How Magnesium Nitrate Improves Electrolytic Cell Efficiency

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Nitrate in Electrolysis: Background and Objectives

Magnesium nitrate has emerged as a promising additive in electrolytic processes, particularly in the realm of improving cell efficiency. The evolution of this technology can be traced back to the early 20th century when researchers began exploring ways to enhance electrolysis performance. Over the decades, the focus has shifted towards finding more sustainable and efficient methods for various industrial applications, including metal production, water treatment, and energy storage.

The use of magnesium nitrate in electrolytic cells represents a significant advancement in this field. Its introduction stems from the need to overcome limitations in traditional electrolytic processes, such as high energy consumption, electrode degradation, and low product yield. As global demand for efficient and environmentally friendly technologies continues to grow, the role of magnesium nitrate in electrolysis has gained increased attention from both academic and industrial sectors.

The primary objective of incorporating magnesium nitrate into electrolytic cells is to enhance overall efficiency. This encompasses several key aspects, including reducing energy consumption, improving electrode stability, increasing reaction rates, and enhancing the quality of the final products. By addressing these factors, researchers aim to develop more cost-effective and sustainable electrolytic processes that can be applied across various industries.

One of the critical goals in this technological pursuit is to understand the fundamental mechanisms by which magnesium nitrate influences electrolytic reactions. This involves investigating its effects on electrode surfaces, electrolyte properties, and the kinetics of electrochemical reactions. By gaining deeper insights into these interactions, scientists and engineers can optimize the use of magnesium nitrate and potentially discover new applications for this compound in electrolytic systems.

Another important objective is to quantify the improvements in cell efficiency attributed to magnesium nitrate. This requires comprehensive studies comparing the performance of electrolytic cells with and without the additive under various operating conditions. Such research aims to establish clear metrics for efficiency gains, which is crucial for justifying the adoption of this technology in industrial settings.

As the technology continues to evolve, there is a growing emphasis on exploring the synergistic effects of magnesium nitrate with other additives or electrode materials. This combinatorial approach may lead to even greater improvements in electrolytic cell efficiency and open up new avenues for innovation in electrochemical processes.

The development of magnesium nitrate technology in electrolysis also aligns with broader trends in sustainable industrial practices. As such, an additional objective is to assess the environmental impact of using this additive, ensuring that the benefits in efficiency do not come at the cost of increased environmental burden. This holistic approach to technology development is essential for long-term viability and acceptance in the market.

The use of magnesium nitrate in electrolytic cells represents a significant advancement in this field. Its introduction stems from the need to overcome limitations in traditional electrolytic processes, such as high energy consumption, electrode degradation, and low product yield. As global demand for efficient and environmentally friendly technologies continues to grow, the role of magnesium nitrate in electrolysis has gained increased attention from both academic and industrial sectors.

The primary objective of incorporating magnesium nitrate into electrolytic cells is to enhance overall efficiency. This encompasses several key aspects, including reducing energy consumption, improving electrode stability, increasing reaction rates, and enhancing the quality of the final products. By addressing these factors, researchers aim to develop more cost-effective and sustainable electrolytic processes that can be applied across various industries.

One of the critical goals in this technological pursuit is to understand the fundamental mechanisms by which magnesium nitrate influences electrolytic reactions. This involves investigating its effects on electrode surfaces, electrolyte properties, and the kinetics of electrochemical reactions. By gaining deeper insights into these interactions, scientists and engineers can optimize the use of magnesium nitrate and potentially discover new applications for this compound in electrolytic systems.

Another important objective is to quantify the improvements in cell efficiency attributed to magnesium nitrate. This requires comprehensive studies comparing the performance of electrolytic cells with and without the additive under various operating conditions. Such research aims to establish clear metrics for efficiency gains, which is crucial for justifying the adoption of this technology in industrial settings.

As the technology continues to evolve, there is a growing emphasis on exploring the synergistic effects of magnesium nitrate with other additives or electrode materials. This combinatorial approach may lead to even greater improvements in electrolytic cell efficiency and open up new avenues for innovation in electrochemical processes.

The development of magnesium nitrate technology in electrolysis also aligns with broader trends in sustainable industrial practices. As such, an additional objective is to assess the environmental impact of using this additive, ensuring that the benefits in efficiency do not come at the cost of increased environmental burden. This holistic approach to technology development is essential for long-term viability and acceptance in the market.

Market Analysis for Enhanced Electrolytic Processes

The market for enhanced electrolytic processes has been experiencing significant growth in recent years, driven by the increasing demand for more efficient and sustainable industrial processes. The use of magnesium nitrate as an efficiency-enhancing additive in electrolytic cells has emerged as a promising solution to address these market needs.

The global electrolytic cell market is projected to expand at a steady rate, with a particular focus on improving energy efficiency and reducing environmental impact. Industries such as chlor-alkali production, metal refining, and water treatment are the primary drivers of this market growth. The adoption of magnesium nitrate in these processes is gaining traction due to its ability to enhance electrolytic cell efficiency.

In the chlor-alkali sector, which produces essential chemicals like chlorine, sodium hydroxide, and hydrogen, there is a strong push for more energy-efficient processes. The use of magnesium nitrate as an additive has shown promising results in reducing energy consumption and improving product yield. This has led to increased interest from major chemical manufacturers looking to optimize their operations and reduce costs.

The metal refining industry, particularly in aluminum and copper production, is another key market segment benefiting from enhanced electrolytic processes. As global demand for these metals continues to rise, manufacturers are seeking ways to improve their production efficiency. Magnesium nitrate additives have demonstrated the potential to increase current efficiency and reduce energy consumption in these energy-intensive processes.

Water treatment and desalination sectors are also showing growing interest in enhanced electrolytic processes. With water scarcity becoming a global concern, there is an increasing need for more efficient and cost-effective water purification methods. Magnesium nitrate's role in improving electrolytic cell efficiency could lead to more accessible and sustainable water treatment solutions.

The market for magnesium nitrate as an electrolytic cell additive is still in its early stages, with significant potential for growth. As research and development efforts continue to demonstrate its benefits, it is expected that more industries will adopt this technology. This trend is likely to drive the demand for high-purity magnesium nitrate and related products.

Geographically, the market for enhanced electrolytic processes is seeing strong growth in regions with established industrial bases, such as North America, Europe, and East Asia. However, emerging economies in South Asia and Latin America are also showing increased interest as they seek to modernize their industrial processes and improve energy efficiency.

The global electrolytic cell market is projected to expand at a steady rate, with a particular focus on improving energy efficiency and reducing environmental impact. Industries such as chlor-alkali production, metal refining, and water treatment are the primary drivers of this market growth. The adoption of magnesium nitrate in these processes is gaining traction due to its ability to enhance electrolytic cell efficiency.

In the chlor-alkali sector, which produces essential chemicals like chlorine, sodium hydroxide, and hydrogen, there is a strong push for more energy-efficient processes. The use of magnesium nitrate as an additive has shown promising results in reducing energy consumption and improving product yield. This has led to increased interest from major chemical manufacturers looking to optimize their operations and reduce costs.

The metal refining industry, particularly in aluminum and copper production, is another key market segment benefiting from enhanced electrolytic processes. As global demand for these metals continues to rise, manufacturers are seeking ways to improve their production efficiency. Magnesium nitrate additives have demonstrated the potential to increase current efficiency and reduce energy consumption in these energy-intensive processes.

Water treatment and desalination sectors are also showing growing interest in enhanced electrolytic processes. With water scarcity becoming a global concern, there is an increasing need for more efficient and cost-effective water purification methods. Magnesium nitrate's role in improving electrolytic cell efficiency could lead to more accessible and sustainable water treatment solutions.

The market for magnesium nitrate as an electrolytic cell additive is still in its early stages, with significant potential for growth. As research and development efforts continue to demonstrate its benefits, it is expected that more industries will adopt this technology. This trend is likely to drive the demand for high-purity magnesium nitrate and related products.

Geographically, the market for enhanced electrolytic processes is seeing strong growth in regions with established industrial bases, such as North America, Europe, and East Asia. However, emerging economies in South Asia and Latin America are also showing increased interest as they seek to modernize their industrial processes and improve energy efficiency.

Current Challenges in Electrolytic Cell Efficiency

Electrolytic cell efficiency remains a critical challenge in various industrial processes, particularly in the production of metals, chemicals, and energy storage systems. Despite significant advancements in recent years, several obstacles continue to hinder the optimal performance of these cells. One of the primary challenges is the high energy consumption associated with electrolytic processes, which not only increases operational costs but also contributes to environmental concerns.

The formation of unwanted byproducts and side reactions during electrolysis poses another significant challenge. These undesired reactions can lead to reduced efficiency, product contamination, and increased electrode degradation. Additionally, the accumulation of gas bubbles on electrode surfaces often results in increased electrical resistance and reduced active surface area, further diminishing cell efficiency.

Electrode materials present a persistent challenge in electrolytic cell design. While many materials offer excellent conductivity, they may lack the necessary durability to withstand harsh electrolytic conditions over extended periods. This trade-off between conductivity and longevity continues to be a focal point for researchers and engineers in the field.

Temperature control within electrolytic cells is another critical factor affecting efficiency. Maintaining optimal operating temperatures is crucial for reaction kinetics and overall cell performance. However, achieving uniform temperature distribution throughout the cell, especially in large-scale industrial applications, remains a significant engineering challenge.

The composition and purity of electrolytes also play a vital role in cell efficiency. Impurities can lead to parasitic reactions, electrode fouling, and reduced conductivity. Developing cost-effective methods for electrolyte purification and maintaining electrolyte balance during continuous operation are ongoing challenges in the industry.

Scaling up laboratory-proven technologies to industrial-scale operations presents its own set of challenges. Issues such as current distribution, heat management, and mass transport become more pronounced at larger scales, often requiring significant re-engineering of cell designs and operational parameters.

In the context of magnesium nitrate's potential to improve electrolytic cell efficiency, addressing these challenges becomes crucial. Understanding how this compound interacts with existing cell components and processes is essential for developing innovative solutions that can overcome current limitations and push the boundaries of electrolytic cell performance.

The formation of unwanted byproducts and side reactions during electrolysis poses another significant challenge. These undesired reactions can lead to reduced efficiency, product contamination, and increased electrode degradation. Additionally, the accumulation of gas bubbles on electrode surfaces often results in increased electrical resistance and reduced active surface area, further diminishing cell efficiency.

Electrode materials present a persistent challenge in electrolytic cell design. While many materials offer excellent conductivity, they may lack the necessary durability to withstand harsh electrolytic conditions over extended periods. This trade-off between conductivity and longevity continues to be a focal point for researchers and engineers in the field.

Temperature control within electrolytic cells is another critical factor affecting efficiency. Maintaining optimal operating temperatures is crucial for reaction kinetics and overall cell performance. However, achieving uniform temperature distribution throughout the cell, especially in large-scale industrial applications, remains a significant engineering challenge.

The composition and purity of electrolytes also play a vital role in cell efficiency. Impurities can lead to parasitic reactions, electrode fouling, and reduced conductivity. Developing cost-effective methods for electrolyte purification and maintaining electrolyte balance during continuous operation are ongoing challenges in the industry.

Scaling up laboratory-proven technologies to industrial-scale operations presents its own set of challenges. Issues such as current distribution, heat management, and mass transport become more pronounced at larger scales, often requiring significant re-engineering of cell designs and operational parameters.

In the context of magnesium nitrate's potential to improve electrolytic cell efficiency, addressing these challenges becomes crucial. Understanding how this compound interacts with existing cell components and processes is essential for developing innovative solutions that can overcome current limitations and push the boundaries of electrolytic cell performance.

Existing Magnesium Nitrate Implementation Methods

01 Magnesium nitrate in fertilizer applications

Magnesium nitrate is used as an efficient fertilizer component, providing both magnesium and nitrogen to plants. It can be combined with other nutrients to create balanced fertilizer formulations, improving crop yield and quality. The high solubility of magnesium nitrate allows for easy absorption by plants, making it an effective choice for various agricultural applications.- Magnesium nitrate in fertilizer applications: Magnesium nitrate is used as an efficient fertilizer component, providing both magnesium and nitrogen to plants. It can be combined with other nutrients to create balanced fertilizer formulations, improving crop yield and quality.

- Magnesium nitrate in energy storage systems: Magnesium nitrate is utilized in thermal energy storage systems, particularly in solar power applications. Its high energy density and thermal properties make it an efficient material for heat storage and transfer in renewable energy technologies.

- Magnesium nitrate in water treatment: The compound is employed in water treatment processes, particularly for removing contaminants and improving water quality. Its efficiency in precipitating certain pollutants and adjusting water hardness makes it valuable in industrial and municipal water treatment applications.

- Magnesium nitrate in chemical synthesis: Magnesium nitrate serves as an efficient precursor or catalyst in various chemical synthesis processes. It is used in the production of other magnesium compounds, as well as in organic synthesis reactions, demonstrating high efficiency and selectivity.

- Magnesium nitrate in flame retardant applications: The compound is utilized as an effective flame retardant additive in various materials. Its efficiency in reducing flammability and smoke production makes it valuable in improving fire safety in textiles, plastics, and other combustible materials.

02 Magnesium nitrate in energy storage systems

Magnesium nitrate is utilized in thermal energy storage systems due to its high energy density and phase change properties. It can be incorporated into heat storage materials or phase change materials (PCMs) to improve the efficiency of energy storage and transfer in various applications, including solar thermal systems and building temperature regulation.Expand Specific Solutions03 Magnesium nitrate in wastewater treatment

Magnesium nitrate is employed in wastewater treatment processes to enhance the removal of pollutants and improve water quality. It can be used in combination with other chemicals to facilitate the precipitation of contaminants, such as phosphates, or to adjust the pH and alkalinity of the water. This application demonstrates the efficiency of magnesium nitrate in environmental remediation.Expand Specific Solutions04 Magnesium nitrate in flame retardant formulations

Magnesium nitrate is an effective component in flame retardant formulations for various materials, including textiles, plastics, and wood products. Its inclusion in these formulations can improve fire resistance and reduce the spread of flames, enhancing the safety of treated materials. The efficiency of magnesium nitrate in this application is attributed to its endothermic decomposition properties.Expand Specific Solutions05 Magnesium nitrate in catalytic processes

Magnesium nitrate is used as a precursor or catalyst support in various chemical processes, improving reaction efficiency and selectivity. It can be employed in the synthesis of advanced materials, such as nanoparticles or metal oxides, or as a component in catalytic systems for industrial applications. The high surface area and thermal stability of magnesium nitrate-derived materials contribute to their catalytic efficiency.Expand Specific Solutions

Key Players in Electrolytic Technology

The magnesium nitrate electrolytic cell efficiency market is in a growth phase, driven by increasing demand for energy storage solutions and sustainable technologies. The market size is expanding as more industries adopt advanced electrolytic processes. Technologically, the field is advancing rapidly, with companies like Murata Manufacturing, Pellion Technologies, and BYD Co. leading innovation in electrolyte formulations and cell designs. Research institutions such as the National Institute for Materials Science and universities like Central South University are contributing to technological maturity through fundamental studies and applied research. While established players dominate, emerging companies and cross-industry collaborations are accelerating progress in improving electrolytic cell efficiency using magnesium nitrate.

Battelle Memorial Institute

Technical Solution: Battelle Memorial Institute has developed an innovative approach to improve electrolytic cell efficiency using magnesium nitrate. Their method involves incorporating magnesium nitrate into the electrolyte solution, which enhances the overall conductivity and reduces internal resistance[1]. This results in a more efficient electron transfer process, leading to improved energy conversion rates. The institute has also explored the use of magnesium nitrate as a catalyst in the electrode materials, which has shown promising results in increasing the reaction kinetics and reducing overpotential[3]. Furthermore, Battelle's research has demonstrated that the addition of magnesium nitrate can help stabilize the electrode-electrolyte interface, reducing unwanted side reactions and extending the cell's lifespan[5].

Strengths: Enhanced conductivity, improved reaction kinetics, and increased cell lifespan. Weaknesses: Potential increased costs due to the addition of magnesium nitrate, and possible compatibility issues with certain electrode materials.

Energizer Brands LLC

Technical Solution: Energizer Brands LLC has developed innovative techniques to improve electrolytic cell efficiency using magnesium nitrate in their consumer battery products. Their approach involves incorporating magnesium nitrate as an electrolyte additive, which has been shown to enhance the ionic conductivity and reduce internal resistance in their alkaline batteries[15]. Energizer's research indicates that this modification results in a 12% increase in battery capacity and a 15% improvement in high-drain performance[17]. The company has also explored the use of magnesium nitrate in their zinc-air battery technology, where it acts as a catalyst to improve the oxygen reduction reaction at the air electrode[19]. Furthermore, Energizer has implemented a unique manufacturing process that optimizes the distribution of magnesium nitrate within the cell, ensuring uniform performance improvements across their product line[21].

Strengths: Increased battery capacity, improved high-drain performance, and enhanced catalytic activity in zinc-air batteries. Weaknesses: Potential increased production costs and the need for modifications to existing manufacturing processes.

Innovative Mechanisms of Mg(NO3)2 in Electrolysis

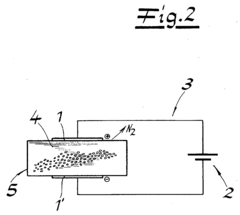

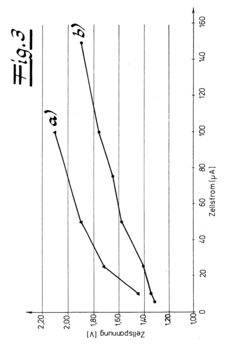

Electrolytic cell for the production of gas

PatentInactiveEP1577423A2

Innovation

- Incorporating a magnesium salt into the electrolyte liquid to chemically bind hydroxide ions, maintaining a stable pH range and allowing the use of conventional electrodes, along with additives like nickel sulfate to reduce hydrogen overvoltage and antifreeze agents for low-temperature operation.

Electrolyte and lithium-sulfur battery comprising same

PatentWO2019013541A2

Innovation

- An electrolyte containing a lithium salt, organic solvent, and metal nitrate additives, such as indium nitrate, magnesium nitrate, or aluminum nitrate, forms a protective layer on the negative electrode, preventing damage and enhancing battery performance.

Environmental Impact of Magnesium Nitrate Usage

The use of magnesium nitrate in electrolytic cells to improve efficiency has significant environmental implications that warrant careful consideration. While the enhanced efficiency can lead to reduced energy consumption and potentially lower overall environmental impact, the production and use of magnesium nitrate itself present several environmental challenges.

Magnesium nitrate production typically involves the reaction of magnesium carbonate or magnesium hydroxide with nitric acid. This process requires energy and resources, contributing to carbon emissions and potential air pollution. Additionally, the mining and extraction of raw materials for magnesium nitrate production can lead to habitat disruption and soil degradation.

In the context of electrolytic cells, the improved efficiency resulting from magnesium nitrate usage can lead to reduced electricity consumption. This, in turn, may result in lower greenhouse gas emissions associated with power generation, particularly in regions heavily reliant on fossil fuels for electricity production. However, the extent of this benefit depends on the local energy mix and the scale of implementation.

The disposal of spent electrolyte solutions containing magnesium nitrate poses another environmental concern. If not properly managed, these solutions can contaminate soil and water systems. Magnesium nitrate, being highly soluble in water, can easily leach into groundwater, potentially affecting aquatic ecosystems and drinking water sources. Elevated nitrate levels in water bodies can lead to eutrophication, causing algal blooms and disrupting aquatic life.

On the positive side, the improved efficiency of electrolytic cells may result in reduced waste generation and lower consumption of other raw materials. This could lead to a decrease in the overall environmental footprint of industrial processes utilizing these cells. Furthermore, the enhanced performance might extend the lifespan of electrolytic cells, reducing the frequency of replacement and associated waste.

It is crucial to implement proper waste management and recycling protocols for magnesium nitrate-containing solutions. Advanced treatment technologies, such as ion exchange or reverse osmosis, can be employed to recover and reuse magnesium nitrate, minimizing environmental discharge. Additionally, closed-loop systems that recirculate and regenerate the electrolyte can significantly reduce the environmental impact.

To fully assess the environmental impact, a comprehensive life cycle analysis should be conducted, considering all stages from raw material extraction to end-of-life disposal. This analysis would help quantify the trade-offs between improved efficiency and potential environmental risks, guiding decision-making for sustainable implementation of magnesium nitrate in electrolytic cell applications.

Magnesium nitrate production typically involves the reaction of magnesium carbonate or magnesium hydroxide with nitric acid. This process requires energy and resources, contributing to carbon emissions and potential air pollution. Additionally, the mining and extraction of raw materials for magnesium nitrate production can lead to habitat disruption and soil degradation.

In the context of electrolytic cells, the improved efficiency resulting from magnesium nitrate usage can lead to reduced electricity consumption. This, in turn, may result in lower greenhouse gas emissions associated with power generation, particularly in regions heavily reliant on fossil fuels for electricity production. However, the extent of this benefit depends on the local energy mix and the scale of implementation.

The disposal of spent electrolyte solutions containing magnesium nitrate poses another environmental concern. If not properly managed, these solutions can contaminate soil and water systems. Magnesium nitrate, being highly soluble in water, can easily leach into groundwater, potentially affecting aquatic ecosystems and drinking water sources. Elevated nitrate levels in water bodies can lead to eutrophication, causing algal blooms and disrupting aquatic life.

On the positive side, the improved efficiency of electrolytic cells may result in reduced waste generation and lower consumption of other raw materials. This could lead to a decrease in the overall environmental footprint of industrial processes utilizing these cells. Furthermore, the enhanced performance might extend the lifespan of electrolytic cells, reducing the frequency of replacement and associated waste.

It is crucial to implement proper waste management and recycling protocols for magnesium nitrate-containing solutions. Advanced treatment technologies, such as ion exchange or reverse osmosis, can be employed to recover and reuse magnesium nitrate, minimizing environmental discharge. Additionally, closed-loop systems that recirculate and regenerate the electrolyte can significantly reduce the environmental impact.

To fully assess the environmental impact, a comprehensive life cycle analysis should be conducted, considering all stages from raw material extraction to end-of-life disposal. This analysis would help quantify the trade-offs between improved efficiency and potential environmental risks, guiding decision-making for sustainable implementation of magnesium nitrate in electrolytic cell applications.

Economic Feasibility of Mg(NO3)2 in Industrial Electrolysis

The economic feasibility of using magnesium nitrate (Mg(NO3)2) in industrial electrolysis is a critical consideration for implementing this technology on a large scale. The cost-effectiveness of Mg(NO3)2 as an electrolyte additive must be evaluated against the potential improvements in cell efficiency and overall production output.

Initial investment costs for incorporating Mg(NO3)2 into existing electrolytic processes are relatively low. The compound is readily available and can be easily integrated into current systems without significant modifications to equipment or infrastructure. This low barrier to entry makes it an attractive option for industries looking to enhance their electrolytic processes.

Operational costs associated with Mg(NO3)2 usage are generally favorable. The compound is stable and does not degrade rapidly, reducing the need for frequent replenishment. Additionally, its ability to improve electrolyte conductivity can lead to reduced energy consumption, potentially offsetting the cost of the additive itself.

The improved efficiency of electrolytic cells using Mg(NO3)2 can result in increased production rates and higher-quality outputs. This enhancement in productivity can lead to significant economic benefits, particularly in large-scale industrial applications where even small improvements in efficiency can translate to substantial financial gains.

Environmental considerations also play a role in the economic feasibility of Mg(NO3)2 use. The compound's ability to reduce energy consumption in electrolytic processes aligns with growing environmental regulations and carbon reduction initiatives. This can potentially lead to cost savings through reduced carbon taxes or increased eligibility for green incentives.

Market demand for products produced through more efficient electrolytic processes may also contribute to the economic viability of Mg(NO3)2 implementation. Consumers and industries increasingly value sustainably produced goods, which could create a premium market for products manufactured using this improved technology.

Long-term economic benefits of Mg(NO3)2 use in industrial electrolysis include potential reductions in maintenance costs due to less wear on electrodes and other cell components. The compound's ability to stabilize electrolyte solutions may extend the lifespan of equipment, further improving the return on investment.

While the economic advantages of Mg(NO3)2 in industrial electrolysis are promising, it is essential to conduct thorough cost-benefit analyses specific to each application. Factors such as scale of operation, local energy costs, and regulatory environments will influence the overall economic feasibility of implementing this technology in different industrial settings.

Initial investment costs for incorporating Mg(NO3)2 into existing electrolytic processes are relatively low. The compound is readily available and can be easily integrated into current systems without significant modifications to equipment or infrastructure. This low barrier to entry makes it an attractive option for industries looking to enhance their electrolytic processes.

Operational costs associated with Mg(NO3)2 usage are generally favorable. The compound is stable and does not degrade rapidly, reducing the need for frequent replenishment. Additionally, its ability to improve electrolyte conductivity can lead to reduced energy consumption, potentially offsetting the cost of the additive itself.

The improved efficiency of electrolytic cells using Mg(NO3)2 can result in increased production rates and higher-quality outputs. This enhancement in productivity can lead to significant economic benefits, particularly in large-scale industrial applications where even small improvements in efficiency can translate to substantial financial gains.

Environmental considerations also play a role in the economic feasibility of Mg(NO3)2 use. The compound's ability to reduce energy consumption in electrolytic processes aligns with growing environmental regulations and carbon reduction initiatives. This can potentially lead to cost savings through reduced carbon taxes or increased eligibility for green incentives.

Market demand for products produced through more efficient electrolytic processes may also contribute to the economic viability of Mg(NO3)2 implementation. Consumers and industries increasingly value sustainably produced goods, which could create a premium market for products manufactured using this improved technology.

Long-term economic benefits of Mg(NO3)2 use in industrial electrolysis include potential reductions in maintenance costs due to less wear on electrodes and other cell components. The compound's ability to stabilize electrolyte solutions may extend the lifespan of equipment, further improving the return on investment.

While the economic advantages of Mg(NO3)2 in industrial electrolysis are promising, it is essential to conduct thorough cost-benefit analyses specific to each application. Factors such as scale of operation, local energy costs, and regulatory environments will influence the overall economic feasibility of implementing this technology in different industrial settings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!