LFP Battery Fast-Charge Limits: Lithium Plating Risk, Thermal Rise And Control

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Fast-Charging Background and Objectives

Lithium iron phosphate (LFP) batteries have emerged as a significant technology in the energy storage landscape over the past two decades. Initially developed in the late 1990s, LFP chemistry has gained substantial traction due to its inherent safety advantages, longer cycle life, and lower cost compared to other lithium-ion variants. The evolution of this technology has been marked by continuous improvements in energy density, manufacturing processes, and application versatility.

The fast-charging capability of batteries has become increasingly critical as electric vehicles (EVs) gain market share and consumer expectations evolve. While conventional charging typically takes hours, fast charging aims to replenish significant battery capacity within 15-30 minutes. This acceleration represents a paradigm shift in how energy storage systems are utilized and perceived by end-users.

For LFP batteries specifically, fast charging presents unique challenges and opportunities. The phospho-olivine structure of LFP cathodes offers excellent thermal stability but exhibits lower electronic conductivity compared to nickel-based alternatives. This fundamental characteristic has historically limited charging rates, creating a technological barrier that researchers and manufacturers have been working to overcome.

Recent technological advancements have focused on nano-structuring LFP materials, surface modifications, and electrolyte optimizations to enhance ion transport kinetics. These developments have gradually pushed the boundaries of what's possible with LFP fast charging, though significant challenges remain regarding efficiency and battery longevity under rapid charging conditions.

The primary technical objectives in LFP fast-charging research center around three interconnected challenges: preventing lithium plating on the anode during high-rate charging, managing the thermal rise that accompanies rapid energy transfer, and developing sophisticated control algorithms that can maximize charging speed while preserving battery health and safety.

Lithium plating represents a particularly critical concern as it can lead to capacity fade, internal short circuits, and safety hazards. This phenomenon occurs when lithium ions deposit as metallic lithium on the anode surface rather than intercalating into the graphite structure, becoming more prevalent at lower temperatures and higher charging rates.

Thermal management during fast charging constitutes another major objective, as temperature increases can accelerate side reactions, degrade battery components, and in extreme cases, trigger thermal runaway. Developing effective cooling systems and thermally responsive charging protocols remains essential for practical implementation.

The industry trajectory suggests continued research emphasis on advanced materials, cell design optimization, and intelligent battery management systems that can adapt charging parameters based on real-time battery state assessment. These technological pursuits align with broader market demands for electric vehicles with reduced charging times comparable to conventional refueling experiences.

The fast-charging capability of batteries has become increasingly critical as electric vehicles (EVs) gain market share and consumer expectations evolve. While conventional charging typically takes hours, fast charging aims to replenish significant battery capacity within 15-30 minutes. This acceleration represents a paradigm shift in how energy storage systems are utilized and perceived by end-users.

For LFP batteries specifically, fast charging presents unique challenges and opportunities. The phospho-olivine structure of LFP cathodes offers excellent thermal stability but exhibits lower electronic conductivity compared to nickel-based alternatives. This fundamental characteristic has historically limited charging rates, creating a technological barrier that researchers and manufacturers have been working to overcome.

Recent technological advancements have focused on nano-structuring LFP materials, surface modifications, and electrolyte optimizations to enhance ion transport kinetics. These developments have gradually pushed the boundaries of what's possible with LFP fast charging, though significant challenges remain regarding efficiency and battery longevity under rapid charging conditions.

The primary technical objectives in LFP fast-charging research center around three interconnected challenges: preventing lithium plating on the anode during high-rate charging, managing the thermal rise that accompanies rapid energy transfer, and developing sophisticated control algorithms that can maximize charging speed while preserving battery health and safety.

Lithium plating represents a particularly critical concern as it can lead to capacity fade, internal short circuits, and safety hazards. This phenomenon occurs when lithium ions deposit as metallic lithium on the anode surface rather than intercalating into the graphite structure, becoming more prevalent at lower temperatures and higher charging rates.

Thermal management during fast charging constitutes another major objective, as temperature increases can accelerate side reactions, degrade battery components, and in extreme cases, trigger thermal runaway. Developing effective cooling systems and thermally responsive charging protocols remains essential for practical implementation.

The industry trajectory suggests continued research emphasis on advanced materials, cell design optimization, and intelligent battery management systems that can adapt charging parameters based on real-time battery state assessment. These technological pursuits align with broader market demands for electric vehicles with reduced charging times comparable to conventional refueling experiences.

Market Demand Analysis for Fast-Charging LFP Batteries

The global market for fast-charging LFP (Lithium Iron Phosphate) batteries has experienced significant growth in recent years, driven primarily by the rapid expansion of electric vehicle (EV) adoption. Market research indicates that the EV segment alone is expected to grow at a CAGR of 24.3% through 2030, with fast-charging capability becoming a critical consumer demand factor.

Consumer surveys reveal that charging time anxiety has surpassed range anxiety as the primary concern for potential EV buyers. A 2022 J.D. Power study showed that 76% of prospective EV customers consider charging speed a decisive factor in their purchasing decisions, highlighting the market pressure for improved fast-charging capabilities.

The commercial vehicle sector represents another substantial market driver, with fleet operators increasingly transitioning to electric solutions. These operators require minimal downtime, making fast-charging LFP batteries particularly attractive due to their lower cost compared to other lithium-ion chemistries. The logistics and delivery sector specifically has shown 35% year-over-year growth in electric vehicle adoption, with charging speed cited as a critical operational requirement.

Energy storage systems (ESS) constitute a rapidly expanding application area for fast-charging LFP batteries. Grid stabilization applications require batteries capable of rapid charge and discharge cycles, with the global grid storage market growing at 28% annually. LFP chemistry's inherent safety advantages make it particularly suitable for these applications, especially when enhanced with fast-charging capabilities.

Consumer electronics manufacturers are also driving demand for fast-charging LFP solutions, seeking to differentiate their products in competitive markets. The ability to recharge devices in minutes rather than hours has become a key selling point, with market research showing consumers willing to pay a 15-20% premium for significantly reduced charging times.

Regional analysis shows China leading the fast-charging LFP battery market with approximately 65% of global production capacity, followed by emerging manufacturing hubs in Europe and North America. Government policies worldwide are accelerating this trend, with the EU's Green Deal and the US Inflation Reduction Act providing substantial incentives for domestic battery production with advanced capabilities.

Market forecasts predict that fast-charging LFP batteries will capture an increasing share of the overall LFP market, growing from current levels to represent over half of all LFP battery production by 2028. This growth trajectory is contingent upon successfully addressing the technical challenges of lithium plating and thermal management during rapid charging cycles.

Consumer surveys reveal that charging time anxiety has surpassed range anxiety as the primary concern for potential EV buyers. A 2022 J.D. Power study showed that 76% of prospective EV customers consider charging speed a decisive factor in their purchasing decisions, highlighting the market pressure for improved fast-charging capabilities.

The commercial vehicle sector represents another substantial market driver, with fleet operators increasingly transitioning to electric solutions. These operators require minimal downtime, making fast-charging LFP batteries particularly attractive due to their lower cost compared to other lithium-ion chemistries. The logistics and delivery sector specifically has shown 35% year-over-year growth in electric vehicle adoption, with charging speed cited as a critical operational requirement.

Energy storage systems (ESS) constitute a rapidly expanding application area for fast-charging LFP batteries. Grid stabilization applications require batteries capable of rapid charge and discharge cycles, with the global grid storage market growing at 28% annually. LFP chemistry's inherent safety advantages make it particularly suitable for these applications, especially when enhanced with fast-charging capabilities.

Consumer electronics manufacturers are also driving demand for fast-charging LFP solutions, seeking to differentiate their products in competitive markets. The ability to recharge devices in minutes rather than hours has become a key selling point, with market research showing consumers willing to pay a 15-20% premium for significantly reduced charging times.

Regional analysis shows China leading the fast-charging LFP battery market with approximately 65% of global production capacity, followed by emerging manufacturing hubs in Europe and North America. Government policies worldwide are accelerating this trend, with the EU's Green Deal and the US Inflation Reduction Act providing substantial incentives for domestic battery production with advanced capabilities.

Market forecasts predict that fast-charging LFP batteries will capture an increasing share of the overall LFP market, growing from current levels to represent over half of all LFP battery production by 2028. This growth trajectory is contingent upon successfully addressing the technical challenges of lithium plating and thermal management during rapid charging cycles.

Technical Challenges and Limitations in LFP Fast-Charging

LFP (Lithium Iron Phosphate) batteries face significant technical challenges when subjected to fast-charging conditions, primarily centered around lithium plating, thermal management, and structural integrity. Lithium plating occurs when lithium ions deposit as metallic lithium on the anode surface rather than intercalating into the graphite structure. This phenomenon is particularly pronounced during fast charging at low temperatures, where the diffusion rate of lithium ions into graphite is substantially reduced. The risk increases exponentially as charging rates exceed 1C, with critical thresholds observed at 3C and above for most commercial LFP cells.

Thermal management presents another formidable challenge. During fast charging, internal resistance generates substantial heat that can trigger thermal runaway if not properly dissipated. LFP cells typically experience temperature increases of 15-25°C during 3C charging, with hotspots forming near the tabs and in the core regions. This temperature gradient not only accelerates aging but also creates mechanical stress that can compromise cell integrity over time.

The inherent low ionic conductivity of LFP cathode materials (approximately one order of magnitude lower than NMC cathodes) creates significant concentration polarization during high-rate charging. This limitation manifests as a steep voltage rise near the end of charging, effectively capping the practical fast-charging capability of LFP cells to 80-85% of nominal capacity when using conventional charging protocols.

Structural degradation represents another critical limitation. Repeated fast-charging cycles induce mechanical stress through volume changes in both cathode and anode materials. The graphite anode experiences approximately 10% volume expansion during lithiation, while the LFP cathode undergoes a phase transition that creates lattice strain. These mechanical stresses accelerate capacity fade through particle cracking, electrode delamination, and increased SEI (Solid Electrolyte Interphase) formation.

Current density distribution poses additional challenges, as non-uniform current distribution during fast charging leads to localized overcharging and undercharging within the cell. This heterogeneity is particularly problematic in large-format LFP cells used in automotive applications, where tab design and electrode thickness create inherent current density gradients that are exacerbated during high-rate charging.

The electrolyte stability window is also compromised during fast charging, as higher voltages accelerate electrolyte decomposition reactions. This leads to gas generation, increased internal pressure, and accelerated capacity fade. Standard carbonate-based electrolytes show significant degradation when LFP cells are repeatedly fast-charged above 3C, with gas evolution rates increasing by 200-300% compared to 1C charging rates.

Thermal management presents another formidable challenge. During fast charging, internal resistance generates substantial heat that can trigger thermal runaway if not properly dissipated. LFP cells typically experience temperature increases of 15-25°C during 3C charging, with hotspots forming near the tabs and in the core regions. This temperature gradient not only accelerates aging but also creates mechanical stress that can compromise cell integrity over time.

The inherent low ionic conductivity of LFP cathode materials (approximately one order of magnitude lower than NMC cathodes) creates significant concentration polarization during high-rate charging. This limitation manifests as a steep voltage rise near the end of charging, effectively capping the practical fast-charging capability of LFP cells to 80-85% of nominal capacity when using conventional charging protocols.

Structural degradation represents another critical limitation. Repeated fast-charging cycles induce mechanical stress through volume changes in both cathode and anode materials. The graphite anode experiences approximately 10% volume expansion during lithiation, while the LFP cathode undergoes a phase transition that creates lattice strain. These mechanical stresses accelerate capacity fade through particle cracking, electrode delamination, and increased SEI (Solid Electrolyte Interphase) formation.

Current density distribution poses additional challenges, as non-uniform current distribution during fast charging leads to localized overcharging and undercharging within the cell. This heterogeneity is particularly problematic in large-format LFP cells used in automotive applications, where tab design and electrode thickness create inherent current density gradients that are exacerbated during high-rate charging.

The electrolyte stability window is also compromised during fast charging, as higher voltages accelerate electrolyte decomposition reactions. This leads to gas generation, increased internal pressure, and accelerated capacity fade. Standard carbonate-based electrolytes show significant degradation when LFP cells are repeatedly fast-charged above 3C, with gas evolution rates increasing by 200-300% compared to 1C charging rates.

Current Fast-Charging Solutions for LFP Batteries

01 Fast-charging limitations and thermal management in LFP batteries

LFP batteries face limitations during fast charging due to their inherent properties. The charging process generates heat that must be managed effectively to prevent thermal runaway. Advanced thermal management systems are essential to dissipate heat during fast charging, including liquid cooling systems, phase change materials, and heat sinks. These systems help maintain optimal operating temperatures, extending battery life and enabling faster charging rates while preventing thermal rise that could compromise safety and performance.- Fast-charging limitations and lithium plating prevention in LFP batteries: LFP batteries face limitations during fast charging due to their lower conductivity compared to other lithium-ion chemistries. Lithium plating occurs when lithium ions deposit as metallic lithium on the anode surface instead of intercalating into the graphite structure, particularly at high charging rates and low temperatures. Prevention strategies include optimized charging protocols that adjust current based on temperature and state of charge, specialized electrode designs with improved lithium-ion diffusion pathways, and advanced battery management systems that can detect early signs of plating.

- Thermal management systems for LFP batteries during fast charging: Thermal rise during fast charging of LFP batteries can lead to accelerated degradation and safety risks. Effective thermal management systems employ various cooling methods including liquid cooling circuits, phase change materials, and air cooling systems to maintain optimal temperature ranges. Advanced thermal management strategies incorporate temperature sensors throughout the battery pack to identify hotspots and adjust charging parameters accordingly. Some systems integrate predictive thermal modeling to anticipate temperature rises before they become problematic, allowing for proactive adjustments to charging current.

- Advanced charging algorithms to optimize LFP battery performance: Sophisticated charging algorithms specifically designed for LFP chemistry can significantly improve fast-charging capabilities while minimizing risks. These algorithms typically employ multi-stage charging approaches that vary current and voltage based on the battery's state of charge, temperature, and aging condition. Some incorporate machine learning techniques to adapt to individual battery characteristics over time. Pulse charging methods that alternate between charging periods and rest periods allow for better ion distribution within the electrode materials, reducing concentration gradients that can lead to lithium plating.

- Electrode and electrolyte modifications for improved fast-charging: Material innovations in electrode design and electrolyte formulation can enhance LFP batteries' fast-charging capabilities. Modified electrode structures with optimized porosity, particle size distribution, and conductive additives improve lithium-ion transport kinetics. Novel electrolyte compositions with additives that form more stable solid-electrolyte interphase (SEI) layers can withstand higher charging currents. Some approaches incorporate gradient or dual-layer electrode designs that balance the requirements for high power and energy density, allowing faster charging without compromising capacity or cycle life.

- Diagnostic and safety systems for fast-charging LFP batteries: Advanced diagnostic tools and safety systems are crucial for monitoring LFP batteries during fast charging to prevent catastrophic failures. These systems employ electrochemical impedance spectroscopy, voltage relaxation analysis, and differential voltage analysis to detect early signs of lithium plating and other degradation mechanisms. Real-time monitoring systems track multiple parameters including individual cell voltages, internal resistance changes, and temperature distribution patterns. Some advanced systems incorporate fail-safe mechanisms that automatically reduce charging current or terminate charging when abnormal conditions are detected, preventing thermal runaway and ensuring long-term battery health.

02 Lithium plating mechanisms and prevention strategies

Lithium plating occurs when lithium ions deposit as metallic lithium on the anode surface instead of intercalating into the graphite structure during fast charging. This phenomenon is particularly problematic at low temperatures and high charging rates. Prevention strategies include modified charging protocols that adjust current based on temperature and state of charge, specialized electrode designs with improved lithium diffusion pathways, and electrolyte additives that form protective interfaces. These approaches help minimize lithium plating risk while maintaining acceptable charging speeds.Expand Specific Solutions03 Advanced battery management systems for safe fast charging

Battery management systems (BMS) play a crucial role in enabling safe fast charging of LFP batteries. These systems employ sophisticated algorithms to monitor cell voltage, temperature, and current in real-time. By analyzing these parameters, the BMS can dynamically adjust charging parameters to prevent lithium plating and excessive thermal rise. Machine learning approaches are increasingly being used to predict battery behavior and optimize charging profiles based on historical data and operating conditions, maximizing charging speed while maintaining safety margins.Expand Specific Solutions04 Electrode and cell design optimizations for fast charging

Innovations in electrode and cell design significantly impact fast-charging capabilities of LFP batteries. Thinner electrodes reduce lithium diffusion distances, allowing for faster ion transport during charging. Structured electrodes with optimized porosity and tortuosity improve electrolyte penetration and ion movement. Novel three-dimensional electrode architectures provide increased surface area for reactions while maintaining good mechanical stability. These design improvements help mitigate concentration polarization and reduce internal resistance, enabling higher charging rates without compromising safety.Expand Specific Solutions05 Electrolyte formulations for enhanced fast-charging performance

Specialized electrolyte formulations can significantly improve fast-charging performance in LFP batteries. Additives that form stable solid electrolyte interphase (SEI) layers help prevent lithium plating during rapid charging. Low-viscosity solvents enhance ion mobility at low temperatures, addressing a key limitation of LFP chemistry. Electrolytes with high thermal stability reduce degradation risks during thermal rise events. Dual-salt electrolyte systems provide improved conductivity and interfacial stability, allowing for higher charging currents while maintaining cycle life and safety.Expand Specific Solutions

Key Industry Players in LFP Battery Technology

The LFP battery fast-charging market is in a growth phase, with increasing demand driven by electric vehicle adoption despite technical challenges. The market is projected to expand significantly as manufacturers address lithium plating risks and thermal management issues. Leading companies like BYD, CATL (Ningde Amperex), and LG Energy Solution are advancing LFP battery technology with innovative approaches to overcome fast-charging limitations. Tesla and GM are implementing sophisticated battery management systems to mitigate thermal rise concerns, while emerging players like Qnovo and Iontra are developing specialized control algorithms. The competitive landscape is characterized by a balance between established automotive manufacturers and specialized battery technology firms, with significant R&D investments focused on extending battery life while enabling faster charging capabilities.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a comprehensive approach to address fast-charging limitations in LFP batteries. Their technology combines advanced materials engineering with sophisticated control systems to mitigate lithium plating and manage thermal rise. At the cell level, LG has engineered specialized electrode coatings and electrolyte additives that enhance lithium-ion transport at low temperatures, a critical factor in reducing plating risk during fast charging. Their proprietary "Variable Pressure Constant Current" (VPCC) charging protocol dynamically adjusts charging parameters based on real-time impedance measurements, allowing for maximum charging speeds while staying below critical plating thresholds. The thermal management system employs a network of embedded temperature sensors with 0.1°C precision, coupled with a predictive thermal model that anticipates hot spots before they develop. LG's solution also incorporates differential pressure sensors to detect minute cell expansion during charging, providing an early warning system for potential lithium plating events before voltage or temperature indicators would show problems[2][5].

Strengths: The multi-parameter approach (voltage, temperature, pressure, impedance) provides redundant safety mechanisms against lithium plating. The specialized electrode coatings enable faster charging particularly in cold conditions where LFP batteries typically struggle. Weaknesses: The complex sensor array increases manufacturing costs and potential points of failure. The system requires frequent calibration to maintain accuracy as the battery ages.

Tesla, Inc.

Technical Solution: Tesla has developed a sophisticated approach to managing LFP battery fast-charging limitations through its integrated hardware and software ecosystem. Their solution centers on a predictive charging algorithm that utilizes vehicle usage data, environmental conditions, and battery health metrics to optimize charging profiles. Tesla's system employs a dual-frequency impedance spectroscopy technique that can detect early signs of lithium plating by measuring subtle changes in electrochemical impedance during charging. This allows for real-time adjustments to charging current before plating occurs. For thermal management, Tesla utilizes a patented cooling system with microchannels directly integrated into the battery pack structure, providing more uniform temperature control across cells. Their BMS incorporates a "charging fence" concept that establishes dynamic safety boundaries based on multiple parameters including temperature gradients, cell voltage deviation, and coulombic efficiency measurements. Tesla's approach also leverages fleet data from millions of charging sessions to continuously refine their charging algorithms through over-the-air updates, allowing the system to improve over time and adapt to battery aging characteristics[6][8].

Strengths: The integration of vehicle usage patterns and environmental data allows for more contextual charging optimization than systems that only monitor battery parameters. The extensive fleet data enables continuous improvement of charging algorithms based on real-world performance. Weaknesses: The system's effectiveness is partially dependent on consistent connectivity for receiving algorithm updates. The sophisticated cooling system adds weight and complexity to the battery pack design.

Core Technologies for Lithium Plating Prevention

Battery charging with lithium plating detection and battery degradation detection and separation

PatentWO2021002898A1

Innovation

- A system that detects lithium plating without a third electrode by monitoring battery voltage and comparing the slope of the charging voltage with a reference slope, allowing for adjustment of the charge current to prevent lithium plating and detect degraded battery cells in parallel connected batteries by measuring impedance, enabling safe charging and separation of degraded cells.

Doped iron phosphate, and preparation method therefor and use thereof

PatentPendingUS20250122080A1

Innovation

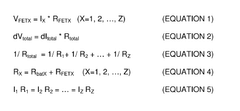

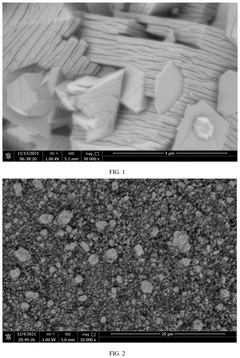

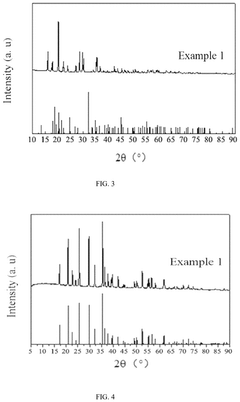

- The use of manganese-doped iron phosphate with a chemical formula of (MnxFe1−x)@FePO4·2H2O, where 0<x<1, as a precursor to improve the electrochemical performance of LiFePO4/C, achieved through a method that involves adding a phosphorus source to an iron-containing solution, mixing with ferromanganese phosphate, and heating to induce precipitation, without the need for alkali or ammonia to adjust the pH.

Safety Standards and Certification Requirements

The regulatory landscape for fast-charging LFP batteries encompasses multiple international and regional standards that manufacturers must adhere to. IEC 62660 series and ISO 12405 standards specifically address the safety requirements for lithium-ion batteries in electric vehicles, with particular emphasis on thermal management during rapid charging scenarios. These standards establish testing protocols for thermal runaway, overcharging protection, and cell stability under various charging rates.

UL 1642 and UL 2580 provide comprehensive safety requirements for lithium batteries in North America, with UL 2580 specifically focusing on batteries for use in electric vehicles. These standards mandate rigorous testing for lithium plating detection and prevention mechanisms, especially during fast-charging operations where the risk significantly increases. The standards require demonstration of thermal control systems that can effectively manage heat generation during high C-rate charging.

In Europe, the ECE R100 regulation governs the safety aspects of electric powertrains, including battery systems. This regulation has been updated to include specific provisions for fast-charging scenarios, requiring manufacturers to implement robust battery management systems (BMS) that can detect and prevent lithium plating conditions. The regulation also mandates thermal monitoring systems with multiple redundancies during rapid charging operations.

China's GB/T 31485 standard specifically addresses the safety requirements for lithium-ion batteries in electric vehicles, with detailed protocols for fast-charging safety evaluation. This standard has recently been updated to include more stringent requirements for thermal management systems and real-time monitoring of lithium plating indicators during high-rate charging operations.

Certification processes typically require manufacturers to demonstrate compliance through extensive testing under worst-case fast-charging scenarios. This includes cycling tests at maximum rated charging speeds while monitoring temperature gradients, voltage profiles, and impedance changes that might indicate lithium plating. Documentation must include detailed thermal management strategies and fail-safe mechanisms that activate when thermal rise exceeds predetermined thresholds.

Recent regulatory trends show increasing focus on battery state-of-health monitoring during fast charging, with requirements for systems that can adaptively adjust charging profiles based on battery degradation status. Certification bodies are also beginning to require demonstration of artificial intelligence algorithms that can predict and prevent lithium plating based on real-time battery parameters during rapid charging sessions.

For manufacturers seeking global market access, navigating these overlapping but distinct regulatory requirements presents significant challenges, particularly as standards continue to evolve in response to emerging research on fast-charging safety limits for LFP chemistry.

UL 1642 and UL 2580 provide comprehensive safety requirements for lithium batteries in North America, with UL 2580 specifically focusing on batteries for use in electric vehicles. These standards mandate rigorous testing for lithium plating detection and prevention mechanisms, especially during fast-charging operations where the risk significantly increases. The standards require demonstration of thermal control systems that can effectively manage heat generation during high C-rate charging.

In Europe, the ECE R100 regulation governs the safety aspects of electric powertrains, including battery systems. This regulation has been updated to include specific provisions for fast-charging scenarios, requiring manufacturers to implement robust battery management systems (BMS) that can detect and prevent lithium plating conditions. The regulation also mandates thermal monitoring systems with multiple redundancies during rapid charging operations.

China's GB/T 31485 standard specifically addresses the safety requirements for lithium-ion batteries in electric vehicles, with detailed protocols for fast-charging safety evaluation. This standard has recently been updated to include more stringent requirements for thermal management systems and real-time monitoring of lithium plating indicators during high-rate charging operations.

Certification processes typically require manufacturers to demonstrate compliance through extensive testing under worst-case fast-charging scenarios. This includes cycling tests at maximum rated charging speeds while monitoring temperature gradients, voltage profiles, and impedance changes that might indicate lithium plating. Documentation must include detailed thermal management strategies and fail-safe mechanisms that activate when thermal rise exceeds predetermined thresholds.

Recent regulatory trends show increasing focus on battery state-of-health monitoring during fast charging, with requirements for systems that can adaptively adjust charging profiles based on battery degradation status. Certification bodies are also beginning to require demonstration of artificial intelligence algorithms that can predict and prevent lithium plating based on real-time battery parameters during rapid charging sessions.

For manufacturers seeking global market access, navigating these overlapping but distinct regulatory requirements presents significant challenges, particularly as standards continue to evolve in response to emerging research on fast-charging safety limits for LFP chemistry.

Battery Lifecycle Impact of Fast-Charging Protocols

Fast-charging protocols significantly impact the overall lifecycle of LFP (Lithium Iron Phosphate) batteries, with effects that extend well beyond immediate performance considerations. The acceleration of charging rates introduces complex degradation mechanisms that can substantially reduce battery longevity if not properly managed.

Primary lifecycle impacts manifest through accelerated capacity fade, which occurs at rates 2-3 times faster under aggressive charging protocols compared to standard charging. Research indicates that LFP batteries subjected to regular fast charging above 3C rates typically experience 20-30% reduction in cycle life compared to those charged at moderate 0.5-1C rates.

Mechanical degradation represents another critical concern, as rapid lithium insertion during fast charging creates volume expansion stresses within electrode materials. These stresses lead to particle cracking and electrode delamination over time, compromising structural integrity. Studies have documented up to 15% increase in electrode particle fracturing after 500 cycles under fast-charging conditions.

The solid-electrolyte interphase (SEI) layer undergoes accelerated growth and decomposition cycles during fast charging, consuming active lithium and increasing internal resistance. This process becomes particularly problematic at charging rates above 2C, where thermal effects exacerbate SEI instability. Data shows SEI-related capacity losses can account for 40-50% of total capacity fade in fast-charged LFP cells.

Temperature management emerges as a critical factor in mitigating lifecycle degradation. Fast-charging protocols that incorporate dynamic thermal management systems demonstrate 30-40% improvement in cycle life retention compared to unmanaged fast charging. Adaptive protocols that modulate charging rates based on battery state-of-health show particular promise, extending usable life by up to 25%.

Economic implications of these lifecycle impacts are substantial. While fast charging offers convenience benefits, the accelerated replacement costs must be factored into total ownership calculations. Analysis indicates that optimal fast-charging protocols balance charging speed with degradation effects, typically limiting charging rates to 1-2C with appropriate thermal management to achieve acceptable lifecycle performance.

Recent advancements in electrolyte formulations specifically designed for fast-charging applications show potential to mitigate some lifecycle impacts, with novel additives demonstrating up to 35% improvement in capacity retention under high-rate charging conditions compared to conventional electrolytes.

Primary lifecycle impacts manifest through accelerated capacity fade, which occurs at rates 2-3 times faster under aggressive charging protocols compared to standard charging. Research indicates that LFP batteries subjected to regular fast charging above 3C rates typically experience 20-30% reduction in cycle life compared to those charged at moderate 0.5-1C rates.

Mechanical degradation represents another critical concern, as rapid lithium insertion during fast charging creates volume expansion stresses within electrode materials. These stresses lead to particle cracking and electrode delamination over time, compromising structural integrity. Studies have documented up to 15% increase in electrode particle fracturing after 500 cycles under fast-charging conditions.

The solid-electrolyte interphase (SEI) layer undergoes accelerated growth and decomposition cycles during fast charging, consuming active lithium and increasing internal resistance. This process becomes particularly problematic at charging rates above 2C, where thermal effects exacerbate SEI instability. Data shows SEI-related capacity losses can account for 40-50% of total capacity fade in fast-charged LFP cells.

Temperature management emerges as a critical factor in mitigating lifecycle degradation. Fast-charging protocols that incorporate dynamic thermal management systems demonstrate 30-40% improvement in cycle life retention compared to unmanaged fast charging. Adaptive protocols that modulate charging rates based on battery state-of-health show particular promise, extending usable life by up to 25%.

Economic implications of these lifecycle impacts are substantial. While fast charging offers convenience benefits, the accelerated replacement costs must be factored into total ownership calculations. Analysis indicates that optimal fast-charging protocols balance charging speed with degradation effects, typically limiting charging rates to 1-2C with appropriate thermal management to achieve acceptable lifecycle performance.

Recent advancements in electrolyte formulations specifically designed for fast-charging applications show potential to mitigate some lifecycle impacts, with novel additives demonstrating up to 35% improvement in capacity retention under high-rate charging conditions compared to conventional electrolytes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!