KERS dependency on vehicle weight and size

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

KERS Background and Objectives

Kinetic Energy Recovery Systems (KERS) have emerged as a pivotal technology in the automotive industry, particularly in the realm of energy efficiency and performance enhancement. The concept of KERS originated in the early 2000s, primarily in motorsports, as a means to capture and reuse energy that would otherwise be lost during braking. Over time, this technology has evolved and found applications beyond racing, extending to passenger vehicles and commercial transport.

The development of KERS has been driven by several factors, including the growing emphasis on fuel efficiency, the push for reduced emissions, and the increasing electrification of vehicles. As global regulations continue to tighten around vehicle emissions and fuel consumption, KERS has become an attractive solution for automakers seeking to meet these stringent requirements while maintaining or improving vehicle performance.

The fundamental principle behind KERS is to harness the kinetic energy of a moving vehicle during deceleration, store it temporarily, and then redeploy it to assist in acceleration. This process not only improves fuel efficiency but also enhances overall vehicle performance by providing an additional power boost when needed.

One of the key technological trends in KERS development has been the exploration of various energy storage methods. While early systems primarily used mechanical flywheels, modern KERS implementations often utilize electrical systems with batteries or supercapacitors. This shift has been influenced by advancements in battery technology and the broader trend towards vehicle electrification.

The relationship between KERS efficiency and vehicle characteristics, particularly weight and size, has become a critical area of focus. As vehicles vary greatly in these aspects, understanding how KERS performance is affected by these parameters is essential for optimizing system design and implementation across different vehicle categories.

The primary objectives of investigating KERS dependency on vehicle weight and size are multifaceted. Firstly, there is a need to quantify the impact of these variables on KERS efficiency and effectiveness. This understanding will enable engineers to tailor KERS designs to specific vehicle types, maximizing energy recovery and utilization.

Secondly, researchers aim to develop scalable KERS solutions that can be effectively implemented across a wide range of vehicle sizes and weights. This scalability is crucial for widespread adoption of the technology in diverse automotive segments, from compact city cars to heavy-duty trucks.

Lastly, the investigation seeks to identify potential limitations or thresholds where KERS implementation becomes less effective or economically viable based on vehicle characteristics. This knowledge will guide strategic decisions on where to focus KERS development efforts and which vehicle categories are most suitable for this technology.

The development of KERS has been driven by several factors, including the growing emphasis on fuel efficiency, the push for reduced emissions, and the increasing electrification of vehicles. As global regulations continue to tighten around vehicle emissions and fuel consumption, KERS has become an attractive solution for automakers seeking to meet these stringent requirements while maintaining or improving vehicle performance.

The fundamental principle behind KERS is to harness the kinetic energy of a moving vehicle during deceleration, store it temporarily, and then redeploy it to assist in acceleration. This process not only improves fuel efficiency but also enhances overall vehicle performance by providing an additional power boost when needed.

One of the key technological trends in KERS development has been the exploration of various energy storage methods. While early systems primarily used mechanical flywheels, modern KERS implementations often utilize electrical systems with batteries or supercapacitors. This shift has been influenced by advancements in battery technology and the broader trend towards vehicle electrification.

The relationship between KERS efficiency and vehicle characteristics, particularly weight and size, has become a critical area of focus. As vehicles vary greatly in these aspects, understanding how KERS performance is affected by these parameters is essential for optimizing system design and implementation across different vehicle categories.

The primary objectives of investigating KERS dependency on vehicle weight and size are multifaceted. Firstly, there is a need to quantify the impact of these variables on KERS efficiency and effectiveness. This understanding will enable engineers to tailor KERS designs to specific vehicle types, maximizing energy recovery and utilization.

Secondly, researchers aim to develop scalable KERS solutions that can be effectively implemented across a wide range of vehicle sizes and weights. This scalability is crucial for widespread adoption of the technology in diverse automotive segments, from compact city cars to heavy-duty trucks.

Lastly, the investigation seeks to identify potential limitations or thresholds where KERS implementation becomes less effective or economically viable based on vehicle characteristics. This knowledge will guide strategic decisions on where to focus KERS development efforts and which vehicle categories are most suitable for this technology.

Market Analysis for KERS

The market for Kinetic Energy Recovery Systems (KERS) has shown significant growth potential in recent years, driven by increasing demand for fuel-efficient and environmentally friendly vehicles. The global KERS market is expected to expand at a compound annual growth rate of 8.5% from 2021 to 2026, reaching a value of $25.3 billion by the end of the forecast period.

The automotive sector remains the primary driver of KERS adoption, with passenger vehicles and commercial vehicles being the key application areas. The growing emphasis on reducing carbon emissions and improving fuel economy in the automotive industry has led to increased interest in KERS technology. Government regulations and incentives promoting the use of energy-efficient technologies in vehicles have further boosted market growth.

In terms of regional distribution, Europe currently leads the KERS market, followed by North America and Asia-Pacific. The European market's dominance can be attributed to stringent emission norms and a strong focus on sustainable transportation solutions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing vehicle production, and growing environmental awareness in countries like China and India.

The market for KERS is segmented based on system type, with electric, hydraulic, and flywheel-based systems being the main categories. Electric KERS currently holds the largest market share due to its higher efficiency and compatibility with hybrid and electric vehicles. However, hydraulic KERS is gaining traction in heavy-duty vehicles and construction equipment due to its ability to handle higher power densities.

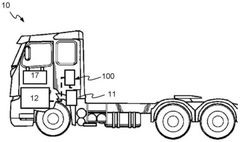

The dependency of KERS on vehicle weight and size plays a crucial role in market dynamics. Larger and heavier vehicles, such as trucks and buses, offer greater potential for energy recovery due to their higher kinetic energy during deceleration. This has led to increased adoption of KERS in commercial vehicle segments. Conversely, the challenge lies in adapting KERS for smaller passenger vehicles while maintaining cost-effectiveness and efficiency.

The market analysis reveals a growing trend towards the integration of KERS with other advanced technologies, such as regenerative braking systems and start-stop systems, to maximize energy recovery and fuel efficiency. This integration is expected to create new opportunities for market growth and technological advancements in the coming years.

The automotive sector remains the primary driver of KERS adoption, with passenger vehicles and commercial vehicles being the key application areas. The growing emphasis on reducing carbon emissions and improving fuel economy in the automotive industry has led to increased interest in KERS technology. Government regulations and incentives promoting the use of energy-efficient technologies in vehicles have further boosted market growth.

In terms of regional distribution, Europe currently leads the KERS market, followed by North America and Asia-Pacific. The European market's dominance can be attributed to stringent emission norms and a strong focus on sustainable transportation solutions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing vehicle production, and growing environmental awareness in countries like China and India.

The market for KERS is segmented based on system type, with electric, hydraulic, and flywheel-based systems being the main categories. Electric KERS currently holds the largest market share due to its higher efficiency and compatibility with hybrid and electric vehicles. However, hydraulic KERS is gaining traction in heavy-duty vehicles and construction equipment due to its ability to handle higher power densities.

The dependency of KERS on vehicle weight and size plays a crucial role in market dynamics. Larger and heavier vehicles, such as trucks and buses, offer greater potential for energy recovery due to their higher kinetic energy during deceleration. This has led to increased adoption of KERS in commercial vehicle segments. Conversely, the challenge lies in adapting KERS for smaller passenger vehicles while maintaining cost-effectiveness and efficiency.

The market analysis reveals a growing trend towards the integration of KERS with other advanced technologies, such as regenerative braking systems and start-stop systems, to maximize energy recovery and fuel efficiency. This integration is expected to create new opportunities for market growth and technological advancements in the coming years.

KERS Challenges and Limitations

Kinetic Energy Recovery Systems (KERS) face significant challenges and limitations, particularly in relation to vehicle weight and size. One of the primary challenges is the system's efficiency, which is heavily influenced by the vehicle's mass. Heavier vehicles require more energy to accelerate, resulting in increased energy dissipation during braking. This relationship creates a complex balance between energy recovery potential and overall vehicle performance.

The size of the vehicle also plays a crucial role in KERS implementation. Larger vehicles typically have more space available for system components, but they also face greater aerodynamic drag, which can offset the benefits of energy recovery. Conversely, smaller vehicles may struggle to accommodate the necessary KERS components without compromising interior space or cargo capacity.

Another significant challenge is the added weight of the KERS itself. The system's components, including the energy storage device, power electronics, and associated cooling systems, contribute to the overall vehicle mass. This additional weight can potentially negate some of the efficiency gains provided by the energy recovery process, especially in lighter vehicles where the relative impact is more pronounced.

The power density of KERS is also a limiting factor, particularly for smaller vehicles. The system must be capable of capturing and releasing large amounts of energy quickly during braking and acceleration events. However, achieving high power density while maintaining reasonable system size and weight is technically challenging, especially within the constraints of compact vehicle designs.

Thermal management presents another hurdle in KERS implementation. The rapid energy transfer during braking generates significant heat, which must be efficiently dissipated to maintain system performance and longevity. This challenge is exacerbated in smaller vehicles with limited space for cooling systems, potentially leading to reduced system efficiency or the need for more complex thermal management solutions.

Furthermore, the integration of KERS with existing vehicle systems poses substantial engineering challenges. The system must seamlessly interface with the vehicle's powertrain, braking system, and control electronics. This integration becomes increasingly complex as vehicle size decreases, requiring more compact and sophisticated solutions to maintain functionality without compromising other vehicle systems.

Lastly, the cost-effectiveness of KERS implementation varies significantly with vehicle weight and size. While larger vehicles may benefit more from energy recovery due to their higher kinetic energy during deceleration, the system's cost may be harder to justify in smaller, more affordable vehicles. This economic consideration often limits the widespread adoption of KERS technology across different vehicle segments.

The size of the vehicle also plays a crucial role in KERS implementation. Larger vehicles typically have more space available for system components, but they also face greater aerodynamic drag, which can offset the benefits of energy recovery. Conversely, smaller vehicles may struggle to accommodate the necessary KERS components without compromising interior space or cargo capacity.

Another significant challenge is the added weight of the KERS itself. The system's components, including the energy storage device, power electronics, and associated cooling systems, contribute to the overall vehicle mass. This additional weight can potentially negate some of the efficiency gains provided by the energy recovery process, especially in lighter vehicles where the relative impact is more pronounced.

The power density of KERS is also a limiting factor, particularly for smaller vehicles. The system must be capable of capturing and releasing large amounts of energy quickly during braking and acceleration events. However, achieving high power density while maintaining reasonable system size and weight is technically challenging, especially within the constraints of compact vehicle designs.

Thermal management presents another hurdle in KERS implementation. The rapid energy transfer during braking generates significant heat, which must be efficiently dissipated to maintain system performance and longevity. This challenge is exacerbated in smaller vehicles with limited space for cooling systems, potentially leading to reduced system efficiency or the need for more complex thermal management solutions.

Furthermore, the integration of KERS with existing vehicle systems poses substantial engineering challenges. The system must seamlessly interface with the vehicle's powertrain, braking system, and control electronics. This integration becomes increasingly complex as vehicle size decreases, requiring more compact and sophisticated solutions to maintain functionality without compromising other vehicle systems.

Lastly, the cost-effectiveness of KERS implementation varies significantly with vehicle weight and size. While larger vehicles may benefit more from energy recovery due to their higher kinetic energy during deceleration, the system's cost may be harder to justify in smaller, more affordable vehicles. This economic consideration often limits the widespread adoption of KERS technology across different vehicle segments.

Current KERS Solutions

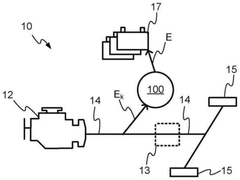

01 Integration of KERS with vehicle systems

KERS is integrated with various vehicle systems to optimize energy recovery and utilization. This integration involves connecting KERS with the powertrain, braking system, and energy management systems to efficiently capture, store, and deploy kinetic energy. The system's dependency on these interconnected components is crucial for its overall performance and effectiveness in improving vehicle efficiency.- Integration with vehicle systems: KERS is integrated with various vehicle systems to optimize energy recovery and utilization. This includes integration with braking systems, powertrain, and energy storage components. The system is designed to work in harmony with existing vehicle architectures, enhancing overall efficiency and performance.

- Energy storage and management: KERS relies on efficient energy storage and management systems. This involves the use of advanced batteries, supercapacitors, or flywheels to store recovered kinetic energy. Sophisticated control systems are employed to manage energy flow, ensuring optimal distribution between storage and propulsion needs.

- Application in different vehicle types: KERS technology is adapted for use in various vehicle types, including passenger cars, commercial vehicles, and racing cars. Each application requires specific modifications to the system to suit the vehicle's characteristics and intended use, such as power output, weight considerations, and driving cycles.

- Regenerative braking optimization: A key aspect of KERS is the optimization of regenerative braking. This involves developing advanced algorithms and control strategies to maximize energy recovery during deceleration and braking events. The system must balance energy recovery with traditional friction braking to ensure vehicle safety and performance.

- Integration with hybrid and electric powertrains: KERS is increasingly integrated with hybrid and electric vehicle powertrains. This integration allows for seamless energy transfer between the kinetic energy recovery system and the electric propulsion system, enhancing overall vehicle efficiency and extending electric driving range.

02 Energy storage technologies for KERS

KERS relies on various energy storage technologies to temporarily hold recovered kinetic energy. These may include high-performance batteries, supercapacitors, or flywheels. The choice and design of energy storage systems significantly impact the KERS's efficiency, power density, and response time, making it a critical dependency for the overall system performance.Expand Specific Solutions03 Control systems and algorithms for KERS

Sophisticated control systems and algorithms are essential for managing the operation of KERS. These systems optimize energy recovery during deceleration, determine the most efficient deployment of stored energy, and coordinate with other vehicle systems. The dependency on advanced control strategies is crucial for maximizing the benefits of KERS while ensuring smooth vehicle operation.Expand Specific Solutions04 KERS application in different vehicle types

KERS technology is adapted for use in various vehicle types, including passenger cars, commercial vehicles, and racing cars. Each application requires specific modifications to the KERS design and integration, considering factors such as vehicle weight, performance requirements, and driving cycles. The system's dependency on vehicle-specific parameters is crucial for optimizing its effectiveness across different platforms.Expand Specific Solutions05 Environmental and regulatory factors affecting KERS

The development and implementation of KERS are influenced by environmental regulations and energy efficiency standards. These external factors drive the need for more efficient energy recovery systems in vehicles. The dependency of KERS on evolving regulatory frameworks and environmental policies shapes its design, adoption, and continuous improvement in the automotive industry.Expand Specific Solutions

Key KERS Industry Players

The KERS (Kinetic Energy Recovery System) technology market is in a growth phase, with increasing adoption across the automotive industry. The market size is expanding as more manufacturers integrate KERS into their vehicle designs. The technology's maturity varies, with some companies like Toyota, Volvo, and Bosch leading in development and implementation. Smaller players such as Tactile Mobility and Punch Flybrid are also contributing to innovation. The dependency on vehicle weight and size presents both challenges and opportunities for differentiation among competitors, with larger manufacturers like Toyota and Volvo potentially having an advantage in scaling solutions across diverse vehicle platforms.

Robert Bosch GmbH

Technical Solution: Bosch has developed a modular KERS solution that addresses the dependency on vehicle weight and size through a scalable architecture. Their system utilizes a combination of high-power density lithium-ion batteries and advanced power electronics to manage energy flow. Bosch's KERS incorporates a smart energy management unit that continuously monitors vehicle weight through load sensors in the suspension system. This data is used to adjust the regenerative braking force and energy storage capacity in real-time. For larger vehicles, the system can distribute energy recovery across multiple axles, maximizing efficiency. Bosch's technology also features a unique thermal management system that maintains optimal battery temperature across different vehicle sizes and operating conditions, ensuring consistent performance[5]. The system has demonstrated energy recovery improvements of up to 25% in heavy commercial vehicles compared to standard regenerative braking systems[6].

Strengths: Modular design allows for easy integration across various vehicle platforms; advanced thermal management enhances system longevity. Weaknesses: Higher initial cost due to sophisticated components; potential for increased vehicle complexity.

Scania CV AB

Technical Solution: Scania has developed a KERS specifically tailored for heavy-duty vehicles, addressing the unique challenges posed by large vehicle sizes and weights. Their system utilizes a high-capacity hydraulic accumulator as the primary energy storage medium, which can handle the large energy loads associated with heavy vehicles. Scania's KERS incorporates an adaptive pressure control system that adjusts the hydraulic pressure based on the vehicle's current weight, optimizing energy recovery and release. For varying vehicle sizes within their heavy-duty range, Scania employs modular hydraulic circuits that can be configured to match the vehicle's specifications. The system also features an intelligent energy management unit that uses real-time weight data from the vehicle's air suspension system to fine-tune the energy recovery strategy[9]. This weight-adaptive approach has demonstrated fuel savings of up to 20% in urban delivery scenarios for trucks of different sizes and load conditions[10].

Strengths: Robust design suitable for heavy-duty applications; hydraulic system provides high power density for rapid energy recovery. Weaknesses: Limited applicability to lighter vehicle categories; potential for reduced efficiency in long-haul scenarios with infrequent braking.

KERS Core Technologies

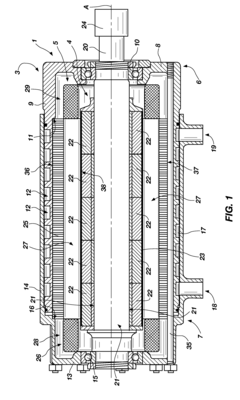

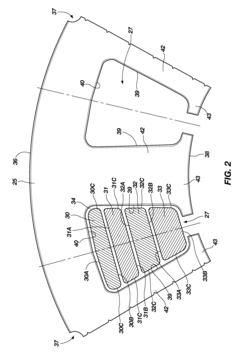

Electric motor with bar winding and connection plates

PatentActiveUS8076817B2

Innovation

- A compact, high-power-density multiphase synchronous electrical machine with a rotor and stator design featuring axial connection plates that extend the stator pack, providing large joining surfaces and efficient heat exchange, allowing for a high power-to-weight and power-to-volume ratio.

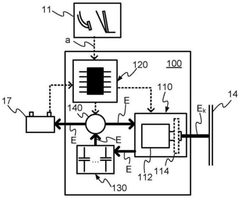

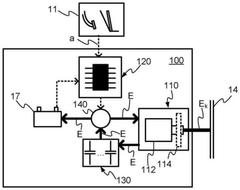

Kinetic energy recovery system

PatentPendingCN118722205A

Innovation

- Employs a kinetic energy recovery system (KERS) connected to the vehicle's propulsion shaft, which converts energy from the propulsion shaft into electrical energy through internal energy storage and processing circuitry, and distributes it to non-propulsion batteries or propulsion shafts when appropriate, in lieu of generator charging and provide motivation.

KERS Efficiency Optimization

The optimization of Kinetic Energy Recovery System (KERS) efficiency is intricately linked to vehicle weight and size. As vehicles become heavier, the potential energy that can be recovered during braking increases, theoretically improving KERS efficiency. However, this relationship is not linear and is subject to various constraints.

For lighter vehicles, KERS efficiency tends to be lower due to the reduced kinetic energy available for recovery. This presents a challenge for compact and lightweight vehicles, where the energy recovery potential is inherently limited. Conversely, heavier vehicles offer more opportunities for energy recuperation, but they also face increased energy demands for acceleration, potentially offsetting the gains from KERS.

Vehicle size plays a crucial role in KERS efficiency optimization. Larger vehicles provide more space for KERS components, allowing for more robust and potentially more efficient systems. This additional space can accommodate larger energy storage units, more powerful electric motors, and more sophisticated power electronics. However, larger vehicles also tend to have higher aerodynamic drag, which can negatively impact overall energy efficiency.

The optimization process must consider the trade-offs between weight, size, and KERS performance. For instance, increasing the capacity of energy storage systems can improve energy recovery but also adds weight to the vehicle. Similarly, more powerful electric motors can enhance energy regeneration but may increase the system's complexity and weight.

To address these challenges, engineers are exploring innovative approaches to KERS efficiency optimization. One strategy involves the use of lightweight materials for KERS components, such as carbon fiber flywheels or advanced battery technologies. This allows for increased energy storage capacity without significantly impacting vehicle weight.

Another approach focuses on adaptive KERS strategies that dynamically adjust the system's operation based on vehicle weight and driving conditions. This can involve real-time optimization algorithms that balance energy recovery with the vehicle's instantaneous power requirements, maximizing efficiency across a range of operating conditions.

Furthermore, the integration of KERS with other vehicle systems is being explored to enhance overall efficiency. For example, combining KERS with intelligent power management systems can optimize energy distribution between regenerative braking, propulsion, and auxiliary systems, taking into account vehicle weight and size constraints.

As vehicle electrification continues to advance, the role of KERS in hybrid and electric vehicles is evolving. The integration of KERS with electric powertrains offers new opportunities for efficiency optimization, particularly in the context of varying vehicle weights and sizes. This synergy between KERS and electric propulsion systems is expected to drive further innovations in energy recovery and management technologies.

For lighter vehicles, KERS efficiency tends to be lower due to the reduced kinetic energy available for recovery. This presents a challenge for compact and lightweight vehicles, where the energy recovery potential is inherently limited. Conversely, heavier vehicles offer more opportunities for energy recuperation, but they also face increased energy demands for acceleration, potentially offsetting the gains from KERS.

Vehicle size plays a crucial role in KERS efficiency optimization. Larger vehicles provide more space for KERS components, allowing for more robust and potentially more efficient systems. This additional space can accommodate larger energy storage units, more powerful electric motors, and more sophisticated power electronics. However, larger vehicles also tend to have higher aerodynamic drag, which can negatively impact overall energy efficiency.

The optimization process must consider the trade-offs between weight, size, and KERS performance. For instance, increasing the capacity of energy storage systems can improve energy recovery but also adds weight to the vehicle. Similarly, more powerful electric motors can enhance energy regeneration but may increase the system's complexity and weight.

To address these challenges, engineers are exploring innovative approaches to KERS efficiency optimization. One strategy involves the use of lightweight materials for KERS components, such as carbon fiber flywheels or advanced battery technologies. This allows for increased energy storage capacity without significantly impacting vehicle weight.

Another approach focuses on adaptive KERS strategies that dynamically adjust the system's operation based on vehicle weight and driving conditions. This can involve real-time optimization algorithms that balance energy recovery with the vehicle's instantaneous power requirements, maximizing efficiency across a range of operating conditions.

Furthermore, the integration of KERS with other vehicle systems is being explored to enhance overall efficiency. For example, combining KERS with intelligent power management systems can optimize energy distribution between regenerative braking, propulsion, and auxiliary systems, taking into account vehicle weight and size constraints.

As vehicle electrification continues to advance, the role of KERS in hybrid and electric vehicles is evolving. The integration of KERS with electric powertrains offers new opportunities for efficiency optimization, particularly in the context of varying vehicle weights and sizes. This synergy between KERS and electric propulsion systems is expected to drive further innovations in energy recovery and management technologies.

Environmental Impact of KERS

The environmental impact of Kinetic Energy Recovery Systems (KERS) is closely tied to vehicle weight and size, as these factors significantly influence the system's efficiency and overall performance. KERS technology, designed to capture and reuse kinetic energy during braking, has the potential to reduce fuel consumption and emissions across various vehicle types.

For lighter vehicles, KERS can provide substantial benefits in terms of energy recovery and fuel efficiency. The reduced mass allows for more effective energy capture during deceleration, as less energy is required to slow down the vehicle. This translates to a higher percentage of recoverable energy, which can be stored and reused for acceleration or powering auxiliary systems. Consequently, lighter vehicles equipped with KERS tend to exhibit greater improvements in fuel economy and reduced emissions.

In contrast, heavier vehicles present unique challenges and opportunities for KERS implementation. While the absolute amount of energy available for recovery during braking is higher due to greater mass, the relative efficiency of the system may be lower. Heavier vehicles require more energy to accelerate, potentially offsetting some of the gains from energy recovery. However, in urban environments with frequent stop-and-start traffic, even modest improvements in efficiency can lead to significant reductions in fuel consumption and emissions for larger vehicles.

Vehicle size also plays a crucial role in the environmental impact of KERS. Compact vehicles benefit from easier integration of KERS components, as space constraints are less restrictive. This allows for more optimal placement of energy storage systems and power electronics, potentially leading to better overall system efficiency. Larger vehicles, while facing more complex integration challenges, can accommodate larger energy storage capacities, potentially enabling greater energy recovery and utilization over longer periods.

The relationship between KERS efficiency and vehicle characteristics has important implications for environmental policy and automotive design. As regulations increasingly focus on reducing carbon emissions and improving fuel economy, manufacturers are incentivized to optimize KERS for different vehicle classes. This has led to the development of tailored KERS solutions that maximize environmental benefits across a range of vehicle weights and sizes.

Furthermore, the environmental impact of KERS extends beyond operational efficiency to consider the entire lifecycle of the system. The production and disposal of KERS components, particularly energy storage devices, must be factored into the overall environmental assessment. Lighter, more compact vehicles may require smaller KERS units, potentially reducing the environmental footprint associated with manufacturing and end-of-life processing.

In conclusion, the dependency of KERS on vehicle weight and size significantly influences its environmental impact. While generally more beneficial for lighter and smaller vehicles, advancements in KERS technology continue to expand its effectiveness across various vehicle categories, contributing to broader efforts in reducing transportation-related environmental impacts.

For lighter vehicles, KERS can provide substantial benefits in terms of energy recovery and fuel efficiency. The reduced mass allows for more effective energy capture during deceleration, as less energy is required to slow down the vehicle. This translates to a higher percentage of recoverable energy, which can be stored and reused for acceleration or powering auxiliary systems. Consequently, lighter vehicles equipped with KERS tend to exhibit greater improvements in fuel economy and reduced emissions.

In contrast, heavier vehicles present unique challenges and opportunities for KERS implementation. While the absolute amount of energy available for recovery during braking is higher due to greater mass, the relative efficiency of the system may be lower. Heavier vehicles require more energy to accelerate, potentially offsetting some of the gains from energy recovery. However, in urban environments with frequent stop-and-start traffic, even modest improvements in efficiency can lead to significant reductions in fuel consumption and emissions for larger vehicles.

Vehicle size also plays a crucial role in the environmental impact of KERS. Compact vehicles benefit from easier integration of KERS components, as space constraints are less restrictive. This allows for more optimal placement of energy storage systems and power electronics, potentially leading to better overall system efficiency. Larger vehicles, while facing more complex integration challenges, can accommodate larger energy storage capacities, potentially enabling greater energy recovery and utilization over longer periods.

The relationship between KERS efficiency and vehicle characteristics has important implications for environmental policy and automotive design. As regulations increasingly focus on reducing carbon emissions and improving fuel economy, manufacturers are incentivized to optimize KERS for different vehicle classes. This has led to the development of tailored KERS solutions that maximize environmental benefits across a range of vehicle weights and sizes.

Furthermore, the environmental impact of KERS extends beyond operational efficiency to consider the entire lifecycle of the system. The production and disposal of KERS components, particularly energy storage devices, must be factored into the overall environmental assessment. Lighter, more compact vehicles may require smaller KERS units, potentially reducing the environmental footprint associated with manufacturing and end-of-life processing.

In conclusion, the dependency of KERS on vehicle weight and size significantly influences its environmental impact. While generally more beneficial for lighter and smaller vehicles, advancements in KERS technology continue to expand its effectiveness across various vehicle categories, contributing to broader efforts in reducing transportation-related environmental impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!