LFP Battery Compliance: UN38.3, IEC And Transport Safety Acceptance

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Standards Evolution and Objectives

Lithium Iron Phosphate (LFP) battery technology has evolved significantly since its commercial introduction in the late 1990s. Initially developed as a safer alternative to lithium cobalt oxide batteries, LFP batteries have gained prominence due to their enhanced thermal stability, longer cycle life, and reduced environmental impact. The evolution of safety standards for these batteries has paralleled their technological development, with increasingly stringent requirements being implemented to address emerging safety concerns.

The UN38.3 standard, first established in the United Nations Manual of Tests and Criteria, has undergone multiple revisions to adapt to the evolving LFP battery landscape. The initial framework focused primarily on basic safety parameters during transport, while subsequent updates have incorporated more comprehensive testing protocols addressing altitude simulation, thermal cycling, vibration, shock, external short circuit, impact, overcharge, and forced discharge scenarios.

Similarly, the International Electrotechnical Commission (IEC) standards have evolved from basic safety guidelines to sophisticated protocols addressing the unique characteristics of LFP chemistry. The IEC 62133 standard, which initially covered nickel and lithium systems broadly, has been refined to address specific safety concerns related to phosphate-based lithium batteries, with particular attention to thermal runaway prevention and electrical safety parameters.

Transport safety acceptance criteria have undergone perhaps the most dramatic evolution, driven by high-profile incidents involving lithium batteries in cargo aircraft and other transportation modes. Initial regulations focused primarily on packaging and labeling, while current standards incorporate sophisticated risk assessment methodologies, state-of-charge limitations during transport, and detailed emergency response protocols.

The primary objective of these evolving standards is to establish a globally harmonized framework that ensures LFP batteries can be safely transported, stored, and utilized across diverse applications and environments. Secondary objectives include facilitating international trade by reducing regulatory barriers, promoting technological innovation while maintaining safety margins, and establishing clear liability frameworks for manufacturers, transporters, and end-users.

Future evolution of these standards aims to address emerging challenges such as the increasing energy density of LFP cells, the growing scale of battery systems in electric vehicles and grid storage applications, and the need for standardized end-of-life management protocols. Additionally, there is a growing focus on developing testing methodologies that can better predict real-world failure modes and accelerate the certification process without compromising safety margins.

The UN38.3 standard, first established in the United Nations Manual of Tests and Criteria, has undergone multiple revisions to adapt to the evolving LFP battery landscape. The initial framework focused primarily on basic safety parameters during transport, while subsequent updates have incorporated more comprehensive testing protocols addressing altitude simulation, thermal cycling, vibration, shock, external short circuit, impact, overcharge, and forced discharge scenarios.

Similarly, the International Electrotechnical Commission (IEC) standards have evolved from basic safety guidelines to sophisticated protocols addressing the unique characteristics of LFP chemistry. The IEC 62133 standard, which initially covered nickel and lithium systems broadly, has been refined to address specific safety concerns related to phosphate-based lithium batteries, with particular attention to thermal runaway prevention and electrical safety parameters.

Transport safety acceptance criteria have undergone perhaps the most dramatic evolution, driven by high-profile incidents involving lithium batteries in cargo aircraft and other transportation modes. Initial regulations focused primarily on packaging and labeling, while current standards incorporate sophisticated risk assessment methodologies, state-of-charge limitations during transport, and detailed emergency response protocols.

The primary objective of these evolving standards is to establish a globally harmonized framework that ensures LFP batteries can be safely transported, stored, and utilized across diverse applications and environments. Secondary objectives include facilitating international trade by reducing regulatory barriers, promoting technological innovation while maintaining safety margins, and establishing clear liability frameworks for manufacturers, transporters, and end-users.

Future evolution of these standards aims to address emerging challenges such as the increasing energy density of LFP cells, the growing scale of battery systems in electric vehicles and grid storage applications, and the need for standardized end-of-life management protocols. Additionally, there is a growing focus on developing testing methodologies that can better predict real-world failure modes and accelerate the certification process without compromising safety margins.

Global Market Demand for Compliant LFP Batteries

The global market for LFP (Lithium Iron Phosphate) batteries has experienced substantial growth in recent years, driven primarily by the expanding electric vehicle (EV) sector, stationary energy storage systems, and portable electronics. Market research indicates that the global LFP battery market was valued at approximately $10.2 billion in 2022 and is projected to reach $25.5 billion by 2028, growing at a CAGR of 16.4% during the forecast period.

Compliance with international safety standards, particularly UN38.3 and IEC certifications, has become a critical market driver as manufacturers seek to ensure their products meet global transportation and operational safety requirements. The demand for compliant LFP batteries is especially pronounced in regions with stringent regulatory frameworks, such as the European Union, North America, and parts of Asia-Pacific, particularly Japan and South Korea.

China currently dominates the global LFP battery production landscape, accounting for over 70% of worldwide manufacturing capacity. However, recent geopolitical tensions and supply chain vulnerabilities have accelerated efforts in North America and Europe to establish domestic LFP battery production capabilities, further driving demand for standardized compliance protocols across different jurisdictions.

The automotive sector represents the largest market segment for compliant LFP batteries, with major manufacturers including Tesla, BYD, and Volkswagen incorporating these batteries into their electric vehicle fleets. Market analysis shows that approximately 30% of all electric vehicles manufactured in 2022 utilized LFP battery technology, with this percentage expected to increase to 40% by 2025.

Energy storage systems constitute the second-largest application segment, with utility-scale projects increasingly favoring LFP batteries due to their enhanced safety profile, longer cycle life, and compliance with stringent fire safety regulations. The market for grid-scale energy storage using LFP technology grew by 45% in 2022 alone, with particularly strong demand in Australia, Germany, and California.

Consumer electronics manufacturers are also transitioning toward LFP batteries for certain applications, driven by safety concerns and transportation regulations. This segment is expected to grow at 12% annually through 2027, with particular emphasis on products requiring UN38.3 certification for air transport.

Regionally, Asia-Pacific accounts for approximately 65% of global demand for compliant LFP batteries, followed by Europe (20%) and North America (12%). However, the fastest growth rates are being observed in emerging markets across Latin America and Africa, where LFP batteries are increasingly deployed in off-grid and microgrid applications requiring IEC compliance for safety and reliability.

Compliance with international safety standards, particularly UN38.3 and IEC certifications, has become a critical market driver as manufacturers seek to ensure their products meet global transportation and operational safety requirements. The demand for compliant LFP batteries is especially pronounced in regions with stringent regulatory frameworks, such as the European Union, North America, and parts of Asia-Pacific, particularly Japan and South Korea.

China currently dominates the global LFP battery production landscape, accounting for over 70% of worldwide manufacturing capacity. However, recent geopolitical tensions and supply chain vulnerabilities have accelerated efforts in North America and Europe to establish domestic LFP battery production capabilities, further driving demand for standardized compliance protocols across different jurisdictions.

The automotive sector represents the largest market segment for compliant LFP batteries, with major manufacturers including Tesla, BYD, and Volkswagen incorporating these batteries into their electric vehicle fleets. Market analysis shows that approximately 30% of all electric vehicles manufactured in 2022 utilized LFP battery technology, with this percentage expected to increase to 40% by 2025.

Energy storage systems constitute the second-largest application segment, with utility-scale projects increasingly favoring LFP batteries due to their enhanced safety profile, longer cycle life, and compliance with stringent fire safety regulations. The market for grid-scale energy storage using LFP technology grew by 45% in 2022 alone, with particularly strong demand in Australia, Germany, and California.

Consumer electronics manufacturers are also transitioning toward LFP batteries for certain applications, driven by safety concerns and transportation regulations. This segment is expected to grow at 12% annually through 2027, with particular emphasis on products requiring UN38.3 certification for air transport.

Regionally, Asia-Pacific accounts for approximately 65% of global demand for compliant LFP batteries, followed by Europe (20%) and North America (12%). However, the fastest growth rates are being observed in emerging markets across Latin America and Africa, where LFP batteries are increasingly deployed in off-grid and microgrid applications requiring IEC compliance for safety and reliability.

Current Compliance Challenges and Technical Barriers

Despite significant advancements in LFP (Lithium Iron Phosphate) battery technology, manufacturers continue to face substantial compliance challenges and technical barriers when seeking international certification and transport approval. The UN38.3 testing protocol, which is mandatory for lithium battery transport, presents rigorous requirements including altitude simulation, thermal testing, vibration, shock, external short circuit, impact, overcharge, and forced discharge tests. Many LFP battery producers struggle with the thermal runaway resistance aspects of these tests, particularly when scaling up from cell to pack level.

IEC standards, especially IEC 62133 for portable batteries and IEC 61960 for performance requirements, introduce another layer of complexity. These standards demand extensive documentation of manufacturing processes, quality control procedures, and detailed technical specifications that many emerging manufacturers find difficult to compile comprehensively. The technical barrier is heightened by the fact that testing procedures often require specialized equipment and expertise that is not universally available.

Transport safety acceptance presents perhaps the most significant operational challenge. Different jurisdictions and transportation modes (air, sea, land) maintain varying interpretations of safety requirements, creating a fragmented regulatory landscape. For instance, air transport under IATA Dangerous Goods Regulations imposes stricter limitations on state-of-charge during shipping than maritime regulations, forcing manufacturers to maintain multiple compliance protocols simultaneously.

The certification process itself constitutes a substantial barrier due to its time-consuming and costly nature. Testing cycles can extend from 3-6 months, creating significant delays in bringing products to market. This timeline is particularly problematic given the rapid pace of innovation in battery chemistry and design, meaning that by the time certification is achieved, newer technologies may already be emerging.

Technical documentation requirements represent another significant hurdle. Authorities require detailed information about cell chemistry, manufacturing processes, and safety mechanisms. For proprietary technologies, this creates tension between compliance requirements and intellectual property protection. Many manufacturers struggle to provide sufficient technical detail while safeguarding their competitive advantages.

Cross-border compliance variations further complicate matters, with China, the EU, and the US each maintaining distinct certification requirements. This necessitates multiple testing regimes for globally distributed products, substantially increasing compliance costs and technical complexity. The absence of a truly harmonized global standard remains one of the most significant barriers to efficient LFP battery commercialization and distribution.

IEC standards, especially IEC 62133 for portable batteries and IEC 61960 for performance requirements, introduce another layer of complexity. These standards demand extensive documentation of manufacturing processes, quality control procedures, and detailed technical specifications that many emerging manufacturers find difficult to compile comprehensively. The technical barrier is heightened by the fact that testing procedures often require specialized equipment and expertise that is not universally available.

Transport safety acceptance presents perhaps the most significant operational challenge. Different jurisdictions and transportation modes (air, sea, land) maintain varying interpretations of safety requirements, creating a fragmented regulatory landscape. For instance, air transport under IATA Dangerous Goods Regulations imposes stricter limitations on state-of-charge during shipping than maritime regulations, forcing manufacturers to maintain multiple compliance protocols simultaneously.

The certification process itself constitutes a substantial barrier due to its time-consuming and costly nature. Testing cycles can extend from 3-6 months, creating significant delays in bringing products to market. This timeline is particularly problematic given the rapid pace of innovation in battery chemistry and design, meaning that by the time certification is achieved, newer technologies may already be emerging.

Technical documentation requirements represent another significant hurdle. Authorities require detailed information about cell chemistry, manufacturing processes, and safety mechanisms. For proprietary technologies, this creates tension between compliance requirements and intellectual property protection. Many manufacturers struggle to provide sufficient technical detail while safeguarding their competitive advantages.

Cross-border compliance variations further complicate matters, with China, the EU, and the US each maintaining distinct certification requirements. This necessitates multiple testing regimes for globally distributed products, substantially increasing compliance costs and technical complexity. The absence of a truly harmonized global standard remains one of the most significant barriers to efficient LFP battery commercialization and distribution.

UN38.3 and IEC Compliance Implementation Strategies

01 Battery Management Systems for LFP Safety

Battery Management Systems (BMS) are crucial for ensuring the safety and compliance of LFP batteries. These systems monitor battery parameters such as temperature, voltage, and current to prevent overcharging, overheating, and other potentially hazardous conditions. Advanced BMS implementations include real-time monitoring capabilities, predictive analytics for failure prevention, and automatic shutdown mechanisms when unsafe conditions are detected, significantly enhancing the overall safety profile of LFP battery systems.- Battery Management Systems for LFP Safety: Battery Management Systems (BMS) are crucial for ensuring the safety and compliance of LFP batteries. These systems monitor battery parameters such as temperature, voltage, and current to prevent overcharging, overheating, and other potentially hazardous conditions. Advanced BMS implementations include real-time monitoring capabilities, predictive analytics for failure prevention, and automatic shutdown mechanisms when unsafe conditions are detected, significantly enhancing the overall safety profile of LFP battery systems.

- Thermal Management and Fire Prevention: Thermal management is essential for LFP battery safety compliance. Innovations include cooling systems, heat dissipation materials, and thermal runaway prevention mechanisms. These solutions help maintain optimal operating temperatures, prevent thermal propagation between cells, and reduce fire risks. Fire suppression technologies and flame-retardant materials are also incorporated into battery designs to contain potential fires and minimize damage, meeting stringent safety regulations for various applications including electric vehicles and energy storage systems.

- Safety Testing and Certification Protocols: Comprehensive testing and certification protocols are implemented to ensure LFP batteries meet international safety standards. These include abuse tests such as crush, puncture, short circuit, and overcharge tests to evaluate battery behavior under extreme conditions. Certification processes involve verification of compliance with regulations like UN 38.3 for transport safety, IEC standards for electrical safety, and region-specific requirements. Standardized testing methodologies help manufacturers validate safety features and demonstrate regulatory compliance before market entry.

- Cell Design and Material Innovations: Advancements in LFP battery cell design and materials significantly improve safety profiles. Innovations include enhanced separator technologies that prevent internal short circuits, improved electrode formulations that reduce gas generation during cycling, and structural reinforcements that maintain cell integrity under mechanical stress. Novel electrolyte compositions with flame-retardant additives and solid-state electrolyte implementations further enhance safety by reducing flammability risks while maintaining or improving electrochemical performance.

- Regulatory Compliance and Transportation Safety: Ensuring regulatory compliance for LFP batteries involves adherence to evolving international standards and transportation regulations. This includes proper packaging, labeling, and documentation for shipping lithium batteries according to dangerous goods regulations. Compliance frameworks address the entire battery lifecycle from manufacturing to disposal, with specific requirements for different applications and markets. Transportation safety measures include specialized containers, state-of-charge limitations during shipping, and detailed handling protocols to prevent incidents during transit.

02 Thermal Management and Fire Prevention

Effective thermal management is essential for LFP battery safety compliance. This includes cooling systems, thermal insulation, and heat dissipation mechanisms designed to maintain optimal operating temperatures and prevent thermal runaway. Fire prevention strategies incorporate flame-retardant materials, thermal barriers, and specialized cell designs that minimize propagation risk. These systems work together to reduce the likelihood of thermal incidents and contain potential fires, addressing one of the primary safety concerns associated with lithium-based batteries.Expand Specific Solutions03 Regulatory Compliance and Testing Protocols

LFP batteries must undergo rigorous testing and certification to meet international safety standards and regulations. This includes compliance with standards such as UN 38.3 for transport safety, IEC 62133 for cell safety, and various regional certifications. Testing protocols involve abuse testing (crush, puncture, short circuit), environmental testing (temperature extremes, humidity), and cycle life testing to ensure long-term safety. Manufacturers must document compliance through detailed test reports and certifications to legally market their products in different jurisdictions.Expand Specific Solutions04 Cell Design and Material Innovations

Advancements in LFP battery cell design and materials have significantly improved safety profiles. These innovations include enhanced electrode structures, safer electrolyte formulations with reduced flammability, improved separator technologies that prevent internal short circuits, and robust cell casing designs. The inherent stability of lithium iron phosphate chemistry provides a safety advantage over other lithium-ion chemistries, with higher thermal runaway thresholds and reduced risk of oxygen release during failure conditions.Expand Specific Solutions05 Safety Monitoring and Diagnostic Systems

Advanced monitoring and diagnostic systems enhance LFP battery safety through continuous assessment of battery health and early detection of potential issues. These systems employ sensors, data analytics, and artificial intelligence to identify abnormal patterns that might indicate developing problems. Remote monitoring capabilities allow for proactive maintenance and emergency response, while diagnostic tools help technicians identify and address safety concerns before they escalate. Integration with vehicle or energy storage system controls enables automatic protective measures when unsafe conditions are detected.Expand Specific Solutions

Leading Manufacturers and Certification Bodies

The LFP battery compliance landscape is evolving rapidly as the market enters a growth phase, with global demand projected to exceed $25 billion by 2025. Technical compliance with UN38.3 and IEC standards has become a critical differentiator in this competitive field. Major players like Contemporary Amperex Technology (CATL), BYD, and Samsung SDI have established leadership positions through advanced safety certification protocols, while emerging companies such as CALB Group and Lithionics are gaining market share through specialized transport safety innovations. The competitive dynamics are intensifying as automotive manufacturers like Toyota and GM increasingly integrate with battery suppliers to ensure seamless compliance across global supply chains, creating a market where technical certification expertise has become as valuable as production capacity.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a comprehensive LFP battery compliance system that meets UN38.3, IEC 62133, and IEC 61960 standards. Their approach includes a multi-stage testing protocol that subjects batteries to altitude simulation, thermal cycling, vibration, shock, external short circuit, impact, overcharge, and forced discharge tests. CATL's LFP cells feature a proprietary phosphate-based cathode material with nano-scale particle optimization that enhances safety performance during transport and usage. Their compliance strategy includes real-time monitoring systems during transportation with temperature, pressure, and voltage sensors integrated into battery management systems. CATL has also developed specialized packaging solutions with flame-retardant materials and thermal insulation specifically designed for air, sea, and land transport of LFP batteries[1][3].

Strengths: Industry-leading safety features with proprietary BMS technology that exceeds standard requirements; extensive global certification network allowing seamless international shipping. Weaknesses: Higher compliance costs passed to customers; slightly lower energy density compared to NMC alternatives while maintaining safety standards.

BYD Co., Ltd.

Technical Solution: BYD has pioneered the Blade Battery technology using LFP chemistry that specifically addresses transport safety concerns through a novel structural design. The Blade Battery passes UN38.3 requirements with significant safety margins by utilizing a cell-to-pack design that eliminates traditional module structures. BYD's compliance approach integrates mechanical, thermal, and electrical safety features through their proprietary battery management system that continuously monitors cell conditions during transport. Their LFP batteries undergo rigorous testing including nail penetration tests without ignition, extreme heat tests up to 300°C, and crush tests that exceed regulatory requirements. For international transport, BYD implements a specialized tracking system with real-time monitoring capabilities and temperature-controlled shipping containers designed specifically for their LFP batteries[2][5]. The company has established dedicated certification teams in major markets to ensure compliance with regional variations of IEC standards.

Strengths: Revolutionary cell-to-pack design eliminates potential failure points during transport; exceptional thermal stability even in extreme conditions; simplified logistics due to inherent safety features. Weaknesses: Proprietary form factor limits compatibility with third-party systems; slightly higher weight compared to some competitors' solutions.

Critical Safety Test Protocols and Documentation

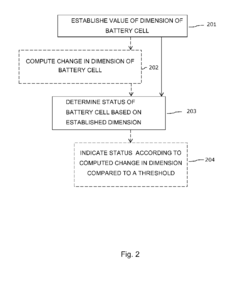

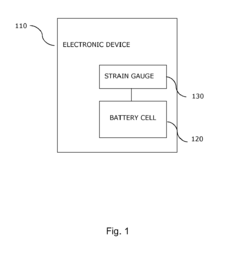

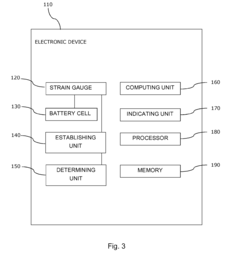

Electronic device and methods therein

PatentInactiveEP2827436A1

Innovation

- Attaching a strain gauge, such as an ultra-high sensitivity graphene-based strain gauge, to the battery cell within an electronic device to measure dimensional changes, which are then compared to reference values and thresholds to determine the cell's status, allowing for precise monitoring of charge and discharge states.

Passive equalization method and system for lithium iron phosphate battery pack

PatentActiveUS20160190829A1

Innovation

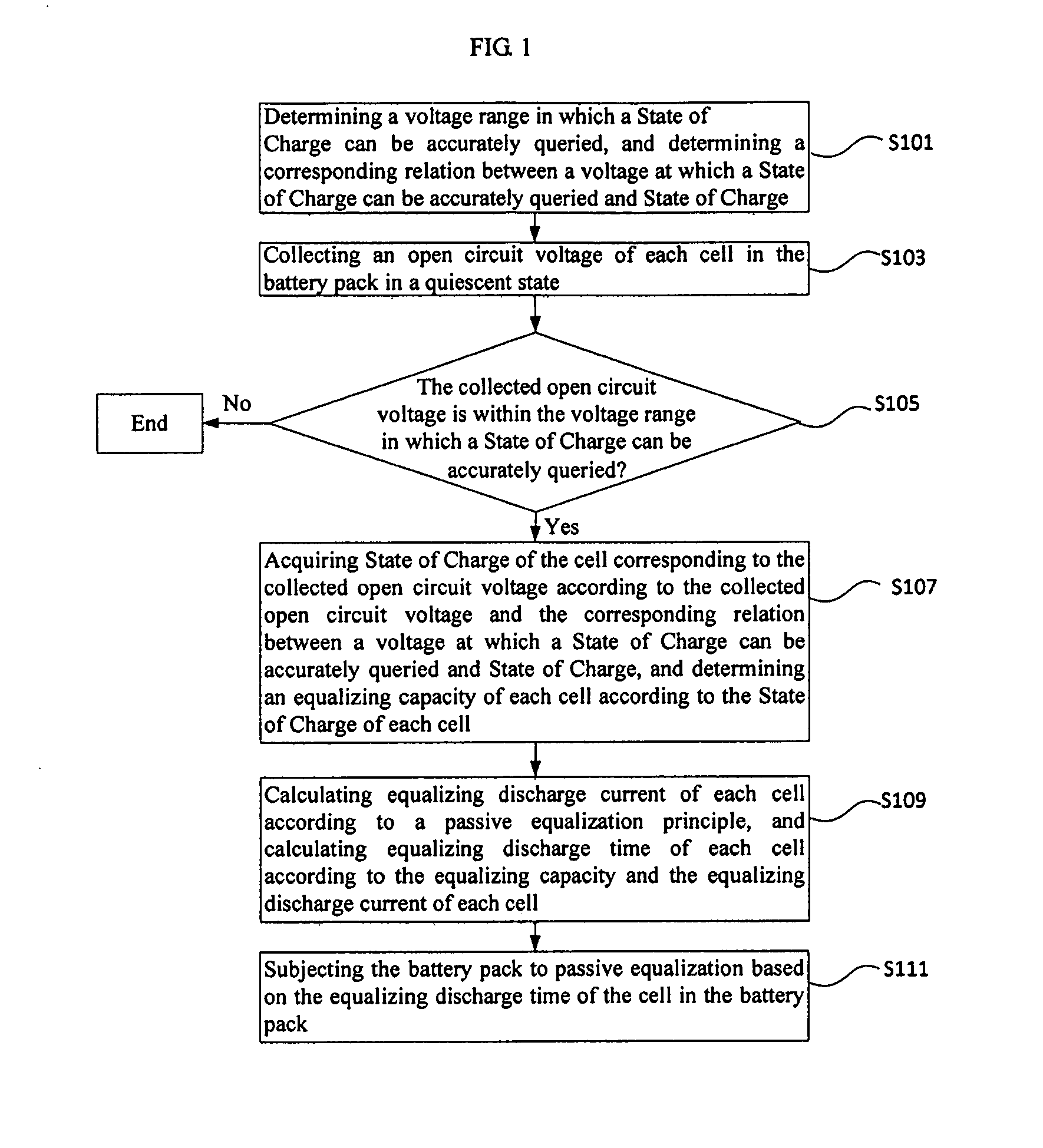

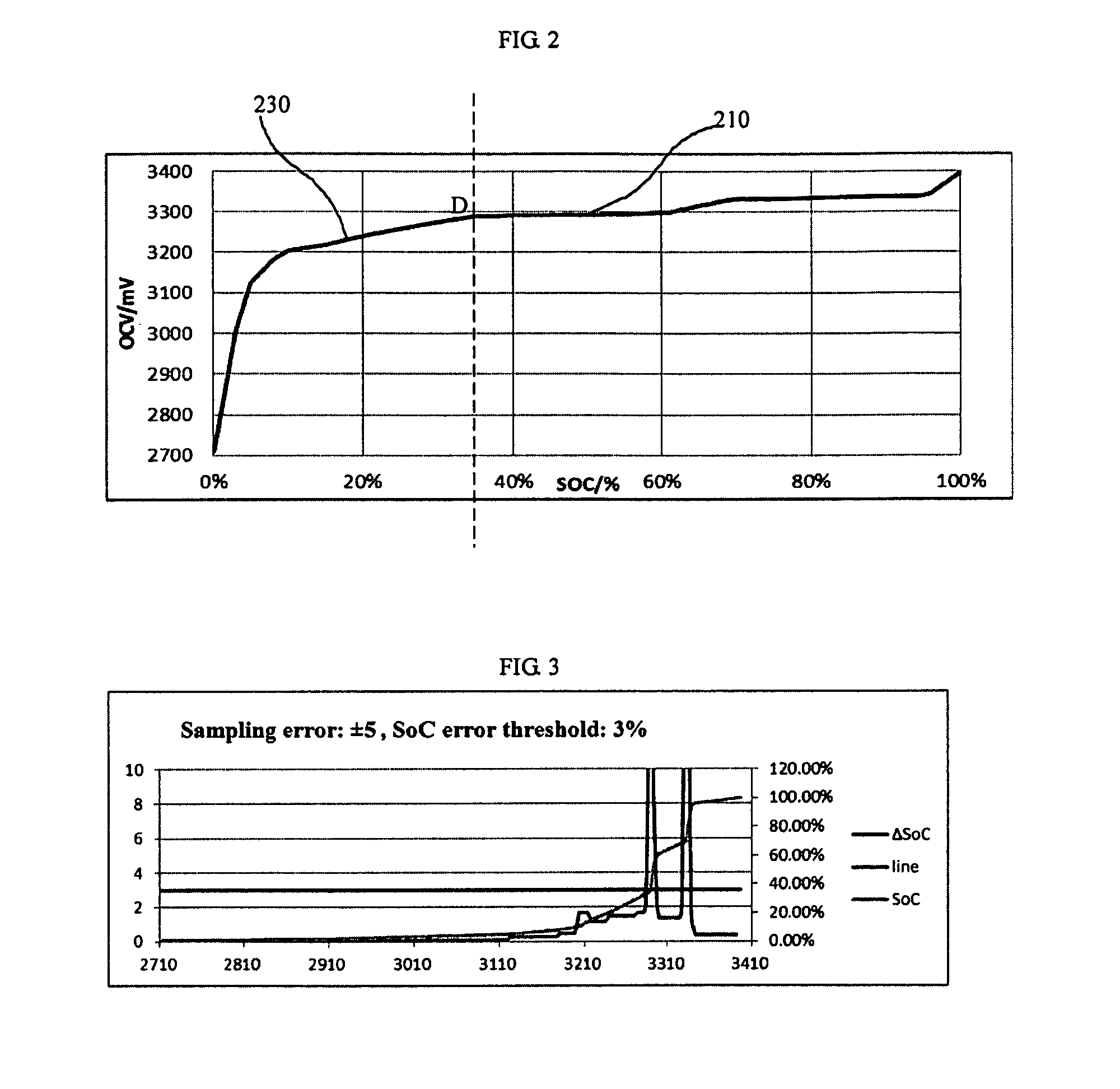

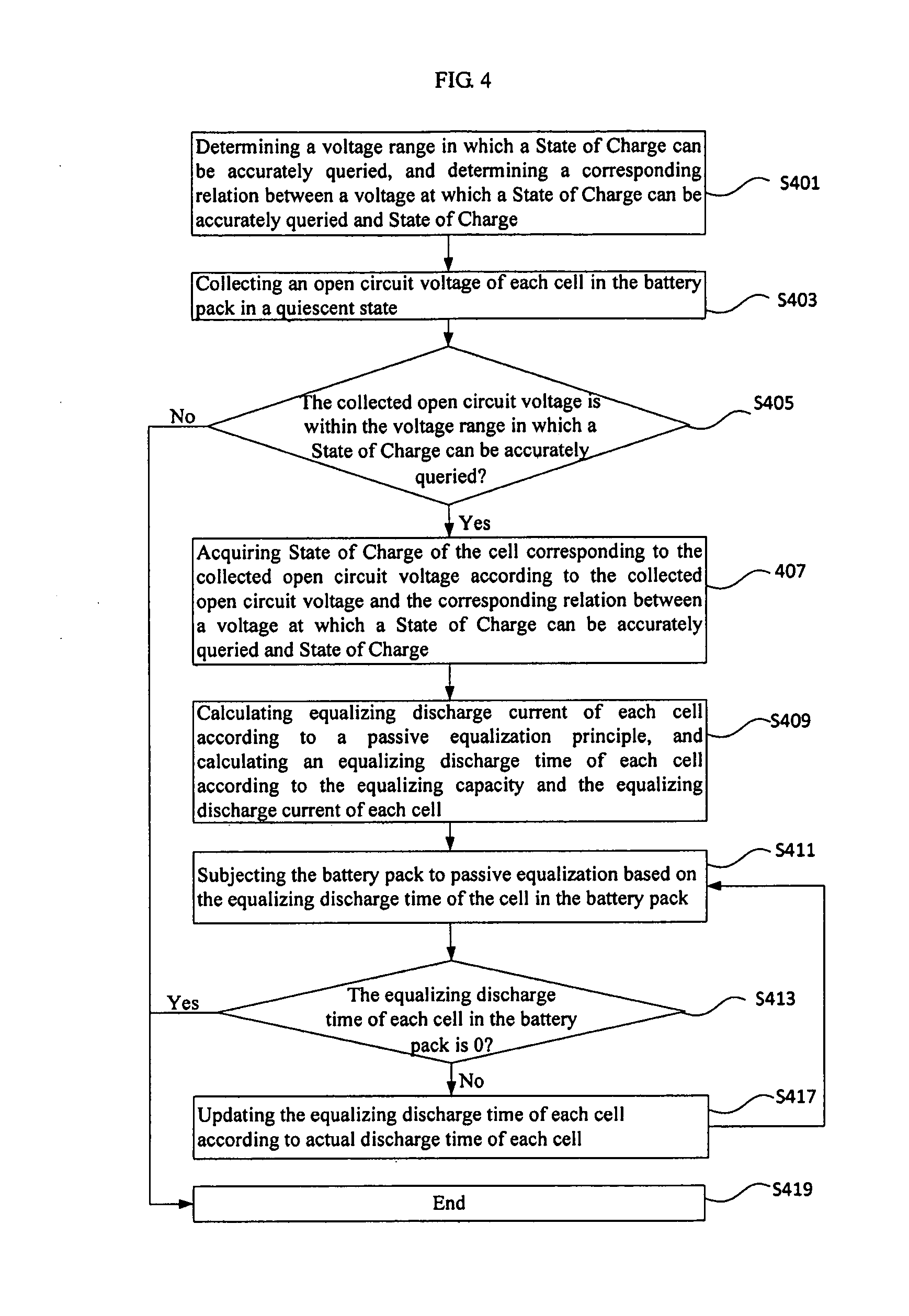

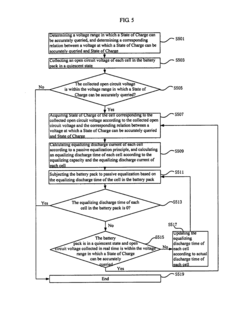

- A passive equalization method and system that determines an accurate voltage range for SoC querying, calculates equalizing capacity and discharge time for each cell, and subjects the battery pack to passive equalization based on these calculations, using a system with a storage module, collection module, judgment module, acquisition module, and equalization module, including an energy consumption circuit with a discharge equalizing resistor and field effect transistor.

International Transport Regulations for LFP Batteries

The international transport of Lithium Iron Phosphate (LFP) batteries is governed by a complex framework of regulations designed to ensure safety during shipping. These regulations have evolved significantly over the past decade in response to incidents involving lithium batteries and the rapid growth of the electric vehicle and energy storage markets.

The United Nations Model Regulations on the Transport of Dangerous Goods serves as the foundation for most international transport regulations. Specifically, the UN Manual of Tests and Criteria Section 38.3 (UN38.3) establishes the baseline testing requirements that all lithium batteries, including LFP, must meet before transport. These tests include altitude simulation, thermal testing, vibration, shock, external short circuit, impact, overcharge, and forced discharge tests.

For air transport, the International Air Transport Association (IATA) Dangerous Goods Regulations and the International Civil Aviation Organization (ICAO) Technical Instructions impose the strictest requirements. Since 2016, standalone LFP batteries are prohibited as cargo on passenger aircraft unless shipped at a state of charge not exceeding 30% and in limited quantities.

Maritime transport follows the International Maritime Dangerous Goods (IMDG) Code, which requires proper declaration, packaging, marking, and documentation of LFP batteries. Special provision 188 provides exemptions for smaller batteries that meet certain conditions, reducing regulatory burden for smaller energy storage systems.

Road and rail transport regulations vary by region. In Europe, the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) and the Regulations concerning the International Carriage of Dangerous Goods by Rail (RID) govern these modes. In North America, the US Department of Transportation (DOT) and Transport Canada regulations apply, with specific provisions in 49 CFR for the United States.

Recent regulatory trends include increased scrutiny of state-of-charge limitations during transport, enhanced packaging requirements, and more detailed documentation. The 2020 amendments to the IMDG Code introduced new segregation requirements for LFP batteries from certain other dangerous goods classes.

Compliance with these regulations requires manufacturers and shippers to maintain comprehensive test reports, safety data sheets, and UN38.3 test summaries. Since January 2020, the UN38.3 test summary must accompany all shipments of LFP batteries throughout the supply chain, providing transparency regarding safety compliance.

For international shipments, proper classification is critical: LFP batteries are typically classified as UN3480 (lithium-ion batteries) or UN3481 (lithium-ion batteries packed with or contained in equipment), with corresponding packaging instructions varying by transport mode and battery configuration.

The United Nations Model Regulations on the Transport of Dangerous Goods serves as the foundation for most international transport regulations. Specifically, the UN Manual of Tests and Criteria Section 38.3 (UN38.3) establishes the baseline testing requirements that all lithium batteries, including LFP, must meet before transport. These tests include altitude simulation, thermal testing, vibration, shock, external short circuit, impact, overcharge, and forced discharge tests.

For air transport, the International Air Transport Association (IATA) Dangerous Goods Regulations and the International Civil Aviation Organization (ICAO) Technical Instructions impose the strictest requirements. Since 2016, standalone LFP batteries are prohibited as cargo on passenger aircraft unless shipped at a state of charge not exceeding 30% and in limited quantities.

Maritime transport follows the International Maritime Dangerous Goods (IMDG) Code, which requires proper declaration, packaging, marking, and documentation of LFP batteries. Special provision 188 provides exemptions for smaller batteries that meet certain conditions, reducing regulatory burden for smaller energy storage systems.

Road and rail transport regulations vary by region. In Europe, the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) and the Regulations concerning the International Carriage of Dangerous Goods by Rail (RID) govern these modes. In North America, the US Department of Transportation (DOT) and Transport Canada regulations apply, with specific provisions in 49 CFR for the United States.

Recent regulatory trends include increased scrutiny of state-of-charge limitations during transport, enhanced packaging requirements, and more detailed documentation. The 2020 amendments to the IMDG Code introduced new segregation requirements for LFP batteries from certain other dangerous goods classes.

Compliance with these regulations requires manufacturers and shippers to maintain comprehensive test reports, safety data sheets, and UN38.3 test summaries. Since January 2020, the UN38.3 test summary must accompany all shipments of LFP batteries throughout the supply chain, providing transparency regarding safety compliance.

For international shipments, proper classification is critical: LFP batteries are typically classified as UN3480 (lithium-ion batteries) or UN3481 (lithium-ion batteries packed with or contained in equipment), with corresponding packaging instructions varying by transport mode and battery configuration.

Environmental Impact and Sustainability Considerations

The environmental impact of LFP (Lithium Iron Phosphate) batteries extends beyond their operational performance and safety compliance. When considering UN38.3, IEC standards, and transport safety acceptance, environmental sustainability becomes increasingly relevant as regulatory frameworks evolve to address ecological concerns.

LFP batteries offer significant environmental advantages compared to other lithium-ion chemistries. The absence of cobalt and nickel—materials associated with ethical mining concerns and environmental degradation—positions LFP as a more sustainable option. This characteristic aligns with the growing emphasis on environmental considerations within compliance frameworks, particularly as regulatory bodies integrate lifecycle assessment requirements into safety standards.

The manufacturing process for LFP batteries compliant with international standards typically consumes less energy than other lithium-ion technologies. This reduced carbon footprint during production represents an important sustainability metric that increasingly factors into comprehensive compliance evaluations. Companies demonstrating lower environmental impact during manufacturing may gain competitive advantages as regulatory frameworks evolve to incorporate carbon accounting.

End-of-life management presents both challenges and opportunities for LFP battery sustainability. Current UN38.3 and IEC standards primarily address operational safety but are gradually expanding to include recycling considerations. The phosphate components in LFP batteries are more environmentally benign than materials in other lithium-ion chemistries, potentially simplifying the recycling process and reducing environmental hazards during disposal.

Transport regulations for LFP batteries increasingly incorporate environmental risk assessments alongside traditional safety parameters. While UN38.3 testing focuses primarily on transport safety, the environmental implications of battery failures during shipping are gaining regulatory attention. This includes potential soil and water contamination risks from damaged batteries and the associated remediation requirements.

The sustainability profile of LFP batteries also influences their market acceptance and regulatory compliance pathway. As governments worldwide implement stricter environmental regulations, batteries with demonstrable sustainability advantages may face streamlined approval processes. This trend is particularly evident in regions with advanced environmental policies, where compliance frameworks increasingly reward technologies with reduced ecological footprints.

Looking forward, the integration of environmental criteria into battery safety and transport regulations appears inevitable. Companies developing LFP batteries that not only meet current UN38.3 and IEC requirements but also anticipate future sustainability standards will likely secure competitive advantages in an increasingly environmentally conscious regulatory landscape.

LFP batteries offer significant environmental advantages compared to other lithium-ion chemistries. The absence of cobalt and nickel—materials associated with ethical mining concerns and environmental degradation—positions LFP as a more sustainable option. This characteristic aligns with the growing emphasis on environmental considerations within compliance frameworks, particularly as regulatory bodies integrate lifecycle assessment requirements into safety standards.

The manufacturing process for LFP batteries compliant with international standards typically consumes less energy than other lithium-ion technologies. This reduced carbon footprint during production represents an important sustainability metric that increasingly factors into comprehensive compliance evaluations. Companies demonstrating lower environmental impact during manufacturing may gain competitive advantages as regulatory frameworks evolve to incorporate carbon accounting.

End-of-life management presents both challenges and opportunities for LFP battery sustainability. Current UN38.3 and IEC standards primarily address operational safety but are gradually expanding to include recycling considerations. The phosphate components in LFP batteries are more environmentally benign than materials in other lithium-ion chemistries, potentially simplifying the recycling process and reducing environmental hazards during disposal.

Transport regulations for LFP batteries increasingly incorporate environmental risk assessments alongside traditional safety parameters. While UN38.3 testing focuses primarily on transport safety, the environmental implications of battery failures during shipping are gaining regulatory attention. This includes potential soil and water contamination risks from damaged batteries and the associated remediation requirements.

The sustainability profile of LFP batteries also influences their market acceptance and regulatory compliance pathway. As governments worldwide implement stricter environmental regulations, batteries with demonstrable sustainability advantages may face streamlined approval processes. This trend is particularly evident in regions with advanced environmental policies, where compliance frameworks increasingly reward technologies with reduced ecological footprints.

Looking forward, the integration of environmental criteria into battery safety and transport regulations appears inevitable. Companies developing LFP batteries that not only meet current UN38.3 and IEC requirements but also anticipate future sustainability standards will likely secure competitive advantages in an increasingly environmentally conscious regulatory landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!