Examining KERS influence in urban logistics vehicles

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

KERS Background & Objectives

Kinetic Energy Recovery Systems (KERS) have emerged as a promising technology in the automotive industry, with potential applications extending beyond traditional racing environments. In the context of urban logistics vehicles, KERS presents an opportunity to address the growing challenges of energy efficiency and environmental sustainability in city transportation.

The evolution of KERS technology can be traced back to its origins in Formula 1 racing, where it was introduced to enhance vehicle performance and energy recovery. Over time, the technology has matured and found applications in various sectors, including passenger vehicles and public transportation. The adaptation of KERS for urban logistics vehicles represents a natural progression in its development trajectory.

The primary objective of examining KERS influence in urban logistics vehicles is to assess its potential for improving energy efficiency, reducing emissions, and enhancing overall performance in the demanding stop-start conditions of urban environments. This investigation aims to determine the feasibility and benefits of integrating KERS into delivery vans, trucks, and other logistics vehicles that operate primarily within city limits.

Urban logistics vehicles face unique challenges, including frequent stops, heavy traffic, and the need for rapid acceleration and deceleration. These conditions often result in significant energy waste through conventional braking systems. KERS technology offers a solution by capturing and storing kinetic energy during braking, which can then be redeployed to assist in acceleration, potentially reducing fuel consumption and emissions.

The exploration of KERS in this context aligns with broader industry trends towards electrification and hybridization of vehicle powertrains. As cities worldwide implement stricter emissions regulations and low-emission zones, the logistics sector is under increasing pressure to adopt cleaner technologies. KERS represents a potential bridge technology that can enhance the efficiency of both conventional and electric powertrains.

Furthermore, the examination of KERS influence extends beyond mere technical performance. It encompasses an evaluation of the economic viability, considering factors such as installation costs, maintenance requirements, and potential fuel savings. The goal is to determine whether KERS can provide a cost-effective solution for fleet operators while contributing to urban sustainability goals.

In conclusion, the background and objectives of examining KERS influence in urban logistics vehicles are rooted in the need for innovative solutions to address the environmental and operational challenges of city-based transportation. This investigation seeks to uncover the potential of KERS to revolutionize urban logistics, offering a pathway to more efficient, sustainable, and economically viable fleet operations in the complex landscape of modern cities.

The evolution of KERS technology can be traced back to its origins in Formula 1 racing, where it was introduced to enhance vehicle performance and energy recovery. Over time, the technology has matured and found applications in various sectors, including passenger vehicles and public transportation. The adaptation of KERS for urban logistics vehicles represents a natural progression in its development trajectory.

The primary objective of examining KERS influence in urban logistics vehicles is to assess its potential for improving energy efficiency, reducing emissions, and enhancing overall performance in the demanding stop-start conditions of urban environments. This investigation aims to determine the feasibility and benefits of integrating KERS into delivery vans, trucks, and other logistics vehicles that operate primarily within city limits.

Urban logistics vehicles face unique challenges, including frequent stops, heavy traffic, and the need for rapid acceleration and deceleration. These conditions often result in significant energy waste through conventional braking systems. KERS technology offers a solution by capturing and storing kinetic energy during braking, which can then be redeployed to assist in acceleration, potentially reducing fuel consumption and emissions.

The exploration of KERS in this context aligns with broader industry trends towards electrification and hybridization of vehicle powertrains. As cities worldwide implement stricter emissions regulations and low-emission zones, the logistics sector is under increasing pressure to adopt cleaner technologies. KERS represents a potential bridge technology that can enhance the efficiency of both conventional and electric powertrains.

Furthermore, the examination of KERS influence extends beyond mere technical performance. It encompasses an evaluation of the economic viability, considering factors such as installation costs, maintenance requirements, and potential fuel savings. The goal is to determine whether KERS can provide a cost-effective solution for fleet operators while contributing to urban sustainability goals.

In conclusion, the background and objectives of examining KERS influence in urban logistics vehicles are rooted in the need for innovative solutions to address the environmental and operational challenges of city-based transportation. This investigation seeks to uncover the potential of KERS to revolutionize urban logistics, offering a pathway to more efficient, sustainable, and economically viable fleet operations in the complex landscape of modern cities.

Urban Logistics Market Analysis

The urban logistics market has experienced significant growth in recent years, driven by the rise of e-commerce, changing consumer behaviors, and the increasing demand for fast and efficient delivery services. This market segment encompasses the transportation and distribution of goods within urban areas, focusing on last-mile delivery and the optimization of supply chain operations in densely populated regions.

The global urban logistics market size was valued at approximately $160 billion in 2020 and is projected to reach $365 billion by 2025, growing at a compound annual growth rate (CAGR) of 17.9%. This rapid expansion is primarily attributed to the surge in online shopping, particularly accelerated by the COVID-19 pandemic, which has fundamentally altered consumer purchasing habits and expectations for rapid delivery.

In the context of urban logistics vehicles, there is a growing emphasis on sustainability and efficiency. This has led to increased interest in technologies such as Kinetic Energy Recovery Systems (KERS), which can potentially reduce fuel consumption and emissions while improving overall vehicle performance. The adoption of KERS in urban logistics vehicles aligns with the broader industry trends towards greener and more cost-effective transportation solutions.

The market demand for urban logistics services is characterized by several key factors. Firstly, there is a strong consumer preference for same-day or next-day deliveries, putting pressure on logistics providers to optimize their operations and vehicle fleets. Secondly, there is an increasing focus on reducing the environmental impact of urban deliveries, with many cities implementing stricter emissions regulations and promoting the use of electric or hybrid vehicles.

The urban logistics market is highly fragmented, with a mix of established players and innovative startups competing for market share. Major logistics companies such as DHL, UPS, and FedEx are investing heavily in urban logistics solutions, including the development and deployment of more efficient delivery vehicles. At the same time, new entrants are disrupting the market with innovative technologies and business models, such as crowd-sourced delivery platforms and autonomous delivery robots.

Looking ahead, the urban logistics market is expected to continue its rapid growth trajectory. Key trends shaping the future of this market include the increasing adoption of electric and hybrid vehicles, the integration of artificial intelligence and machine learning for route optimization, and the exploration of alternative delivery methods such as drones and autonomous vehicles. The potential implementation of KERS in urban logistics vehicles represents an important development in this evolving landscape, offering a promising solution to address both efficiency and sustainability challenges in the sector.

The global urban logistics market size was valued at approximately $160 billion in 2020 and is projected to reach $365 billion by 2025, growing at a compound annual growth rate (CAGR) of 17.9%. This rapid expansion is primarily attributed to the surge in online shopping, particularly accelerated by the COVID-19 pandemic, which has fundamentally altered consumer purchasing habits and expectations for rapid delivery.

In the context of urban logistics vehicles, there is a growing emphasis on sustainability and efficiency. This has led to increased interest in technologies such as Kinetic Energy Recovery Systems (KERS), which can potentially reduce fuel consumption and emissions while improving overall vehicle performance. The adoption of KERS in urban logistics vehicles aligns with the broader industry trends towards greener and more cost-effective transportation solutions.

The market demand for urban logistics services is characterized by several key factors. Firstly, there is a strong consumer preference for same-day or next-day deliveries, putting pressure on logistics providers to optimize their operations and vehicle fleets. Secondly, there is an increasing focus on reducing the environmental impact of urban deliveries, with many cities implementing stricter emissions regulations and promoting the use of electric or hybrid vehicles.

The urban logistics market is highly fragmented, with a mix of established players and innovative startups competing for market share. Major logistics companies such as DHL, UPS, and FedEx are investing heavily in urban logistics solutions, including the development and deployment of more efficient delivery vehicles. At the same time, new entrants are disrupting the market with innovative technologies and business models, such as crowd-sourced delivery platforms and autonomous delivery robots.

Looking ahead, the urban logistics market is expected to continue its rapid growth trajectory. Key trends shaping the future of this market include the increasing adoption of electric and hybrid vehicles, the integration of artificial intelligence and machine learning for route optimization, and the exploration of alternative delivery methods such as drones and autonomous vehicles. The potential implementation of KERS in urban logistics vehicles represents an important development in this evolving landscape, offering a promising solution to address both efficiency and sustainability challenges in the sector.

KERS Challenges in Urban Vehicles

Kinetic Energy Recovery Systems (KERS) face several significant challenges when implemented in urban logistics vehicles. The stop-start nature of urban driving, characterized by frequent acceleration and deceleration, presents both opportunities and obstacles for KERS technology.

One primary challenge is the system's weight and space requirements. Urban logistics vehicles, often designed for maximum cargo capacity, have limited space for additional components. KERS systems, particularly those using flywheel or hydraulic technologies, can be bulky and heavy, potentially reducing the vehicle's payload capacity and fuel efficiency.

The durability and lifespan of KERS components in urban environments pose another concern. Constant engagement of the system due to frequent stops and starts can lead to increased wear and tear, potentially resulting in higher maintenance costs and reduced system reliability over time.

Heat management is a critical issue, especially in electric or hybrid urban logistics vehicles. The frequent energy conversion processes in KERS generate significant heat, which must be efficiently dissipated to prevent system degradation and ensure optimal performance. This challenge is compounded in densely packed urban vehicles where space for cooling systems is at a premium.

The cost-effectiveness of KERS in urban logistics vehicles remains a significant hurdle. While the technology offers potential fuel savings and emissions reductions, the initial investment and ongoing maintenance costs must be balanced against these benefits. For many logistics companies, especially smaller operators, the return on investment may not be immediately apparent or achievable within a reasonable timeframe.

Integration with existing vehicle systems presents technical challenges. KERS must seamlessly interface with the vehicle's powertrain, braking system, and electronic control units. This integration is particularly complex in hybrid or electric vehicles, where multiple energy sources and power management systems are already in place.

The variability of urban driving conditions impacts KERS efficiency. Traffic patterns, road gradients, and load variations can affect the system's ability to capture and utilize energy effectively. Developing adaptive control strategies that optimize KERS performance across diverse urban scenarios remains a significant technical challenge.

Regulatory compliance and safety considerations add another layer of complexity. KERS systems must meet stringent safety standards, particularly concerning energy storage and rapid discharge. Additionally, the added complexity of KERS may require specialized training for maintenance personnel and drivers, potentially increasing operational costs for logistics companies.

One primary challenge is the system's weight and space requirements. Urban logistics vehicles, often designed for maximum cargo capacity, have limited space for additional components. KERS systems, particularly those using flywheel or hydraulic technologies, can be bulky and heavy, potentially reducing the vehicle's payload capacity and fuel efficiency.

The durability and lifespan of KERS components in urban environments pose another concern. Constant engagement of the system due to frequent stops and starts can lead to increased wear and tear, potentially resulting in higher maintenance costs and reduced system reliability over time.

Heat management is a critical issue, especially in electric or hybrid urban logistics vehicles. The frequent energy conversion processes in KERS generate significant heat, which must be efficiently dissipated to prevent system degradation and ensure optimal performance. This challenge is compounded in densely packed urban vehicles where space for cooling systems is at a premium.

The cost-effectiveness of KERS in urban logistics vehicles remains a significant hurdle. While the technology offers potential fuel savings and emissions reductions, the initial investment and ongoing maintenance costs must be balanced against these benefits. For many logistics companies, especially smaller operators, the return on investment may not be immediately apparent or achievable within a reasonable timeframe.

Integration with existing vehicle systems presents technical challenges. KERS must seamlessly interface with the vehicle's powertrain, braking system, and electronic control units. This integration is particularly complex in hybrid or electric vehicles, where multiple energy sources and power management systems are already in place.

The variability of urban driving conditions impacts KERS efficiency. Traffic patterns, road gradients, and load variations can affect the system's ability to capture and utilize energy effectively. Developing adaptive control strategies that optimize KERS performance across diverse urban scenarios remains a significant technical challenge.

Regulatory compliance and safety considerations add another layer of complexity. KERS systems must meet stringent safety standards, particularly concerning energy storage and rapid discharge. Additionally, the added complexity of KERS may require specialized training for maintenance personnel and drivers, potentially increasing operational costs for logistics companies.

Current KERS Solutions

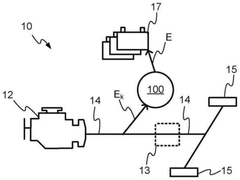

01 KERS integration in vehicle powertrains

KERS is integrated into vehicle powertrains to recover and store kinetic energy during braking, which can then be used to boost acceleration or improve fuel efficiency. This system can be applied to various vehicle types, including cars, trucks, and motorcycles, enhancing overall vehicle performance and energy efficiency.- Energy recovery and storage in vehicles: KERS influences vehicle energy efficiency by recovering kinetic energy during braking and storing it for later use. This system can be applied to various vehicle types, including cars, trucks, and motorcycles, to improve fuel economy and reduce emissions. The recovered energy can be stored in different forms, such as electrical, mechanical, or hydraulic, depending on the specific KERS design.

- Integration with hybrid and electric powertrains: KERS plays a significant role in hybrid and electric vehicle powertrains, enhancing overall system efficiency. It can be integrated with electric motors, batteries, and power electronics to optimize energy management. This integration allows for improved acceleration, regenerative braking, and extended electric-only driving range in hybrid vehicles.

- Application in motorsports and performance vehicles: KERS has a notable influence on motorsports and high-performance vehicles, providing additional power for overtaking and improved lap times. The system can be tailored for specific racing regulations and vehicle designs, offering a competitive advantage. In performance road cars, KERS can enhance acceleration and overall driving dynamics.

- Advancements in KERS technology: Ongoing research and development in KERS technology focus on improving efficiency, reducing weight, and enhancing durability. Innovations include advanced energy storage systems, such as high-power capacitors and flywheels, as well as more efficient power electronics and control strategies. These advancements aim to maximize energy recovery and utilization while minimizing system complexity and cost.

- Environmental and economic impact: The influence of KERS extends to environmental and economic aspects of transportation. By improving vehicle efficiency and reducing fuel consumption, KERS contributes to lower greenhouse gas emissions and operating costs. This technology aligns with global efforts to reduce the environmental impact of transportation and promote sustainable mobility solutions.

02 Energy storage mechanisms for KERS

Different energy storage mechanisms are employed in KERS, including flywheels, batteries, and supercapacitors. Each storage method has its advantages in terms of energy density, power density, and response time. The choice of storage mechanism affects the system's efficiency and its ability to capture and release energy quickly.Expand Specific Solutions03 KERS application in motorsports

KERS has significantly influenced motorsports, particularly in Formula 1 racing. It provides drivers with additional power for overtaking and has led to changes in racing strategies. The technology has also trickled down to production vehicles, improving their performance and efficiency.Expand Specific Solutions04 KERS impact on vehicle design and weight distribution

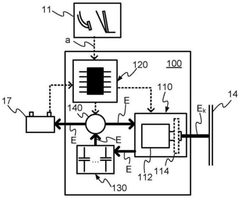

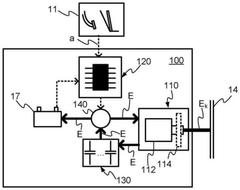

The integration of KERS affects vehicle design, particularly in terms of weight distribution and packaging. Engineers must consider the placement of KERS components to optimize vehicle balance and handling. This has led to innovations in compact and lightweight energy recovery systems.Expand Specific Solutions05 KERS control systems and algorithms

Advanced control systems and algorithms are crucial for optimizing KERS performance. These systems manage energy recovery, storage, and deployment based on various factors such as vehicle speed, driver input, and road conditions. Machine learning and AI are increasingly being used to enhance KERS efficiency and adaptability.Expand Specific Solutions

Key KERS Industry Players

The KERS (Kinetic Energy Recovery System) technology in urban logistics vehicles is in an early growth stage, with increasing market potential as cities focus on sustainable transportation. The global market for KERS in commercial vehicles is expanding, driven by stringent emissions regulations and the push for energy efficiency. While the technology is maturing, it's not yet widely adopted in urban logistics. Companies like Volvo Lastvagnar AB, Marelli Europe SpA, and Punch Flybrid Ltd are at the forefront of KERS development for commercial vehicles, with established automotive players such as Robert Bosch GmbH and emerging specialists like Flybrid Automotive Ltd also contributing to the competitive landscape. The technology's integration in urban logistics vehicles is expected to accelerate as performance improves and costs decrease.

Volvo Lastvagnar AB

Technical Solution: Volvo Lastvagnar AB has developed an advanced KERS (Kinetic Energy Recovery System) for urban logistics vehicles. Their system utilizes a high-speed flywheel to capture and store kinetic energy during braking, which is then used to assist acceleration. This technology has been integrated into their FE Hybrid truck model, designed specifically for urban distribution and refuse collection. The system can reduce fuel consumption by up to 30% in stop-start traffic conditions typical of urban environments [1]. Volvo's KERS also incorporates an electric motor-generator that can operate in both motor and generator modes, allowing for seamless energy transfer between the flywheel and the vehicle's drivetrain [2].

Strengths: Significant fuel savings in urban environments, reduced emissions, and improved vehicle performance during frequent starts and stops. Weaknesses: Higher initial cost compared to conventional vehicles, and added complexity in maintenance and repair.

Punch Flybrid Ltd

Technical Solution: Punch Flybrid Ltd specializes in flywheel-based KERS technology for various applications, including urban logistics vehicles. Their system uses a carbon fiber flywheel spinning at up to 60,000 rpm in a vacuum chamber to store energy [3]. For urban logistics, Punch Flybrid has developed a compact KERS unit that can be easily integrated into existing vehicle platforms. The system is capable of capturing up to 70% of the kinetic energy during braking and can deliver power bursts of up to 60 kW for acceleration [4]. Punch Flybrid's technology also includes a continuously variable transmission (CVT) that allows for efficient energy transfer between the flywheel and the vehicle's powertrain, optimizing energy recovery and deployment based on driving conditions [5].

Strengths: High energy density, rapid charge/discharge capability, and long operational life without degradation. Weaknesses: Complexity of the mechanical system and potential safety concerns with high-speed rotating components.

KERS Core Innovations

Kinetic energy recovery system

PatentPendingCN118722205A

Innovation

- Employs a kinetic energy recovery system (KERS) connected to the vehicle's propulsion shaft, which converts energy from the propulsion shaft into electrical energy through internal energy storage and processing circuitry, and distributes it to non-propulsion batteries or propulsion shafts when appropriate, in lieu of generator charging and provide motivation.

Kinetic energy recovery system

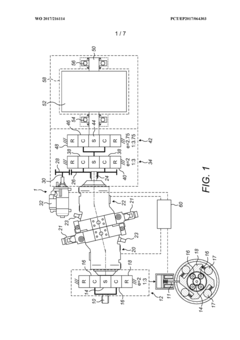

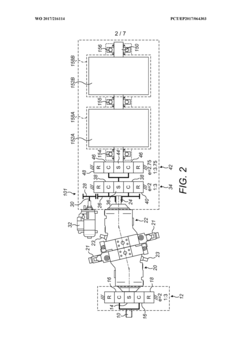

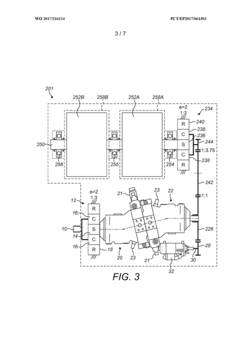

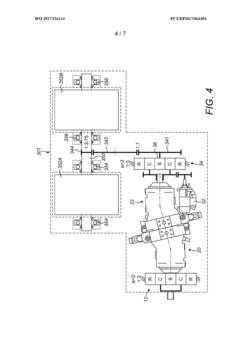

PatentWO2017216114A1

Innovation

- A kinetic energy recovery system utilizing a hydraulic variator with bent axis motors and a flywheel located in a vacuum chamber, connected through speed-up gear arrangements, allowing for efficient energy storage and retrieval by varying motor displacement in response to vehicle powertrain demands.

Environmental Impact of KERS

The implementation of Kinetic Energy Recovery Systems (KERS) in urban logistics vehicles has significant environmental implications. By capturing and reusing kinetic energy that would otherwise be lost during braking, KERS technology contributes to reduced fuel consumption and lower emissions in urban environments.

One of the primary environmental benefits of KERS is the reduction in greenhouse gas emissions. Urban logistics vehicles equipped with KERS can achieve fuel savings of up to 25% in stop-and-go traffic conditions, typical of city environments. This translates to a proportional decrease in CO2 emissions, helping cities meet their carbon reduction targets and improve air quality.

KERS also contributes to noise pollution reduction in urban areas. As the system allows for more efficient acceleration, vehicles can operate more quietly, especially during start-stop cycles. This is particularly beneficial in residential areas and during night-time deliveries, where noise regulations are often stricter.

The technology's impact on particulate matter emissions is another crucial environmental consideration. By reducing the reliance on traditional braking systems, KERS-equipped vehicles generate less brake dust, a significant contributor to urban air pollution. This reduction in particulate matter can lead to improved respiratory health for urban residents.

Furthermore, KERS technology promotes the adoption of hybrid and electric powertrains in logistics vehicles. The system's ability to capture and store energy complements these alternative propulsion methods, extending the range of electric vehicles and enhancing the overall efficiency of hybrid systems. This synergy accelerates the transition towards cleaner transportation solutions in urban logistics.

However, the environmental impact of KERS must also consider the lifecycle of the system components. The production and disposal of energy storage devices, such as batteries or flywheels, can have environmental implications. Manufacturers are increasingly focusing on developing more sustainable and recyclable components to mitigate these concerns.

In conclusion, while KERS technology offers significant environmental benefits for urban logistics vehicles, a holistic approach considering the entire lifecycle of the system is necessary to fully assess its environmental impact. As the technology continues to evolve, its positive contribution to urban sustainability is expected to grow, making it an increasingly valuable tool in the pursuit of greener cities and more efficient logistics operations.

One of the primary environmental benefits of KERS is the reduction in greenhouse gas emissions. Urban logistics vehicles equipped with KERS can achieve fuel savings of up to 25% in stop-and-go traffic conditions, typical of city environments. This translates to a proportional decrease in CO2 emissions, helping cities meet their carbon reduction targets and improve air quality.

KERS also contributes to noise pollution reduction in urban areas. As the system allows for more efficient acceleration, vehicles can operate more quietly, especially during start-stop cycles. This is particularly beneficial in residential areas and during night-time deliveries, where noise regulations are often stricter.

The technology's impact on particulate matter emissions is another crucial environmental consideration. By reducing the reliance on traditional braking systems, KERS-equipped vehicles generate less brake dust, a significant contributor to urban air pollution. This reduction in particulate matter can lead to improved respiratory health for urban residents.

Furthermore, KERS technology promotes the adoption of hybrid and electric powertrains in logistics vehicles. The system's ability to capture and store energy complements these alternative propulsion methods, extending the range of electric vehicles and enhancing the overall efficiency of hybrid systems. This synergy accelerates the transition towards cleaner transportation solutions in urban logistics.

However, the environmental impact of KERS must also consider the lifecycle of the system components. The production and disposal of energy storage devices, such as batteries or flywheels, can have environmental implications. Manufacturers are increasingly focusing on developing more sustainable and recyclable components to mitigate these concerns.

In conclusion, while KERS technology offers significant environmental benefits for urban logistics vehicles, a holistic approach considering the entire lifecycle of the system is necessary to fully assess its environmental impact. As the technology continues to evolve, its positive contribution to urban sustainability is expected to grow, making it an increasingly valuable tool in the pursuit of greener cities and more efficient logistics operations.

KERS Integration Strategies

The integration of Kinetic Energy Recovery Systems (KERS) in urban logistics vehicles requires careful consideration of various strategies to maximize efficiency and performance. One key approach is the optimization of regenerative braking systems, which capture and store energy typically lost during deceleration. This strategy involves fine-tuning the brake-by-wire systems and enhancing energy storage capabilities to ensure maximum energy recovery during frequent stop-and-go urban driving patterns.

Another crucial integration strategy focuses on the development of hybrid powertrains specifically designed for urban logistics vehicles. These powertrains combine traditional internal combustion engines with electric motors and KERS, allowing for seamless power distribution and energy management. The integration of advanced control algorithms is essential to optimize the interplay between these different power sources, ensuring that KERS contributes effectively to overall vehicle efficiency.

Weight reduction and aerodynamic improvements form another critical aspect of KERS integration. By utilizing lightweight materials and redesigning vehicle bodies to reduce air resistance, the energy recovered through KERS can have a more significant impact on vehicle performance and fuel economy. This strategy often involves the use of composite materials and advanced manufacturing techniques to achieve the desired weight reductions without compromising structural integrity.

The integration of KERS also necessitates the development of sophisticated energy management systems. These systems must be capable of real-time decision-making, balancing the use of recovered energy with the vehicle's immediate power needs and anticipating future energy demands based on route information and traffic conditions. Machine learning algorithms and predictive analytics play a crucial role in optimizing these energy management strategies.

Lastly, the integration of KERS in urban logistics vehicles must consider the specific operational requirements of logistics companies. This includes designing systems that can withstand frequent starts and stops, heavy loads, and extended operating hours. Strategies may involve the development of more durable components, enhanced cooling systems for KERS components, and modular designs that allow for easy maintenance and upgrades. Additionally, integration strategies should address the need for driver training and fleet management systems that can maximize the benefits of KERS across entire vehicle fleets.

Another crucial integration strategy focuses on the development of hybrid powertrains specifically designed for urban logistics vehicles. These powertrains combine traditional internal combustion engines with electric motors and KERS, allowing for seamless power distribution and energy management. The integration of advanced control algorithms is essential to optimize the interplay between these different power sources, ensuring that KERS contributes effectively to overall vehicle efficiency.

Weight reduction and aerodynamic improvements form another critical aspect of KERS integration. By utilizing lightweight materials and redesigning vehicle bodies to reduce air resistance, the energy recovered through KERS can have a more significant impact on vehicle performance and fuel economy. This strategy often involves the use of composite materials and advanced manufacturing techniques to achieve the desired weight reductions without compromising structural integrity.

The integration of KERS also necessitates the development of sophisticated energy management systems. These systems must be capable of real-time decision-making, balancing the use of recovered energy with the vehicle's immediate power needs and anticipating future energy demands based on route information and traffic conditions. Machine learning algorithms and predictive analytics play a crucial role in optimizing these energy management strategies.

Lastly, the integration of KERS in urban logistics vehicles must consider the specific operational requirements of logistics companies. This includes designing systems that can withstand frequent starts and stops, heavy loads, and extended operating hours. Strategies may involve the development of more durable components, enhanced cooling systems for KERS components, and modular designs that allow for easy maintenance and upgrades. Additionally, integration strategies should address the need for driver training and fleet management systems that can maximize the benefits of KERS across entire vehicle fleets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!