widespread adoption and optimization of magnesium nitrate in bio-inspired designs. One of the primary concerns is the potential environmental impact of excessive use, particularly in agricultural settings. Over-application can lead to soil salinization and nutrient imbalances, affecting long-term soil health and ecosystem stability.

Another significant challenge lies in the energy-intensive production process of magnesium nitrate. Current manufacturing methods often rely on fossil fuels, contributing to greenhouse gas emissions. Developing more sustainable and eco-friendly production techniques remains a priority for researchers and industry professionals.

The hygroscopic nature of magnesium nitrate poses storage and handling challenges, especially in humid environments. This property can lead to caking and reduced shelf life, necessitating specialized storage solutions and careful handling procedures. Addressing these issues is crucial for improving the compound's practicality in various applications.

In the realm of materials science, controlling the morphology and size distribution of magnesium nitrate-derived nanoparticles remains a challenge. Achieving consistent and tailored properties is essential for optimizing performance in specific applications. Researchers are actively exploring novel synthesis methods and surface modification techniques to overcome these limitations.

As bio-inspired designs continue to evolve, integrating magnesium nitrate into complex systems while maintaining its beneficial properties presents ongoing challenges. Interdisciplinary collaboration between materials scientists, biologists, and engineers is essential to unlock the full potential of this compound in mimicking natural processes and creating innovative solutions.

Existing Bio-Inspired Solutions Using Magnesium Nitrate

01 Magnesium nitrate in fertilizer compositions

Magnesium nitrate is used in various fertilizer compositions to provide essential nutrients for plant growth. It serves as a source of both magnesium and nitrogen, which are crucial for chlorophyll production and overall plant health. These fertilizer compositions can be tailored for specific crops or soil conditions.- Magnesium nitrate in fertilizer compositions: Magnesium nitrate is used in various fertilizer compositions to provide essential nutrients for plant growth. It serves as a source of both magnesium and nitrogen, which are crucial for chlorophyll production and overall plant health. These fertilizer compositions can be tailored for specific crops or soil conditions.

- Magnesium nitrate in energy storage applications: Magnesium nitrate is utilized in energy storage systems, particularly in thermal energy storage applications. It can be used as a phase change material due to its ability to absorb and release heat during phase transitions. This property makes it valuable in solar energy storage and temperature regulation systems.

- Magnesium nitrate in flame retardant formulations: Magnesium nitrate is incorporated into flame retardant formulations for various materials. It acts as an inorganic flame retardant, enhancing the fire resistance of treated materials. These formulations can be applied to textiles, plastics, and other combustible materials to improve their safety characteristics.

- Magnesium nitrate in water treatment processes: Magnesium nitrate is employed in water treatment processes for various purposes. It can be used to remove contaminants, adjust water hardness, or as a coagulant aid in wastewater treatment. The compound's properties make it effective in improving water quality and meeting environmental standards.

- Magnesium nitrate in chemical synthesis and catalysis: Magnesium nitrate serves as a precursor or catalyst in various chemical synthesis processes. It is used in the production of other magnesium compounds, as a catalyst support, or as a reagent in organic and inorganic reactions. Its versatility in chemical processes makes it valuable in industrial applications and research.

02 Magnesium nitrate in energy storage applications

Magnesium nitrate is utilized in energy storage systems, particularly in thermal energy storage applications. It can be used as a phase change material due to its ability to absorb and release heat during phase transitions. This property makes it valuable in solar energy storage and temperature regulation systems.Expand Specific Solutions03 Magnesium nitrate in flame retardant formulations

Magnesium nitrate is incorporated into flame retardant formulations for various materials. It acts as an inorganic flame retardant, enhancing fire resistance properties. These formulations can be applied to textiles, plastics, and other combustible materials to improve their fire safety characteristics.Expand Specific Solutions04 Magnesium nitrate in water treatment processes

Magnesium nitrate is employed in water treatment processes for various purposes. It can be used for removing contaminants, adjusting water hardness, or as a coagulant aid. The compound's properties make it effective in improving water quality in both industrial and municipal water treatment applications.Expand Specific Solutions05 Magnesium nitrate in chemical synthesis

Magnesium nitrate serves as a precursor or reagent in various chemical synthesis processes. It is used in the production of other magnesium compounds, catalysts, and specialty chemicals. The compound's reactivity and solubility make it valuable in organic and inorganic synthesis applications across different industries.Expand Specific Solutions

Key Players in Bio-Inspired Design Industry

The field of bio-inspired designs utilizing magnesium nitrate is in an early developmental stage, with a growing market driven by increasing interest in sustainable and biomimetic solutions. The technology's maturity is still evolving, as evidenced by the diverse range of institutions involved in research and development. Academic institutions like the University of Pittsburgh, Chongqing University, and Nanyang Technological University are at the forefront of fundamental research, while companies such as Shanxi Jiaocheng Hongxing Chemicals Co. Ltd. and Bioforte Biotechnology (Shenzhen) Co., Ltd. are exploring commercial applications. The involvement of national research entities like the National Institute for Materials Science IAI suggests significant potential for future growth and innovation in this field.

The Regents of the University of California

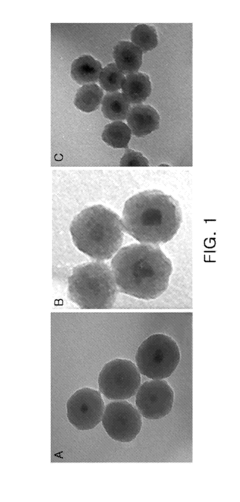

Technical Solution: The University of California has developed bio-inspired designs utilizing magnesium nitrate for advanced material applications. Their approach involves incorporating magnesium nitrate into polymer matrices to create biomimetic composites with enhanced mechanical properties. The research team has successfully synthesized nanostructured magnesium nitrate particles with controlled morphology, which are then integrated into various polymer systems[1]. This method has shown significant improvements in the strength and toughness of the resulting materials, mimicking the hierarchical structures found in natural materials like nacre[3]. The university has also explored the use of magnesium nitrate in self-healing materials, where the compound acts as a catalyst for the healing process when damage occurs[5].

Strengths: Innovative approach to biomimetic materials, potential for self-healing properties, and improved mechanical characteristics. Weaknesses: Possible challenges in scaling up production and ensuring long-term stability of the magnesium nitrate-polymer composites.

National Institute for Materials Science IAI

Technical Solution: The National Institute for Materials Science (NIMS) in Japan has conducted extensive research on the role of magnesium nitrate in bio-inspired designs, particularly focusing on its application in energy storage and conversion systems. NIMS researchers have developed a novel approach using magnesium nitrate as a precursor for synthesizing high-performance cathode materials for magnesium-ion batteries[2]. The bio-inspired aspect of their design lies in mimicking the ion transport mechanisms found in biological systems. By carefully controlling the crystallization process of magnesium nitrate, they have created nanostructured materials with enhanced ionic conductivity and stability[4]. Additionally, NIMS has explored the use of magnesium nitrate in creating bio-inspired catalysts for water splitting reactions, drawing inspiration from natural photosynthetic systems[6].

Strengths: Cutting-edge research in energy storage materials, potential for high-performance magnesium-ion batteries, and innovative catalytic systems. Weaknesses: Possible limitations in the availability and cost of high-purity magnesium nitrate for large-scale applications.

Core Innovations in Magnesium Nitrate-Based Biomimicry

Preparation of magnetite nanoparticles and uses thereof

PatentPendingUS20220371912A1

Innovation

- A method involving a gas-liquid reaction interface between an ammonia gas headspace and an aqueous ferrous and ferric iron salts solution, without agitation, to synthesize magnetite nanoparticles with high yield and phase purity, using a total iron salts concentration of 1-10 mM, and varying ammonia gas concentrations to control the reaction.

Multifunctional particles providing cellular uptake and magnetic motor effect

PatentInactiveUS20120156686A1

Innovation

- A well-controlled magnetic particle system is developed, comprising magnetic particles with a core-shell structure, where the core is made of magnetic material and the shell is an inorganic glass with covalently bound fluorescent dye and surface agents, allowing for precise control over particle size, cytotoxicity, and cellular uptake, enabling magnetic movement and gene delivery.

Environmental Impact of Magnesium Nitrate in Bio-Inspired Designs

The environmental impact of magnesium nitrate in bio-inspired designs is a critical consideration for sustainable development and ecological preservation. As a widely used compound in various applications, including agriculture, construction, and energy storage, magnesium nitrate's role in bio-inspired designs necessitates a thorough examination of its environmental implications.

One of the primary environmental concerns associated with magnesium nitrate is its potential contribution to eutrophication in aquatic ecosystems. When excess magnesium nitrate enters water bodies through runoff or leaching, it can lead to increased algal growth and oxygen depletion, adversely affecting aquatic life and water quality. This impact is particularly significant in areas where bio-inspired designs incorporating magnesium nitrate are implemented near sensitive water systems.

Furthermore, the production and disposal of magnesium nitrate can have substantial environmental consequences. The manufacturing process often involves energy-intensive methods and may result in greenhouse gas emissions, contributing to climate change. Improper disposal or accidental release of magnesium nitrate can contaminate soil and groundwater, potentially affecting local flora and fauna.

However, the environmental impact of magnesium nitrate in bio-inspired designs is not entirely negative. When used judiciously, it can contribute to more sustainable practices in various fields. For instance, in agriculture, magnesium nitrate-based fertilizers can enhance crop yields and reduce the need for excessive land use, potentially mitigating deforestation and habitat loss.

In the context of energy storage applications, magnesium nitrate's role in thermal energy storage systems can indirectly benefit the environment by promoting renewable energy adoption. These systems can improve the efficiency of solar power plants, reducing reliance on fossil fuels and decreasing overall carbon emissions.

The environmental impact of magnesium nitrate also extends to its influence on soil chemistry and plant growth. While it can provide essential nutrients for plants, excessive use may lead to soil imbalances and altered pH levels, affecting local ecosystems and biodiversity. This underscores the importance of precise application and monitoring in bio-inspired designs utilizing magnesium nitrate.

To mitigate negative environmental impacts, researchers and designers are exploring innovative approaches to magnesium nitrate use in bio-inspired designs. These include developing closed-loop systems to minimize leaching, implementing advanced filtration techniques to prevent water contamination, and investigating alternative compounds with similar properties but reduced environmental footprints.

In conclusion, the environmental impact of magnesium nitrate in bio-inspired designs is multifaceted, encompassing both potential risks and benefits. As the field of bio-inspired design continues to evolve, it is crucial to prioritize comprehensive environmental assessments and sustainable practices to maximize the positive contributions of magnesium nitrate while minimizing its ecological footprint.

One of the primary environmental concerns associated with magnesium nitrate is its potential contribution to eutrophication in aquatic ecosystems. When excess magnesium nitrate enters water bodies through runoff or leaching, it can lead to increased algal growth and oxygen depletion, adversely affecting aquatic life and water quality. This impact is particularly significant in areas where bio-inspired designs incorporating magnesium nitrate are implemented near sensitive water systems.

Furthermore, the production and disposal of magnesium nitrate can have substantial environmental consequences. The manufacturing process often involves energy-intensive methods and may result in greenhouse gas emissions, contributing to climate change. Improper disposal or accidental release of magnesium nitrate can contaminate soil and groundwater, potentially affecting local flora and fauna.

However, the environmental impact of magnesium nitrate in bio-inspired designs is not entirely negative. When used judiciously, it can contribute to more sustainable practices in various fields. For instance, in agriculture, magnesium nitrate-based fertilizers can enhance crop yields and reduce the need for excessive land use, potentially mitigating deforestation and habitat loss.

In the context of energy storage applications, magnesium nitrate's role in thermal energy storage systems can indirectly benefit the environment by promoting renewable energy adoption. These systems can improve the efficiency of solar power plants, reducing reliance on fossil fuels and decreasing overall carbon emissions.

The environmental impact of magnesium nitrate also extends to its influence on soil chemistry and plant growth. While it can provide essential nutrients for plants, excessive use may lead to soil imbalances and altered pH levels, affecting local ecosystems and biodiversity. This underscores the importance of precise application and monitoring in bio-inspired designs utilizing magnesium nitrate.

To mitigate negative environmental impacts, researchers and designers are exploring innovative approaches to magnesium nitrate use in bio-inspired designs. These include developing closed-loop systems to minimize leaching, implementing advanced filtration techniques to prevent water contamination, and investigating alternative compounds with similar properties but reduced environmental footprints.

In conclusion, the environmental impact of magnesium nitrate in bio-inspired designs is multifaceted, encompassing both potential risks and benefits. As the field of bio-inspired design continues to evolve, it is crucial to prioritize comprehensive environmental assessments and sustainable practices to maximize the positive contributions of magnesium nitrate while minimizing its ecological footprint.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for incorporating magnesium nitrate in bio-inspired designs present both challenges and opportunities. As the potential applications of magnesium nitrate in biomimetic materials expand, it becomes crucial to address the issues of large-scale production and cost-effective manufacturing processes.

One of the primary challenges in scaling up the use of magnesium nitrate in bio-inspired designs is maintaining the precise control over material properties that is achievable in laboratory settings. The delicate balance of magnesium nitrate concentration and its interaction with other components in biomimetic materials can be difficult to replicate consistently at industrial scales. This necessitates the development of advanced process control systems and quality assurance protocols to ensure uniformity across large production batches.

The sourcing of high-purity magnesium nitrate in sufficient quantities for large-scale manufacturing is another important consideration. While magnesium nitrate is not a rare compound, ensuring a stable supply chain for pharmaceutical or food-grade quality material may require strategic partnerships with chemical suppliers or investment in dedicated production facilities.

From a manufacturing perspective, the integration of magnesium nitrate into existing production lines may require significant modifications to equipment and processes. This is particularly true for industries that have not traditionally worked with hygroscopic materials like magnesium nitrate. The compound's sensitivity to moisture necessitates careful handling and storage throughout the manufacturing process, potentially requiring the implementation of climate-controlled environments and moisture-resistant packaging solutions.

The environmental impact of increased magnesium nitrate usage in manufacturing must also be carefully evaluated. While magnesium nitrate itself is not highly toxic, its production and disposal at industrial scales could have implications for water quality and soil composition. Developing closed-loop systems for recycling and reusing magnesium nitrate within the manufacturing process could help mitigate these concerns and improve overall sustainability.

Cost considerations play a crucial role in the scalability of magnesium nitrate-based bio-inspired designs. While the compound itself is relatively inexpensive, the specialized equipment and processes required for its incorporation into advanced materials may drive up production costs. Manufacturers will need to balance these increased costs against the potential performance benefits and market demand for bio-inspired products.

As the field progresses, there is a growing need for standardization in the use of magnesium nitrate in bio-inspired materials. Establishing industry-wide standards for material composition, testing protocols, and performance metrics will be essential for ensuring consistency and reliability across different manufacturers and applications. This standardization will also facilitate regulatory approval processes, particularly for applications in sensitive fields such as medical devices or aerospace components.

One of the primary challenges in scaling up the use of magnesium nitrate in bio-inspired designs is maintaining the precise control over material properties that is achievable in laboratory settings. The delicate balance of magnesium nitrate concentration and its interaction with other components in biomimetic materials can be difficult to replicate consistently at industrial scales. This necessitates the development of advanced process control systems and quality assurance protocols to ensure uniformity across large production batches.

The sourcing of high-purity magnesium nitrate in sufficient quantities for large-scale manufacturing is another important consideration. While magnesium nitrate is not a rare compound, ensuring a stable supply chain for pharmaceutical or food-grade quality material may require strategic partnerships with chemical suppliers or investment in dedicated production facilities.

From a manufacturing perspective, the integration of magnesium nitrate into existing production lines may require significant modifications to equipment and processes. This is particularly true for industries that have not traditionally worked with hygroscopic materials like magnesium nitrate. The compound's sensitivity to moisture necessitates careful handling and storage throughout the manufacturing process, potentially requiring the implementation of climate-controlled environments and moisture-resistant packaging solutions.

The environmental impact of increased magnesium nitrate usage in manufacturing must also be carefully evaluated. While magnesium nitrate itself is not highly toxic, its production and disposal at industrial scales could have implications for water quality and soil composition. Developing closed-loop systems for recycling and reusing magnesium nitrate within the manufacturing process could help mitigate these concerns and improve overall sustainability.

Cost considerations play a crucial role in the scalability of magnesium nitrate-based bio-inspired designs. While the compound itself is relatively inexpensive, the specialized equipment and processes required for its incorporation into advanced materials may drive up production costs. Manufacturers will need to balance these increased costs against the potential performance benefits and market demand for bio-inspired products.

As the field progresses, there is a growing need for standardization in the use of magnesium nitrate in bio-inspired materials. Establishing industry-wide standards for material composition, testing protocols, and performance metrics will be essential for ensuring consistency and reliability across different manufacturers and applications. This standardization will also facilitate regulatory approval processes, particularly for applications in sensitive fields such as medical devices or aerospace components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!