Chemical Vapor Deposition of CNTs for Energy Storage Applications

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CNT CVD Technology Evolution and Objectives

Carbon Nanotube (CNT) Chemical Vapor Deposition (CVD) technology has evolved significantly since its inception in the early 1990s. Initially developed as a method to produce carbon nanostructures, CVD has become the predominant technique for synthesizing CNTs due to its scalability, cost-effectiveness, and ability to produce high-quality nanotubes with controlled properties. The evolution of this technology has been marked by continuous improvements in catalyst design, process parameters, and reactor configurations.

The early development phase (1991-2000) focused primarily on establishing fundamental CVD processes for CNT growth, utilizing simple thermal decomposition of hydrocarbon gases over metal catalysts. During this period, researchers achieved limited control over CNT morphology and structure, with production yields remaining relatively low.

The refinement phase (2001-2010) witnessed significant advancements in catalyst preparation techniques and process optimization. Researchers developed methods for controlling CNT diameter, length, and alignment through precise manipulation of catalyst particle size and reaction conditions. This period also saw the emergence of specialized CVD variants such as plasma-enhanced CVD and floating catalyst CVD, each offering unique advantages for specific applications.

The current maturation phase (2011-present) has been characterized by industrial scaling efforts and application-specific optimizations. Continuous production methods have been developed, enabling higher throughput and reduced costs. Simultaneously, researchers have focused on tailoring CNT properties specifically for energy storage applications, including controlled surface functionalization, defect engineering, and hierarchical structure design.

The primary objectives of CNT CVD technology development for energy storage applications include achieving precise control over CNT morphology (diameter, length, wall number), enhancing structural quality (reducing defects while introducing beneficial functionalities), and developing scalable, environmentally sustainable production processes. Researchers aim to optimize CNT properties to maximize specific surface area, electrical conductivity, and electrochemical stability – critical parameters for energy storage performance.

Additional objectives include reducing production costs to enable commercial viability, developing in-situ hybridization techniques to create CNT-based composite materials with enhanced properties, and establishing standardized quality control protocols for consistent performance in energy storage devices. The ultimate goal is to enable mass production of application-specific CNTs that can significantly improve the energy density, power density, and cycle life of next-generation energy storage systems such as lithium-ion batteries, supercapacitors, and emerging battery technologies.

The early development phase (1991-2000) focused primarily on establishing fundamental CVD processes for CNT growth, utilizing simple thermal decomposition of hydrocarbon gases over metal catalysts. During this period, researchers achieved limited control over CNT morphology and structure, with production yields remaining relatively low.

The refinement phase (2001-2010) witnessed significant advancements in catalyst preparation techniques and process optimization. Researchers developed methods for controlling CNT diameter, length, and alignment through precise manipulation of catalyst particle size and reaction conditions. This period also saw the emergence of specialized CVD variants such as plasma-enhanced CVD and floating catalyst CVD, each offering unique advantages for specific applications.

The current maturation phase (2011-present) has been characterized by industrial scaling efforts and application-specific optimizations. Continuous production methods have been developed, enabling higher throughput and reduced costs. Simultaneously, researchers have focused on tailoring CNT properties specifically for energy storage applications, including controlled surface functionalization, defect engineering, and hierarchical structure design.

The primary objectives of CNT CVD technology development for energy storage applications include achieving precise control over CNT morphology (diameter, length, wall number), enhancing structural quality (reducing defects while introducing beneficial functionalities), and developing scalable, environmentally sustainable production processes. Researchers aim to optimize CNT properties to maximize specific surface area, electrical conductivity, and electrochemical stability – critical parameters for energy storage performance.

Additional objectives include reducing production costs to enable commercial viability, developing in-situ hybridization techniques to create CNT-based composite materials with enhanced properties, and establishing standardized quality control protocols for consistent performance in energy storage devices. The ultimate goal is to enable mass production of application-specific CNTs that can significantly improve the energy density, power density, and cycle life of next-generation energy storage systems such as lithium-ion batteries, supercapacitors, and emerging battery technologies.

Energy Storage Market Demand Analysis

The global energy storage market is experiencing unprecedented growth, driven by the increasing adoption of renewable energy sources and the electrification of transportation. As of 2023, the market was valued at approximately $211 billion and is projected to reach $413 billion by 2030, representing a compound annual growth rate (CAGR) of 10.2%. This remarkable expansion underscores the critical need for advanced energy storage technologies that can meet the escalating demand for efficient, high-capacity, and sustainable energy solutions.

Within this burgeoning market, lithium-ion batteries currently dominate with over 70% market share. However, they face significant limitations in energy density, charging speed, and cycle life. These constraints have created substantial market opportunities for next-generation energy storage technologies, particularly those incorporating carbon nanotubes (CNTs) produced via Chemical Vapor Deposition (CVD).

The automotive sector represents the largest demand segment, with electric vehicle (EV) battery requirements growing at 25% annually. Major automakers have publicly committed to transitioning their fleets to electric power, with several pledging 100% electric production by 2035. This transition necessitates energy storage solutions with higher energy density and faster charging capabilities than current technologies can provide.

Renewable energy integration presents another significant market driver. The intermittent nature of solar and wind power generation requires advanced energy storage systems to ensure grid stability. The utility-scale energy storage market is expanding at 32% annually, with grid operators increasingly mandating storage capacity alongside new renewable installations.

Consumer electronics constitutes the third major market segment, with demand for longer-lasting, faster-charging batteries growing steadily at 15% annually. Manufacturers are actively seeking technologies that can double current energy densities while maintaining safety standards.

Market research indicates that energy storage technologies incorporating CNTs could capture up to 25% of the total energy storage market by 2028 if current technical challenges are overcome. The superior electrical conductivity, mechanical strength, and thermal stability of CNTs make them ideal candidates for enhancing existing battery technologies and enabling entirely new storage paradigms.

Regional analysis shows Asia-Pacific leading market demand (45%), followed by North America (30%) and Europe (20%). However, Europe is experiencing the fastest growth rate at 35% annually, driven by aggressive renewable energy targets and supportive regulatory frameworks.

Within this burgeoning market, lithium-ion batteries currently dominate with over 70% market share. However, they face significant limitations in energy density, charging speed, and cycle life. These constraints have created substantial market opportunities for next-generation energy storage technologies, particularly those incorporating carbon nanotubes (CNTs) produced via Chemical Vapor Deposition (CVD).

The automotive sector represents the largest demand segment, with electric vehicle (EV) battery requirements growing at 25% annually. Major automakers have publicly committed to transitioning their fleets to electric power, with several pledging 100% electric production by 2035. This transition necessitates energy storage solutions with higher energy density and faster charging capabilities than current technologies can provide.

Renewable energy integration presents another significant market driver. The intermittent nature of solar and wind power generation requires advanced energy storage systems to ensure grid stability. The utility-scale energy storage market is expanding at 32% annually, with grid operators increasingly mandating storage capacity alongside new renewable installations.

Consumer electronics constitutes the third major market segment, with demand for longer-lasting, faster-charging batteries growing steadily at 15% annually. Manufacturers are actively seeking technologies that can double current energy densities while maintaining safety standards.

Market research indicates that energy storage technologies incorporating CNTs could capture up to 25% of the total energy storage market by 2028 if current technical challenges are overcome. The superior electrical conductivity, mechanical strength, and thermal stability of CNTs make them ideal candidates for enhancing existing battery technologies and enabling entirely new storage paradigms.

Regional analysis shows Asia-Pacific leading market demand (45%), followed by North America (30%) and Europe (20%). However, Europe is experiencing the fastest growth rate at 35% annually, driven by aggressive renewable energy targets and supportive regulatory frameworks.

Global CNT CVD Technical Challenges

Despite significant advancements in CNT CVD technology, several critical technical challenges persist globally that impede the widespread application of CNTs in energy storage systems. The primary challenge remains achieving precise control over CNT morphology, including diameter, length, chirality, and wall number. This control is essential as these structural parameters directly influence the electrochemical properties of CNTs in energy storage applications. Current CVD processes struggle to maintain consistency across large-scale production batches.

Scalability presents another significant hurdle. While laboratory-scale CVD processes can produce high-quality CNTs, transitioning to industrial-scale production often results in compromised quality and increased defect density. The trade-off between production volume and CNT structural integrity continues to challenge manufacturers seeking to commercialize CNT-based energy storage solutions.

Catalyst development remains a critical bottleneck in CNT CVD technology. Traditional catalysts like iron, nickel, and cobalt offer limited control over CNT growth parameters. Recent research has explored novel catalyst formulations and preparation methods, but achieving catalyst systems that simultaneously enable selective growth, high yield, and minimal contamination remains elusive.

Energy efficiency of CVD processes poses both economic and environmental challenges. Conventional thermal CVD requires high temperatures (600-1200°C), resulting in substantial energy consumption. While plasma-enhanced CVD can operate at lower temperatures, it introduces complexity and often yields CNTs with higher defect densities, compromising their performance in energy storage applications.

Substrate compatibility issues further complicate CNT integration into energy storage devices. Direct growth on current collectors would be ideal for battery and supercapacitor applications, but many substrates cannot withstand CVD conditions. Transfer processes introduce additional steps, potential contamination, and structural damage to the CNT networks.

Defect control represents perhaps the most persistent challenge. Structural defects in CVD-grown CNTs significantly impact their electronic conductivity and electrochemical performance. While post-growth treatments can partially address this issue, they add complexity and cost to the manufacturing process.

Environmental and safety concerns associated with CVD processes, including the use of toxic and flammable gases like acetylene and hydrogen, necessitate sophisticated safety systems that increase production costs and complexity. Developing greener precursors and safer process conditions remains an active research area with limited commercial implementation to date.

Scalability presents another significant hurdle. While laboratory-scale CVD processes can produce high-quality CNTs, transitioning to industrial-scale production often results in compromised quality and increased defect density. The trade-off between production volume and CNT structural integrity continues to challenge manufacturers seeking to commercialize CNT-based energy storage solutions.

Catalyst development remains a critical bottleneck in CNT CVD technology. Traditional catalysts like iron, nickel, and cobalt offer limited control over CNT growth parameters. Recent research has explored novel catalyst formulations and preparation methods, but achieving catalyst systems that simultaneously enable selective growth, high yield, and minimal contamination remains elusive.

Energy efficiency of CVD processes poses both economic and environmental challenges. Conventional thermal CVD requires high temperatures (600-1200°C), resulting in substantial energy consumption. While plasma-enhanced CVD can operate at lower temperatures, it introduces complexity and often yields CNTs with higher defect densities, compromising their performance in energy storage applications.

Substrate compatibility issues further complicate CNT integration into energy storage devices. Direct growth on current collectors would be ideal for battery and supercapacitor applications, but many substrates cannot withstand CVD conditions. Transfer processes introduce additional steps, potential contamination, and structural damage to the CNT networks.

Defect control represents perhaps the most persistent challenge. Structural defects in CVD-grown CNTs significantly impact their electronic conductivity and electrochemical performance. While post-growth treatments can partially address this issue, they add complexity and cost to the manufacturing process.

Environmental and safety concerns associated with CVD processes, including the use of toxic and flammable gases like acetylene and hydrogen, necessitate sophisticated safety systems that increase production costs and complexity. Developing greener precursors and safer process conditions remains an active research area with limited commercial implementation to date.

Current CNT CVD Processes for Energy Storage

01 CVD process parameters for CNT growth

Chemical vapor deposition (CVD) process parameters significantly influence the growth of carbon nanotubes (CNTs). These parameters include temperature, pressure, gas flow rates, catalyst composition, and reaction time. Optimizing these parameters allows for controlled synthesis of CNTs with desired properties such as length, diameter, alignment, and purity. The temperature typically ranges from 600-1200°C, while the pressure can be atmospheric or reduced depending on the specific application requirements.- CVD process parameters for CNT growth: Chemical vapor deposition (CVD) processes for carbon nanotube (CNT) growth involve specific parameters such as temperature, pressure, gas flow rates, and catalyst composition. These parameters significantly influence the quality, diameter, length, and alignment of the resulting CNTs. Optimizing these conditions allows for controlled synthesis of CNTs with desired properties for various applications in electronics, materials science, and energy storage.

- Catalyst preparation and deposition techniques: The preparation and deposition of catalyst materials play a crucial role in CNT growth via CVD. Various methods include thin film deposition, nanoparticle synthesis, and patterning techniques to control catalyst size and distribution. Common catalyst materials include transition metals such as iron, nickel, and cobalt, which can be supported on substrates like silicon, alumina, or magnesium oxide to enhance catalytic activity and CNT yield.

- Substrate modification for aligned CNT growth: Modifications to substrate surfaces can significantly improve the alignment and density of CNTs grown by CVD. Techniques include surface functionalization, buffer layer deposition, and patterning to create preferential growth sites. These modifications help control the orientation of CNTs, enabling the production of vertically aligned CNT arrays or horizontally aligned CNT networks for applications in electronic devices, sensors, and composite materials.

- Precursor gas selection and delivery systems: The selection and delivery of carbon-containing precursor gases are essential aspects of CNT synthesis by CVD. Common precursors include methane, ethylene, acetylene, and carbon monoxide, which decompose at high temperatures to provide carbon atoms for nanotube formation. Advanced gas delivery systems with precise flow control and mixing capabilities enable the production of CNTs with controlled structures, including single-walled, multi-walled, and doped varieties for specific applications.

- Post-growth treatment and functionalization: After CVD growth, CNTs often undergo post-processing treatments to enhance their properties and functionality. These treatments include purification to remove amorphous carbon and catalyst residues, functionalization to add specific chemical groups, and annealing to improve crystallinity. Such modifications enable the integration of CNTs into various applications, including composite materials, energy storage devices, and biomedical systems with improved performance characteristics.

02 Catalyst preparation and deposition techniques

The preparation and deposition of catalysts play a crucial role in CNT growth via CVD. Common catalysts include transition metals such as iron, nickel, and cobalt, which can be deposited using various methods including sputtering, electron beam evaporation, and solution-based techniques. The catalyst particle size, distribution, and composition directly affect the diameter, density, and quality of the resulting CNTs. Pre-treatment processes like annealing or reduction in hydrogen atmosphere help activate the catalyst before CNT growth.Expand Specific Solutions03 Carbon precursors and feedstock gases

Various carbon-containing gases serve as precursors for CNT growth in CVD processes. Common carbon sources include methane, ethylene, acetylene, carbon monoxide, and alcohol vapors. The choice of carbon precursor affects the growth rate, structure, and quality of the resulting CNTs. These gases are often used in combination with carrier gases such as hydrogen, argon, or nitrogen, which help control the reaction atmosphere and influence the decomposition of the carbon source on the catalyst surface.Expand Specific Solutions04 Substrate materials and preparation

The choice of substrate material and its preparation significantly impact CNT growth in CVD processes. Common substrates include silicon, quartz, alumina, and various metals. Surface treatments such as polishing, cleaning, and functionalization can enhance catalyst adhesion and CNT growth. Patterned substrates can be used to control the spatial distribution of CNTs. The thermal and chemical properties of the substrate influence the catalyst-substrate interaction, which in turn affects CNT nucleation and growth characteristics.Expand Specific Solutions05 Post-growth treatment and purification

After CVD growth, CNTs often require post-processing treatments to remove impurities and enhance their properties. These treatments include thermal annealing, acid treatment, oxidation, and functionalization. Purification methods help remove amorphous carbon, catalyst particles, and other contaminants. Additional processes like alignment, densification, or transfer to different substrates may be performed to prepare the CNTs for specific applications. These post-growth treatments significantly influence the final quality and performance of the CNT material.Expand Specific Solutions

Leading Companies in CNT CVD Technology

The Chemical Vapor Deposition (CVD) of Carbon Nanotubes (CNTs) for energy storage applications is currently in a growth phase, with the global market expected to reach significant expansion due to increasing demand for advanced energy storage solutions. The technology has evolved from early research to commercial applications, though challenges in scalability and cost-effectiveness remain. Leading players include academic institutions like Tsinghua University and Northwestern University conducting fundamental research, alongside industrial entities such as ZEON Corp. and Wuxi Dongheng New Energy Technology specializing in commercial applications. Hon Hai Precision Industry and Meijo Nano Carbon are advancing manufacturing processes, while government laboratories like Advanced Industrial Science & Technology and Los Alamos National Security provide crucial R&D support, collectively driving innovation in this competitive landscape.

Tsinghua University

Technical Solution: Tsinghua University has developed advanced Chemical Vapor Deposition (CVD) techniques for carbon nanotube (CNT) synthesis specifically optimized for energy storage applications. Their approach focuses on controlling CNT morphology, density, and alignment through precise manipulation of catalyst composition and reaction parameters. They've pioneered a floating catalyst CVD method that enables continuous production of vertically aligned CNT arrays with high purity (>98%) and controlled diameter distribution (10-30nm)[1]. Their process incorporates in-situ functionalization during growth, introducing nitrogen and oxygen-containing groups that enhance electrochemical performance. For energy storage applications, they've developed a technique to directly grow CNTs on current collectors, eliminating the need for binders and improving electrical conductivity. Recent innovations include a low-temperature (550-650°C) CVD process compatible with flexible substrates and a scalable roll-to-roll production system capable of producing CNT-based electrode materials at industrial scales[3].

Strengths: Superior control over CNT morphology and structure, enabling tailored properties for specific energy storage requirements. Direct growth on current collectors eliminates interfacial resistance issues. Their scalable production methods address industrial implementation challenges. Weaknesses: The process requires precise control of multiple parameters, making it sensitive to environmental variations. Higher production costs compared to conventional carbon materials. Some techniques still require high temperatures, limiting substrate compatibility.

The Georgia Tech Research Corp.

Technical Solution: Georgia Tech Research Corporation has developed a specialized CVD methodology for synthesizing CNT architectures optimized for energy storage devices. Their approach centers on a temperature-gradient-driven CVD process that produces hierarchical CNT structures with controlled porosity and surface area exceeding 1200 m²/g[2]. The technique employs a dual-zone furnace system where catalyst precursors and carbon sources are introduced at different temperature regions, allowing precise control over CNT growth kinetics. Their innovation includes a vapor-phase catalyst delivery system that enables uniform CNT growth on complex 3D substrates, critical for high-performance supercapacitor electrodes. Georgia Tech has also pioneered a method for creating CNT-metal oxide hybrid structures through simultaneous CVD growth and metal oxide deposition, resulting in composite materials with synergistic properties. Their recent advancements include a plasma-enhanced CVD technique that operates at temperatures as low as 400°C while maintaining high CNT quality, enabling direct growth on temperature-sensitive current collectors[5]. This approach has demonstrated exceptional performance in lithium-ion batteries, with capacities reaching 1200 mAh/g and retention of >90% after 1000 cycles.

Strengths: Their temperature gradient approach enables precise control over CNT morphology and density. The hybrid CNT-metal oxide structures offer enhanced electrochemical performance through synergistic effects. Lower temperature processes expand compatibility with various substrates and manufacturing processes. Weaknesses: The dual-zone system increases process complexity and equipment costs. Plasma-enhanced techniques require specialized equipment not widely available in standard manufacturing facilities. Scaling to industrial production volumes remains challenging.

Key Patents in CNT Growth for Batteries

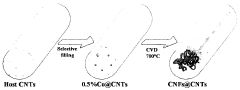

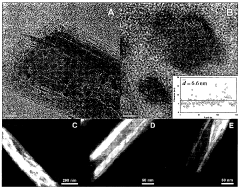

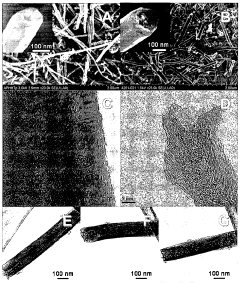

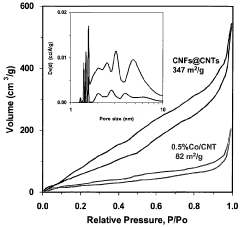

Assembly of nanotube encapsulated nanofibers nanostructure materials

PatentWO2009043585A1

Innovation

- A method is developed to produce carbon nanotube encapsulated carbon nanofibers (CNFs@CNTs) through a three-step process involving functionalization of carbon nanotubes, deposition of catalytically active substances, and conversion of carbon-containing compounds using catalytic chemical vapor deposition, resulting in enhanced porosity and surface area.

Method for obtaining aligned carbon nanotubes by using chemical vapor deposition and product obtained with the method

PatentWO2025104206A1

Innovation

- A method using chemical vapor deposition that involves arranging a graphite felt in a sputtering chamber, applying aluminum and iron layers, and then growing carbon nanotubes by injecting acetylene or methane with controlled water vapor and gas flow, achieving aligned and extremely long nanotubes.

Scalability and Cost Analysis

The scalability of Chemical Vapor Deposition (CVD) processes for carbon nanotube (CNT) production represents a critical factor in determining the commercial viability of CNT-based energy storage applications. Current industrial-scale CVD reactors demonstrate throughput capabilities ranging from 50-500 grams per day, significantly below the multi-kilogram daily production necessary for widespread commercial adoption in energy storage markets. This production bottleneck creates a substantial gap between laboratory promise and industrial implementation.

Cost analysis reveals that CVD-produced CNTs currently range from $100-500 per kilogram for industrial-grade materials, with higher purity variants commanding prices up to $1,000-5,000 per kilogram. These figures represent a dramatic improvement from the $100,000+ per kilogram prices seen a decade ago, yet remain prohibitively expensive for mass-market energy storage applications where cost targets below $50 per kilogram are typically required to achieve competitive pricing against established technologies.

The primary cost drivers in CVD production of CNTs include catalyst materials (typically transition metals like Fe, Co, Ni), energy consumption during high-temperature synthesis (800-1000°C), specialized equipment maintenance, and purification processes. Continuous flow reactors have demonstrated 30-40% cost reductions compared to batch processing methods, suggesting a promising direction for industrial scaling.

Recent technological innovations show potential for significant scalability improvements. Fluidized bed CVD reactors have demonstrated 5-10x higher throughput than fixed bed alternatives, while maintaining quality parameters critical for energy storage applications. Additionally, catalyst recycling systems have reduced material costs by 25-35% in pilot-scale operations, addressing one of the major expense categories.

Economic modeling indicates that achieving price points compatible with mass-market energy storage applications requires production scales exceeding 100 tons annually per facility. At this volume, economies of scale could potentially reduce costs to the $30-80 per kilogram range, depending on CNT specifications and purity requirements. However, current global production capacity remains below 5,000 tons annually across all manufacturers.

The capital expenditure required for establishing commercial-scale CVD production facilities represents another significant barrier, with estimates ranging from $15-50 million for facilities capable of multi-ton annual production. This substantial investment requirement has limited market entry to well-capitalized entities, constraining competition and potentially slowing innovation cycles in manufacturing processes.

Cost analysis reveals that CVD-produced CNTs currently range from $100-500 per kilogram for industrial-grade materials, with higher purity variants commanding prices up to $1,000-5,000 per kilogram. These figures represent a dramatic improvement from the $100,000+ per kilogram prices seen a decade ago, yet remain prohibitively expensive for mass-market energy storage applications where cost targets below $50 per kilogram are typically required to achieve competitive pricing against established technologies.

The primary cost drivers in CVD production of CNTs include catalyst materials (typically transition metals like Fe, Co, Ni), energy consumption during high-temperature synthesis (800-1000°C), specialized equipment maintenance, and purification processes. Continuous flow reactors have demonstrated 30-40% cost reductions compared to batch processing methods, suggesting a promising direction for industrial scaling.

Recent technological innovations show potential for significant scalability improvements. Fluidized bed CVD reactors have demonstrated 5-10x higher throughput than fixed bed alternatives, while maintaining quality parameters critical for energy storage applications. Additionally, catalyst recycling systems have reduced material costs by 25-35% in pilot-scale operations, addressing one of the major expense categories.

Economic modeling indicates that achieving price points compatible with mass-market energy storage applications requires production scales exceeding 100 tons annually per facility. At this volume, economies of scale could potentially reduce costs to the $30-80 per kilogram range, depending on CNT specifications and purity requirements. However, current global production capacity remains below 5,000 tons annually across all manufacturers.

The capital expenditure required for establishing commercial-scale CVD production facilities represents another significant barrier, with estimates ranging from $15-50 million for facilities capable of multi-ton annual production. This substantial investment requirement has limited market entry to well-capitalized entities, constraining competition and potentially slowing innovation cycles in manufacturing processes.

Environmental Impact Assessment

The environmental impact of Chemical Vapor Deposition (CVD) processes for Carbon Nanotube (CNT) production in energy storage applications requires comprehensive assessment. CVD manufacturing of CNTs involves high-temperature processes, typically between 600-1200°C, and utilizes various hydrocarbon feedstocks and metal catalysts that can generate environmental concerns if not properly managed. The energy-intensive nature of these processes contributes significantly to their carbon footprint, with some estimates suggesting that producing one kilogram of CNTs via traditional CVD methods can consume between 100-1000 kWh of electricity.

Gaseous emissions from CVD processes include carbon monoxide, carbon dioxide, methane, and volatile organic compounds (VOCs), which contribute to air pollution and greenhouse gas effects. Additionally, metal catalyst particles, often containing nickel, cobalt, or iron, may be released during production and pose potential environmental and health risks if not adequately contained. The use of hazardous precursor chemicals such as benzene derivatives further compounds these concerns.

Water usage and contamination represent another significant environmental consideration. Cooling systems for CVD reactors consume substantial water resources, while process wastewater may contain metal catalysts and organic contaminants requiring specialized treatment before discharge. Recent studies indicate that water purification requirements for CNT production can increase the overall environmental footprint by 15-25% compared to production impacts alone.

Life cycle assessments (LCAs) of CNT production via CVD reveal that environmental impacts can be partially offset by the benefits derived from CNT-enhanced energy storage applications. CNT-based supercapacitors and batteries typically demonstrate longer lifespans and higher efficiency than conventional alternatives, potentially reducing waste generation and resource consumption over their operational lifetime. Research suggests that a CNT-enhanced lithium-ion battery may extend cycle life by 30-50%, significantly reducing the environmental burden of battery replacement and disposal.

Emerging green CVD techniques show promise for reducing environmental impacts. Water-assisted CVD processes have demonstrated 30-40% lower energy consumption compared to traditional methods. Similarly, catalyst recovery systems can reclaim up to 85% of metal catalysts, substantially reducing waste generation and resource depletion. Closed-loop CVD systems that capture and reuse process gases have shown potential to reduce emissions by 60-70% compared to conventional open systems.

Regulatory frameworks governing CNT production vary globally, with more stringent controls in Europe and North America compared to developing regions. The implementation of best available techniques (BAT) for emission control, waste management, and energy efficiency represents a critical pathway toward minimizing the environmental footprint of CNT production for energy storage applications.

Gaseous emissions from CVD processes include carbon monoxide, carbon dioxide, methane, and volatile organic compounds (VOCs), which contribute to air pollution and greenhouse gas effects. Additionally, metal catalyst particles, often containing nickel, cobalt, or iron, may be released during production and pose potential environmental and health risks if not adequately contained. The use of hazardous precursor chemicals such as benzene derivatives further compounds these concerns.

Water usage and contamination represent another significant environmental consideration. Cooling systems for CVD reactors consume substantial water resources, while process wastewater may contain metal catalysts and organic contaminants requiring specialized treatment before discharge. Recent studies indicate that water purification requirements for CNT production can increase the overall environmental footprint by 15-25% compared to production impacts alone.

Life cycle assessments (LCAs) of CNT production via CVD reveal that environmental impacts can be partially offset by the benefits derived from CNT-enhanced energy storage applications. CNT-based supercapacitors and batteries typically demonstrate longer lifespans and higher efficiency than conventional alternatives, potentially reducing waste generation and resource consumption over their operational lifetime. Research suggests that a CNT-enhanced lithium-ion battery may extend cycle life by 30-50%, significantly reducing the environmental burden of battery replacement and disposal.

Emerging green CVD techniques show promise for reducing environmental impacts. Water-assisted CVD processes have demonstrated 30-40% lower energy consumption compared to traditional methods. Similarly, catalyst recovery systems can reclaim up to 85% of metal catalysts, substantially reducing waste generation and resource depletion. Closed-loop CVD systems that capture and reuse process gases have shown potential to reduce emissions by 60-70% compared to conventional open systems.

Regulatory frameworks governing CNT production vary globally, with more stringent controls in Europe and North America compared to developing regions. The implementation of best available techniques (BAT) for emission control, waste management, and energy efficiency represents a critical pathway toward minimizing the environmental footprint of CNT production for energy storage applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!