Comparative lifespan studies of KERS-based vehicles

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

KERS Technology Evolution

The evolution of Kinetic Energy Recovery System (KERS) technology in vehicles has been marked by significant advancements and innovations over the past few decades. Initially developed for Formula One racing in the late 2000s, KERS has since found its way into various automotive applications, including passenger vehicles and public transportation.

In its early stages, KERS primarily utilized mechanical flywheel systems to store and release energy. These systems were relatively simple but faced challenges in terms of weight, packaging, and efficiency. As technology progressed, electrical KERS systems emerged, employing high-power electric motors and advanced battery technologies to capture and deploy kinetic energy more effectively.

The mid-2010s saw a shift towards more sophisticated hybrid KERS solutions, combining mechanical and electrical components to optimize energy recovery and deployment. This period also witnessed the integration of KERS with other vehicle systems, such as regenerative braking and start-stop technology, to further enhance overall vehicle efficiency.

Recent years have brought about significant improvements in KERS durability and lifespan. Advanced materials and manufacturing techniques have led to more robust components, capable of withstanding the high stresses associated with frequent energy capture and release cycles. Additionally, the development of smart control algorithms has enabled more precise management of energy flow, reducing wear on system components and extending operational life.

The evolution of KERS technology has also been influenced by advancements in related fields, such as battery technology and power electronics. The introduction of high-capacity, fast-charging batteries and more efficient power conversion systems has greatly enhanced the performance and practicality of KERS-based vehicles.

Looking at the comparative lifespan studies of KERS-based vehicles, researchers have observed a steady improvement in system longevity and reliability. Early KERS implementations often faced issues with component degradation and system failures, limiting their practical application in everyday vehicles. However, as the technology matured, these challenges have been largely overcome, resulting in KERS systems that can now match or even exceed the lifespan of traditional vehicle powertrains.

Recent studies have shown that modern KERS-equipped vehicles can maintain their energy recovery and deployment capabilities for well over 100,000 miles of operation, with some high-end systems demonstrating reliability up to 200,000 miles or more. This increased lifespan has been crucial in making KERS technology more viable for mass-market adoption, as it addresses concerns about long-term maintenance costs and vehicle resale value.

In its early stages, KERS primarily utilized mechanical flywheel systems to store and release energy. These systems were relatively simple but faced challenges in terms of weight, packaging, and efficiency. As technology progressed, electrical KERS systems emerged, employing high-power electric motors and advanced battery technologies to capture and deploy kinetic energy more effectively.

The mid-2010s saw a shift towards more sophisticated hybrid KERS solutions, combining mechanical and electrical components to optimize energy recovery and deployment. This period also witnessed the integration of KERS with other vehicle systems, such as regenerative braking and start-stop technology, to further enhance overall vehicle efficiency.

Recent years have brought about significant improvements in KERS durability and lifespan. Advanced materials and manufacturing techniques have led to more robust components, capable of withstanding the high stresses associated with frequent energy capture and release cycles. Additionally, the development of smart control algorithms has enabled more precise management of energy flow, reducing wear on system components and extending operational life.

The evolution of KERS technology has also been influenced by advancements in related fields, such as battery technology and power electronics. The introduction of high-capacity, fast-charging batteries and more efficient power conversion systems has greatly enhanced the performance and practicality of KERS-based vehicles.

Looking at the comparative lifespan studies of KERS-based vehicles, researchers have observed a steady improvement in system longevity and reliability. Early KERS implementations often faced issues with component degradation and system failures, limiting their practical application in everyday vehicles. However, as the technology matured, these challenges have been largely overcome, resulting in KERS systems that can now match or even exceed the lifespan of traditional vehicle powertrains.

Recent studies have shown that modern KERS-equipped vehicles can maintain their energy recovery and deployment capabilities for well over 100,000 miles of operation, with some high-end systems demonstrating reliability up to 200,000 miles or more. This increased lifespan has been crucial in making KERS technology more viable for mass-market adoption, as it addresses concerns about long-term maintenance costs and vehicle resale value.

Market Demand Analysis

The market demand for Kinetic Energy Recovery System (KERS)-based vehicles has been steadily growing, driven by increasing environmental concerns and the push for more fuel-efficient transportation solutions. As governments worldwide implement stricter emissions regulations, automotive manufacturers are turning to KERS technology to meet these standards while improving vehicle performance.

The global market for KERS-based vehicles is expected to expand significantly in the coming years. This growth is primarily fueled by the rising adoption of hybrid and electric vehicles, where KERS plays a crucial role in energy recuperation and overall efficiency. The passenger car segment currently dominates the market, with a growing interest in KERS applications for commercial vehicles and high-performance sports cars.

Consumer awareness and demand for eco-friendly vehicles are key factors driving the market. As fuel prices fluctuate and environmental consciousness increases, consumers are increasingly seeking vehicles that offer improved fuel economy and reduced emissions. KERS-based vehicles address these concerns by capturing and reusing energy that would otherwise be lost during braking, thereby enhancing overall vehicle efficiency.

The automotive industry's shift towards electrification has also boosted the demand for KERS technology. Many automakers are incorporating KERS into their hybrid and electric vehicle lineups as a means to extend range and improve performance. This trend is particularly evident in the luxury and sports car segments, where KERS is being used to enhance acceleration and power delivery.

In the commercial vehicle sector, there is a growing interest in KERS technology for applications in buses, trucks, and other heavy-duty vehicles. The potential for significant fuel savings and emissions reductions in these larger vehicles makes KERS an attractive option for fleet operators and logistics companies looking to reduce their operating costs and environmental impact.

The racing industry has been a significant driver of KERS development and adoption. Formula 1's implementation of KERS has not only improved race performance but has also served as a testing ground for technologies that can be adapted for road vehicles. This has led to increased consumer interest in KERS-equipped vehicles, particularly among automotive enthusiasts.

However, the market for KERS-based vehicles faces some challenges. The additional cost of KERS technology can be a barrier to widespread adoption, particularly in lower-priced vehicle segments. Additionally, the complexity of KERS systems requires specialized maintenance and repair services, which may not be readily available in all markets.

Despite these challenges, the long-term outlook for KERS-based vehicles remains positive. As technology advances and production scales up, costs are expected to decrease, making KERS more accessible across various vehicle segments. The ongoing focus on sustainability and energy efficiency in the automotive industry suggests that KERS will continue to play an important role in the evolution of vehicle powertrains.

The global market for KERS-based vehicles is expected to expand significantly in the coming years. This growth is primarily fueled by the rising adoption of hybrid and electric vehicles, where KERS plays a crucial role in energy recuperation and overall efficiency. The passenger car segment currently dominates the market, with a growing interest in KERS applications for commercial vehicles and high-performance sports cars.

Consumer awareness and demand for eco-friendly vehicles are key factors driving the market. As fuel prices fluctuate and environmental consciousness increases, consumers are increasingly seeking vehicles that offer improved fuel economy and reduced emissions. KERS-based vehicles address these concerns by capturing and reusing energy that would otherwise be lost during braking, thereby enhancing overall vehicle efficiency.

The automotive industry's shift towards electrification has also boosted the demand for KERS technology. Many automakers are incorporating KERS into their hybrid and electric vehicle lineups as a means to extend range and improve performance. This trend is particularly evident in the luxury and sports car segments, where KERS is being used to enhance acceleration and power delivery.

In the commercial vehicle sector, there is a growing interest in KERS technology for applications in buses, trucks, and other heavy-duty vehicles. The potential for significant fuel savings and emissions reductions in these larger vehicles makes KERS an attractive option for fleet operators and logistics companies looking to reduce their operating costs and environmental impact.

The racing industry has been a significant driver of KERS development and adoption. Formula 1's implementation of KERS has not only improved race performance but has also served as a testing ground for technologies that can be adapted for road vehicles. This has led to increased consumer interest in KERS-equipped vehicles, particularly among automotive enthusiasts.

However, the market for KERS-based vehicles faces some challenges. The additional cost of KERS technology can be a barrier to widespread adoption, particularly in lower-priced vehicle segments. Additionally, the complexity of KERS systems requires specialized maintenance and repair services, which may not be readily available in all markets.

Despite these challenges, the long-term outlook for KERS-based vehicles remains positive. As technology advances and production scales up, costs are expected to decrease, making KERS more accessible across various vehicle segments. The ongoing focus on sustainability and energy efficiency in the automotive industry suggests that KERS will continue to play an important role in the evolution of vehicle powertrains.

KERS Challenges

Kinetic Energy Recovery Systems (KERS) in vehicles face several significant challenges that impact their widespread adoption and long-term viability. One of the primary concerns is the system's durability and reliability over extended periods. KERS components, particularly the energy storage devices such as flywheels or batteries, are subject to high stress and frequent charge-discharge cycles, which can lead to accelerated wear and potential failure.

The integration of KERS into existing vehicle architectures presents another substantial challenge. Engineers must optimize the placement of components to maintain vehicle balance, safety, and performance while minimizing the impact on passenger and cargo space. This often requires extensive redesign of vehicle layouts, which can increase production costs and complexity.

Weight management is a critical issue for KERS-equipped vehicles. While the system offers energy recovery benefits, the additional components add significant mass to the vehicle. This extra weight can partially offset the fuel efficiency gains provided by KERS, particularly in smaller vehicles or those designed for urban environments where frequent stops and starts occur.

Thermal management poses another significant challenge for KERS technology. The frequent energy conversion processes generate considerable heat, which must be effectively dissipated to maintain system efficiency and prevent component degradation. Developing robust cooling systems that can handle these thermal loads without adding excessive weight or complexity is an ongoing engineering challenge.

Cost remains a major barrier to widespread KERS adoption. The sophisticated components and materials required for efficient energy recovery and storage systems contribute to higher vehicle prices. This cost premium can be difficult to justify for many consumers, especially if the fuel savings do not offset the initial investment within a reasonable timeframe.

Maintenance and repair considerations also present challenges for KERS-equipped vehicles. The specialized nature of these systems often requires additional training for service technicians and may necessitate specialized diagnostic equipment. This can lead to higher maintenance costs and potential difficulties in finding qualified repair facilities, particularly in regions where KERS technology is less common.

Lastly, the environmental impact of KERS components, particularly in terms of manufacturing and end-of-life disposal, remains a concern. The production of high-performance batteries or flywheels often involves energy-intensive processes and rare materials. Developing sustainable production methods and effective recycling strategies for these components is crucial for ensuring the overall environmental benefits of KERS technology in vehicles.

The integration of KERS into existing vehicle architectures presents another substantial challenge. Engineers must optimize the placement of components to maintain vehicle balance, safety, and performance while minimizing the impact on passenger and cargo space. This often requires extensive redesign of vehicle layouts, which can increase production costs and complexity.

Weight management is a critical issue for KERS-equipped vehicles. While the system offers energy recovery benefits, the additional components add significant mass to the vehicle. This extra weight can partially offset the fuel efficiency gains provided by KERS, particularly in smaller vehicles or those designed for urban environments where frequent stops and starts occur.

Thermal management poses another significant challenge for KERS technology. The frequent energy conversion processes generate considerable heat, which must be effectively dissipated to maintain system efficiency and prevent component degradation. Developing robust cooling systems that can handle these thermal loads without adding excessive weight or complexity is an ongoing engineering challenge.

Cost remains a major barrier to widespread KERS adoption. The sophisticated components and materials required for efficient energy recovery and storage systems contribute to higher vehicle prices. This cost premium can be difficult to justify for many consumers, especially if the fuel savings do not offset the initial investment within a reasonable timeframe.

Maintenance and repair considerations also present challenges for KERS-equipped vehicles. The specialized nature of these systems often requires additional training for service technicians and may necessitate specialized diagnostic equipment. This can lead to higher maintenance costs and potential difficulties in finding qualified repair facilities, particularly in regions where KERS technology is less common.

Lastly, the environmental impact of KERS components, particularly in terms of manufacturing and end-of-life disposal, remains a concern. The production of high-performance batteries or flywheels often involves energy-intensive processes and rare materials. Developing sustainable production methods and effective recycling strategies for these components is crucial for ensuring the overall environmental benefits of KERS technology in vehicles.

Current KERS Solutions

01 KERS system design for extended vehicle lifespan

Kinetic Energy Recovery Systems (KERS) are designed to improve vehicle efficiency and longevity. Advanced KERS designs focus on optimizing energy recovery and storage, reducing wear on traditional braking systems, and integrating with other vehicle systems to enhance overall performance and lifespan.- KERS system design for extended vehicle lifespan: Kinetic Energy Recovery Systems (KERS) are designed to improve the overall lifespan of vehicles by efficiently capturing and reusing energy during braking. These systems reduce wear on traditional braking components and enhance energy efficiency, potentially extending the operational life of KERS-equipped vehicles.

- Battery management for KERS longevity: Advanced battery management systems are crucial for maintaining the longevity of KERS-based vehicles. These systems optimize charging and discharging cycles, monitor battery health, and implement protective measures to prevent degradation, thereby extending the overall lifespan of the energy storage components and the vehicle itself.

- Thermal management in KERS for durability: Effective thermal management is essential for ensuring the longevity of KERS components. Advanced cooling systems and heat dissipation techniques are employed to maintain optimal operating temperatures, preventing premature wear and extending the lifespan of both the KERS and the vehicle.

- Predictive maintenance for KERS-based vehicles: Implementing predictive maintenance strategies using advanced sensors and data analytics helps in early detection of potential issues in KERS-based vehicles. This proactive approach allows for timely interventions, reducing downtime and extending the overall operational lifespan of the vehicle.

- Integration of KERS with other vehicle systems: Seamless integration of KERS with other vehicle systems, such as the powertrain and electronic control units, is crucial for optimizing performance and longevity. This integration ensures efficient energy distribution, reduces system stress, and contributes to an extended lifespan of KERS-based vehicles.

02 Battery management for KERS-based vehicles

Effective battery management is crucial for extending the lifespan of KERS-based vehicles. This includes advanced charging strategies, thermal management, and state-of-health monitoring to maintain battery performance over time and prevent premature degradation.Expand Specific Solutions03 Regenerative braking optimization

Optimizing regenerative braking systems in KERS-based vehicles can significantly impact vehicle lifespan. This involves fine-tuning the balance between energy recovery and traditional braking, adapting to various driving conditions, and minimizing wear on mechanical components.Expand Specific Solutions04 Predictive maintenance for KERS components

Implementing predictive maintenance strategies for KERS components can extend vehicle lifespan. This includes using sensors and data analytics to monitor system performance, predict potential failures, and schedule maintenance before issues arise.Expand Specific Solutions05 Integration of KERS with advanced vehicle control systems

Seamless integration of KERS with other vehicle control systems, such as traction control and stability management, can enhance overall vehicle performance and longevity. This integration allows for more efficient energy use and reduces stress on individual components.Expand Specific Solutions

Key KERS Manufacturers

The comparative lifespan studies of KERS-based vehicles are currently in a nascent stage of development, with the market showing promising growth potential. The technology's maturity varies across companies, with established automotive manufacturers like Volvo Lastvagnar AB, Honda Motor Co., Ltd., and Caterpillar, Inc. leading the way in research and development. Emerging players such as Punch Flybrid Ltd and Flybrid Automotive Ltd. are focusing on specialized KERS solutions. The competitive landscape is diverse, including traditional automakers, technology firms, and research institutions like Southwest Jiaotong University and the University of Science & Technology of China, indicating a multidisciplinary approach to advancing KERS technology for improved vehicle longevity and performance.

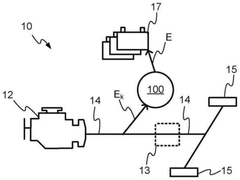

Volvo Lastvagnar AB

Technical Solution: Volvo Trucks has developed a kinetic energy recovery system (KERS) specifically designed for heavy-duty trucks. Their system, known as I-See, combines KERS technology with advanced GPS and topographical data to optimize energy recovery and usage based on the road ahead[8]. The I-See system uses a flywheel to store recovered energy, which can then be used to power the truck's electrical systems or provide additional torque to the driveline. Volvo's KERS technology can reduce fuel consumption by up to 5% on hilly routes[9]. Additionally, Volvo has integrated this system with their I-Shift automated manual transmission, allowing for seamless energy recovery and deployment. The company has also explored the use of KERS in hybrid powertrains for their trucks, further enhancing fuel efficiency and reducing emissions in long-haul transportation.

Strengths: Integration with GPS and topographical data for optimized energy management, specific design for heavy-duty trucks. Weaknesses: Effectiveness may be limited on flat terrains, potential for increased complexity in truck maintenance.

Punch Flybrid Ltd

Technical Solution: Punch Flybrid has developed an advanced Kinetic Energy Recovery System (KERS) for vehicles, utilizing a high-speed flywheel to store and release energy. Their system can capture up to 70% of braking energy and deliver power bursts of up to 60 kW[1]. The flywheel spins at speeds up to 60,000 rpm, encased in a vacuum chamber to minimize friction losses[2]. This technology has been successfully applied in various motorsports, including Formula 1 and Le Mans racing, demonstrating its effectiveness in high-performance environments[3]. Punch Flybrid's KERS technology has also been adapted for use in city buses and commercial vehicles, showing potential for significant fuel savings and emissions reductions in urban transport applications.

Strengths: High energy density, rapid power delivery, and proven performance in motorsports. Weaknesses: Complexity of integration into existing vehicle designs and potential safety concerns with high-speed rotating components.

KERS Lifespan Research

Kinetic energy recovery system

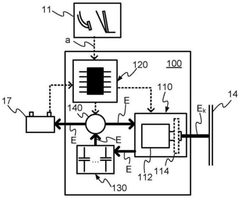

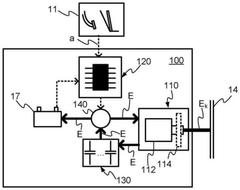

PatentPendingCN118722205A

Innovation

- Employs a kinetic energy recovery system (KERS) connected to the vehicle's propulsion shaft, which converts energy from the propulsion shaft into electrical energy through internal energy storage and processing circuitry, and distributes it to non-propulsion batteries or propulsion shafts when appropriate, in lieu of generator charging and provide motivation.

Kinetic energy regeneration system

PatentActiveJP2019521032A

Innovation

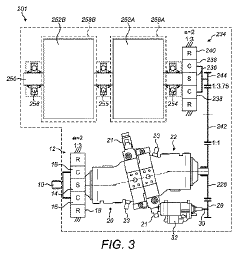

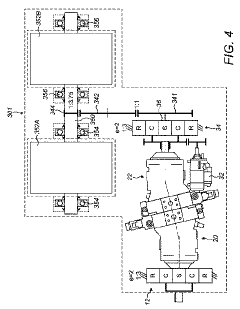

- A kinetic energy recovery system (KERS) incorporating a first speed increasing gear unit, hydraulic variator with oblique axis motors, and a flywheel positioned in a vacuum chamber, controlled by an electronic control unit (ECU) to manage energy storage and retrieval efficiently.

Environmental Impact

The environmental impact of KERS-based vehicles is a crucial aspect to consider when evaluating their overall sustainability and long-term viability. These vehicles, which utilize Kinetic Energy Recovery Systems (KERS) to capture and reuse energy during braking, offer potential benefits in terms of reduced fuel consumption and emissions. However, a comprehensive assessment of their environmental impact requires consideration of multiple factors throughout their lifecycle.

During the operational phase, KERS-based vehicles demonstrate significant advantages in urban driving scenarios. The frequent stop-start nature of city traffic allows for optimal energy recovery, leading to reduced fuel consumption and lower greenhouse gas emissions. Studies have shown that KERS can improve fuel efficiency by up to 25% in urban environments, translating to a proportional decrease in CO2 emissions. This reduction in tailpipe emissions contributes to improved air quality in densely populated areas, potentially mitigating health risks associated with air pollution.

However, the environmental benefits of KERS-based vehicles extend beyond their operational phase. The manufacturing process of KERS components, particularly the energy storage systems, requires careful scrutiny. The production of high-capacity batteries or flywheels used in KERS may involve energy-intensive processes and the extraction of rare earth materials. These factors can contribute to a higher carbon footprint during the manufacturing stage compared to conventional vehicles.

End-of-life considerations also play a crucial role in assessing the environmental impact of KERS-based vehicles. The recyclability and proper disposal of KERS components, especially energy storage systems, are essential to minimize waste and recover valuable materials. Advanced recycling technologies and well-established recycling infrastructure are necessary to ensure that the environmental benefits gained during the vehicle's operational life are not offset by end-of-life challenges.

Comparative lifespan studies of KERS-based vehicles must also account for the potential environmental trade-offs. While these vehicles may offer reduced emissions during operation, the increased complexity of their powertrains could lead to more frequent maintenance requirements. This may result in higher resource consumption for replacement parts and potentially shorter overall vehicle lifespans if not properly managed.

Furthermore, the environmental impact of KERS-based vehicles is closely tied to the energy mix of the regions in which they operate. In areas with a high proportion of renewable energy in the grid, the benefits of KERS in reducing fossil fuel consumption are amplified. Conversely, in regions heavily reliant on fossil fuels for electricity generation, the net environmental benefits may be less pronounced.

During the operational phase, KERS-based vehicles demonstrate significant advantages in urban driving scenarios. The frequent stop-start nature of city traffic allows for optimal energy recovery, leading to reduced fuel consumption and lower greenhouse gas emissions. Studies have shown that KERS can improve fuel efficiency by up to 25% in urban environments, translating to a proportional decrease in CO2 emissions. This reduction in tailpipe emissions contributes to improved air quality in densely populated areas, potentially mitigating health risks associated with air pollution.

However, the environmental benefits of KERS-based vehicles extend beyond their operational phase. The manufacturing process of KERS components, particularly the energy storage systems, requires careful scrutiny. The production of high-capacity batteries or flywheels used in KERS may involve energy-intensive processes and the extraction of rare earth materials. These factors can contribute to a higher carbon footprint during the manufacturing stage compared to conventional vehicles.

End-of-life considerations also play a crucial role in assessing the environmental impact of KERS-based vehicles. The recyclability and proper disposal of KERS components, especially energy storage systems, are essential to minimize waste and recover valuable materials. Advanced recycling technologies and well-established recycling infrastructure are necessary to ensure that the environmental benefits gained during the vehicle's operational life are not offset by end-of-life challenges.

Comparative lifespan studies of KERS-based vehicles must also account for the potential environmental trade-offs. While these vehicles may offer reduced emissions during operation, the increased complexity of their powertrains could lead to more frequent maintenance requirements. This may result in higher resource consumption for replacement parts and potentially shorter overall vehicle lifespans if not properly managed.

Furthermore, the environmental impact of KERS-based vehicles is closely tied to the energy mix of the regions in which they operate. In areas with a high proportion of renewable energy in the grid, the benefits of KERS in reducing fossil fuel consumption are amplified. Conversely, in regions heavily reliant on fossil fuels for electricity generation, the net environmental benefits may be less pronounced.

Cost-Benefit Analysis

The cost-benefit analysis of KERS-based vehicles requires a comprehensive evaluation of both the financial and performance aspects over the vehicle's lifespan. Initial investment in KERS technology is typically higher than conventional vehicles, primarily due to the sophisticated energy recovery and storage systems. However, this upfront cost can be offset by long-term fuel savings and reduced maintenance expenses.

Fuel efficiency improvements are a significant benefit of KERS-equipped vehicles. Studies have shown that KERS can reduce fuel consumption by 15-25% in urban driving conditions, where frequent braking and acceleration occur. This translates to substantial cost savings over the vehicle's lifetime, especially in regions with high fuel prices or for fleet operators with high mileage vehicles.

Maintenance costs for KERS-based vehicles can be lower in some aspects but higher in others. The regenerative braking system reduces wear on conventional brake components, potentially extending their lifespan and reducing replacement frequency. However, the KERS system itself introduces new components that may require specialized maintenance and occasional replacement, such as energy storage units and power electronics.

The environmental benefits of KERS technology also factor into the cost-benefit analysis. Reduced fuel consumption leads to lower emissions, which can result in tax incentives or reduced environmental compliance costs for fleet operators. In some jurisdictions, this may translate to direct financial benefits through carbon credit systems or reduced urban access charges.

Resale value is another consideration in the cost-benefit analysis. As KERS technology becomes more mainstream, vehicles equipped with these systems may retain higher resale values due to their improved efficiency and performance characteristics. This could partially offset the higher initial purchase price.

The lifespan of KERS components is a critical factor in the overall cost-benefit equation. Energy storage systems, such as batteries or flywheels, may require replacement before the end of the vehicle's useful life. The frequency and cost of these replacements must be weighed against the ongoing fuel savings and performance benefits.

In conclusion, the cost-benefit analysis of KERS-based vehicles over their lifespan is complex and depends on various factors including driving patterns, fuel prices, maintenance costs, and regulatory environments. While the initial investment is higher, the potential for significant operational cost savings and environmental benefits can make KERS technology an attractive option for many vehicle applications.

Fuel efficiency improvements are a significant benefit of KERS-equipped vehicles. Studies have shown that KERS can reduce fuel consumption by 15-25% in urban driving conditions, where frequent braking and acceleration occur. This translates to substantial cost savings over the vehicle's lifetime, especially in regions with high fuel prices or for fleet operators with high mileage vehicles.

Maintenance costs for KERS-based vehicles can be lower in some aspects but higher in others. The regenerative braking system reduces wear on conventional brake components, potentially extending their lifespan and reducing replacement frequency. However, the KERS system itself introduces new components that may require specialized maintenance and occasional replacement, such as energy storage units and power electronics.

The environmental benefits of KERS technology also factor into the cost-benefit analysis. Reduced fuel consumption leads to lower emissions, which can result in tax incentives or reduced environmental compliance costs for fleet operators. In some jurisdictions, this may translate to direct financial benefits through carbon credit systems or reduced urban access charges.

Resale value is another consideration in the cost-benefit analysis. As KERS technology becomes more mainstream, vehicles equipped with these systems may retain higher resale values due to their improved efficiency and performance characteristics. This could partially offset the higher initial purchase price.

The lifespan of KERS components is a critical factor in the overall cost-benefit equation. Energy storage systems, such as batteries or flywheels, may require replacement before the end of the vehicle's useful life. The frequency and cost of these replacements must be weighed against the ongoing fuel savings and performance benefits.

In conclusion, the cost-benefit analysis of KERS-based vehicles over their lifespan is complex and depends on various factors including driving patterns, fuel prices, maintenance costs, and regulatory environments. While the initial investment is higher, the potential for significant operational cost savings and environmental benefits can make KERS technology an attractive option for many vehicle applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!