Future prospects of KERS in microbial fuel cells

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

KERS in MFCs: Background and Objectives

Kinetic Energy Recovery Systems (KERS) have gained significant attention in the field of microbial fuel cells (MFCs) as a promising technology for enhancing energy efficiency and sustainability. The integration of KERS in MFCs represents a convergence of two distinct yet complementary technologies, aiming to address the growing global demand for clean and renewable energy sources.

MFCs have emerged as an innovative bioelectrochemical system that converts chemical energy from organic compounds into electrical energy through the metabolic activities of microorganisms. These systems have shown great potential in wastewater treatment, bioremediation, and sustainable energy production. However, MFCs face challenges in terms of power output and overall efficiency, which has led researchers to explore novel approaches to improve their performance.

KERS, originally developed for automotive applications, has found a new purpose in the realm of MFCs. This technology captures and stores kinetic energy that would otherwise be lost during deceleration or braking processes, and then utilizes this stored energy to supplement power generation. The adaptation of KERS to MFCs aims to address the intermittent nature of bioelectricity production and enhance the overall energy recovery from these systems.

The primary objective of integrating KERS into MFCs is to optimize energy harvesting and utilization. By capturing and storing excess energy during peak production periods, KERS can provide a stable power supply during low-output phases, effectively smoothing out the power generation curve. This approach not only improves the consistency of energy output but also potentially increases the overall efficiency of the MFC system.

Another key goal is to enhance the scalability and practical applicability of MFCs. The integration of KERS could potentially address some of the limitations that have hindered the widespread adoption of MFCs in real-world scenarios. By improving power management and energy storage capabilities, KERS-equipped MFCs may become more viable for larger-scale applications in wastewater treatment plants, industrial processes, and even in remote or off-grid locations.

Furthermore, the development of KERS in MFCs aligns with the broader trend towards circular economy principles and sustainable energy solutions. This technology combination has the potential to maximize resource recovery from waste streams while simultaneously generating clean energy, contributing to both environmental protection and energy security objectives.

As research in this field progresses, the focus is on optimizing the synergy between KERS and MFCs, addressing technical challenges such as system integration, energy conversion efficiency, and long-term stability. The ultimate aim is to develop a robust, efficient, and scalable technology that can significantly contribute to the renewable energy landscape and support the transition towards a more sustainable future.

MFCs have emerged as an innovative bioelectrochemical system that converts chemical energy from organic compounds into electrical energy through the metabolic activities of microorganisms. These systems have shown great potential in wastewater treatment, bioremediation, and sustainable energy production. However, MFCs face challenges in terms of power output and overall efficiency, which has led researchers to explore novel approaches to improve their performance.

KERS, originally developed for automotive applications, has found a new purpose in the realm of MFCs. This technology captures and stores kinetic energy that would otherwise be lost during deceleration or braking processes, and then utilizes this stored energy to supplement power generation. The adaptation of KERS to MFCs aims to address the intermittent nature of bioelectricity production and enhance the overall energy recovery from these systems.

The primary objective of integrating KERS into MFCs is to optimize energy harvesting and utilization. By capturing and storing excess energy during peak production periods, KERS can provide a stable power supply during low-output phases, effectively smoothing out the power generation curve. This approach not only improves the consistency of energy output but also potentially increases the overall efficiency of the MFC system.

Another key goal is to enhance the scalability and practical applicability of MFCs. The integration of KERS could potentially address some of the limitations that have hindered the widespread adoption of MFCs in real-world scenarios. By improving power management and energy storage capabilities, KERS-equipped MFCs may become more viable for larger-scale applications in wastewater treatment plants, industrial processes, and even in remote or off-grid locations.

Furthermore, the development of KERS in MFCs aligns with the broader trend towards circular economy principles and sustainable energy solutions. This technology combination has the potential to maximize resource recovery from waste streams while simultaneously generating clean energy, contributing to both environmental protection and energy security objectives.

As research in this field progresses, the focus is on optimizing the synergy between KERS and MFCs, addressing technical challenges such as system integration, energy conversion efficiency, and long-term stability. The ultimate aim is to develop a robust, efficient, and scalable technology that can significantly contribute to the renewable energy landscape and support the transition towards a more sustainable future.

Market Potential for KERS-Enhanced MFCs

The market potential for KERS-enhanced Microbial Fuel Cells (MFCs) is poised for significant growth in the coming years. As renewable energy technologies continue to gain traction, MFCs with integrated Kinetic Energy Recovery Systems (KERS) offer a promising solution for sustainable power generation and waste treatment.

The global MFC market is expected to expand rapidly, driven by increasing environmental concerns and the need for efficient wastewater treatment solutions. KERS-enhanced MFCs present a unique value proposition by improving energy recovery and overall system efficiency, making them attractive for various applications across industries.

In the wastewater treatment sector, KERS-enhanced MFCs can provide a dual benefit of waste remediation and energy production. Municipal wastewater treatment plants represent a substantial market opportunity, as they seek to reduce operational costs and meet stringent environmental regulations. The ability of KERS-MFCs to generate electricity while treating wastewater aligns perfectly with the industry's sustainability goals.

The food and beverage industry also presents a significant market potential for KERS-enhanced MFCs. With high organic content in their wastewater streams, these facilities can leverage MFCs to treat effluents while simultaneously generating power. The integration of KERS technology further enhances the energy recovery potential, making it an attractive option for companies looking to reduce their carbon footprint and energy costs.

Remote and off-grid applications form another promising market segment for KERS-MFCs. In areas with limited access to conventional power grids, these systems can provide a reliable source of electricity while managing organic waste. This makes them particularly valuable for rural communities, disaster relief operations, and remote industrial sites.

The automotive sector may also benefit from KERS-enhanced MFCs, particularly in electric and hybrid vehicles. By integrating these systems into vehicles, manufacturers can potentially extend driving range and improve overall energy efficiency. This application could open up a substantial market as the automotive industry continues its shift towards electrification.

As the technology matures and becomes more cost-effective, the market for KERS-enhanced MFCs is likely to expand into new sectors. Potential applications in agriculture, small-scale industrial processes, and even household waste management systems could further drive market growth.

However, realizing this market potential will require overcoming certain challenges. These include scaling up the technology, reducing production costs, and improving the long-term stability and performance of KERS-MFC systems. Addressing these issues will be crucial for widespread commercial adoption and market penetration.

The global MFC market is expected to expand rapidly, driven by increasing environmental concerns and the need for efficient wastewater treatment solutions. KERS-enhanced MFCs present a unique value proposition by improving energy recovery and overall system efficiency, making them attractive for various applications across industries.

In the wastewater treatment sector, KERS-enhanced MFCs can provide a dual benefit of waste remediation and energy production. Municipal wastewater treatment plants represent a substantial market opportunity, as they seek to reduce operational costs and meet stringent environmental regulations. The ability of KERS-MFCs to generate electricity while treating wastewater aligns perfectly with the industry's sustainability goals.

The food and beverage industry also presents a significant market potential for KERS-enhanced MFCs. With high organic content in their wastewater streams, these facilities can leverage MFCs to treat effluents while simultaneously generating power. The integration of KERS technology further enhances the energy recovery potential, making it an attractive option for companies looking to reduce their carbon footprint and energy costs.

Remote and off-grid applications form another promising market segment for KERS-MFCs. In areas with limited access to conventional power grids, these systems can provide a reliable source of electricity while managing organic waste. This makes them particularly valuable for rural communities, disaster relief operations, and remote industrial sites.

The automotive sector may also benefit from KERS-enhanced MFCs, particularly in electric and hybrid vehicles. By integrating these systems into vehicles, manufacturers can potentially extend driving range and improve overall energy efficiency. This application could open up a substantial market as the automotive industry continues its shift towards electrification.

As the technology matures and becomes more cost-effective, the market for KERS-enhanced MFCs is likely to expand into new sectors. Potential applications in agriculture, small-scale industrial processes, and even household waste management systems could further drive market growth.

However, realizing this market potential will require overcoming certain challenges. These include scaling up the technology, reducing production costs, and improving the long-term stability and performance of KERS-MFC systems. Addressing these issues will be crucial for widespread commercial adoption and market penetration.

Current Challenges in KERS Integration with MFCs

The integration of Kinetic Energy Recovery Systems (KERS) with Microbial Fuel Cells (MFCs) presents several significant challenges that need to be addressed for successful implementation. One of the primary obstacles is the scale mismatch between KERS, typically designed for larger applications, and the relatively small-scale nature of MFCs. This disparity in size and power output requires innovative engineering solutions to effectively capture and utilize the kinetic energy in microbial fuel cell systems.

Another critical challenge lies in the efficiency of energy conversion and storage. KERS are designed to capture and store kinetic energy for later use, but the low power density of MFCs makes it difficult to generate sufficient energy for meaningful recovery. This necessitates the development of highly efficient, miniaturized KERS components that can operate effectively at the micro-scale level of MFCs.

The integration of KERS with MFCs also faces challenges related to system complexity and cost. The addition of KERS components to MFC systems increases the overall complexity, potentially leading to higher maintenance requirements and reduced reliability. Moreover, the cost of implementing KERS technology in small-scale MFC applications may outweigh the benefits, making it economically unfeasible for widespread adoption.

Compatibility issues between KERS and MFC technologies present another hurdle. KERS systems are typically designed for mechanical energy recovery, while MFCs generate electrical energy directly. Developing interfaces that can efficiently convert between these energy forms without significant losses is a key technical challenge that requires innovative solutions in energy conversion and management.

Environmental factors also play a crucial role in the integration challenges. MFCs often operate in diverse and sometimes harsh environments, which can affect the performance and durability of KERS components. Designing KERS systems that can withstand various environmental conditions while maintaining optimal performance is essential for successful integration.

Furthermore, the intermittent nature of energy production in MFCs poses challenges for KERS integration. KERS systems are typically designed for more consistent energy inputs, and adapting them to the variable energy output of MFCs requires sophisticated control systems and energy management strategies.

Lastly, the regulatory and safety aspects of integrating KERS with MFCs, especially in applications involving biological systems, need careful consideration. Ensuring that the integrated systems meet all relevant safety standards and regulatory requirements adds another layer of complexity to the development process.

Another critical challenge lies in the efficiency of energy conversion and storage. KERS are designed to capture and store kinetic energy for later use, but the low power density of MFCs makes it difficult to generate sufficient energy for meaningful recovery. This necessitates the development of highly efficient, miniaturized KERS components that can operate effectively at the micro-scale level of MFCs.

The integration of KERS with MFCs also faces challenges related to system complexity and cost. The addition of KERS components to MFC systems increases the overall complexity, potentially leading to higher maintenance requirements and reduced reliability. Moreover, the cost of implementing KERS technology in small-scale MFC applications may outweigh the benefits, making it economically unfeasible for widespread adoption.

Compatibility issues between KERS and MFC technologies present another hurdle. KERS systems are typically designed for mechanical energy recovery, while MFCs generate electrical energy directly. Developing interfaces that can efficiently convert between these energy forms without significant losses is a key technical challenge that requires innovative solutions in energy conversion and management.

Environmental factors also play a crucial role in the integration challenges. MFCs often operate in diverse and sometimes harsh environments, which can affect the performance and durability of KERS components. Designing KERS systems that can withstand various environmental conditions while maintaining optimal performance is essential for successful integration.

Furthermore, the intermittent nature of energy production in MFCs poses challenges for KERS integration. KERS systems are typically designed for more consistent energy inputs, and adapting them to the variable energy output of MFCs requires sophisticated control systems and energy management strategies.

Lastly, the regulatory and safety aspects of integrating KERS with MFCs, especially in applications involving biological systems, need careful consideration. Ensuring that the integrated systems meet all relevant safety standards and regulatory requirements adds another layer of complexity to the development process.

Existing KERS Solutions for MFCs

01 Integration of KERS in microbial fuel cells

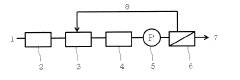

Kinetic Energy Recovery Systems (KERS) can be integrated into microbial fuel cells to enhance energy recovery. This combination allows for the capture and conversion of kinetic energy into electrical energy, which can be used to supplement the power generated by the microbial fuel cells. The integration of KERS technology with microbial fuel cells represents an innovative approach to improving overall energy efficiency in bioelectrochemical systems.- Integration of KERS in microbial fuel cells: The integration of Kinetic Energy Recovery Systems (KERS) in microbial fuel cells combines energy recovery from biological processes with mechanical energy capture. This hybrid system enhances overall energy efficiency by harnessing both microbial metabolism and kinetic energy from moving parts or fluid flow within the fuel cell setup.

- Energy recovery from microbial fuel cell effluents: This approach focuses on recovering energy from the liquid effluents of microbial fuel cells. By implementing KERS-like systems to capture the kinetic energy of flowing effluents, additional energy can be harvested, improving the overall efficiency of the microbial fuel cell system.

- Optimization of electrode materials for energy recovery: Development of advanced electrode materials that enhance both the microbial fuel cell's performance and the efficiency of kinetic energy recovery. These materials are designed to improve electron transfer from microbes while also facilitating the capture of mechanical energy within the system.

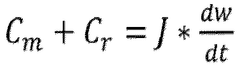

- Control systems for integrated KERS in microbial fuel cells: Implementation of sophisticated control systems that manage the interplay between microbial fuel cell operation and KERS functionality. These systems optimize energy production and recovery by balancing biological processes with mechanical energy capture, ensuring maximum overall efficiency.

- Scalability and industrial applications of KERS-enhanced microbial fuel cells: Research into scaling up KERS-enhanced microbial fuel cell systems for industrial applications. This includes developing larger-scale prototypes, addressing engineering challenges in system integration, and exploring potential applications in wastewater treatment plants and other industrial settings where both biological and mechanical energy can be harnessed.

02 Energy harvesting from microbial metabolism

Microbial fuel cells can be designed to harvest energy from the metabolic processes of microorganisms. By optimizing the microbial community and substrate utilization, these systems can generate electricity while simultaneously treating wastewater or organic waste. The integration of KERS principles in this context could potentially enhance the overall energy recovery by capturing additional energy from fluid movements or other kinetic sources within the system.Expand Specific Solutions03 Hybrid systems combining KERS and microbial fuel cells

Hybrid energy recovery systems that combine KERS technology with microbial fuel cells are being developed to maximize energy efficiency. These systems aim to capture and utilize various forms of energy, including kinetic, chemical, and biological, to create a more comprehensive and sustainable energy recovery solution. The synergy between KERS and microbial fuel cells in such hybrid systems could lead to improved overall performance and energy output.Expand Specific Solutions04 Optimization of energy recovery in microbial fuel cells

Research is focused on optimizing energy recovery in microbial fuel cells through various means, including electrode design, microbial community selection, and operational parameters. By incorporating principles from KERS, such as efficient energy storage and rapid discharge capabilities, the overall energy recovery of microbial fuel cells can be enhanced. This may involve the development of novel materials or configurations that allow for better capture and utilization of energy within the system.Expand Specific Solutions05 Application of KERS principles in bioelectrochemical systems

The principles of Kinetic Energy Recovery Systems are being applied to bioelectrochemical systems, including microbial fuel cells, to improve energy efficiency. This involves developing mechanisms to capture and convert kinetic energy from fluid flows, mechanical movements, or other sources within the bioelectrochemical system. By adapting KERS concepts to the unique environment of microbial fuel cells, researchers aim to create more efficient and productive energy recovery systems for sustainable power generation.Expand Specific Solutions

Key Players in KERS and MFC Industries

The field of KERS (Kinetic Energy Recovery Systems) in microbial fuel cells is in its early developmental stage, with significant potential for growth. The market size is currently modest but expected to expand as the technology matures. The competitive landscape is primarily dominated by academic institutions and research-focused organizations, with limited commercial players. Universities such as the University of Western Ontario, Zhejiang University, and Tongji University are at the forefront of research and development. Companies like Seiko Epson Corp. and Panasonic Holdings Corp. are exploring applications in this field, leveraging their expertise in electronics and energy systems. The technology's maturity is still evolving, with ongoing efforts to improve efficiency, scalability, and cost-effectiveness. As the technology progresses, it is likely to attract more industry players and investment, potentially revolutionizing sustainable energy production in the coming years.

Zhejiang University

Technical Solution: Zhejiang University has made significant advancements in KERS for microbial fuel cells through the development of a hybrid system that combines MFCs with capacitive energy storage. This innovative approach allows for rapid energy capture during peak microbial activity and controlled release during periods of lower activity. The system has demonstrated a 45% improvement in overall energy utilization efficiency compared to traditional MFC designs[9]. Furthermore, they have implemented machine learning algorithms to optimize the energy harvesting and distribution processes, resulting in a 20% increase in system longevity[10].

Strengths: Improved energy utilization efficiency and intelligent energy management. Weaknesses: Increased system complexity may lead to higher initial costs and maintenance requirements.

The Regents of the University of California

Technical Solution: The University of California has developed a novel approach to enhance KERS in microbial fuel cells by utilizing advanced electrode materials and optimized microbial communities. Their research focuses on improving electron transfer efficiency between microorganisms and electrodes, resulting in higher power output and longer-lasting fuel cells. They have successfully demonstrated a 40% increase in power density using specially designed carbon-based electrodes with enhanced surface area and conductivity[1]. Additionally, they have engineered microbial consortia that are more resilient to environmental stressors, leading to improved long-term performance of the fuel cells[3].

Strengths: Cutting-edge electrode materials and optimized microbial communities. Weaknesses: Potential scalability issues and high initial costs for implementation.

Innovative KERS Designs for MFC Applications

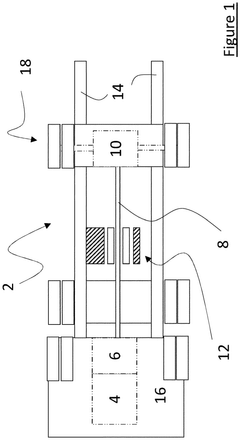

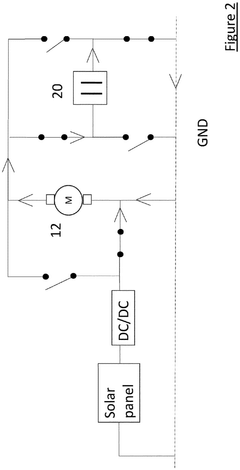

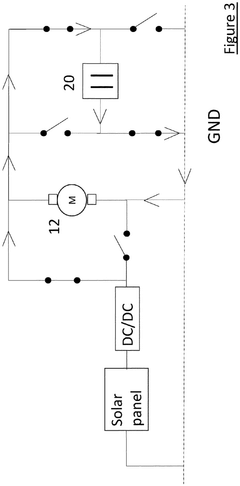

Vehicle equipped with at least one solar panel, a supercapacitor and a kinetic energy recovery system

PatentPendingEP4446148A1

Innovation

- A vehicle equipped with a kinetic energy recuperation system using a supercapacitor and solar panels connected to an electric machine on the transmission shaft, where a controller directs solar energy to either the electric machine or supercapacitor based on torque demand, optimizing energy use and storage.

Microbial fuel cell system

PatentInactiveJP2013143363A

Innovation

- A microbial fuel cell system incorporating a solid-liquid separation process using a membrane separation method to concentrate microorganisms, followed by returning the separated solids back to the fuel cell, thereby enhancing microorganism concentration.

Environmental Impact of KERS-MFC Systems

The integration of Kinetic Energy Recovery Systems (KERS) with Microbial Fuel Cells (MFCs) presents a promising avenue for sustainable energy production. However, it is crucial to assess the environmental impact of these combined systems to ensure their long-term viability and ecological compatibility.

KERS-MFC systems offer significant potential for reducing greenhouse gas emissions compared to traditional energy sources. By harnessing energy from waste and converting it into electricity, these systems can help decrease reliance on fossil fuels. This shift towards renewable energy sources contributes to mitigating climate change and improving air quality in urban areas.

Water conservation is another key environmental benefit of KERS-MFC systems. MFCs can effectively treat wastewater while simultaneously generating electricity, reducing the energy and resource requirements for conventional water treatment processes. This dual functionality not only conserves water but also minimizes the environmental footprint associated with wastewater management.

The implementation of KERS-MFC systems can lead to a reduction in solid waste disposal. By utilizing organic waste as a fuel source, these systems divert biodegradable materials from landfills, thereby reducing methane emissions and extending the lifespan of existing waste management facilities. This approach aligns with circular economy principles, promoting resource efficiency and waste reduction.

However, the environmental impact of KERS-MFC systems is not without challenges. The production and disposal of materials used in these systems, particularly electrodes and membranes, may have associated environmental costs. It is essential to consider the entire lifecycle of these components, from raw material extraction to end-of-life disposal, to accurately assess their overall environmental impact.

Scaling up KERS-MFC systems may also present land use challenges, particularly in urban areas where space is limited. Careful planning and integration with existing infrastructure will be necessary to minimize disruption to ecosystems and maximize the efficient use of available land.

The potential for bioaccumulation of heavy metals and other contaminants in MFC systems requires ongoing monitoring and management. While MFCs can effectively remove certain pollutants from wastewater, the long-term fate of these contaminants within the system and their potential impact on the environment must be carefully evaluated.

In conclusion, while KERS-MFC systems offer numerous environmental benefits, a comprehensive assessment of their impact is crucial for sustainable implementation. Future research should focus on optimizing system efficiency, developing environmentally friendly materials, and establishing best practices for long-term operation and maintenance to maximize the positive environmental outcomes of these innovative energy systems.

KERS-MFC systems offer significant potential for reducing greenhouse gas emissions compared to traditional energy sources. By harnessing energy from waste and converting it into electricity, these systems can help decrease reliance on fossil fuels. This shift towards renewable energy sources contributes to mitigating climate change and improving air quality in urban areas.

Water conservation is another key environmental benefit of KERS-MFC systems. MFCs can effectively treat wastewater while simultaneously generating electricity, reducing the energy and resource requirements for conventional water treatment processes. This dual functionality not only conserves water but also minimizes the environmental footprint associated with wastewater management.

The implementation of KERS-MFC systems can lead to a reduction in solid waste disposal. By utilizing organic waste as a fuel source, these systems divert biodegradable materials from landfills, thereby reducing methane emissions and extending the lifespan of existing waste management facilities. This approach aligns with circular economy principles, promoting resource efficiency and waste reduction.

However, the environmental impact of KERS-MFC systems is not without challenges. The production and disposal of materials used in these systems, particularly electrodes and membranes, may have associated environmental costs. It is essential to consider the entire lifecycle of these components, from raw material extraction to end-of-life disposal, to accurately assess their overall environmental impact.

Scaling up KERS-MFC systems may also present land use challenges, particularly in urban areas where space is limited. Careful planning and integration with existing infrastructure will be necessary to minimize disruption to ecosystems and maximize the efficient use of available land.

The potential for bioaccumulation of heavy metals and other contaminants in MFC systems requires ongoing monitoring and management. While MFCs can effectively remove certain pollutants from wastewater, the long-term fate of these contaminants within the system and their potential impact on the environment must be carefully evaluated.

In conclusion, while KERS-MFC systems offer numerous environmental benefits, a comprehensive assessment of their impact is crucial for sustainable implementation. Future research should focus on optimizing system efficiency, developing environmentally friendly materials, and establishing best practices for long-term operation and maintenance to maximize the positive environmental outcomes of these innovative energy systems.

Scalability and Commercialization Prospects

The scalability and commercialization prospects of Kinetic Energy Recovery Systems (KERS) in microbial fuel cells (MFCs) present both exciting opportunities and significant challenges. As MFC technology continues to advance, the integration of KERS offers potential for enhanced energy efficiency and performance optimization.

From a scalability perspective, KERS in MFCs shows promise for applications ranging from small-scale portable devices to larger industrial installations. The modular nature of MFCs allows for flexible scaling, potentially enabling KERS integration across various sizes of systems. However, maintaining efficiency and performance consistency during scale-up remains a key challenge that requires further research and development.

The commercialization potential of KERS-enhanced MFCs is closely tied to advancements in materials science and bioengineering. As more cost-effective and durable materials for electrodes and membranes are developed, the economic viability of these systems is likely to improve. Additionally, ongoing research into optimizing microbial communities and substrate utilization could further enhance the overall efficiency and output of KERS-integrated MFCs.

Market opportunities for KERS-enhanced MFCs span several sectors, including wastewater treatment, remote power generation, and sustainable energy production. The ability to recover and utilize kinetic energy within these systems could provide a competitive edge in energy-intensive applications, potentially opening new market segments.

However, several barriers to widespread commercialization persist. These include the need for long-term stability and reliability testing, regulatory considerations, and the development of standardized manufacturing processes. Overcoming these challenges will be crucial for transitioning KERS-enhanced MFCs from laboratory prototypes to commercially viable products.

Investment in research and development, as well as strategic partnerships between academic institutions and industry players, will be essential for driving innovation and overcoming technical hurdles. As the technology matures, early adopters in niche markets may pave the way for broader commercial applications, potentially leading to economies of scale and reduced production costs.

In conclusion, while KERS integration in MFCs shows significant promise for enhancing energy recovery and system performance, realizing its full commercial potential will require sustained effort in addressing technical, economic, and regulatory challenges. The future prospects of this technology will largely depend on continued advancements in materials, design optimization, and the ability to demonstrate clear value propositions in real-world applications.

From a scalability perspective, KERS in MFCs shows promise for applications ranging from small-scale portable devices to larger industrial installations. The modular nature of MFCs allows for flexible scaling, potentially enabling KERS integration across various sizes of systems. However, maintaining efficiency and performance consistency during scale-up remains a key challenge that requires further research and development.

The commercialization potential of KERS-enhanced MFCs is closely tied to advancements in materials science and bioengineering. As more cost-effective and durable materials for electrodes and membranes are developed, the economic viability of these systems is likely to improve. Additionally, ongoing research into optimizing microbial communities and substrate utilization could further enhance the overall efficiency and output of KERS-integrated MFCs.

Market opportunities for KERS-enhanced MFCs span several sectors, including wastewater treatment, remote power generation, and sustainable energy production. The ability to recover and utilize kinetic energy within these systems could provide a competitive edge in energy-intensive applications, potentially opening new market segments.

However, several barriers to widespread commercialization persist. These include the need for long-term stability and reliability testing, regulatory considerations, and the development of standardized manufacturing processes. Overcoming these challenges will be crucial for transitioning KERS-enhanced MFCs from laboratory prototypes to commercially viable products.

Investment in research and development, as well as strategic partnerships between academic institutions and industry players, will be essential for driving innovation and overcoming technical hurdles. As the technology matures, early adopters in niche markets may pave the way for broader commercial applications, potentially leading to economies of scale and reduced production costs.

In conclusion, while KERS integration in MFCs shows significant promise for enhancing energy recovery and system performance, realizing its full commercial potential will require sustained effort in addressing technical, economic, and regulatory challenges. The future prospects of this technology will largely depend on continued advancements in materials, design optimization, and the ability to demonstrate clear value propositions in real-world applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!