Breakthroughs in miniaturizing submersible pumps for laboratory settings.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Submersible Pump Miniaturization Background and Objectives

Submersible pumps have been an integral part of laboratory equipment for decades, playing a crucial role in various scientific and industrial applications. The miniaturization of these pumps represents a significant technological advancement, addressing the growing demand for more compact and efficient laboratory setups. This trend towards miniaturization aligns with the broader movement in scientific instrumentation, where researchers and manufacturers strive to create more space-efficient and portable devices.

The evolution of submersible pump technology can be traced back to the mid-20th century, with continuous improvements in design, materials, and manufacturing processes. Initially, these pumps were bulky and limited in their applications within laboratory settings. However, as research needs became more specialized and laboratory spaces more constrained, the impetus for smaller, yet equally powerful pumps grew stronger.

The primary objective of miniaturizing submersible pumps for laboratory settings is to enhance the efficiency and versatility of research environments. By reducing the size of these pumps, laboratories can optimize space utilization, allowing for more equipment to be accommodated in limited areas. This is particularly crucial in urban research facilities where space comes at a premium.

Another key goal is to improve the portability of laboratory equipment. Miniaturized submersible pumps enable the development of more mobile research setups, facilitating field studies and on-site experiments. This increased mobility has the potential to revolutionize various fields of scientific research, from environmental studies to medical diagnostics.

The miniaturization process also aims to maintain or even enhance the performance capabilities of these pumps. Engineers and researchers face the challenge of reducing size without compromising on flow rate, pressure, and reliability. This necessitates innovations in materials science, fluid dynamics, and precision engineering.

Furthermore, the drive towards miniaturization is closely linked to the broader trend of lab-on-a-chip technologies. As microfluidic systems become more prevalent in research and diagnostic applications, the demand for compatible, miniaturized pumping solutions has intensified. This convergence of technologies opens up new possibilities for integrated, compact laboratory systems.

The pursuit of miniaturized submersible pumps also aligns with sustainability goals in scientific research. Smaller pumps typically consume less energy and require fewer materials to manufacture, contributing to more environmentally friendly laboratory practices. This aspect is increasingly important as research institutions worldwide strive to reduce their carbon footprint and operational costs.

The evolution of submersible pump technology can be traced back to the mid-20th century, with continuous improvements in design, materials, and manufacturing processes. Initially, these pumps were bulky and limited in their applications within laboratory settings. However, as research needs became more specialized and laboratory spaces more constrained, the impetus for smaller, yet equally powerful pumps grew stronger.

The primary objective of miniaturizing submersible pumps for laboratory settings is to enhance the efficiency and versatility of research environments. By reducing the size of these pumps, laboratories can optimize space utilization, allowing for more equipment to be accommodated in limited areas. This is particularly crucial in urban research facilities where space comes at a premium.

Another key goal is to improve the portability of laboratory equipment. Miniaturized submersible pumps enable the development of more mobile research setups, facilitating field studies and on-site experiments. This increased mobility has the potential to revolutionize various fields of scientific research, from environmental studies to medical diagnostics.

The miniaturization process also aims to maintain or even enhance the performance capabilities of these pumps. Engineers and researchers face the challenge of reducing size without compromising on flow rate, pressure, and reliability. This necessitates innovations in materials science, fluid dynamics, and precision engineering.

Furthermore, the drive towards miniaturization is closely linked to the broader trend of lab-on-a-chip technologies. As microfluidic systems become more prevalent in research and diagnostic applications, the demand for compatible, miniaturized pumping solutions has intensified. This convergence of technologies opens up new possibilities for integrated, compact laboratory systems.

The pursuit of miniaturized submersible pumps also aligns with sustainability goals in scientific research. Smaller pumps typically consume less energy and require fewer materials to manufacture, contributing to more environmentally friendly laboratory practices. This aspect is increasingly important as research institutions worldwide strive to reduce their carbon footprint and operational costs.

Lab Equipment Market Analysis

The laboratory equipment market has been experiencing significant growth in recent years, driven by advancements in research and development across various scientific disciplines. The global lab equipment market was valued at approximately $27.8 billion in 2020 and is projected to reach $41.2 billion by 2026, growing at a CAGR of 6.8% during the forecast period. This growth is primarily attributed to increasing investments in life sciences research, rising demand for personalized medicine, and technological innovations in laboratory instruments.

The market for submersible pumps in laboratory settings is a niche but rapidly expanding segment within the broader lab equipment industry. These pumps are essential for various applications, including fluid transfer, sample preparation, and waste management in research laboratories. The miniaturization of submersible pumps has become a key focus area for manufacturers, as it offers numerous advantages in terms of space efficiency, reduced sample volumes, and improved precision in microfluidic applications.

The demand for miniaturized submersible pumps is particularly strong in academic and research institutions, pharmaceutical companies, and biotechnology firms. These organizations are increasingly adopting advanced laboratory automation systems and microfluidic devices, which require compact and efficient pumping solutions. The trend towards miniaturization aligns with the broader movement towards lab-on-a-chip technologies and point-of-care diagnostics, further driving the market growth for miniaturized submersible pumps.

Geographically, North America and Europe dominate the market for advanced laboratory equipment, including miniaturized submersible pumps. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by increasing R&D investments in countries like China, Japan, and South Korea. The region's rapid economic growth, coupled with government initiatives to boost scientific research, is creating lucrative opportunities for lab equipment manufacturers.

Key players in the miniaturized submersible pump market include established laboratory equipment manufacturers as well as specialized pump manufacturers. These companies are investing heavily in research and development to create innovative, compact pump designs that offer high performance and reliability. The competitive landscape is characterized by a focus on product differentiation, with manufacturers striving to develop pumps that can handle smaller volumes, operate at higher pressures, and integrate seamlessly with existing laboratory systems.

The market for submersible pumps in laboratory settings is a niche but rapidly expanding segment within the broader lab equipment industry. These pumps are essential for various applications, including fluid transfer, sample preparation, and waste management in research laboratories. The miniaturization of submersible pumps has become a key focus area for manufacturers, as it offers numerous advantages in terms of space efficiency, reduced sample volumes, and improved precision in microfluidic applications.

The demand for miniaturized submersible pumps is particularly strong in academic and research institutions, pharmaceutical companies, and biotechnology firms. These organizations are increasingly adopting advanced laboratory automation systems and microfluidic devices, which require compact and efficient pumping solutions. The trend towards miniaturization aligns with the broader movement towards lab-on-a-chip technologies and point-of-care diagnostics, further driving the market growth for miniaturized submersible pumps.

Geographically, North America and Europe dominate the market for advanced laboratory equipment, including miniaturized submersible pumps. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by increasing R&D investments in countries like China, Japan, and South Korea. The region's rapid economic growth, coupled with government initiatives to boost scientific research, is creating lucrative opportunities for lab equipment manufacturers.

Key players in the miniaturized submersible pump market include established laboratory equipment manufacturers as well as specialized pump manufacturers. These companies are investing heavily in research and development to create innovative, compact pump designs that offer high performance and reliability. The competitive landscape is characterized by a focus on product differentiation, with manufacturers striving to develop pumps that can handle smaller volumes, operate at higher pressures, and integrate seamlessly with existing laboratory systems.

Current Challenges in Miniature Submersible Pump Technology

The miniaturization of submersible pumps for laboratory settings faces several significant challenges that hinder further advancements in this field. One of the primary obstacles is the difficulty in maintaining pump efficiency while reducing size. As pumps are scaled down, the surface area-to-volume ratio increases, leading to greater frictional losses and reduced overall efficiency. This challenge is particularly pronounced in the impeller design, where smaller dimensions can result in decreased fluid flow and pressure generation.

Another critical issue is the limitation of materials suitable for miniature pump components. The need for corrosion-resistant, biocompatible, and chemically inert materials becomes more crucial as pump sizes decrease. Finding materials that meet these requirements while also possessing the necessary mechanical properties for pump operation at small scales is a significant engineering challenge.

Heat dissipation presents a substantial hurdle in miniature submersible pump design. Smaller pumps generate more heat per unit volume due to their compact nature and increased relative friction. This excess heat can lead to premature component failure, reduced lifespan, and potential sample contamination in sensitive laboratory applications.

Power supply and energy efficiency pose additional challenges. Miniature pumps require specialized power sources that can deliver consistent, regulated power in a compact form factor. Balancing power consumption with pump performance becomes increasingly difficult as dimensions shrink, often necessitating trade-offs between flow rate, pressure, and energy efficiency.

The integration of control systems and sensors into miniature pumps presents another layer of complexity. Incorporating precise flow control, pressure monitoring, and feedback mechanisms within the confined spaces of miniaturized pumps requires innovative approaches to sensor design and integration.

Manufacturing processes also face limitations when producing extremely small pump components. Traditional manufacturing methods may not be suitable for creating intricate parts at the microscale, necessitating the development of new fabrication techniques such as micro-molding, 3D printing at the microscale, or advanced etching processes.

Lastly, ensuring consistent performance and reliability at miniature scales remains a significant challenge. The impact of manufacturing tolerances becomes more pronounced as pump sizes decrease, potentially leading to greater variability in pump performance between units. Addressing this issue requires advancements in quality control processes and the development of more precise manufacturing techniques.

These challenges collectively represent the current technological barriers in the field of miniature submersible pumps for laboratory settings. Overcoming these obstacles will require interdisciplinary approaches, combining innovations in materials science, fluid dynamics, microfabrication, and control systems to push the boundaries of pump miniaturization while maintaining or improving performance characteristics.

Another critical issue is the limitation of materials suitable for miniature pump components. The need for corrosion-resistant, biocompatible, and chemically inert materials becomes more crucial as pump sizes decrease. Finding materials that meet these requirements while also possessing the necessary mechanical properties for pump operation at small scales is a significant engineering challenge.

Heat dissipation presents a substantial hurdle in miniature submersible pump design. Smaller pumps generate more heat per unit volume due to their compact nature and increased relative friction. This excess heat can lead to premature component failure, reduced lifespan, and potential sample contamination in sensitive laboratory applications.

Power supply and energy efficiency pose additional challenges. Miniature pumps require specialized power sources that can deliver consistent, regulated power in a compact form factor. Balancing power consumption with pump performance becomes increasingly difficult as dimensions shrink, often necessitating trade-offs between flow rate, pressure, and energy efficiency.

The integration of control systems and sensors into miniature pumps presents another layer of complexity. Incorporating precise flow control, pressure monitoring, and feedback mechanisms within the confined spaces of miniaturized pumps requires innovative approaches to sensor design and integration.

Manufacturing processes also face limitations when producing extremely small pump components. Traditional manufacturing methods may not be suitable for creating intricate parts at the microscale, necessitating the development of new fabrication techniques such as micro-molding, 3D printing at the microscale, or advanced etching processes.

Lastly, ensuring consistent performance and reliability at miniature scales remains a significant challenge. The impact of manufacturing tolerances becomes more pronounced as pump sizes decrease, potentially leading to greater variability in pump performance between units. Addressing this issue requires advancements in quality control processes and the development of more precise manufacturing techniques.

These challenges collectively represent the current technological barriers in the field of miniature submersible pumps for laboratory settings. Overcoming these obstacles will require interdisciplinary approaches, combining innovations in materials science, fluid dynamics, microfabrication, and control systems to push the boundaries of pump miniaturization while maintaining or improving performance characteristics.

Existing Miniaturization Techniques for Submersible Pumps

01 Pump size optimization for specific applications

Submersible pump sizes are optimized for specific applications, considering factors such as flow rate, head pressure, and well diameter. Manufacturers design pumps with various dimensions to fit different well sizes and meet diverse pumping requirements. This optimization ensures efficient operation and proper installation in various environments.- Sizing considerations for submersible pumps: The size of submersible pumps is crucial for their performance and efficiency. Factors such as flow rate, head pressure, and power requirements are considered when determining the appropriate pump size. Proper sizing ensures optimal operation in various applications, including well pumping, wastewater management, and industrial processes.

- Compact design for improved installation: Manufacturers focus on developing compact submersible pump designs to facilitate easier installation and maintenance in confined spaces. These designs often incorporate innovative components and arrangements to reduce overall pump dimensions while maintaining or improving performance characteristics.

- Modular and scalable pump systems: Modular submersible pump systems allow for flexibility in sizing and configuration. These systems can be easily scaled up or down to meet specific application requirements, offering a range of pump sizes within a single product line. This approach simplifies selection, installation, and maintenance processes.

- Size optimization for specific applications: Submersible pumps are designed and sized for specific applications such as oil and gas extraction, mining, and offshore operations. These specialized pumps are engineered to meet the unique requirements of each industry, including pressure ratings, corrosion resistance, and ability to handle particulates.

- Integration of advanced control systems: Modern submersible pumps incorporate advanced control systems that can affect pump sizing. These systems allow for variable speed operation, real-time monitoring, and automatic adjustment of pump performance. This integration can lead to more efficient pump sizing and operation across a wider range of conditions.

02 Modular and adjustable pump designs

Some submersible pumps feature modular designs that allow for size adjustments. These pumps can be customized by adding or removing stages to alter their length and performance characteristics. This flexibility enables users to adapt the pump size to changing well conditions or pumping needs without replacing the entire unit.Expand Specific Solutions03 Compact and slim pump designs

Manufacturers are developing compact and slim submersible pump designs to fit into narrow wells or confined spaces. These pumps maintain high performance while minimizing their diameter and overall size. Such designs are particularly useful in applications where space is limited or in wells with small diameters.Expand Specific Solutions04 Size considerations for specific industries

Different industries have unique requirements for submersible pump sizes. For example, the oil and gas sector may require larger, high-capacity pumps for deep well applications, while the water treatment industry might need smaller, more compact designs for residential use. Pump sizes are tailored to meet these industry-specific needs and regulations.Expand Specific Solutions05 Innovative materials and manufacturing techniques

Advanced materials and manufacturing techniques are being employed to reduce the size of submersible pumps while maintaining or improving their performance. These innovations allow for the creation of smaller, lighter pumps that can operate efficiently in challenging environments. 3D printing and composite materials are examples of technologies used to achieve these size reductions.Expand Specific Solutions

Key Players in Lab Pump Manufacturing

The miniaturization of submersible pumps for laboratory settings is in an early growth stage, with increasing market demand driven by advancements in microfluidics and precision fluid control. The global market for these specialized pumps is expanding, though still relatively niche. Technologically, progress is being made, but challenges remain in balancing size reduction with performance. Companies like Hitachi High-Tech America and STMicroelectronics are leveraging their expertise in miniaturization and semiconductor technologies to develop innovative solutions. Research institutions such as Fraunhofer-Gesellschaft and the Agency for Science, Technology & Research are also contributing to advancements in this field, indicating a collaborative approach to overcoming technical hurdles.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger Technologies has made significant advancements in miniaturizing submersible pumps for laboratory settings, leveraging their extensive experience in oil and gas industry technologies. Their approach focuses on developing high-pressure, low-flow pumps suitable for microfluidic applications in laboratories. Schlumberger has implemented advanced micro-fabrication techniques to create intricate pump components at the millimeter scale. Their pumps incorporate a novel piezoelectric actuation system, allowing for precise control of fluid displacement in microscale channels. The company has developed a proprietary surface treatment process that reduces friction and prevents fluid adhesion, enhancing pump efficiency in miniaturized formats. Schlumberger's pumps also feature integrated microfluidic chips that enable on-chip sample preparation and analysis, crucial for many laboratory applications. They have implemented advanced sensor arrays for real-time monitoring of pump performance and fluid characteristics[7][9].

Strengths: Expertise in high-pressure applications, advanced micro-fabrication techniques, and integrated microfluidic capabilities. Weaknesses: May be overly specialized for some general laboratory applications, potentially high cost due to advanced technology.

SPX FLOW, Inc.

Technical Solution: SPX FLOW has made notable progress in miniaturizing submersible pumps for laboratory settings. Their approach centers on developing multi-stage micro-impeller designs that maximize efficiency in small form factors. The company has implemented advanced computational fluid dynamics (CFD) simulations to optimize flow paths and reduce turbulence in miniaturized pump chambers. SPX FLOW's pumps incorporate a novel magnetic coupling system, eliminating the need for shaft seals and reducing the overall pump size. They have also developed a proprietary cooling system that allows for continuous operation in confined laboratory spaces without overheating. The pumps feature a modular construction that facilitates easy maintenance and component replacement. SPX FLOW has integrated precision flow control mechanisms, allowing for accurate dosing and sampling in laboratory experiments. Additionally, their pumps utilize corrosion-resistant materials suitable for a wide range of laboratory chemicals[6][8].

Strengths: Advanced CFD-optimized designs, innovative magnetic coupling, and precision flow control. Weaknesses: May have limitations in extremely high-pressure applications, potentially higher cost due to specialized components.

Innovative Materials and Designs for Pump Miniaturization

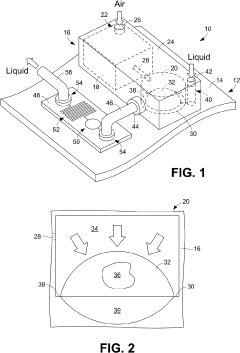

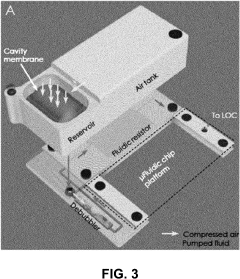

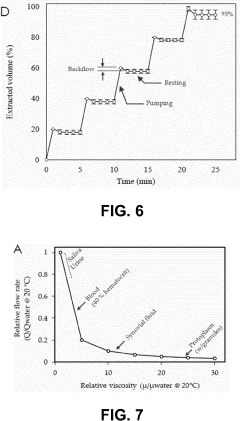

Miniature pressure-driven pumps

PatentPendingUS20230242330A1

Innovation

- A miniature, zero-power, plug-and-play pump with a refillable liquid reservoir defined by a deformable membrane, which is compressed by pneumatic pressure to discharge liquid without generating restoring forces, minimizing backflow and allowing direct integration with microfluidic devices.

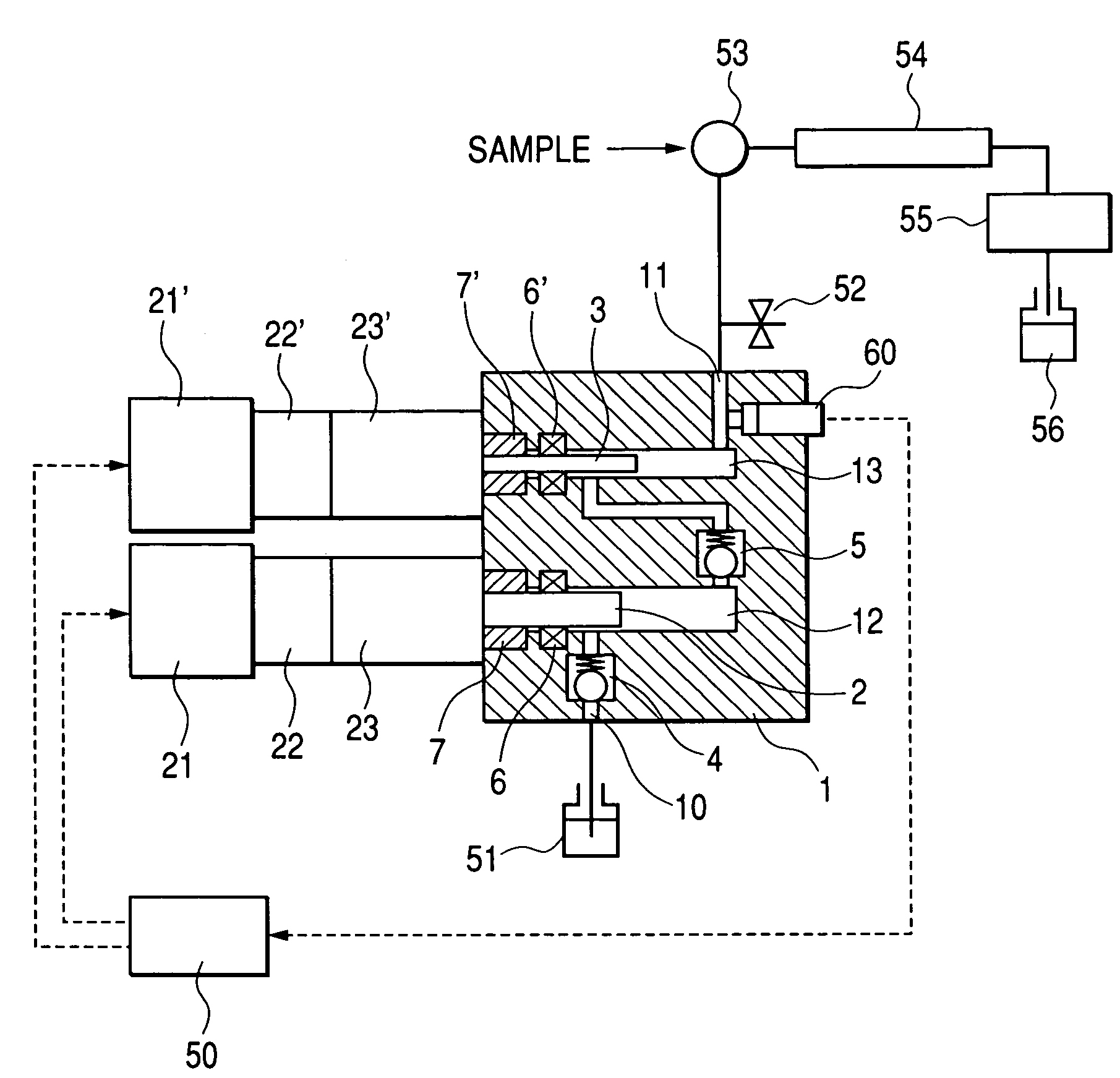

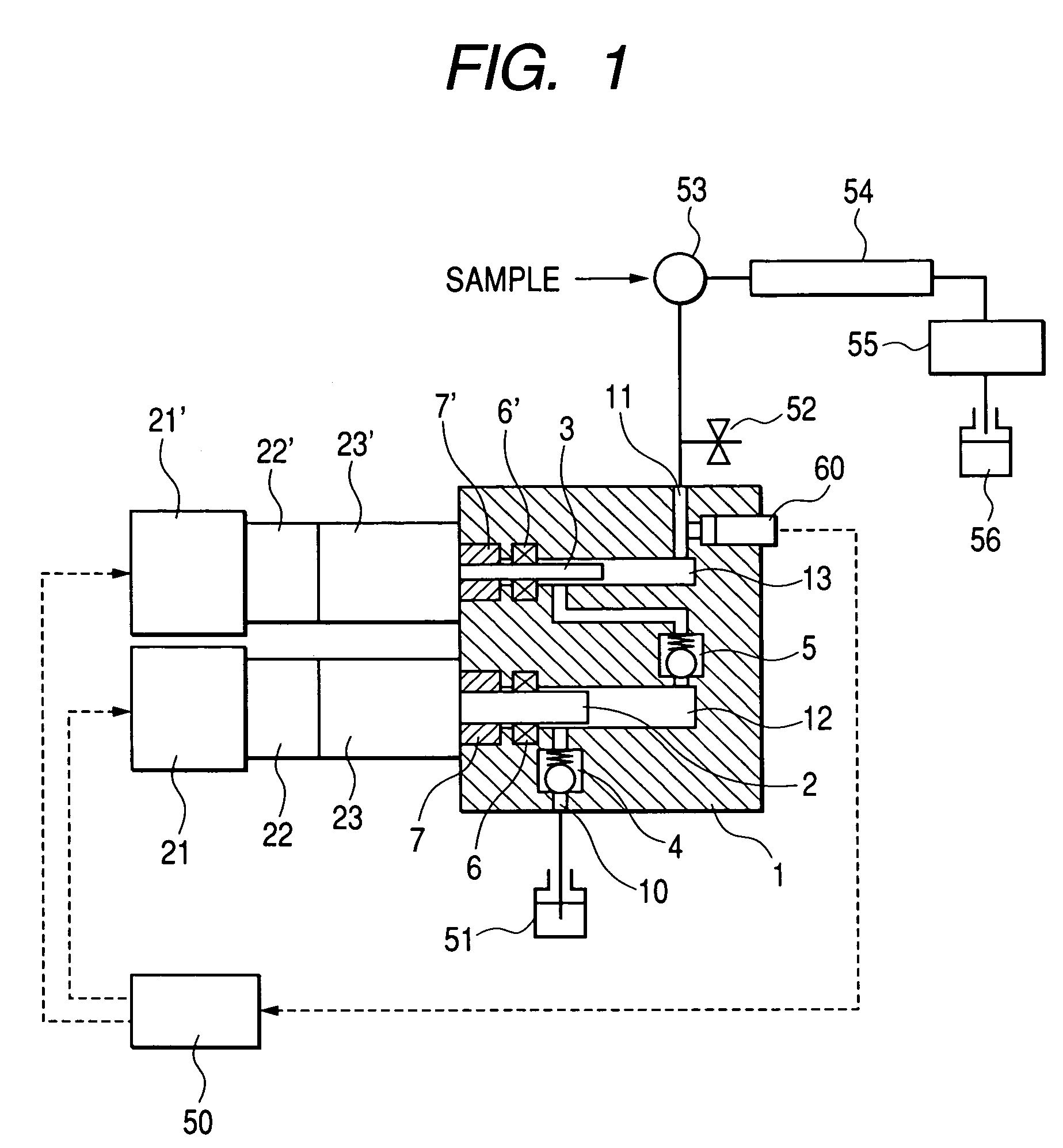

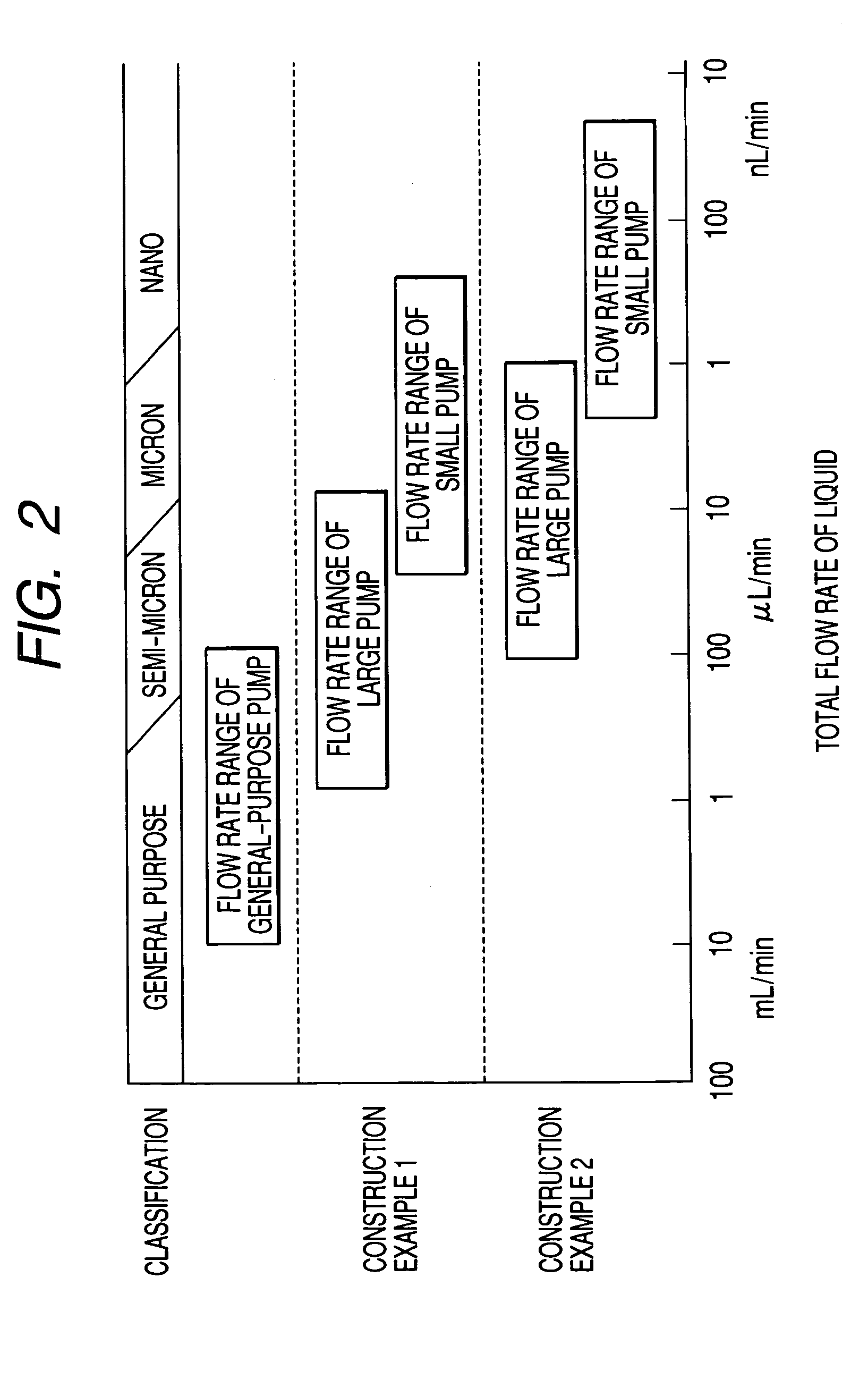

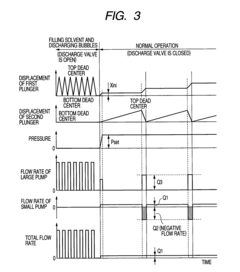

Pump for liquid chromatography

PatentInactiveUS7063785B2

Innovation

- A pump design featuring independent first and second plungers driven by separate actuators, with the first plunger capable of higher maximum flow rates and lower minimum flow rates, and a check valve made of soft materials like resin to minimize leakage, allowing for precise control of flow rates down to 1 μL/min and efficient bubble discharge.

Energy Efficiency in Miniaturized Submersible Pumps

Energy efficiency is a critical factor in the development and application of miniaturized submersible pumps for laboratory settings. As these pumps become smaller, the challenge of maintaining or improving energy efficiency becomes more pronounced. Recent breakthroughs in this area have focused on innovative designs and materials that optimize power consumption while maintaining or enhancing pump performance.

One significant advancement has been the implementation of high-efficiency motors in miniaturized submersible pumps. These motors utilize advanced magnetic materials and precision engineering to reduce energy losses during operation. By minimizing friction and optimizing the conversion of electrical energy to mechanical energy, these motors can achieve higher efficiency ratings even at smaller scales.

Another area of innovation is in the pump impeller design. Researchers have developed micro-scale impellers with optimized blade geometries that maximize fluid flow while minimizing energy input. These designs often incorporate computational fluid dynamics (CFD) simulations to fine-tune the impeller shape for specific laboratory applications, resulting in pumps that can move fluids more efficiently in confined spaces.

The integration of smart control systems has also contributed to improved energy efficiency in miniaturized submersible pumps. These systems can adjust pump speed and power output based on real-time demand, ensuring that energy is not wasted during periods of low fluid transfer requirements. Some advanced models even incorporate machine learning algorithms to predict usage patterns and optimize pump operation over time.

Material science has played a crucial role in enhancing energy efficiency as well. The use of low-friction coatings on pump components reduces energy loss due to mechanical resistance. Additionally, the development of lightweight, corrosion-resistant materials has allowed for the creation of pump housings and internal components that require less energy to operate while maintaining durability in various laboratory environments.

Thermal management techniques have been refined to address heat dissipation challenges in compact pump designs. Efficient heat sinking methods and the use of thermally conductive materials help prevent energy losses due to overheating, thereby maintaining optimal pump performance and longevity.

The miniaturization of power electronics has enabled the integration of more efficient power conversion and control circuits directly within the pump assembly. This reduces energy losses associated with power transmission and allows for more precise control of the pump's operation, further contributing to overall energy efficiency.

One significant advancement has been the implementation of high-efficiency motors in miniaturized submersible pumps. These motors utilize advanced magnetic materials and precision engineering to reduce energy losses during operation. By minimizing friction and optimizing the conversion of electrical energy to mechanical energy, these motors can achieve higher efficiency ratings even at smaller scales.

Another area of innovation is in the pump impeller design. Researchers have developed micro-scale impellers with optimized blade geometries that maximize fluid flow while minimizing energy input. These designs often incorporate computational fluid dynamics (CFD) simulations to fine-tune the impeller shape for specific laboratory applications, resulting in pumps that can move fluids more efficiently in confined spaces.

The integration of smart control systems has also contributed to improved energy efficiency in miniaturized submersible pumps. These systems can adjust pump speed and power output based on real-time demand, ensuring that energy is not wasted during periods of low fluid transfer requirements. Some advanced models even incorporate machine learning algorithms to predict usage patterns and optimize pump operation over time.

Material science has played a crucial role in enhancing energy efficiency as well. The use of low-friction coatings on pump components reduces energy loss due to mechanical resistance. Additionally, the development of lightweight, corrosion-resistant materials has allowed for the creation of pump housings and internal components that require less energy to operate while maintaining durability in various laboratory environments.

Thermal management techniques have been refined to address heat dissipation challenges in compact pump designs. Efficient heat sinking methods and the use of thermally conductive materials help prevent energy losses due to overheating, thereby maintaining optimal pump performance and longevity.

The miniaturization of power electronics has enabled the integration of more efficient power conversion and control circuits directly within the pump assembly. This reduces energy losses associated with power transmission and allows for more precise control of the pump's operation, further contributing to overall energy efficiency.

Biocompatibility Considerations for Lab-scale Pumps

Biocompatibility is a critical consideration in the development of miniaturized submersible pumps for laboratory settings. As these pumps are designed to handle various biological samples and reagents, ensuring their compatibility with living tissues and cells is paramount. The materials used in the construction of these pumps must not leach harmful substances or interfere with the biological processes being studied.

One of the primary concerns in biocompatibility is the selection of appropriate materials for pump components. Polymers such as polytetrafluoroethylene (PTFE) and polypropylene are often favored due to their chemical inertness and resistance to biological fouling. These materials minimize the risk of contamination and ensure the integrity of the samples being processed. Additionally, certain grades of stainless steel, particularly 316L, are widely used for their corrosion resistance and biocompatibility in medical and laboratory applications.

Surface modifications play a crucial role in enhancing the biocompatibility of lab-scale pumps. Techniques such as plasma treatment or the application of hydrophilic coatings can reduce protein adsorption and cell adhesion, preventing the formation of biofilms that could compromise pump performance. These modifications also facilitate easier cleaning and sterilization of the pump components, which is essential for maintaining a sterile laboratory environment.

The potential for leaching of materials from pump components into the sample stream is a significant biocompatibility concern. Rigorous testing protocols, including extraction studies and cytotoxicity assays, are necessary to evaluate the potential release of harmful substances from pump materials. This is particularly important when working with sensitive biological samples or when the pump is intended for long-term use in continuous flow applications.

Thermal management is another critical aspect of biocompatibility in miniaturized submersible pumps. The heat generated by pump operation must be carefully controlled to prevent thermal damage to biological samples. This often necessitates the incorporation of efficient heat dissipation mechanisms or the use of materials with high thermal conductivity to maintain sample integrity.

Sterilization compatibility is a key consideration in the design of biocompatible lab-scale pumps. The pump materials and construction must withstand common sterilization methods such as autoclaving, ethylene oxide treatment, or gamma irradiation without degradation or loss of performance. This ensures that the pumps can be effectively sanitized between experiments, preventing cross-contamination and maintaining the validity of research results.

In conclusion, the development of biocompatible miniaturized submersible pumps for laboratory settings requires a multifaceted approach. It involves careful material selection, surface engineering, leachable testing, thermal management, and sterilization compatibility. As research in this field progresses, new materials and surface technologies are likely to emerge, further enhancing the biocompatibility and performance of these essential laboratory tools.

One of the primary concerns in biocompatibility is the selection of appropriate materials for pump components. Polymers such as polytetrafluoroethylene (PTFE) and polypropylene are often favored due to their chemical inertness and resistance to biological fouling. These materials minimize the risk of contamination and ensure the integrity of the samples being processed. Additionally, certain grades of stainless steel, particularly 316L, are widely used for their corrosion resistance and biocompatibility in medical and laboratory applications.

Surface modifications play a crucial role in enhancing the biocompatibility of lab-scale pumps. Techniques such as plasma treatment or the application of hydrophilic coatings can reduce protein adsorption and cell adhesion, preventing the formation of biofilms that could compromise pump performance. These modifications also facilitate easier cleaning and sterilization of the pump components, which is essential for maintaining a sterile laboratory environment.

The potential for leaching of materials from pump components into the sample stream is a significant biocompatibility concern. Rigorous testing protocols, including extraction studies and cytotoxicity assays, are necessary to evaluate the potential release of harmful substances from pump materials. This is particularly important when working with sensitive biological samples or when the pump is intended for long-term use in continuous flow applications.

Thermal management is another critical aspect of biocompatibility in miniaturized submersible pumps. The heat generated by pump operation must be carefully controlled to prevent thermal damage to biological samples. This often necessitates the incorporation of efficient heat dissipation mechanisms or the use of materials with high thermal conductivity to maintain sample integrity.

Sterilization compatibility is a key consideration in the design of biocompatible lab-scale pumps. The pump materials and construction must withstand common sterilization methods such as autoclaving, ethylene oxide treatment, or gamma irradiation without degradation or loss of performance. This ensures that the pumps can be effectively sanitized between experiments, preventing cross-contamination and maintaining the validity of research results.

In conclusion, the development of biocompatible miniaturized submersible pumps for laboratory settings requires a multifaceted approach. It involves careful material selection, surface engineering, leachable testing, thermal management, and sterilization compatibility. As research in this field progresses, new materials and surface technologies are likely to emerge, further enhancing the biocompatibility and performance of these essential laboratory tools.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!