Investigating Magnesium Nitrate as a Fire Retardant in Materials Science

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Nitrate FR Background and Objectives

Fire safety has been a critical concern in materials science for decades, with researchers continuously seeking innovative solutions to enhance the fire resistance of various materials. In recent years, magnesium nitrate has emerged as a promising candidate for fire retardant applications, drawing significant attention from both academia and industry. This technological evolution stems from the growing need for more effective, environmentally friendly, and cost-efficient fire retardant solutions.

The development of magnesium nitrate as a fire retardant is rooted in the broader context of inorganic salt-based flame retardants. These compounds have gained traction due to their ability to form protective char layers, release non-flammable gases, and absorb heat during combustion processes. Magnesium nitrate, in particular, has shown potential for its unique combination of properties that contribute to fire retardancy.

The primary objective of investigating magnesium nitrate as a fire retardant is to address the limitations of current flame retardant technologies. Traditional halogenated flame retardants, while effective, have faced scrutiny due to environmental and health concerns. This has led to a shift towards more sustainable alternatives, with magnesium nitrate positioned as a potential solution that balances efficacy with environmental responsibility.

Research into magnesium nitrate as a fire retardant aims to achieve several key goals. Firstly, it seeks to understand the fundamental mechanisms by which magnesium nitrate imparts fire resistance to materials. This includes studying its thermal decomposition behavior, char-forming capabilities, and interactions with various polymer matrices. Secondly, researchers are working to optimize the incorporation of magnesium nitrate into different materials, exploring various methods such as surface treatments, bulk addition, and nanocomposite formulations.

Another crucial objective is to evaluate the performance of magnesium nitrate-based fire retardants across a wide range of materials and applications. This includes assessing its effectiveness in polymers, textiles, coatings, and construction materials. Researchers are also investigating potential synergistic effects when magnesium nitrate is combined with other fire retardant additives, aiming to develop more robust and versatile flame retardant systems.

As the field progresses, there is a growing focus on addressing practical challenges associated with the use of magnesium nitrate as a fire retardant. This includes improving its compatibility with different material systems, enhancing its long-term stability, and minimizing any negative impacts on the mechanical or aesthetic properties of the host materials. Additionally, researchers are exploring ways to scale up production and application methods to facilitate the widespread adoption of magnesium nitrate-based fire retardants in commercial products.

The development of magnesium nitrate as a fire retardant is rooted in the broader context of inorganic salt-based flame retardants. These compounds have gained traction due to their ability to form protective char layers, release non-flammable gases, and absorb heat during combustion processes. Magnesium nitrate, in particular, has shown potential for its unique combination of properties that contribute to fire retardancy.

The primary objective of investigating magnesium nitrate as a fire retardant is to address the limitations of current flame retardant technologies. Traditional halogenated flame retardants, while effective, have faced scrutiny due to environmental and health concerns. This has led to a shift towards more sustainable alternatives, with magnesium nitrate positioned as a potential solution that balances efficacy with environmental responsibility.

Research into magnesium nitrate as a fire retardant aims to achieve several key goals. Firstly, it seeks to understand the fundamental mechanisms by which magnesium nitrate imparts fire resistance to materials. This includes studying its thermal decomposition behavior, char-forming capabilities, and interactions with various polymer matrices. Secondly, researchers are working to optimize the incorporation of magnesium nitrate into different materials, exploring various methods such as surface treatments, bulk addition, and nanocomposite formulations.

Another crucial objective is to evaluate the performance of magnesium nitrate-based fire retardants across a wide range of materials and applications. This includes assessing its effectiveness in polymers, textiles, coatings, and construction materials. Researchers are also investigating potential synergistic effects when magnesium nitrate is combined with other fire retardant additives, aiming to develop more robust and versatile flame retardant systems.

As the field progresses, there is a growing focus on addressing practical challenges associated with the use of magnesium nitrate as a fire retardant. This includes improving its compatibility with different material systems, enhancing its long-term stability, and minimizing any negative impacts on the mechanical or aesthetic properties of the host materials. Additionally, researchers are exploring ways to scale up production and application methods to facilitate the widespread adoption of magnesium nitrate-based fire retardants in commercial products.

Market Analysis for Fire Retardant Materials

The global fire retardant materials market has been experiencing steady growth, driven by increasing safety regulations and growing awareness of fire hazards across various industries. The market size for fire retardant materials was valued at approximately $7.5 billion in 2020 and is projected to reach $10.3 billion by 2025, with a compound annual growth rate (CAGR) of 6.5%.

The construction sector remains the largest consumer of fire retardant materials, accounting for nearly 40% of the market share. This is primarily due to stringent building codes and regulations mandating the use of fire-resistant materials in residential and commercial structures. The automotive and aerospace industries are also significant contributors to market growth, as manufacturers seek to enhance passenger safety and comply with transportation safety standards.

In recent years, there has been a notable shift towards environmentally friendly and sustainable fire retardant solutions. This trend is driven by increasing environmental concerns and regulatory pressures to reduce the use of halogenated flame retardants, which have been associated with potential health and ecological risks. As a result, manufacturers are investing in research and development of eco-friendly alternatives, including inorganic compounds like magnesium nitrate.

The Asia-Pacific region is expected to witness the highest growth rate in the fire retardant materials market, with China and India leading the expansion. This growth is attributed to rapid industrialization, urbanization, and the implementation of stricter fire safety regulations in these countries. North America and Europe continue to be significant markets, driven by ongoing infrastructure development and renovation projects.

Key players in the fire retardant materials market include BASF SE, Clariant AG, Dow Inc., and Lanxess AG. These companies are focusing on product innovation and strategic partnerships to maintain their competitive edge. The introduction of novel fire retardant solutions, such as those based on magnesium nitrate, presents opportunities for market expansion and differentiation.

Challenges facing the fire retardant materials market include the high cost of advanced fire-resistant materials and the complexity of integrating these materials into existing manufacturing processes. However, the increasing emphasis on fire safety across industries and the potential for cost savings through improved fire protection are expected to drive continued market growth and innovation in the coming years.

The construction sector remains the largest consumer of fire retardant materials, accounting for nearly 40% of the market share. This is primarily due to stringent building codes and regulations mandating the use of fire-resistant materials in residential and commercial structures. The automotive and aerospace industries are also significant contributors to market growth, as manufacturers seek to enhance passenger safety and comply with transportation safety standards.

In recent years, there has been a notable shift towards environmentally friendly and sustainable fire retardant solutions. This trend is driven by increasing environmental concerns and regulatory pressures to reduce the use of halogenated flame retardants, which have been associated with potential health and ecological risks. As a result, manufacturers are investing in research and development of eco-friendly alternatives, including inorganic compounds like magnesium nitrate.

The Asia-Pacific region is expected to witness the highest growth rate in the fire retardant materials market, with China and India leading the expansion. This growth is attributed to rapid industrialization, urbanization, and the implementation of stricter fire safety regulations in these countries. North America and Europe continue to be significant markets, driven by ongoing infrastructure development and renovation projects.

Key players in the fire retardant materials market include BASF SE, Clariant AG, Dow Inc., and Lanxess AG. These companies are focusing on product innovation and strategic partnerships to maintain their competitive edge. The introduction of novel fire retardant solutions, such as those based on magnesium nitrate, presents opportunities for market expansion and differentiation.

Challenges facing the fire retardant materials market include the high cost of advanced fire-resistant materials and the complexity of integrating these materials into existing manufacturing processes. However, the increasing emphasis on fire safety across industries and the potential for cost savings through improved fire protection are expected to drive continued market growth and innovation in the coming years.

Current Status and Challenges in FR Technology

The current status of fire retardant (FR) technology, particularly in the context of magnesium nitrate, reflects a dynamic field with significant advancements and persistent challenges. Globally, there is an increasing focus on developing more effective and environmentally friendly fire retardants, driven by stringent safety regulations and growing awareness of the environmental impact of traditional FR compounds.

Magnesium nitrate has emerged as a promising candidate in the realm of inorganic fire retardants. Its potential lies in its ability to form a protective char layer when exposed to high temperatures, effectively insulating the underlying material. This mechanism aligns with the broader trend in FR technology towards intumescent systems, which expand and carbonize under heat to provide enhanced fire protection.

However, the integration of magnesium nitrate into various materials presents several technical hurdles. One primary challenge is achieving uniform dispersion within polymer matrices, crucial for consistent fire retardant performance. Researchers are exploring various techniques, including nanoencapsulation and surface modification, to improve compatibility and distribution.

Another significant obstacle is the potential impact of magnesium nitrate on the mechanical properties of host materials. While effective as a fire retardant, it can sometimes lead to reduced strength or flexibility in the final product. This necessitates careful balancing of FR efficacy with material performance, a common theme in current FR research.

The hygroscopic nature of magnesium nitrate poses additional challenges, particularly in applications where moisture sensitivity is a concern. Efforts are underway to develop moisture-resistant formulations or protective coatings to mitigate this issue, reflecting the broader industry trend towards more robust and versatile FR solutions.

From a regulatory perspective, the push towards halogen-free flame retardants has accelerated research into inorganic alternatives like magnesium nitrate. This shift is driven by environmental concerns and stricter regulations on persistent organic pollutants. However, meeting diverse international standards while maintaining cost-effectiveness remains a significant challenge for manufacturers.

In terms of geographical distribution, research on magnesium nitrate as a fire retardant is gaining traction globally. European countries, with their stringent fire safety regulations, are at the forefront of this research. Asian countries, particularly China and Japan, are also making significant contributions, driven by their large manufacturing sectors and growing emphasis on fire safety in construction and consumer goods.

The scalability of magnesium nitrate-based FR solutions presents another hurdle. While promising results have been achieved in laboratory settings, translating these into large-scale, cost-effective production processes is an ongoing challenge. This reflects a broader issue in the FR industry, where bridging the gap between research findings and commercial viability often requires substantial investment and technological innovation.

Magnesium nitrate has emerged as a promising candidate in the realm of inorganic fire retardants. Its potential lies in its ability to form a protective char layer when exposed to high temperatures, effectively insulating the underlying material. This mechanism aligns with the broader trend in FR technology towards intumescent systems, which expand and carbonize under heat to provide enhanced fire protection.

However, the integration of magnesium nitrate into various materials presents several technical hurdles. One primary challenge is achieving uniform dispersion within polymer matrices, crucial for consistent fire retardant performance. Researchers are exploring various techniques, including nanoencapsulation and surface modification, to improve compatibility and distribution.

Another significant obstacle is the potential impact of magnesium nitrate on the mechanical properties of host materials. While effective as a fire retardant, it can sometimes lead to reduced strength or flexibility in the final product. This necessitates careful balancing of FR efficacy with material performance, a common theme in current FR research.

The hygroscopic nature of magnesium nitrate poses additional challenges, particularly in applications where moisture sensitivity is a concern. Efforts are underway to develop moisture-resistant formulations or protective coatings to mitigate this issue, reflecting the broader industry trend towards more robust and versatile FR solutions.

From a regulatory perspective, the push towards halogen-free flame retardants has accelerated research into inorganic alternatives like magnesium nitrate. This shift is driven by environmental concerns and stricter regulations on persistent organic pollutants. However, meeting diverse international standards while maintaining cost-effectiveness remains a significant challenge for manufacturers.

In terms of geographical distribution, research on magnesium nitrate as a fire retardant is gaining traction globally. European countries, with their stringent fire safety regulations, are at the forefront of this research. Asian countries, particularly China and Japan, are also making significant contributions, driven by their large manufacturing sectors and growing emphasis on fire safety in construction and consumer goods.

The scalability of magnesium nitrate-based FR solutions presents another hurdle. While promising results have been achieved in laboratory settings, translating these into large-scale, cost-effective production processes is an ongoing challenge. This reflects a broader issue in the FR industry, where bridging the gap between research findings and commercial viability often requires substantial investment and technological innovation.

Existing Magnesium Nitrate FR Solutions

01 Use of magnesium nitrate in fire retardant compositions

Magnesium nitrate is utilized as a key component in fire retardant compositions due to its ability to release non-flammable gases and form a protective char layer when exposed to heat. These compositions can be applied to various materials to enhance their fire resistance properties.- Use of magnesium nitrate as a fire retardant: Magnesium nitrate is utilized as an effective fire retardant in various applications. It can be incorporated into materials to enhance their fire resistance properties. The compound works by releasing non-flammable gases when exposed to high temperatures, which helps to suppress combustion and slow down the spread of fire.

- Combination with other fire retardant compounds: Magnesium nitrate is often combined with other fire retardant compounds to create synergistic effects and improve overall fire resistance. These combinations can include other inorganic salts, phosphorus-based compounds, or nitrogen-containing substances. The resulting mixtures can provide enhanced fire protection across a wider range of materials and conditions.

- Application in textile and fabric treatments: Magnesium nitrate is used in fire retardant treatments for textiles and fabrics. It can be applied as a coating or incorporated into the fiber structure during manufacturing. This treatment helps to reduce the flammability of textiles, making them safer for use in various applications such as clothing, upholstery, and industrial fabrics.

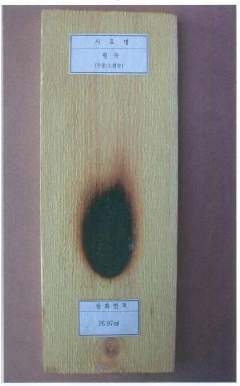

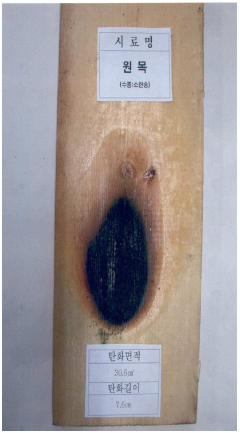

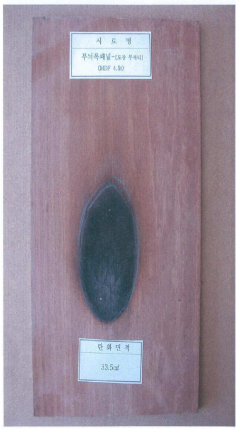

- Incorporation into building materials: Magnesium nitrate is incorporated into various building materials to enhance their fire resistance properties. It can be added to concrete, wood products, and insulation materials. This application helps to improve the overall fire safety of buildings and structures, potentially slowing down the spread of fire and providing additional time for evacuation.

- Use in intumescent coatings: Magnesium nitrate is utilized in the formulation of intumescent coatings, which are designed to expand and form a protective char layer when exposed to high temperatures. These coatings can be applied to various surfaces, including steel structures, to provide passive fire protection. The inclusion of magnesium nitrate enhances the effectiveness of these coatings in delaying the spread of fire and protecting the underlying material.

02 Synergistic effects with other fire retardant additives

Magnesium nitrate is often combined with other fire retardant additives to create synergistic effects, enhancing overall fire retardancy. These combinations can include phosphorus-based compounds, boron-based additives, or other inorganic salts, resulting in improved flame resistance and reduced smoke generation.Expand Specific Solutions03 Application in textile and fabric treatments

Magnesium nitrate is used in fire retardant treatments for textiles and fabrics. It can be applied through various methods such as impregnation, coating, or incorporation into fiber materials during manufacturing processes, providing durable flame-resistant properties to the treated materials.Expand Specific Solutions04 Incorporation in polymer-based fire retardant systems

Magnesium nitrate is incorporated into polymer-based fire retardant systems, including thermoplastics and thermosets. It can be blended with the polymer matrix or used as a surface treatment to improve the fire resistance of plastic materials, composites, and coatings.Expand Specific Solutions05 Use in intumescent coatings and formulations

Magnesium nitrate is employed in intumescent coatings and formulations, which expand and form a protective char layer when exposed to heat. These coatings can be applied to various substrates, including steel structures, wood, and plastics, to provide enhanced fire protection and thermal insulation properties.Expand Specific Solutions

Key Players in FR Materials Industry

The investigation of magnesium nitrate as a fire retardant in materials science is currently in a growth phase, with increasing market demand driven by stringent fire safety regulations across industries. The global fire retardant market is expanding, with projections indicating substantial growth in the coming years. Technologically, the field is advancing rapidly, with companies like Sumitomo Electric Industries, Konoshima Chemical, and Otsuka Chemical leading research efforts. These firms are developing innovative applications and improving the efficacy of magnesium nitrate-based fire retardants. Academic institutions such as Taiyuan University of Technology and the University of Southern Mississippi are also contributing to the advancement of this technology, fostering collaborations between industry and academia to enhance fire safety solutions.

Konoshima Chemical Co., Ltd.

Technical Solution: Konoshima Chemical has developed an innovative magnesium nitrate-based fire retardant solution for materials science applications. Their approach involves incorporating magnesium nitrate into polymer matrices, creating a synergistic effect that enhances fire resistance. The company's research has shown that magnesium nitrate can form a protective char layer when exposed to high temperatures, effectively reducing heat transfer and flame spread[1]. Additionally, they have optimized the particle size distribution of magnesium nitrate to improve its dispersion within various materials, resulting in more uniform fire protection[3]. Konoshima's technology also addresses environmental concerns by ensuring the fire retardant formulation is halogen-free and low in toxicity[5].

Strengths: Effective char formation, improved dispersion in materials, environmentally friendly. Weaknesses: May affect material properties, potential for water absorption in humid conditions.

Otsuka Chemical Co., Ltd.

Technical Solution: Otsuka Chemical has pioneered a magnesium nitrate-based fire retardant system that focuses on intumescent technology. Their approach involves combining magnesium nitrate with other synergistic additives to create a multi-layered fire protection mechanism. When exposed to fire, the intumescent coating expands to form a thick, insulating char layer that protects the underlying material[2]. Otsuka's research has demonstrated that their magnesium nitrate formulation can achieve a UL94 V-0 rating in various polymer systems, indicating excellent flame retardancy[4]. The company has also developed a proprietary encapsulation technique for magnesium nitrate particles, which improves their stability and reduces potential negative interactions with the base material[6].

Strengths: High-performance intumescent protection, achieved UL94 V-0 rating, improved stability through encapsulation. Weaknesses: Potentially higher cost due to complex formulation, may require higher loading levels in some materials.

Core Innovations in Mg(NO3)2 FR Technology

Fire retardant compositions with mold inhibitor

PatentInactiveCA2499114A1

Innovation

- A fire retardant composition combining ammonium phosphate with a nitrogenous spumific and hydroxyl-containing carbonific, along with a mold inhibitor, forming a clear, aqueous solution that can be applied directly to materials, providing both fire retardancy and mold control.

Flame retardant composition soluble in water, method for preparing the same, and flameproof process using the same

PatentInactiveKR1020080086294A

Innovation

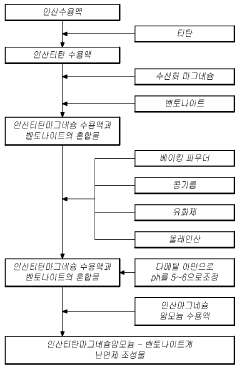

- A magnesium titanium phosphate-bentonite-based water-soluble flame retardant composition is developed, comprising magnesium ammonium phosphate, bentonite, soybean oil, baking powder, emulsifier, oleic acid, and dimethylamine, which synergistically delays ignition, suppresses smoke and toxic gas generation, and provides heat resistance.

Environmental Impact of FR Additives

The environmental impact of fire retardant (FR) additives, particularly magnesium nitrate, is a critical consideration in materials science. As the use of fire retardants becomes more widespread, their potential effects on ecosystems and human health have come under increased scrutiny.

Magnesium nitrate, when used as a fire retardant, presents both advantages and challenges from an environmental perspective. One of its primary benefits is its relatively low toxicity compared to some other FR additives. Unlike halogenated flame retardants, which have been associated with bioaccumulation and persistent environmental contamination, magnesium nitrate is generally considered less harmful to aquatic and terrestrial ecosystems.

However, the release of nitrates into the environment can lead to eutrophication in water bodies. This process occurs when excess nutrients stimulate algal growth, potentially leading to oxygen depletion and adverse effects on aquatic life. Therefore, the application of magnesium nitrate as a fire retardant must be carefully managed to minimize runoff into water systems.

The production and disposal of magnesium nitrate also have environmental implications. The manufacturing process requires energy and resources, contributing to carbon emissions and resource depletion. End-of-life considerations for materials treated with magnesium nitrate are equally important, as improper disposal can lead to soil and water contamination.

On the positive side, magnesium nitrate is a mineral-based flame retardant, which aligns with the growing trend towards more sustainable and bio-based materials in the industry. Its effectiveness as a fire retardant can potentially reduce the overall environmental impact of fires, which can release a wide range of toxic substances and contribute significantly to air pollution.

Research into the long-term environmental effects of magnesium nitrate is ongoing. Studies are examining its potential impact on soil microbial communities, plant growth, and groundwater quality. The results of these investigations will be crucial in determining the overall environmental sustainability of magnesium nitrate as a fire retardant.

In the context of lifecycle assessment, the use of magnesium nitrate as a fire retardant must be evaluated against alternative FR additives and the potential environmental costs of fire damage. This holistic approach considers not only the immediate impacts but also the broader environmental consequences throughout the material's lifecycle.

As regulations around fire retardants continue to evolve, with a focus on reducing environmental harm, the role of magnesium nitrate in materials science may change. Future developments may include encapsulation technologies to further reduce leaching, or the development of synergistic combinations with other environmentally friendly additives to enhance performance while minimizing environmental impact.

Magnesium nitrate, when used as a fire retardant, presents both advantages and challenges from an environmental perspective. One of its primary benefits is its relatively low toxicity compared to some other FR additives. Unlike halogenated flame retardants, which have been associated with bioaccumulation and persistent environmental contamination, magnesium nitrate is generally considered less harmful to aquatic and terrestrial ecosystems.

However, the release of nitrates into the environment can lead to eutrophication in water bodies. This process occurs when excess nutrients stimulate algal growth, potentially leading to oxygen depletion and adverse effects on aquatic life. Therefore, the application of magnesium nitrate as a fire retardant must be carefully managed to minimize runoff into water systems.

The production and disposal of magnesium nitrate also have environmental implications. The manufacturing process requires energy and resources, contributing to carbon emissions and resource depletion. End-of-life considerations for materials treated with magnesium nitrate are equally important, as improper disposal can lead to soil and water contamination.

On the positive side, magnesium nitrate is a mineral-based flame retardant, which aligns with the growing trend towards more sustainable and bio-based materials in the industry. Its effectiveness as a fire retardant can potentially reduce the overall environmental impact of fires, which can release a wide range of toxic substances and contribute significantly to air pollution.

Research into the long-term environmental effects of magnesium nitrate is ongoing. Studies are examining its potential impact on soil microbial communities, plant growth, and groundwater quality. The results of these investigations will be crucial in determining the overall environmental sustainability of magnesium nitrate as a fire retardant.

In the context of lifecycle assessment, the use of magnesium nitrate as a fire retardant must be evaluated against alternative FR additives and the potential environmental costs of fire damage. This holistic approach considers not only the immediate impacts but also the broader environmental consequences throughout the material's lifecycle.

As regulations around fire retardants continue to evolve, with a focus on reducing environmental harm, the role of magnesium nitrate in materials science may change. Future developments may include encapsulation technologies to further reduce leaching, or the development of synergistic combinations with other environmentally friendly additives to enhance performance while minimizing environmental impact.

Fire Safety Standards and Regulations

Fire safety standards and regulations play a crucial role in ensuring the effective implementation and use of fire retardants, including magnesium nitrate, in materials science. These standards are designed to protect lives, property, and the environment by establishing minimum requirements for fire safety in various applications.

In the context of magnesium nitrate as a fire retardant, several key standards and regulations come into play. The International Building Code (IBC) and International Fire Code (IFC) provide comprehensive guidelines for fire safety in buildings and structures. These codes often reference specific standards developed by organizations such as the National Fire Protection Association (NFPA) and ASTM International.

NFPA 701, for instance, outlines the standard methods of fire tests for flame propagation of textiles and films. This standard is particularly relevant when evaluating the effectiveness of magnesium nitrate as a fire retardant in fabric and film applications. Similarly, ASTM E84 provides a standard test method for surface burning characteristics of building materials, which can be applied to materials treated with magnesium nitrate.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is another important consideration. It requires manufacturers and importers to assess and manage the risks associated with chemicals they produce or import, including fire retardants like magnesium nitrate. This regulation ensures that potential health and environmental impacts are thoroughly evaluated before a substance can be widely used in the EU market.

In the United States, the Environmental Protection Agency (EPA) regulates fire retardants under the Toxic Substances Control Act (TSCA). This act requires manufacturers to submit premanufacture notices for new chemical substances, including novel fire retardant formulations. The EPA evaluates these notices to determine potential risks to human health and the environment.

Specific to building materials, the European Standard EN 13501-1 classifies construction products and building elements according to their reaction to fire performance. This standard is crucial for determining the fire safety classification of materials treated with magnesium nitrate or other fire retardants.

It's important to note that fire safety standards and regulations are continually evolving as new research emerges and technologies advance. Researchers and manufacturers working with magnesium nitrate as a fire retardant must stay abreast of these changes to ensure compliance and optimize their formulations to meet or exceed current requirements.

Furthermore, different countries and regions may have their own specific standards and regulations. For example, Australia and New Zealand follow the AS/NZS 1530 series of fire test standards, which may have different requirements compared to European or North American standards. This diversity in regulations underscores the importance of a comprehensive understanding of global fire safety standards when developing and implementing fire retardant solutions using magnesium nitrate.

In the context of magnesium nitrate as a fire retardant, several key standards and regulations come into play. The International Building Code (IBC) and International Fire Code (IFC) provide comprehensive guidelines for fire safety in buildings and structures. These codes often reference specific standards developed by organizations such as the National Fire Protection Association (NFPA) and ASTM International.

NFPA 701, for instance, outlines the standard methods of fire tests for flame propagation of textiles and films. This standard is particularly relevant when evaluating the effectiveness of magnesium nitrate as a fire retardant in fabric and film applications. Similarly, ASTM E84 provides a standard test method for surface burning characteristics of building materials, which can be applied to materials treated with magnesium nitrate.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is another important consideration. It requires manufacturers and importers to assess and manage the risks associated with chemicals they produce or import, including fire retardants like magnesium nitrate. This regulation ensures that potential health and environmental impacts are thoroughly evaluated before a substance can be widely used in the EU market.

In the United States, the Environmental Protection Agency (EPA) regulates fire retardants under the Toxic Substances Control Act (TSCA). This act requires manufacturers to submit premanufacture notices for new chemical substances, including novel fire retardant formulations. The EPA evaluates these notices to determine potential risks to human health and the environment.

Specific to building materials, the European Standard EN 13501-1 classifies construction products and building elements according to their reaction to fire performance. This standard is crucial for determining the fire safety classification of materials treated with magnesium nitrate or other fire retardants.

It's important to note that fire safety standards and regulations are continually evolving as new research emerges and technologies advance. Researchers and manufacturers working with magnesium nitrate as a fire retardant must stay abreast of these changes to ensure compliance and optimize their formulations to meet or exceed current requirements.

Furthermore, different countries and regions may have their own specific standards and regulations. For example, Australia and New Zealand follow the AS/NZS 1530 series of fire test standards, which may have different requirements compared to European or North American standards. This diversity in regulations underscores the importance of a comprehensive understanding of global fire safety standards when developing and implementing fire retardant solutions using magnesium nitrate.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!