LFP Battery Calendar Aging: Iron Dissolution, Electrolyte Oxidation And Storage Windows

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Aging Mechanisms and Research Objectives

Lithium Iron Phosphate (LFP) batteries have emerged as a prominent energy storage solution due to their enhanced safety, cost-effectiveness, and environmental compatibility compared to other lithium-ion battery chemistries. However, calendar aging—degradation that occurs over time regardless of usage—remains a significant challenge limiting their longevity and performance reliability. This technical investigation focuses on understanding the fundamental mechanisms behind LFP battery calendar aging, with particular emphasis on iron dissolution, electrolyte oxidation, and optimal storage conditions.

Iron dissolution represents one of the primary degradation pathways in LFP batteries. During storage, especially at elevated temperatures or high state-of-charge (SOC) levels, iron ions can dissolve from the cathode material into the electrolyte. These dissolved iron species subsequently migrate to the graphite anode, where they catalyze side reactions that lead to solid electrolyte interphase (SEI) growth and lithium inventory loss, ultimately resulting in capacity fade and increased internal resistance.

Electrolyte oxidation constitutes another critical aging mechanism. The standard carbonate-based electrolytes used in LFP batteries are thermodynamically unstable at the operating potentials of the cathode. Over time, these electrolytes undergo oxidative decomposition, forming various degradation products that consume active lithium, increase cell impedance, and potentially accelerate other degradation processes including iron dissolution itself.

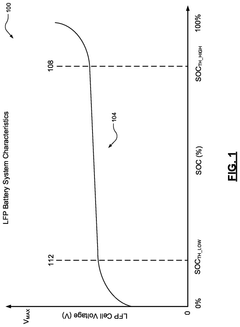

The storage window—defined by temperature and state-of-charge conditions—significantly influences the rate and extent of calendar aging. Research has demonstrated that LFP batteries stored at high temperatures (above 40°C) and high SOC levels (above 80%) experience accelerated capacity fade compared to those maintained at moderate conditions. Conversely, extremely low temperatures can lead to lithium plating during subsequent charging, presenting another degradation risk.

Our research objectives encompass several dimensions of this complex aging phenomenon. First, we aim to elucidate the mechanistic relationship between iron dissolution and electrolyte oxidation, investigating whether these processes occur independently or synergistically. Second, we seek to quantify the impact of various storage parameters (temperature, SOC, time) on aging rates through controlled experiments and advanced characterization techniques.

Additionally, we intend to develop predictive models that can accurately forecast calendar aging under various storage conditions, enabling more precise lifetime estimations for LFP battery systems. Finally, we will explore mitigation strategies, including electrolyte additives, surface coatings, and optimized battery management protocols, to minimize calendar aging effects and extend the useful life of LFP batteries in both stationary and mobile applications.

Iron dissolution represents one of the primary degradation pathways in LFP batteries. During storage, especially at elevated temperatures or high state-of-charge (SOC) levels, iron ions can dissolve from the cathode material into the electrolyte. These dissolved iron species subsequently migrate to the graphite anode, where they catalyze side reactions that lead to solid electrolyte interphase (SEI) growth and lithium inventory loss, ultimately resulting in capacity fade and increased internal resistance.

Electrolyte oxidation constitutes another critical aging mechanism. The standard carbonate-based electrolytes used in LFP batteries are thermodynamically unstable at the operating potentials of the cathode. Over time, these electrolytes undergo oxidative decomposition, forming various degradation products that consume active lithium, increase cell impedance, and potentially accelerate other degradation processes including iron dissolution itself.

The storage window—defined by temperature and state-of-charge conditions—significantly influences the rate and extent of calendar aging. Research has demonstrated that LFP batteries stored at high temperatures (above 40°C) and high SOC levels (above 80%) experience accelerated capacity fade compared to those maintained at moderate conditions. Conversely, extremely low temperatures can lead to lithium plating during subsequent charging, presenting another degradation risk.

Our research objectives encompass several dimensions of this complex aging phenomenon. First, we aim to elucidate the mechanistic relationship between iron dissolution and electrolyte oxidation, investigating whether these processes occur independently or synergistically. Second, we seek to quantify the impact of various storage parameters (temperature, SOC, time) on aging rates through controlled experiments and advanced characterization techniques.

Additionally, we intend to develop predictive models that can accurately forecast calendar aging under various storage conditions, enabling more precise lifetime estimations for LFP battery systems. Finally, we will explore mitigation strategies, including electrolyte additives, surface coatings, and optimized battery management protocols, to minimize calendar aging effects and extend the useful life of LFP batteries in both stationary and mobile applications.

Market Demand Analysis for Long-Life LFP Batteries

The global market for long-life LFP (Lithium Iron Phosphate) batteries has witnessed substantial growth in recent years, driven primarily by the expanding electric vehicle (EV) sector and stationary energy storage applications. Market research indicates that the LFP battery segment is expected to grow at a compound annual growth rate of 15-20% through 2030, with particular emphasis on applications requiring extended calendar life.

Consumer demand for EVs with longer warranties and reduced battery degradation has created significant market pull for improved LFP technologies. Currently, automotive OEMs are seeking battery solutions that can maintain at least 80% capacity after 10-15 years of use, compared to the previous industry standard of 8 years. This shift represents a critical market requirement that directly relates to calendar aging mechanisms including iron dissolution and electrolyte oxidation.

The stationary energy storage sector presents another substantial market opportunity, with grid-scale installations requiring batteries with 15-20 year operational lifespans. In this application, calendar aging becomes even more critical than cycle life, as many grid storage systems experience relatively infrequent deep cycling but must maintain performance during long storage periods at various states of charge.

Commercial fleet operators represent a growing market segment with specific demands for long-life LFP batteries. These customers prioritize total cost of ownership calculations where battery longevity directly impacts return on investment. Market surveys indicate fleet operators are willing to pay a 15-25% premium for battery systems that can demonstrate superior resistance to calendar aging effects.

The marine and aviation sectors are emerging markets with stringent requirements for battery calendar life. These applications often involve extended storage periods followed by critical high-power demands, making resistance to iron dissolution and electrolyte oxidation particularly valuable.

Geographically, the most robust demand for long-life LFP batteries exists in regions with established EV markets and renewable energy integration, including China, Europe, and North America. China currently leads global LFP battery production and implementation, but European markets show the highest premium valuation for extended calendar life specifications.

Market analysis reveals that consumers and industrial buyers increasingly recognize the importance of storage conditions in battery longevity. This has created demand for smart battery management systems that can optimize storage windows based on environmental conditions and usage patterns, potentially commanding price premiums of 10-20% for systems with advanced calendar life management capabilities.

Consumer demand for EVs with longer warranties and reduced battery degradation has created significant market pull for improved LFP technologies. Currently, automotive OEMs are seeking battery solutions that can maintain at least 80% capacity after 10-15 years of use, compared to the previous industry standard of 8 years. This shift represents a critical market requirement that directly relates to calendar aging mechanisms including iron dissolution and electrolyte oxidation.

The stationary energy storage sector presents another substantial market opportunity, with grid-scale installations requiring batteries with 15-20 year operational lifespans. In this application, calendar aging becomes even more critical than cycle life, as many grid storage systems experience relatively infrequent deep cycling but must maintain performance during long storage periods at various states of charge.

Commercial fleet operators represent a growing market segment with specific demands for long-life LFP batteries. These customers prioritize total cost of ownership calculations where battery longevity directly impacts return on investment. Market surveys indicate fleet operators are willing to pay a 15-25% premium for battery systems that can demonstrate superior resistance to calendar aging effects.

The marine and aviation sectors are emerging markets with stringent requirements for battery calendar life. These applications often involve extended storage periods followed by critical high-power demands, making resistance to iron dissolution and electrolyte oxidation particularly valuable.

Geographically, the most robust demand for long-life LFP batteries exists in regions with established EV markets and renewable energy integration, including China, Europe, and North America. China currently leads global LFP battery production and implementation, but European markets show the highest premium valuation for extended calendar life specifications.

Market analysis reveals that consumers and industrial buyers increasingly recognize the importance of storage conditions in battery longevity. This has created demand for smart battery management systems that can optimize storage windows based on environmental conditions and usage patterns, potentially commanding price premiums of 10-20% for systems with advanced calendar life management capabilities.

Current Challenges in LFP Calendar Aging Research

Despite significant advancements in lithium iron phosphate (LFP) battery technology, calendar aging remains a critical challenge that limits long-term performance and reliability. Current research faces several complex obstacles in fully understanding and mitigating the degradation mechanisms during storage periods. One primary challenge is accurately quantifying and modeling iron dissolution from the cathode material, which occurs even without cycling. This dissolution process is influenced by multiple factors including temperature, state of charge (SoC), and electrolyte composition, making it difficult to develop comprehensive predictive models.

Electrolyte oxidation presents another significant research challenge, as the conventional carbonate-based electrolytes undergo gradual decomposition at the electrode-electrolyte interfaces. This leads to the formation of resistive surface films that impede lithium-ion transport. The scientific community still lacks consensus on the exact chemical pathways of these oxidation reactions, particularly how they interact with dissolved iron species to accelerate degradation.

The determination of optimal storage windows represents a third major challenge. While it is generally accepted that extreme SoC values accelerate aging, the precise relationship between storage conditions and capacity fade rates remains incompletely characterized. This is complicated by the non-linear nature of aging processes and their dependence on battery history and manufacturing variations.

Methodological limitations further hinder progress in this field. Traditional aging studies require months or years of testing, creating a significant bottleneck for research advancement. Accelerated aging protocols often fail to accurately represent real-world degradation mechanisms, leading to potentially misleading conclusions about long-term performance.

The analytical techniques currently employed also present limitations. Post-mortem analyses provide valuable insights but are destructive and cannot track progressive changes. In-situ and operando characterization methods are emerging but remain challenging to implement for calendar aging studies due to the slow nature of the degradation processes.

Computational modeling approaches face difficulties in accurately capturing the multiphysics nature of calendar aging phenomena. Current models often oversimplify the complex interplay between chemical, electrochemical, and mechanical degradation mechanisms, limiting their predictive power for diverse operating conditions and cell designs.

Translating laboratory findings to commercial cells represents yet another challenge. The scaling effects and the influence of manufacturing variations on calendar aging behaviors are not fully understood, creating uncertainty in lifetime predictions for real-world applications.

Electrolyte oxidation presents another significant research challenge, as the conventional carbonate-based electrolytes undergo gradual decomposition at the electrode-electrolyte interfaces. This leads to the formation of resistive surface films that impede lithium-ion transport. The scientific community still lacks consensus on the exact chemical pathways of these oxidation reactions, particularly how they interact with dissolved iron species to accelerate degradation.

The determination of optimal storage windows represents a third major challenge. While it is generally accepted that extreme SoC values accelerate aging, the precise relationship between storage conditions and capacity fade rates remains incompletely characterized. This is complicated by the non-linear nature of aging processes and their dependence on battery history and manufacturing variations.

Methodological limitations further hinder progress in this field. Traditional aging studies require months or years of testing, creating a significant bottleneck for research advancement. Accelerated aging protocols often fail to accurately represent real-world degradation mechanisms, leading to potentially misleading conclusions about long-term performance.

The analytical techniques currently employed also present limitations. Post-mortem analyses provide valuable insights but are destructive and cannot track progressive changes. In-situ and operando characterization methods are emerging but remain challenging to implement for calendar aging studies due to the slow nature of the degradation processes.

Computational modeling approaches face difficulties in accurately capturing the multiphysics nature of calendar aging phenomena. Current models often oversimplify the complex interplay between chemical, electrochemical, and mechanical degradation mechanisms, limiting their predictive power for diverse operating conditions and cell designs.

Translating laboratory findings to commercial cells represents yet another challenge. The scaling effects and the influence of manufacturing variations on calendar aging behaviors are not fully understood, creating uncertainty in lifetime predictions for real-world applications.

Current Approaches to Mitigate Iron Dissolution

01 Temperature effects on LFP battery calendar aging

Temperature significantly impacts the calendar aging of LFP batteries. Higher storage temperatures accelerate degradation processes, including SEI layer growth and electrolyte decomposition. Research shows that controlling storage temperature within optimal ranges can substantially extend battery lifespan. Advanced thermal management systems have been developed to maintain batteries at ideal temperatures during idle periods, reducing capacity fade and impedance growth that typically occur during calendar aging.- Factors affecting LFP battery calendar aging: Various factors influence the calendar aging of LFP batteries, including temperature, state of charge (SOC), and storage conditions. Higher temperatures accelerate aging processes such as SEI layer growth and electrolyte decomposition. Maintaining batteries at extreme SOC levels (either very high or very low) during storage can significantly impact their lifespan. Understanding these factors is crucial for developing strategies to mitigate calendar aging effects and extend battery life.

- Testing and measurement methods for calendar aging: Specialized testing protocols and measurement techniques have been developed to evaluate and quantify calendar aging in LFP batteries. These methods include accelerated aging tests under controlled conditions, electrochemical impedance spectroscopy (EIS), capacity retention measurements, and post-mortem analysis. Advanced diagnostic tools help researchers understand degradation mechanisms and validate aging models, enabling more accurate prediction of battery lifetime under various storage conditions.

- Electrolyte additives and formulations to reduce aging: Innovative electrolyte formulations and additives have been developed to mitigate calendar aging effects in LFP batteries. These include film-forming additives that create more stable SEI layers, electrolyte stabilizers that reduce decomposition reactions, and compounds that scavenge harmful reaction products. By modifying the electrolyte chemistry, researchers can significantly improve the calendar life of LFP batteries without compromising their performance characteristics.

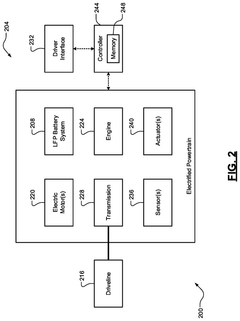

- Battery management systems for aging mitigation: Advanced battery management systems (BMS) employ sophisticated algorithms and control strategies to minimize calendar aging effects. These systems monitor battery parameters in real-time and implement optimal storage protocols, including partial state-of-charge management during idle periods, temperature control, and periodic conditioning cycles. Machine learning approaches are increasingly being used to predict aging behavior and adaptively adjust management strategies based on battery usage patterns and environmental conditions.

- Structural and material innovations for improved calendar life: Novel structural designs and material innovations have been developed to enhance the calendar life of LFP batteries. These include modified cathode coatings that prevent side reactions, engineered particle morphologies that improve stability, advanced separator materials that reduce ion transport resistance over time, and protective surface treatments for electrode materials. These innovations address fundamental degradation mechanisms, resulting in LFP batteries with significantly extended calendar life even under challenging storage conditions.

02 State of charge influence on calendar aging mechanisms

The state of charge (SOC) at which LFP batteries are stored has a profound effect on their calendar aging rate. Batteries stored at high SOC levels experience accelerated aging due to increased electrolyte oxidation and cathode degradation. Studies indicate that maintaining LFP batteries at moderate SOC levels (30-60%) during storage periods significantly reduces capacity loss. Innovative battery management systems have been designed to automatically adjust SOC levels during extended storage to minimize degradation.Expand Specific Solutions03 Electrolyte composition optimization for reduced calendar aging

The composition of electrolytes plays a crucial role in the calendar aging of LFP batteries. Specialized electrolyte additives can form more stable SEI layers that protect electrode surfaces during storage periods. Research has focused on developing novel electrolyte formulations with improved oxidation resistance and reduced reactivity with electrode materials. These advanced electrolytes demonstrate significantly lower rates of calendar aging, particularly in high-temperature environments, by minimizing parasitic reactions that consume lithium inventory.Expand Specific Solutions04 Diagnostic methods for calendar aging assessment

Advanced diagnostic techniques have been developed to accurately assess and predict calendar aging in LFP batteries. These methods include electrochemical impedance spectroscopy, differential voltage analysis, and machine learning algorithms that can identify aging signatures. Non-invasive monitoring systems allow for real-time tracking of battery health parameters during storage periods. These diagnostic approaches enable more precise estimation of remaining useful life and help optimize storage conditions to minimize degradation.Expand Specific Solutions05 Surface coating technologies for enhanced calendar life

Innovative surface coating technologies have been developed to enhance the calendar life of LFP cathode materials. These coatings create protective barriers that prevent direct contact between active materials and the electrolyte, reducing parasitic reactions during storage. Various coating materials, including carbon-based compounds, metal oxides, and polymers, have demonstrated effectiveness in mitigating calendar aging effects. The coatings also help maintain structural stability of electrode particles during long-term storage, preserving capacity and power capability.Expand Specific Solutions

Key Industry Players in LFP Battery Development

The LFP battery calendar aging market is currently in a growth phase, with increasing adoption of LFP chemistry in electric vehicles and energy storage systems driving research into degradation mechanisms. The global market for battery aging analysis and mitigation technologies is expanding rapidly, projected to reach significant scale as EV adoption accelerates. From a technical maturity perspective, understanding of iron dissolution and electrolyte oxidation mechanisms is advancing, with companies like TWAICE Technologies, Forge Nano, and BYD developing sophisticated solutions. Research institutions including Huazhong University and University of California collaborate with industry leaders such as Tesla and BASF to optimize storage conditions and extend battery life. Companies like Eatron Technologies and Princeton NuEnergy are pioneering predictive analytics and recycling technologies to address calendar aging challenges in the evolving battery ecosystem.

Robert Bosch GmbH

Technical Solution: Bosch has developed an integrated approach to LFP battery calendar aging management combining advanced materials engineering with sophisticated battery management strategies. Their technical solution addresses iron dissolution through a dual-protection strategy: first, by implementing nano-engineered protective coatings on LFP particles that create physical barriers against direct electrolyte contact; second, by developing proprietary electrolyte formulations with functional additives that capture dissolved iron species before they can migrate to the anode[7]. Bosch's research has identified specific voltage stability windows for LFP storage, demonstrating that maintaining cells between 30-40% SOC (approximately 3.2-3.3V) can reduce calendar aging rates by up to 60% compared to storage at higher states of charge. Their battery management systems incorporate these findings through adaptive storage protocols that automatically adjust cell voltages based on anticipated storage duration. Additionally, Bosch has developed advanced diagnostic algorithms that can detect early signs of iron dissolution through subtle changes in electrochemical impedance signatures, enabling preventive maintenance before significant capacity loss occurs[8]. Their comprehensive testing has established correlation between storage temperature, voltage, and aging rates, creating detailed aging models that predict calendar life under various conditions.

Strengths: Holistic approach combining materials science with system-level battery management; extensive validation through automotive-grade testing protocols; solutions implemented in commercial energy storage systems with demonstrated longevity. Weaknesses: Higher system complexity increases costs; some management strategies require active intervention during storage periods; solution effectiveness varies with different LFP material sources.

BASF Corp.

Technical Solution: BASF has developed a sophisticated materials science approach to addressing LFP battery calendar aging through their CathoCap™ technology platform. Their solution focuses on nanoscale engineering of LFP particle surfaces to create protective barriers against iron dissolution. BASF's proprietary coating technology applies ultra-thin (2-5nm) amorphous carbon and metal oxide hybrid layers that physically isolate LFP particles from direct electrolyte contact while maintaining excellent lithium-ion conductivity[5]. Their research has demonstrated that these engineered interfaces can reduce iron dissolution rates by up to 75% during extended storage periods. Additionally, BASF has formulated specialized electrolyte additive packages that work synergistically with their coated materials, including functional additives that preferentially react with dissolved iron species to prevent their migration and subsequent reduction at the anode. Through extensive calendar aging studies, BASF has identified optimal storage conditions for their enhanced LFP materials, recommending precise voltage windows (3.0-3.3V) that minimize both iron dissolution and electrolyte oxidation mechanisms, extending calendar life by up to 3x compared to conventional LFP materials stored at higher voltages[6].

Strengths: Industry-leading materials science expertise applied to fundamental aging mechanisms; solutions can be implemented within existing manufacturing processes; comprehensive understanding of interface chemistry. Weaknesses: Premium materials increase cell costs; coating uniformity challenges at mass production scale; some solutions require specialized electrolyte formulations that may not be compatible with all cell designs.

Critical Analysis of Electrolyte Oxidation Mechanisms

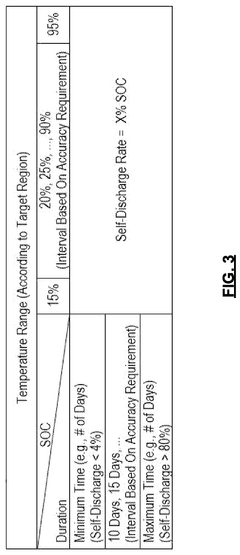

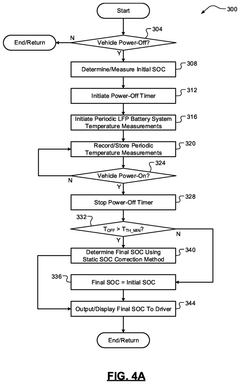

Static state of charge correction techniques for lithium iron phosphate battery systems

PatentPendingUS20250091474A1

Innovation

- A static SOC correction system that uses a calibrated look-up table to relate power-off times and temperatures to self-discharge rates, allowing a controller to determine an initial SOC, initiate and stop a power-off timer, measure temperatures, and calculate a corrected SOC by accounting for self-discharge, thereby overcoming the voltage flat zone limitation.

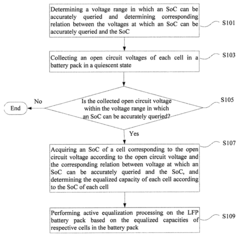

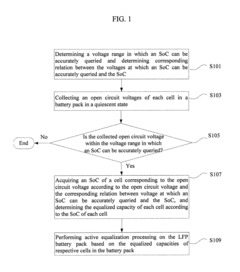

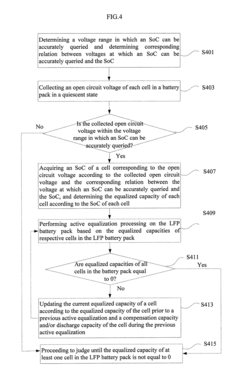

Active equalization method and system of lithium iron phosphate battery pack

PatentActiveUS10027134B2

Innovation

- An active equalization method and system that determines the accurate State of Charge (SoC) for each cell by sampling open circuit voltage and using a corresponding relation to calculate equalized capacities, allowing for targeted equalization processing based on SoC differences within specific voltage ranges.

Optimal Storage Conditions and SOC Windows

Determining optimal storage conditions for LFP batteries is crucial for maximizing their lifespan and maintaining performance integrity. Research indicates that temperature plays a significant role in calendar aging, with elevated temperatures accelerating degradation mechanisms. The ideal storage temperature range appears to be between 15°C and 25°C, with significant acceleration of aging processes observed above 40°C and below 0°C.

State of Charge (SOC) windows represent another critical parameter affecting LFP battery longevity during storage. Studies demonstrate that LFP cells stored at extreme SOC levels (below 10% or above 90%) experience accelerated capacity fade. The optimal SOC window for long-term storage has been identified between 30% and 60%, with 40-50% being the sweet spot that minimizes both iron dissolution and electrolyte oxidation processes.

Humidity control constitutes an often overlooked yet essential storage parameter. Exposure to high humidity environments can compromise cell sealing integrity and accelerate corrosion of external components. Industry standards recommend maintaining relative humidity below 65% in storage facilities to prevent these detrimental effects.

Pressure conditions during storage also influence calendar aging rates. Research indicates that maintaining atmospheric pressure between 86 and 106 kPa helps minimize mechanical stress on cell components. Significant pressure fluctuations can exacerbate degradation mechanisms by creating micro-cracks in electrode materials and accelerating iron dissolution.

The duration of storage periods requires strategic management through periodic maintenance charging. For extended storage exceeding three months, implementing a maintenance charging protocol every 90-120 days helps redistribute lithium ions and minimize concentration gradients that contribute to capacity fade. This practice has demonstrated up to 30% reduction in capacity loss during long-term storage.

Combining these parameters creates a comprehensive storage strategy. The most effective approach involves maintaining LFP cells at 40-50% SOC, storing at 20±5°C, controlling humidity below 65%, avoiding pressure fluctuations, and implementing quarterly maintenance charging for periods exceeding three months. This integrated approach addresses multiple degradation mechanisms simultaneously, effectively extending calendar life by 2-3 times compared to unoptimized storage conditions.

State of Charge (SOC) windows represent another critical parameter affecting LFP battery longevity during storage. Studies demonstrate that LFP cells stored at extreme SOC levels (below 10% or above 90%) experience accelerated capacity fade. The optimal SOC window for long-term storage has been identified between 30% and 60%, with 40-50% being the sweet spot that minimizes both iron dissolution and electrolyte oxidation processes.

Humidity control constitutes an often overlooked yet essential storage parameter. Exposure to high humidity environments can compromise cell sealing integrity and accelerate corrosion of external components. Industry standards recommend maintaining relative humidity below 65% in storage facilities to prevent these detrimental effects.

Pressure conditions during storage also influence calendar aging rates. Research indicates that maintaining atmospheric pressure between 86 and 106 kPa helps minimize mechanical stress on cell components. Significant pressure fluctuations can exacerbate degradation mechanisms by creating micro-cracks in electrode materials and accelerating iron dissolution.

The duration of storage periods requires strategic management through periodic maintenance charging. For extended storage exceeding three months, implementing a maintenance charging protocol every 90-120 days helps redistribute lithium ions and minimize concentration gradients that contribute to capacity fade. This practice has demonstrated up to 30% reduction in capacity loss during long-term storage.

Combining these parameters creates a comprehensive storage strategy. The most effective approach involves maintaining LFP cells at 40-50% SOC, storing at 20±5°C, controlling humidity below 65%, avoiding pressure fluctuations, and implementing quarterly maintenance charging for periods exceeding three months. This integrated approach addresses multiple degradation mechanisms simultaneously, effectively extending calendar life by 2-3 times compared to unoptimized storage conditions.

Sustainability Impact of Extended LFP Battery Lifecycles

The extension of LFP (Lithium Iron Phosphate) battery lifecycles represents a significant advancement in sustainable energy storage solutions. By addressing the key degradation mechanisms—iron dissolution, electrolyte oxidation, and optimizing storage conditions—manufacturers can substantially reduce the environmental footprint associated with battery production and disposal.

Extended battery lifecycles directly translate to reduced raw material extraction requirements. Each additional year of functional battery life means fewer lithium, iron, phosphate, and other critical minerals need to be mined. This is particularly significant considering that mining operations for battery materials often involve substantial land disruption, water usage, and energy consumption.

The carbon footprint reduction achieved through lifecycle extension is substantial. Manufacturing a single EV battery can generate 5-15 tons of CO2 emissions. When battery life doubles from 8 to 16 years through improved calendar aging management, the emissions per year of service are effectively halved, creating a meaningful contribution to climate change mitigation efforts.

Waste reduction represents another critical sustainability benefit. Extended LFP battery lifecycles directly reduce the volume of battery waste entering the recycling stream or landfills. Current estimates suggest that optimized storage protocols and electrolyte formulations that minimize oxidation can extend useful life by 30-50%, potentially preventing millions of tons of battery waste globally by 2030.

From a circular economy perspective, longer-lasting LFP batteries create additional opportunities for second-life applications. Batteries that maintain 70-80% capacity after primary use can serve in less demanding stationary storage applications for many additional years before recycling becomes necessary, further multiplying their sustainability benefits.

Economic sustainability also improves with extended lifecycles. The total cost of ownership decreases significantly when replacement intervals extend, making renewable energy storage more economically viable for a broader range of applications and markets. This economic advantage accelerates the transition away from fossil fuel dependence.

Water conservation benefits emerge as an often-overlooked sustainability impact. Battery manufacturing is water-intensive, with estimates suggesting 7,000-9,000 liters of water consumption per kWh of battery capacity produced. Extended lifecycles directly reduce this water footprint on a per-year-of-service basis, contributing to water conservation efforts in regions where manufacturing occurs.

Extended battery lifecycles directly translate to reduced raw material extraction requirements. Each additional year of functional battery life means fewer lithium, iron, phosphate, and other critical minerals need to be mined. This is particularly significant considering that mining operations for battery materials often involve substantial land disruption, water usage, and energy consumption.

The carbon footprint reduction achieved through lifecycle extension is substantial. Manufacturing a single EV battery can generate 5-15 tons of CO2 emissions. When battery life doubles from 8 to 16 years through improved calendar aging management, the emissions per year of service are effectively halved, creating a meaningful contribution to climate change mitigation efforts.

Waste reduction represents another critical sustainability benefit. Extended LFP battery lifecycles directly reduce the volume of battery waste entering the recycling stream or landfills. Current estimates suggest that optimized storage protocols and electrolyte formulations that minimize oxidation can extend useful life by 30-50%, potentially preventing millions of tons of battery waste globally by 2030.

From a circular economy perspective, longer-lasting LFP batteries create additional opportunities for second-life applications. Batteries that maintain 70-80% capacity after primary use can serve in less demanding stationary storage applications for many additional years before recycling becomes necessary, further multiplying their sustainability benefits.

Economic sustainability also improves with extended lifecycles. The total cost of ownership decreases significantly when replacement intervals extend, making renewable energy storage more economically viable for a broader range of applications and markets. This economic advantage accelerates the transition away from fossil fuel dependence.

Water conservation benefits emerge as an often-overlooked sustainability impact. Battery manufacturing is water-intensive, with estimates suggesting 7,000-9,000 liters of water consumption per kWh of battery capacity produced. Extended lifecycles directly reduce this water footprint on a per-year-of-service basis, contributing to water conservation efforts in regions where manufacturing occurs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!