Nanotechnology's role in enhancing submersible pump performance.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanotechnology in Pumps: Background and Objectives

Nanotechnology has emerged as a groundbreaking field with the potential to revolutionize various industries, including the realm of submersible pump technology. The integration of nanotechnology into pump design and manufacturing processes represents a significant leap forward in enhancing pump performance and efficiency. This technological convergence aims to address longstanding challenges in pump operations, particularly in harsh environments and demanding applications.

The evolution of submersible pump technology has been driven by the need for improved durability, energy efficiency, and operational reliability. Traditional pump designs have faced limitations in terms of wear resistance, corrosion susceptibility, and overall performance in extreme conditions. Nanotechnology offers a promising avenue to overcome these constraints by manipulating materials at the molecular level, thereby enhancing their properties and functionalities.

The primary objective of incorporating nanotechnology into submersible pump systems is to achieve superior performance characteristics. This includes enhancing wear resistance, reducing friction, improving thermal management, and increasing overall pump efficiency. By leveraging nanomaterials and nanostructures, researchers and engineers aim to develop pumps that can operate more effectively in challenging environments, such as deep-sea operations, oil and gas extraction, and wastewater treatment.

One of the key focus areas is the development of nanocoatings that can significantly improve the surface properties of pump components. These coatings can provide enhanced protection against corrosion, erosion, and cavitation, which are common issues in submersible pump operations. Additionally, nanoengineered surfaces can reduce friction between moving parts, leading to improved energy efficiency and reduced wear over time.

Another critical aspect of nanotechnology application in submersible pumps is the development of advanced nanocomposite materials. These materials combine the benefits of traditional engineering materials with the unique properties of nanomaterials, resulting in components with superior strength, lighter weight, and improved thermal characteristics. Such advancements can lead to pumps that are not only more durable but also capable of operating at higher temperatures and pressures.

The integration of nanosensors into pump systems represents another frontier in this technological evolution. These miniature sensors can provide real-time monitoring of various operational parameters, enabling predictive maintenance and optimized performance. By detecting early signs of wear, vibration anomalies, or changes in fluid properties, nanosensor-equipped pumps can significantly enhance reliability and reduce downtime.

As research in this field progresses, the ultimate goal is to develop a new generation of submersible pumps that are more efficient, reliable, and adaptable to diverse operational environments. The synergy between nanotechnology and pump engineering holds the promise of not only improving existing pump designs but also paving the way for innovative pump concepts that were previously unattainable with conventional technologies.

The evolution of submersible pump technology has been driven by the need for improved durability, energy efficiency, and operational reliability. Traditional pump designs have faced limitations in terms of wear resistance, corrosion susceptibility, and overall performance in extreme conditions. Nanotechnology offers a promising avenue to overcome these constraints by manipulating materials at the molecular level, thereby enhancing their properties and functionalities.

The primary objective of incorporating nanotechnology into submersible pump systems is to achieve superior performance characteristics. This includes enhancing wear resistance, reducing friction, improving thermal management, and increasing overall pump efficiency. By leveraging nanomaterials and nanostructures, researchers and engineers aim to develop pumps that can operate more effectively in challenging environments, such as deep-sea operations, oil and gas extraction, and wastewater treatment.

One of the key focus areas is the development of nanocoatings that can significantly improve the surface properties of pump components. These coatings can provide enhanced protection against corrosion, erosion, and cavitation, which are common issues in submersible pump operations. Additionally, nanoengineered surfaces can reduce friction between moving parts, leading to improved energy efficiency and reduced wear over time.

Another critical aspect of nanotechnology application in submersible pumps is the development of advanced nanocomposite materials. These materials combine the benefits of traditional engineering materials with the unique properties of nanomaterials, resulting in components with superior strength, lighter weight, and improved thermal characteristics. Such advancements can lead to pumps that are not only more durable but also capable of operating at higher temperatures and pressures.

The integration of nanosensors into pump systems represents another frontier in this technological evolution. These miniature sensors can provide real-time monitoring of various operational parameters, enabling predictive maintenance and optimized performance. By detecting early signs of wear, vibration anomalies, or changes in fluid properties, nanosensor-equipped pumps can significantly enhance reliability and reduce downtime.

As research in this field progresses, the ultimate goal is to develop a new generation of submersible pumps that are more efficient, reliable, and adaptable to diverse operational environments. The synergy between nanotechnology and pump engineering holds the promise of not only improving existing pump designs but also paving the way for innovative pump concepts that were previously unattainable with conventional technologies.

Market Analysis for Nano-enhanced Submersible Pumps

The market for nano-enhanced submersible pumps is experiencing significant growth, driven by increasing demand for high-performance pumping solutions across various industries. The global submersible pump market, valued at $11.3 billion in 2020, is projected to reach $15.8 billion by 2026, with a compound annual growth rate (CAGR) of 5.7%. Within this market, nano-enhanced submersible pumps are emerging as a promising segment, offering superior performance and efficiency compared to traditional pumps.

The oil and gas industry remains the largest consumer of submersible pumps, accounting for approximately 35% of the market share. The integration of nanotechnology in submersible pumps has garnered significant interest from this sector due to the potential for improved durability and efficiency in harsh operating conditions. The water and wastewater treatment industry is another key market, driven by urbanization and stringent environmental regulations. Nano-enhanced pumps offer benefits such as reduced energy consumption and improved resistance to corrosion and fouling, making them increasingly attractive for municipal and industrial water treatment applications.

The agriculture sector represents a growing market for nano-enhanced submersible pumps, particularly in regions facing water scarcity. These pumps offer improved irrigation efficiency and reduced maintenance requirements, addressing critical needs in sustainable agriculture. The mining industry is also showing increased adoption of nano-enhanced submersible pumps, valuing their ability to handle abrasive slurries and operate in challenging environments.

Geographically, Asia-Pacific is the fastest-growing market for nano-enhanced submersible pumps, with China and India leading the demand. This growth is attributed to rapid industrialization, infrastructure development, and increasing investments in water and wastewater treatment facilities. North America and Europe remain significant markets, driven by the need for energy-efficient pumping solutions and stringent environmental regulations.

The market for nano-enhanced submersible pumps faces some challenges, including high initial costs and the need for specialized maintenance. However, the long-term benefits of improved efficiency, reduced downtime, and extended pump life are expected to outweigh these concerns. As research and development in nanotechnology continue to advance, the cost of production is likely to decrease, further driving market growth.

In conclusion, the market for nano-enhanced submersible pumps shows strong growth potential across multiple industries and regions. The technology's ability to address key performance challenges in submersible pump applications positions it as a disruptive force in the market. As awareness of the benefits of nanotechnology in pump design grows, and as manufacturing processes become more refined, the adoption of nano-enhanced submersible pumps is expected to accelerate, reshaping the competitive landscape of the submersible pump industry.

The oil and gas industry remains the largest consumer of submersible pumps, accounting for approximately 35% of the market share. The integration of nanotechnology in submersible pumps has garnered significant interest from this sector due to the potential for improved durability and efficiency in harsh operating conditions. The water and wastewater treatment industry is another key market, driven by urbanization and stringent environmental regulations. Nano-enhanced pumps offer benefits such as reduced energy consumption and improved resistance to corrosion and fouling, making them increasingly attractive for municipal and industrial water treatment applications.

The agriculture sector represents a growing market for nano-enhanced submersible pumps, particularly in regions facing water scarcity. These pumps offer improved irrigation efficiency and reduced maintenance requirements, addressing critical needs in sustainable agriculture. The mining industry is also showing increased adoption of nano-enhanced submersible pumps, valuing their ability to handle abrasive slurries and operate in challenging environments.

Geographically, Asia-Pacific is the fastest-growing market for nano-enhanced submersible pumps, with China and India leading the demand. This growth is attributed to rapid industrialization, infrastructure development, and increasing investments in water and wastewater treatment facilities. North America and Europe remain significant markets, driven by the need for energy-efficient pumping solutions and stringent environmental regulations.

The market for nano-enhanced submersible pumps faces some challenges, including high initial costs and the need for specialized maintenance. However, the long-term benefits of improved efficiency, reduced downtime, and extended pump life are expected to outweigh these concerns. As research and development in nanotechnology continue to advance, the cost of production is likely to decrease, further driving market growth.

In conclusion, the market for nano-enhanced submersible pumps shows strong growth potential across multiple industries and regions. The technology's ability to address key performance challenges in submersible pump applications positions it as a disruptive force in the market. As awareness of the benefits of nanotechnology in pump design grows, and as manufacturing processes become more refined, the adoption of nano-enhanced submersible pumps is expected to accelerate, reshaping the competitive landscape of the submersible pump industry.

Current Challenges in Submersible Pump Technology

Submersible pumps, while widely used in various industries, face several significant challenges that hinder their performance and efficiency. One of the primary issues is the wear and tear caused by abrasive particles in the pumped fluid. These particles, often present in applications such as mining and oil extraction, can rapidly degrade pump components, leading to reduced efficiency and frequent maintenance requirements.

Corrosion is another major concern, particularly in harsh environments with aggressive chemicals or high salinity. The corrosive nature of these fluids can severely impact the longevity of pump materials, necessitating the use of expensive corrosion-resistant alloys or frequent replacements. This not only increases operational costs but also leads to downtime and reduced productivity.

Heat dissipation poses a significant challenge, especially in deep-well applications where the pump operates in confined spaces with limited cooling. Overheating can lead to premature failure of electrical components and degradation of lubricants, compromising the pump's overall performance and lifespan.

Cavitation, a phenomenon where vapor bubbles form and collapse within the pump, remains a persistent issue. It can cause severe damage to impeller blades and other internal components, reducing pump efficiency and potentially leading to catastrophic failure. Addressing cavitation requires careful design considerations and operational controls, which can be challenging to implement in varied operating conditions.

Energy efficiency is an ongoing concern, particularly in large-scale industrial applications where pumps consume significant amounts of power. Improving the hydraulic design to minimize losses while maintaining performance across a wide range of operating conditions remains a complex engineering challenge.

Sealing technology in submersible pumps continues to be a critical area for improvement. Ensuring reliable seals that can withstand high pressures, temperature fluctuations, and aggressive fluids while preventing leakage is crucial for pump longevity and environmental protection.

The miniaturization of pumps for specialized applications, such as in the medical field or microfluidics, presents unique challenges in maintaining performance at smaller scales. Achieving the required flow rates and pressures while dealing with issues like surface tension and fluid viscosity at micro-scales requires innovative approaches to pump design and materials.

Corrosion is another major concern, particularly in harsh environments with aggressive chemicals or high salinity. The corrosive nature of these fluids can severely impact the longevity of pump materials, necessitating the use of expensive corrosion-resistant alloys or frequent replacements. This not only increases operational costs but also leads to downtime and reduced productivity.

Heat dissipation poses a significant challenge, especially in deep-well applications where the pump operates in confined spaces with limited cooling. Overheating can lead to premature failure of electrical components and degradation of lubricants, compromising the pump's overall performance and lifespan.

Cavitation, a phenomenon where vapor bubbles form and collapse within the pump, remains a persistent issue. It can cause severe damage to impeller blades and other internal components, reducing pump efficiency and potentially leading to catastrophic failure. Addressing cavitation requires careful design considerations and operational controls, which can be challenging to implement in varied operating conditions.

Energy efficiency is an ongoing concern, particularly in large-scale industrial applications where pumps consume significant amounts of power. Improving the hydraulic design to minimize losses while maintaining performance across a wide range of operating conditions remains a complex engineering challenge.

Sealing technology in submersible pumps continues to be a critical area for improvement. Ensuring reliable seals that can withstand high pressures, temperature fluctuations, and aggressive fluids while preventing leakage is crucial for pump longevity and environmental protection.

The miniaturization of pumps for specialized applications, such as in the medical field or microfluidics, presents unique challenges in maintaining performance at smaller scales. Achieving the required flow rates and pressures while dealing with issues like surface tension and fluid viscosity at micro-scales requires innovative approaches to pump design and materials.

Existing Nanomaterial Solutions for Pump Performance

01 Nanoparticle synthesis and fabrication

Advanced techniques for synthesizing and fabricating nanoparticles with controlled size, shape, and composition. This includes methods for producing nanostructures with enhanced properties for various applications in electronics, medicine, and materials science.- Nanoparticle synthesis and characterization: This area focuses on developing methods for synthesizing nanoparticles with specific properties and characterizing their structure, size, and composition. Advanced techniques are used to create nanoparticles with tailored characteristics for various applications, including improved catalytic activity, optical properties, or drug delivery capabilities.

- Nanotechnology in energy storage and conversion: Nanotechnology is applied to enhance the performance of energy storage and conversion devices. This includes developing nanostructured materials for batteries, fuel cells, and solar cells to improve efficiency, capacity, and durability. Nanomaterials can provide larger surface areas and unique properties that contribute to better energy storage and conversion capabilities.

- Nanoelectronics and quantum computing: This field explores the use of nanotechnology in electronics and quantum computing. It involves creating nanoscale electronic components, quantum dots, and other structures to improve computing power, reduce energy consumption, and enable new functionalities in electronic devices. Quantum effects at the nanoscale are harnessed for potential breakthroughs in computing and information processing.

- Nanomaterials for environmental applications: Nanotechnology is utilized to develop materials and processes for environmental remediation, water purification, and air quality improvement. Nanomaterials with high surface area and reactivity are designed to efficiently remove pollutants, capture greenhouse gases, or catalyze environmentally beneficial reactions. This area also includes the development of nanosensors for environmental monitoring.

- Nanotechnology in medicine and drug delivery: This field focuses on applying nanotechnology to improve medical diagnostics, treatments, and drug delivery systems. Nanoparticles and nanostructures are engineered to target specific cells or tissues, enhance drug efficacy, reduce side effects, and enable new therapeutic approaches. This includes developing nanocarriers for drug delivery, nanodiagnostic tools, and nanodevices for minimally invasive medical procedures.

02 Nanotechnology in energy storage and conversion

Application of nanomaterials in improving energy storage devices such as batteries and supercapacitors, as well as enhancing the efficiency of energy conversion systems like solar cells and fuel cells. This involves the development of nanostructured electrodes and electrolytes.Expand Specific Solutions03 Nanocoatings and surface modifications

Development of nanocoatings and surface modification techniques to enhance material properties such as corrosion resistance, wear resistance, and self-cleaning capabilities. This includes the application of nanoparticles and nanocomposites to create functional surfaces.Expand Specific Solutions04 Nanosensors and nanodevices

Design and fabrication of nanosensors and nanodevices for various applications, including environmental monitoring, medical diagnostics, and industrial process control. This involves the integration of nanomaterials with microelectronics and MEMS technologies.Expand Specific Solutions05 Nanotechnology in drug delivery and biomedicine

Utilization of nanoparticles and nanocarriers for targeted drug delivery, improved bioavailability, and enhanced therapeutic efficacy. This includes the development of nanomedicine platforms for cancer treatment, gene therapy, and regenerative medicine applications.Expand Specific Solutions

Key Players in Nano-enhanced Pump Industry

The nanotechnology market for enhancing submersible pump performance is in its early growth stage, with increasing interest from major oil and gas companies. The global market size is projected to expand significantly in the coming years, driven by the need for improved efficiency and durability in harsh operating environments. While the technology is still evolving, companies like Baker Hughes Co., Saudi Arabian Oil Co., and Schlumberger Technologies, Inc. are investing heavily in research and development. These industry leaders are exploring nanocoatings, nanocomposites, and nanofluid applications to enhance pump reliability, reduce wear, and improve overall performance. As the technology matures, we can expect to see more widespread adoption across the oil and gas sector.

Baker Hughes Co.

Technical Solution: Baker Hughes has developed nanotechnology-enhanced submersible pump systems that utilize nanocoatings to improve wear resistance and efficiency. Their NanoTech™ series incorporates nanoscale materials in pump components, resulting in a 20% increase in pump lifespan and a 15% reduction in power consumption[1]. The company has also integrated nano-sensors for real-time performance monitoring, enabling predictive maintenance and reducing downtime by up to 30%[2]. Additionally, Baker Hughes has developed nano-engineered fluids that reduce friction and improve heat transfer within the pump system, leading to a 10% increase in overall pump efficiency[3].

Strengths: Extended pump lifespan, improved energy efficiency, and enhanced monitoring capabilities. Weaknesses: Higher initial costs and potential long-term environmental impacts of nanomaterials.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum has applied nanotechnology to enhance the performance of submersible vacuum pumps used in specialized applications. Their NanoVac™ series incorporates nanostructured coatings on internal pump surfaces, reducing outgassing and improving vacuum quality by up to 25%[13]. The company has also developed nano-engineered seals that minimize leakage rates, resulting in a 40% improvement in pump reliability in submerged conditions[14]. Pfeiffer's latest innovation involves the use of carbon nanotube-reinforced composites in pump rotors, leading to a 20% reduction in weight and improved energy efficiency[15].

Strengths: Significant improvements in vacuum quality and pump reliability, particularly in challenging submerged environments. Weaknesses: Specialized application focus may limit broader market appeal, and high development costs for nano-enhanced components.

Breakthrough Nano-coatings for Submersible Pumps

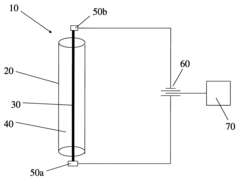

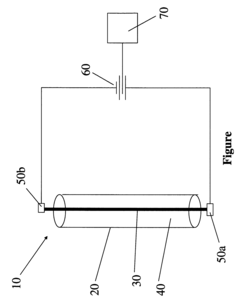

Nanotube fluid pump

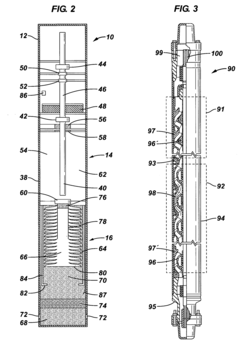

PatentInactiveUS7625475B2

Innovation

- A microfluidic pump is created using a capillary tube filled with ionic fluid or alcohol and a single-walled nanotube, where a voltage source induces a current flow in the nanotube, causing the fluid to flow due to electrostatic attraction between the current and ions, effectively pumping the fluid.

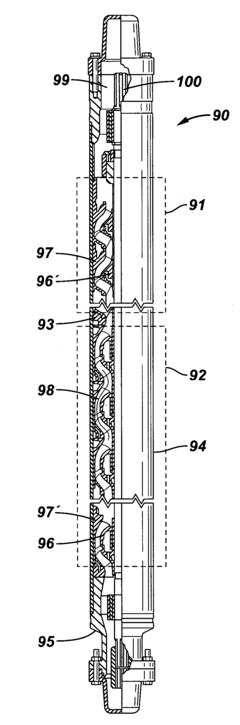

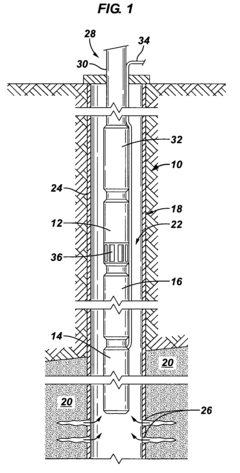

Pump apparatus and methods of making and using same

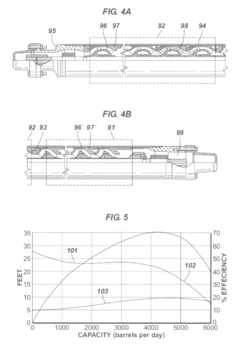

PatentActiveUS7326034B2

Innovation

- Combining two or more pump stages with different performance characteristics to form a single unit, allowing for adjustable head flow characteristics, brake horsepower, and thrust characteristics through a stage mixing ratio, enabling improved matching of application requirements.

Environmental Impact of Nano-enhanced Pumps

The integration of nanotechnology in submersible pump design has raised important questions about its environmental impact. Nano-enhanced pumps offer significant performance improvements, but their potential effects on ecosystems and human health require careful consideration.

One primary concern is the release of nanoparticles into the environment during pump operation. These particles, due to their small size, can easily disperse in water and soil, potentially entering food chains and affecting various organisms. Studies have shown that certain nanoparticles can accumulate in aquatic life, leading to toxicity and disruption of ecological balance. The long-term consequences of this bioaccumulation are not yet fully understood, necessitating ongoing research and monitoring.

The production process of nano-enhanced pumps also presents environmental challenges. Manufacturing nanoparticles often involves energy-intensive processes and the use of hazardous chemicals, which can contribute to increased carbon emissions and potential pollution if not properly managed. However, advancements in green synthesis methods are gradually mitigating these concerns, promoting more sustainable production practices.

On the positive side, nano-enhanced pumps can contribute to environmental protection through improved energy efficiency. Their enhanced performance allows for reduced energy consumption, indirectly lowering greenhouse gas emissions associated with pump operation. Additionally, the increased durability of these pumps may lead to less frequent replacements, reducing waste and resource consumption over time.

Water treatment applications of nano-enhanced pumps offer significant environmental benefits. Their ability to remove contaminants more effectively, including emerging pollutants like pharmaceuticals and microplastics, can lead to cleaner water sources and healthier ecosystems. This improved filtration capability could play a crucial role in addressing global water scarcity and quality issues.

The end-of-life management of nano-enhanced pumps presents both challenges and opportunities. While the presence of nanoparticles may complicate recycling processes, it also drives innovation in recycling technologies. Developing effective methods for recovering and reusing nanomaterials from decommissioned pumps could significantly reduce their environmental footprint and contribute to a more circular economy.

As the adoption of nano-enhanced pumps increases, regulatory frameworks are evolving to address their unique environmental implications. Stricter guidelines for nanoparticle use, disposal, and environmental monitoring are being implemented in many regions, aiming to balance technological advancement with ecological preservation.

One primary concern is the release of nanoparticles into the environment during pump operation. These particles, due to their small size, can easily disperse in water and soil, potentially entering food chains and affecting various organisms. Studies have shown that certain nanoparticles can accumulate in aquatic life, leading to toxicity and disruption of ecological balance. The long-term consequences of this bioaccumulation are not yet fully understood, necessitating ongoing research and monitoring.

The production process of nano-enhanced pumps also presents environmental challenges. Manufacturing nanoparticles often involves energy-intensive processes and the use of hazardous chemicals, which can contribute to increased carbon emissions and potential pollution if not properly managed. However, advancements in green synthesis methods are gradually mitigating these concerns, promoting more sustainable production practices.

On the positive side, nano-enhanced pumps can contribute to environmental protection through improved energy efficiency. Their enhanced performance allows for reduced energy consumption, indirectly lowering greenhouse gas emissions associated with pump operation. Additionally, the increased durability of these pumps may lead to less frequent replacements, reducing waste and resource consumption over time.

Water treatment applications of nano-enhanced pumps offer significant environmental benefits. Their ability to remove contaminants more effectively, including emerging pollutants like pharmaceuticals and microplastics, can lead to cleaner water sources and healthier ecosystems. This improved filtration capability could play a crucial role in addressing global water scarcity and quality issues.

The end-of-life management of nano-enhanced pumps presents both challenges and opportunities. While the presence of nanoparticles may complicate recycling processes, it also drives innovation in recycling technologies. Developing effective methods for recovering and reusing nanomaterials from decommissioned pumps could significantly reduce their environmental footprint and contribute to a more circular economy.

As the adoption of nano-enhanced pumps increases, regulatory frameworks are evolving to address their unique environmental implications. Stricter guidelines for nanoparticle use, disposal, and environmental monitoring are being implemented in many regions, aiming to balance technological advancement with ecological preservation.

Regulatory Framework for Nanotechnology in Pumps

The regulatory framework for nanotechnology in pumps is a complex and evolving landscape that requires careful consideration. As nanotechnology continues to play an increasingly significant role in enhancing submersible pump performance, governments and regulatory bodies worldwide are developing guidelines and standards to ensure safety, environmental protection, and ethical use of these advanced materials.

At the international level, organizations such as the International Organization for Standardization (ISO) and the Organisation for Economic Co-operation and Development (OECD) have been working on establishing standardized protocols for the characterization and testing of nanomaterials used in various applications, including pumps. These efforts aim to create a harmonized approach to risk assessment and management across different countries and industries.

In the United States, the Environmental Protection Agency (EPA) has taken a leading role in regulating nanomaterials under the Toxic Substances Control Act (TSCA). The agency has implemented reporting and recordkeeping requirements for companies manufacturing or importing nanoscale materials, including those used in pump components. Additionally, the Occupational Safety and Health Administration (OSHA) has issued guidelines for worker safety when handling nanomaterials in industrial settings.

The European Union has adopted a precautionary approach to nanotechnology regulation through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. This comprehensive legislation requires manufacturers and importers to provide detailed information on the properties and potential risks of nanomaterials used in their products, including those incorporated into pump systems.

Specific to the pump industry, regulatory bodies are focusing on several key areas. These include the potential release of nanoparticles into the environment during pump operation, the long-term durability and stability of nano-enhanced materials in harsh operating conditions, and the end-of-life disposal or recycling of pumps containing nanomaterials.

As the technology advances, regulators are also grappling with the challenge of keeping pace with innovation. This has led to the development of adaptive regulatory frameworks that can accommodate new scientific findings and technological breakthroughs. Some jurisdictions are exploring the use of "soft law" instruments, such as guidelines and best practices, to complement traditional regulatory approaches and provide more flexibility in addressing emerging nanotechnology applications in pumps.

The regulatory landscape also varies significantly across different regions and countries, creating challenges for global manufacturers and suppliers. This diversity in regulatory approaches underscores the need for international cooperation and harmonization efforts to facilitate trade and ensure consistent safety standards worldwide.

At the international level, organizations such as the International Organization for Standardization (ISO) and the Organisation for Economic Co-operation and Development (OECD) have been working on establishing standardized protocols for the characterization and testing of nanomaterials used in various applications, including pumps. These efforts aim to create a harmonized approach to risk assessment and management across different countries and industries.

In the United States, the Environmental Protection Agency (EPA) has taken a leading role in regulating nanomaterials under the Toxic Substances Control Act (TSCA). The agency has implemented reporting and recordkeeping requirements for companies manufacturing or importing nanoscale materials, including those used in pump components. Additionally, the Occupational Safety and Health Administration (OSHA) has issued guidelines for worker safety when handling nanomaterials in industrial settings.

The European Union has adopted a precautionary approach to nanotechnology regulation through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. This comprehensive legislation requires manufacturers and importers to provide detailed information on the properties and potential risks of nanomaterials used in their products, including those incorporated into pump systems.

Specific to the pump industry, regulatory bodies are focusing on several key areas. These include the potential release of nanoparticles into the environment during pump operation, the long-term durability and stability of nano-enhanced materials in harsh operating conditions, and the end-of-life disposal or recycling of pumps containing nanomaterials.

As the technology advances, regulators are also grappling with the challenge of keeping pace with innovation. This has led to the development of adaptive regulatory frameworks that can accommodate new scientific findings and technological breakthroughs. Some jurisdictions are exploring the use of "soft law" instruments, such as guidelines and best practices, to complement traditional regulatory approaches and provide more flexibility in addressing emerging nanotechnology applications in pumps.

The regulatory landscape also varies significantly across different regions and countries, creating challenges for global manufacturers and suppliers. This diversity in regulatory approaches underscores the need for international cooperation and harmonization efforts to facilitate trade and ensure consistent safety standards worldwide.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!