LFP Battery Vs NMC: Safety Margin, Cycle Life And Low-Temperature Performance

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP vs NMC Battery Technology Background and Objectives

Lithium-ion batteries have revolutionized energy storage systems across multiple industries, from consumer electronics to electric vehicles and renewable energy storage. Among the various lithium-ion battery chemistries, Lithium Iron Phosphate (LFP) and Lithium Nickel Manganese Cobalt Oxide (NMC) have emerged as dominant technologies with distinct characteristics and applications.

The evolution of these battery technologies traces back to the early 1990s when LFP was first developed as a safer alternative to earlier lithium-ion chemistries. LFP batteries gained prominence for their enhanced thermal stability and longer cycle life, albeit with lower energy density. Concurrently, NMC batteries were developed to address the energy density limitations while maintaining reasonable safety profiles.

Over the past decade, both technologies have undergone significant refinements. LFP batteries have seen improvements in energy density and low-temperature performance, while NMC batteries have evolved through multiple generations (NMC111, NMC532, NMC622, and NMC811) with increasing nickel content to enhance energy density and reduce cobalt dependency.

The current technological landscape shows a clear divergence in application focus. LFP batteries dominate in applications where safety and longevity are paramount, such as energy storage systems and certain electric vehicle segments. Meanwhile, NMC batteries lead in applications requiring higher energy density, such as premium electric vehicles and portable electronics.

Market trends indicate a resurgence of interest in LFP technology, particularly in the electric vehicle sector, driven by cost advantages and reduced supply chain risks associated with avoiding cobalt and nickel. Simultaneously, NMC technology continues to advance toward higher nickel formulations to maximize energy density while addressing thermal stability concerns.

The primary technical objectives for both chemistries include enhancing safety margins, extending cycle life, and improving low-temperature performance. For LFP batteries, key goals include increasing energy density without compromising their inherent safety advantages and addressing performance limitations at low temperatures. For NMC batteries, reducing thermal runaway risks while maintaining high energy density and extending cycle life remain critical objectives.

Future technological trajectories point toward hybrid approaches that combine the strengths of both chemistries, such as cell designs incorporating both LFP and NMC materials or gradient cathodes that transition between different compositions. Additionally, research into advanced electrolytes and battery management systems aims to mitigate the inherent limitations of each chemistry.

The evolution of these battery technologies traces back to the early 1990s when LFP was first developed as a safer alternative to earlier lithium-ion chemistries. LFP batteries gained prominence for their enhanced thermal stability and longer cycle life, albeit with lower energy density. Concurrently, NMC batteries were developed to address the energy density limitations while maintaining reasonable safety profiles.

Over the past decade, both technologies have undergone significant refinements. LFP batteries have seen improvements in energy density and low-temperature performance, while NMC batteries have evolved through multiple generations (NMC111, NMC532, NMC622, and NMC811) with increasing nickel content to enhance energy density and reduce cobalt dependency.

The current technological landscape shows a clear divergence in application focus. LFP batteries dominate in applications where safety and longevity are paramount, such as energy storage systems and certain electric vehicle segments. Meanwhile, NMC batteries lead in applications requiring higher energy density, such as premium electric vehicles and portable electronics.

Market trends indicate a resurgence of interest in LFP technology, particularly in the electric vehicle sector, driven by cost advantages and reduced supply chain risks associated with avoiding cobalt and nickel. Simultaneously, NMC technology continues to advance toward higher nickel formulations to maximize energy density while addressing thermal stability concerns.

The primary technical objectives for both chemistries include enhancing safety margins, extending cycle life, and improving low-temperature performance. For LFP batteries, key goals include increasing energy density without compromising their inherent safety advantages and addressing performance limitations at low temperatures. For NMC batteries, reducing thermal runaway risks while maintaining high energy density and extending cycle life remain critical objectives.

Future technological trajectories point toward hybrid approaches that combine the strengths of both chemistries, such as cell designs incorporating both LFP and NMC materials or gradient cathodes that transition between different compositions. Additionally, research into advanced electrolytes and battery management systems aims to mitigate the inherent limitations of each chemistry.

Market Demand Analysis for LFP and NMC Batteries

The global battery market has witnessed significant growth in recent years, primarily driven by the increasing adoption of electric vehicles (EVs) and renewable energy storage systems. Within this landscape, Lithium Iron Phosphate (LFP) and Lithium Nickel Manganese Cobalt Oxide (NMC) batteries have emerged as dominant technologies, each catering to specific market segments based on their unique performance characteristics.

The EV market represents the largest demand driver for both LFP and NMC batteries. According to market research, global EV sales reached 10.5 million units in 2022, with projections indicating a compound annual growth rate (CAGR) of 21% through 2030. This explosive growth has created substantial demand for high-performance batteries that balance safety, longevity, and performance.

Consumer preferences are increasingly segmenting the market between these two technologies. NMC batteries currently dominate in premium and long-range EV segments where energy density is paramount. The higher energy density of NMC batteries (180-220 Wh/kg compared to LFP's 100-160 Wh/kg) allows for greater driving range, a critical factor for consumers in developed markets like North America and Europe.

Conversely, LFP batteries have gained significant traction in cost-sensitive markets and applications where safety and longevity outweigh energy density considerations. The Chinese EV market, the world's largest, has seen LFP battery adoption rise from 39% in 2020 to over 57% in 2022, demonstrating the strong market pull for this technology in certain regions.

The stationary energy storage sector represents another major growth area for both technologies. Grid-scale storage installations grew by 68% in 2022, with forecasts suggesting the market will reach 500 GWh by 2030. In this application, LFP's superior cycle life and safety characteristics have made it the preferred choice, capturing approximately 80% of new grid storage deployments.

Price sensitivity remains a critical market factor. The cost advantage of LFP batteries (approximately 30% lower than NMC on a per kWh basis) has driven their adoption in mass-market vehicles and stationary storage. However, recent supply chain disruptions and raw material price volatility have narrowed this gap, potentially shifting market dynamics.

Regulatory frameworks are increasingly influencing market demand patterns. Safety regulations in densely populated urban areas favor LFP technology, while performance-focused incentives in regions like the European Union tend to benefit NMC batteries. The introduction of the Inflation Reduction Act in the United States has created additional market complexities by prioritizing domestic battery production and specific supply chains.

The EV market represents the largest demand driver for both LFP and NMC batteries. According to market research, global EV sales reached 10.5 million units in 2022, with projections indicating a compound annual growth rate (CAGR) of 21% through 2030. This explosive growth has created substantial demand for high-performance batteries that balance safety, longevity, and performance.

Consumer preferences are increasingly segmenting the market between these two technologies. NMC batteries currently dominate in premium and long-range EV segments where energy density is paramount. The higher energy density of NMC batteries (180-220 Wh/kg compared to LFP's 100-160 Wh/kg) allows for greater driving range, a critical factor for consumers in developed markets like North America and Europe.

Conversely, LFP batteries have gained significant traction in cost-sensitive markets and applications where safety and longevity outweigh energy density considerations. The Chinese EV market, the world's largest, has seen LFP battery adoption rise from 39% in 2020 to over 57% in 2022, demonstrating the strong market pull for this technology in certain regions.

The stationary energy storage sector represents another major growth area for both technologies. Grid-scale storage installations grew by 68% in 2022, with forecasts suggesting the market will reach 500 GWh by 2030. In this application, LFP's superior cycle life and safety characteristics have made it the preferred choice, capturing approximately 80% of new grid storage deployments.

Price sensitivity remains a critical market factor. The cost advantage of LFP batteries (approximately 30% lower than NMC on a per kWh basis) has driven their adoption in mass-market vehicles and stationary storage. However, recent supply chain disruptions and raw material price volatility have narrowed this gap, potentially shifting market dynamics.

Regulatory frameworks are increasingly influencing market demand patterns. Safety regulations in densely populated urban areas favor LFP technology, while performance-focused incentives in regions like the European Union tend to benefit NMC batteries. The introduction of the Inflation Reduction Act in the United States has created additional market complexities by prioritizing domestic battery production and specific supply chains.

Current Technical Challenges in Battery Chemistry

Despite significant advancements in lithium-ion battery technology, both Lithium Iron Phosphate (LFP) and Nickel Manganese Cobalt (NMC) chemistries face substantial technical challenges that limit their performance and widespread adoption. These challenges are particularly evident when comparing their safety margins, cycle life, and low-temperature performance characteristics.

For LFP batteries, thermal stability remains superior to NMC, but this comes at the cost of energy density. Current LFP formulations struggle to exceed 160 Wh/kg, significantly lower than NMC's 200-250 Wh/kg. This energy density limitation restricts LFP's applicability in range-sensitive applications like electric vehicles, despite its excellent safety profile. Additionally, LFP batteries exhibit poor conductivity, necessitating sophisticated particle engineering and conductive additives that increase manufacturing complexity.

Low-temperature performance represents a critical challenge for LFP chemistry. Below 0°C, LFP batteries experience dramatic capacity reduction, sometimes losing up to 40% of their room temperature capacity at -20°C. This limitation stems from reduced lithium-ion diffusion rates within the cathode structure at lower temperatures, creating a significant barrier for cold-climate applications.

NMC batteries face different but equally significant challenges. Their higher energy density comes with inherent safety concerns due to thermal runaway risks, particularly in NMC formulations with higher nickel content (NMC 811). Oxygen release during thermal decomposition can trigger catastrophic cell failure, requiring sophisticated battery management systems and thermal control mechanisms that add cost and complexity.

Cycle life degradation in NMC batteries presents another major challenge. High-nickel NMC variants experience accelerated capacity fade due to structural instability, electrolyte decomposition, and cathode-electrolyte interface degradation. Current research indicates that surface coating technologies and electrolyte additives can mitigate these issues, but often at the expense of initial capacity or increased production costs.

Both chemistries face challenges related to sustainable manufacturing and material sourcing. NMC's reliance on cobalt presents ethical and supply chain concerns, while both technologies require significant lithium resources. The extraction and processing of these materials have substantial environmental impacts that must be addressed for truly sustainable battery technology.

Fast-charging capabilities remain limited in both chemistries, with LFP generally accepting higher C-rates but suffering more severe low-temperature charging limitations. NMC batteries typically require more conservative charging protocols to prevent accelerated degradation, particularly in high-nickel variants.

These technical challenges highlight the need for continued research into advanced electrode materials, electrolyte formulations, and cell design to optimize the performance of both LFP and NMC batteries across their respective application domains.

For LFP batteries, thermal stability remains superior to NMC, but this comes at the cost of energy density. Current LFP formulations struggle to exceed 160 Wh/kg, significantly lower than NMC's 200-250 Wh/kg. This energy density limitation restricts LFP's applicability in range-sensitive applications like electric vehicles, despite its excellent safety profile. Additionally, LFP batteries exhibit poor conductivity, necessitating sophisticated particle engineering and conductive additives that increase manufacturing complexity.

Low-temperature performance represents a critical challenge for LFP chemistry. Below 0°C, LFP batteries experience dramatic capacity reduction, sometimes losing up to 40% of their room temperature capacity at -20°C. This limitation stems from reduced lithium-ion diffusion rates within the cathode structure at lower temperatures, creating a significant barrier for cold-climate applications.

NMC batteries face different but equally significant challenges. Their higher energy density comes with inherent safety concerns due to thermal runaway risks, particularly in NMC formulations with higher nickel content (NMC 811). Oxygen release during thermal decomposition can trigger catastrophic cell failure, requiring sophisticated battery management systems and thermal control mechanisms that add cost and complexity.

Cycle life degradation in NMC batteries presents another major challenge. High-nickel NMC variants experience accelerated capacity fade due to structural instability, electrolyte decomposition, and cathode-electrolyte interface degradation. Current research indicates that surface coating technologies and electrolyte additives can mitigate these issues, but often at the expense of initial capacity or increased production costs.

Both chemistries face challenges related to sustainable manufacturing and material sourcing. NMC's reliance on cobalt presents ethical and supply chain concerns, while both technologies require significant lithium resources. The extraction and processing of these materials have substantial environmental impacts that must be addressed for truly sustainable battery technology.

Fast-charging capabilities remain limited in both chemistries, with LFP generally accepting higher C-rates but suffering more severe low-temperature charging limitations. NMC batteries typically require more conservative charging protocols to prevent accelerated degradation, particularly in high-nickel variants.

These technical challenges highlight the need for continued research into advanced electrode materials, electrolyte formulations, and cell design to optimize the performance of both LFP and NMC batteries across their respective application domains.

Comparative Technical Solutions: LFP vs NMC Architectures

01 Safety margin comparison between LFP and NMC batteries

Lithium iron phosphate (LFP) batteries generally offer superior safety margins compared to nickel manganese cobalt (NMC) batteries. LFP batteries have better thermal stability and are less prone to thermal runaway, making them safer under extreme conditions. The inherent chemical stability of the LFP cathode material contributes to this enhanced safety profile. In contrast, NMC batteries contain cobalt, which can make them more susceptible to thermal issues when damaged or improperly managed, though they offer higher energy density.- Safety margin comparison between LFP and NMC batteries: Lithium iron phosphate (LFP) batteries generally offer superior safety margins compared to nickel manganese cobalt (NMC) batteries. LFP batteries have better thermal stability and are less prone to thermal runaway events due to their more stable cathode structure. They can withstand higher temperatures and abuse conditions without catastrophic failure. NMC batteries, while having higher energy density, present greater safety risks due to their cobalt content and tendency to release oxygen during thermal events, which can accelerate battery degradation under extreme conditions.

- Cycle life performance of LFP versus NMC batteries: LFP batteries typically demonstrate superior cycle life compared to NMC batteries, often achieving 2000-3000 cycles while maintaining 80% capacity retention. This longevity stems from the stable olivine structure of LFP cathodes that experiences minimal structural changes during charge-discharge cycles. NMC batteries generally deliver 1000-2000 cycles before reaching similar degradation levels, with their cycle life heavily dependent on the specific nickel-manganese-cobalt ratio. Higher nickel content in NMC formulations increases energy density but typically reduces cycle life due to greater structural instability during repeated cycling.

- Low-temperature performance characteristics: NMC batteries generally outperform LFP batteries in low-temperature environments. LFP batteries suffer from significant capacity reduction and power limitations when operating below 0°C due to slower lithium-ion diffusion kinetics and increased internal resistance at low temperatures. NMC batteries maintain better capacity retention and discharge capabilities in cold conditions, making them more suitable for applications in cold climates. Various electrolyte additives and electrode modifications are being developed to improve the low-temperature performance of both battery types, with particular focus on enhancing LFP's cold weather limitations.

- Energy density and power capabilities comparison: NMC batteries offer significantly higher energy density (180-220 Wh/kg) compared to LFP batteries (100-160 Wh/kg), making NMC more suitable for applications where weight and space constraints are critical. However, LFP batteries typically provide better power capabilities with higher discharge rates and superior current handling abilities. This makes LFP batteries advantageous for applications requiring high power output and fast charging capabilities. The energy density gap continues to narrow as both technologies evolve, with newer LFP formulations achieving improved energy density while maintaining their inherent safety and longevity advantages.

- Battery management system requirements and optimization: LFP and NMC batteries require different battery management system (BMS) approaches due to their distinct characteristics. LFP batteries present challenges for state-of-charge estimation due to their flat voltage curve, necessitating more sophisticated BMS algorithms. NMC batteries require stricter voltage and temperature monitoring to prevent operation outside safe limits. Advanced BMS designs incorporate cell balancing, thermal management, and predictive analytics to optimize performance and extend battery life for both chemistries. Proper BMS calibration specific to each chemistry can significantly improve safety margins, cycle life, and low-temperature performance.

02 Cycle life performance of LFP versus NMC batteries

LFP batteries typically demonstrate superior cycle life compared to NMC batteries, often achieving 2000-3000 cycles before significant capacity degradation occurs. This longevity is attributed to the stable olivine structure of the LFP cathode that experiences minimal structural changes during charging and discharging. NMC batteries generally offer 1000-2000 cycles depending on the specific formulation, with higher nickel content variants showing faster capacity fade. The trade-off is that NMC batteries provide higher energy density despite their shorter lifespan.Expand Specific Solutions03 Low-temperature performance challenges and solutions

Both LFP and NMC batteries face performance challenges at low temperatures, but NMC generally performs better in cold conditions. LFP batteries experience more significant capacity reduction and power limitations below 0°C due to slower lithium-ion kinetics. Innovations to improve low-temperature performance include electrolyte additives, modified electrode structures, and advanced battery management systems with preheating functions. Some solutions involve incorporating silicon-based materials in anodes or using electrolyte formulations with lower freezing points to maintain conductivity in cold environments.Expand Specific Solutions04 Battery management systems for optimizing performance

Advanced battery management systems (BMS) are crucial for optimizing the performance of both LFP and NMC batteries. These systems monitor and control various parameters including temperature, state of charge, and voltage to ensure safe operation while maximizing efficiency. For LFP batteries, sophisticated BMS algorithms help address the flat voltage curve challenge that makes state-of-charge estimation difficult. For NMC batteries, thermal management is particularly important to prevent overheating. Modern BMS designs incorporate machine learning algorithms to adapt to battery aging patterns and optimize charging protocols based on usage conditions.Expand Specific Solutions05 Hybrid and composite cathode technologies

Innovative approaches combine the advantages of both LFP and NMC chemistries through hybrid or composite cathode designs. These technologies aim to balance safety, cycle life, energy density, and low-temperature performance in a single battery system. Some designs feature layered or blended cathode structures with both LFP and NMC materials, while others incorporate dopants or coatings to enhance specific properties. Advanced manufacturing techniques enable precise control of particle morphology and distribution, optimizing the interface between different cathode materials. These hybrid solutions are particularly valuable for applications requiring a balanced performance profile across multiple parameters.Expand Specific Solutions

Key Industry Players in LFP and NMC Battery Manufacturing

The lithium battery market is experiencing rapid growth, currently in a mature expansion phase with an estimated global market size exceeding $50 billion and projected to reach $135 billion by 2030. The competitive landscape for LFP vs NMC batteries shows distinct technological positioning: Contemporary Amperex Technology (CATL) and LG Energy Solution lead in both chemistries, with CATL dominating LFP production while LG Energy Solution excels in high-performance NMC batteries. Technical maturity varies significantly - LFP technology demonstrates superior safety margins and cycle life (evidenced by CATL's advancements reaching 6,000+ cycles), while NMC offers better energy density and low-temperature performance (showcased by innovations from GM Global Technology and Automotive Cells Company). Research institutions like Karlsruhe Institute of Technology and Industrial Technology Research Institute are advancing both chemistries, with recent breakthroughs focusing on improving LFP's cold-weather performance and NMC's safety profile.

GM Global Technology Operations LLC

Technical Solution: GM has developed the Ultium battery platform that incorporates both NMC and LFP chemistries for different vehicle segments. Their advanced NMC batteries utilize a proprietary NCMA (nickel, cobalt, manganese, aluminum) cathode formulation that reduces cobalt content by over 70% while maintaining energy densities of 230-255 Wh/kg. For safety, GM implements a wireless battery management system that provides real-time cell monitoring and predictive analytics to prevent thermal events. Their comparative testing shows that while their NMC batteries offer approximately 40% higher energy density than LFP alternatives, their enhanced LFP options demonstrate 2-3 times longer cycle life (5,000+ cycles vs. 1,800 for NMC). GM's low-temperature performance innovations include a patented thermal management system that maintains optimal cell temperature across extreme conditions, allowing their NMC batteries to deliver 80% capacity at -20°C compared to 65% for their LFP variants.

Strengths: Flexible battery architecture supporting multiple chemistries; advanced thermal management systems; vertical integration of battery development and vehicle design enabling optimized performance. Weaknesses: NMC options still have higher cost and resource constraints; LFP variants have lower energy density limiting range in smaller vehicles; complex supply chain management required for dual chemistry approach.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed advanced LFP battery technology with their Cell-to-Pack (CTP) solution that significantly improves energy density of LFP batteries. Their third-generation CTP technology achieves energy densities of up to 160-170 Wh/kg for LFP batteries, narrowing the gap with NMC batteries. CATL's LFP batteries feature enhanced low-temperature performance through electrolyte optimization and specialized heating systems that can warm cells from -20°C to operational temperatures within minutes. For cycle life, CATL's LFP batteries demonstrate over 6,000 cycles at 80% capacity retention, substantially outperforming typical NMC batteries (1,000-2,000 cycles). Safety-wise, CATL implements multi-layer protection systems including thermal propagation prevention technology that isolates thermal runaway events to single cells, preventing catastrophic failures across the pack.

Strengths: Superior cycle life and safety performance compared to NMC; cost-effective production; thermal management innovations that address traditional LFP low-temperature weaknesses. Weaknesses: Despite improvements, still has lower energy density than high-nickel NMC batteries; requires more sophisticated thermal management systems for cold weather operation.

Critical Safety and Performance Parameters Analysis

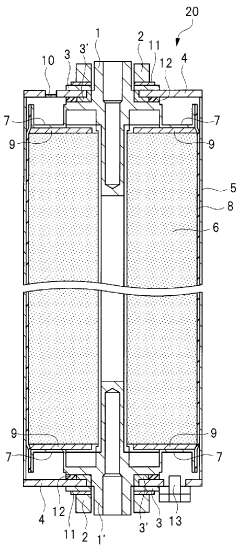

Lithium-ion cell

PatentWO2013129182A1

Innovation

- A lithium-ion battery design featuring a positive electrode mixture of layered lithium-nickel-manganese-cobalt composite oxide (NMC) and olivine-type lithium iron phosphate (LFP) with specific density, coating amount, and weight ratio, optimized to achieve high capacity and input/output performance while ensuring safety through controlled chemical reactions and structural stability.

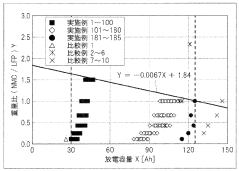

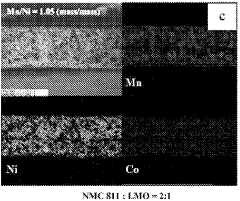

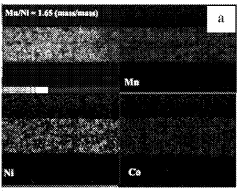

Active material for cathode of lithium-ion battery, cathode comprising said active material, and method for preparing said cathode

PatentWO2023170449A1

Innovation

- A cathode active material is developed by combining lithium manganese oxide (LMO) with lithium nickel manganese cobalt oxide (NMC) in specific mole ratios, enhancing stability and cycle life, and incorporating a binder and conductive material for improved electron and ion transfer, with the mixture's mass ratio optimized for high energy density and long cycle life.

Environmental Impact and Sustainability Assessment

The environmental footprint of battery technologies has become increasingly critical in the sustainable energy transition. LFP (Lithium Iron Phosphate) batteries demonstrate significant environmental advantages over NMC (Nickel Manganese Cobalt) batteries, primarily due to their material composition. LFP batteries avoid the use of nickel and cobalt—metals associated with intensive mining practices, human rights concerns, and substantial carbon emissions during extraction and processing.

Raw material sourcing for LFP batteries generates approximately 30% lower greenhouse gas emissions compared to NMC batteries. This reduction stems from the abundance and accessibility of iron and phosphate, which require less energy-intensive mining operations than nickel and cobalt extraction. Additionally, the supply chain for LFP batteries typically involves fewer geopolitical complications and reduced transportation distances.

Manufacturing processes for both battery types consume significant energy, but LFP production generally requires lower temperatures and less complex synthesis procedures. Studies indicate that LFP battery production can reduce energy consumption by 10-15% compared to equivalent NMC manufacturing processes, translating to a smaller carbon footprint during the production phase.

End-of-life considerations strongly favor LFP batteries. Their inherently safer chemistry facilitates easier recycling processes with reduced risk of thermal events during material recovery. Current recycling technologies can recover up to 95% of materials from LFP batteries, while NMC recycling faces challenges with separating the mixed metal oxides efficiently. This superior recyclability contributes to circular economy principles and reduces the need for virgin material extraction.

Water usage patterns also differ significantly between the two technologies. NMC production requires approximately 50-65% more water than LFP manufacturing, primarily due to the intensive hydrometallurgical processes needed for nickel and cobalt refinement. This difference becomes particularly relevant in regions facing water scarcity challenges.

Lifecycle assessment studies indicate that LFP batteries have 25-30% lower overall environmental impact scores across categories including acidification potential, eutrophication, and human toxicity potential. However, NMC batteries maintain advantages in land use efficiency due to their higher energy density, requiring less physical space for equivalent energy storage capacity.

The sustainability gap between these technologies is expected to narrow as manufacturing processes evolve and recycling infrastructure matures. Nevertheless, current environmental metrics consistently favor LFP batteries, particularly when considering the full lifecycle environmental impact from raw material extraction through end-of-life management.

Raw material sourcing for LFP batteries generates approximately 30% lower greenhouse gas emissions compared to NMC batteries. This reduction stems from the abundance and accessibility of iron and phosphate, which require less energy-intensive mining operations than nickel and cobalt extraction. Additionally, the supply chain for LFP batteries typically involves fewer geopolitical complications and reduced transportation distances.

Manufacturing processes for both battery types consume significant energy, but LFP production generally requires lower temperatures and less complex synthesis procedures. Studies indicate that LFP battery production can reduce energy consumption by 10-15% compared to equivalent NMC manufacturing processes, translating to a smaller carbon footprint during the production phase.

End-of-life considerations strongly favor LFP batteries. Their inherently safer chemistry facilitates easier recycling processes with reduced risk of thermal events during material recovery. Current recycling technologies can recover up to 95% of materials from LFP batteries, while NMC recycling faces challenges with separating the mixed metal oxides efficiently. This superior recyclability contributes to circular economy principles and reduces the need for virgin material extraction.

Water usage patterns also differ significantly between the two technologies. NMC production requires approximately 50-65% more water than LFP manufacturing, primarily due to the intensive hydrometallurgical processes needed for nickel and cobalt refinement. This difference becomes particularly relevant in regions facing water scarcity challenges.

Lifecycle assessment studies indicate that LFP batteries have 25-30% lower overall environmental impact scores across categories including acidification potential, eutrophication, and human toxicity potential. However, NMC batteries maintain advantages in land use efficiency due to their higher energy density, requiring less physical space for equivalent energy storage capacity.

The sustainability gap between these technologies is expected to narrow as manufacturing processes evolve and recycling infrastructure matures. Nevertheless, current environmental metrics consistently favor LFP batteries, particularly when considering the full lifecycle environmental impact from raw material extraction through end-of-life management.

Cost-Performance Trade-offs and Economic Viability

The economic analysis of LFP (Lithium Iron Phosphate) versus NMC (Nickel Manganese Cobalt) batteries reveals significant cost-performance trade-offs that impact their market adoption and economic viability. LFP batteries generally offer a lower cost structure, with current market prices approximately 20-30% less than comparable NMC batteries, primarily due to the absence of expensive metals like nickel and cobalt in their cathode composition.

Initial acquisition costs favor LFP batteries, making them particularly attractive for price-sensitive applications where energy density requirements are moderate. However, when evaluating total cost of ownership (TCO), the calculation becomes more nuanced and application-dependent.

For applications prioritizing longevity, LFP's superior cycle life (typically 3,000-4,000 cycles compared to NMC's 1,000-2,000 cycles) translates to a lower cost per cycle despite the higher upfront cost per kWh of storage capacity. This advantage becomes particularly pronounced in stationary storage applications where weight and volume constraints are less critical.

The economic equation shifts when considering energy density requirements. NMC batteries deliver 30-50% higher energy density, making them more economical for weight and space-constrained applications like electric vehicles, where the cost premium may be justified by extended range capabilities and reduced structural requirements.

Temperature performance considerations also impact economic viability. NMC's superior low-temperature performance reduces the need for additional thermal management systems in cold-climate applications, potentially offsetting some of its higher initial costs through reduced system complexity.

Safety factors introduce another economic dimension, as LFP's enhanced thermal stability may reduce insurance premiums and safety system requirements. This advantage becomes particularly valuable in large-scale installations where thermal runaway risks carry significant financial implications.

Market dynamics and supply chain considerations further influence the economic equation. LFP batteries benefit from more stable raw material pricing due to abundant iron resources, while NMC batteries face volatility in nickel and cobalt markets, creating potential long-term cost advantages for LFP technology despite current performance limitations.

The manufacturing scale also impacts economic viability, with LFP benefiting from significant production capacity expansion in China, driving economies of scale that have narrowed the price gap with NMC technologies in recent years.

Initial acquisition costs favor LFP batteries, making them particularly attractive for price-sensitive applications where energy density requirements are moderate. However, when evaluating total cost of ownership (TCO), the calculation becomes more nuanced and application-dependent.

For applications prioritizing longevity, LFP's superior cycle life (typically 3,000-4,000 cycles compared to NMC's 1,000-2,000 cycles) translates to a lower cost per cycle despite the higher upfront cost per kWh of storage capacity. This advantage becomes particularly pronounced in stationary storage applications where weight and volume constraints are less critical.

The economic equation shifts when considering energy density requirements. NMC batteries deliver 30-50% higher energy density, making them more economical for weight and space-constrained applications like electric vehicles, where the cost premium may be justified by extended range capabilities and reduced structural requirements.

Temperature performance considerations also impact economic viability. NMC's superior low-temperature performance reduces the need for additional thermal management systems in cold-climate applications, potentially offsetting some of its higher initial costs through reduced system complexity.

Safety factors introduce another economic dimension, as LFP's enhanced thermal stability may reduce insurance premiums and safety system requirements. This advantage becomes particularly valuable in large-scale installations where thermal runaway risks carry significant financial implications.

Market dynamics and supply chain considerations further influence the economic equation. LFP batteries benefit from more stable raw material pricing due to abundant iron resources, while NMC batteries face volatility in nickel and cobalt markets, creating potential long-term cost advantages for LFP technology despite current performance limitations.

The manufacturing scale also impacts economic viability, with LFP benefiting from significant production capacity expansion in China, driving economies of scale that have narrowed the price gap with NMC technologies in recent years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!