How KERS integration alters conventional drivetrain systems

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

KERS Evolution & Objectives

Kinetic Energy Recovery Systems (KERS) have undergone significant evolution since their inception in motorsports, particularly in Formula 1 racing. The technology's development trajectory has been marked by continuous improvements in efficiency, power output, and integration with conventional drivetrain systems. Initially introduced as a means to recover and reuse energy that would otherwise be lost during braking, KERS has evolved from simple mechanical flywheel systems to sophisticated electric and hybrid configurations.

The primary objective of KERS integration is to enhance overall vehicle performance by capturing and repurposing kinetic energy. This aligns with broader goals of improving fuel efficiency and reducing emissions in both racing and consumer vehicles. As the technology has matured, its applications have expanded beyond motorsports into mainstream automotive engineering, contributing to the development of hybrid and electric vehicles.

In the context of conventional drivetrain systems, KERS integration represents a paradigm shift in power management and energy utilization. Traditional drivetrains rely solely on the combustion engine for power generation and transmission. The introduction of KERS creates a dual power source system, where recovered energy can be used to supplement the main engine's output during acceleration or to power auxiliary systems.

The evolution of KERS has seen advancements in energy storage technologies, moving from mechanical flywheels to high-capacity batteries and supercapacitors. This progression has enabled greater energy recovery and storage capabilities, allowing for more significant power boosts and extended periods of electric-only operation in hybrid systems.

A key objective in KERS development has been seamless integration with existing drivetrain components. This has led to innovations in power electronics, control systems, and mechanical interfaces. Engineers have focused on minimizing the weight and space requirements of KERS components while maximizing their energy recovery and deployment efficiency.

The integration of KERS has also driven advancements in regenerative braking systems, a critical component in energy recovery. These systems have become increasingly sophisticated, capable of capturing a higher percentage of kinetic energy during deceleration and converting it into usable electrical power.

Looking forward, the objectives for KERS integration include further improvements in energy density, system efficiency, and cost-effectiveness. There is a growing emphasis on developing KERS solutions that can be easily adapted to various vehicle types and drivetrain configurations, from high-performance sports cars to everyday commuter vehicles. This adaptability is crucial for the widespread adoption of KERS technology in the automotive industry.

The primary objective of KERS integration is to enhance overall vehicle performance by capturing and repurposing kinetic energy. This aligns with broader goals of improving fuel efficiency and reducing emissions in both racing and consumer vehicles. As the technology has matured, its applications have expanded beyond motorsports into mainstream automotive engineering, contributing to the development of hybrid and electric vehicles.

In the context of conventional drivetrain systems, KERS integration represents a paradigm shift in power management and energy utilization. Traditional drivetrains rely solely on the combustion engine for power generation and transmission. The introduction of KERS creates a dual power source system, where recovered energy can be used to supplement the main engine's output during acceleration or to power auxiliary systems.

The evolution of KERS has seen advancements in energy storage technologies, moving from mechanical flywheels to high-capacity batteries and supercapacitors. This progression has enabled greater energy recovery and storage capabilities, allowing for more significant power boosts and extended periods of electric-only operation in hybrid systems.

A key objective in KERS development has been seamless integration with existing drivetrain components. This has led to innovations in power electronics, control systems, and mechanical interfaces. Engineers have focused on minimizing the weight and space requirements of KERS components while maximizing their energy recovery and deployment efficiency.

The integration of KERS has also driven advancements in regenerative braking systems, a critical component in energy recovery. These systems have become increasingly sophisticated, capable of capturing a higher percentage of kinetic energy during deceleration and converting it into usable electrical power.

Looking forward, the objectives for KERS integration include further improvements in energy density, system efficiency, and cost-effectiveness. There is a growing emphasis on developing KERS solutions that can be easily adapted to various vehicle types and drivetrain configurations, from high-performance sports cars to everyday commuter vehicles. This adaptability is crucial for the widespread adoption of KERS technology in the automotive industry.

Market Demand Analysis

The integration of Kinetic Energy Recovery Systems (KERS) into conventional drivetrain systems has sparked significant market interest and demand across various sectors of the automotive industry. This technology, initially developed for Formula 1 racing, has found its way into mainstream vehicle production, driven by the increasing focus on fuel efficiency and environmental sustainability.

In the passenger vehicle market, there is a growing demand for KERS-equipped vehicles, particularly in hybrid and electric models. Consumers are increasingly conscious of fuel economy and environmental impact, leading to a surge in interest for vehicles that can capture and reuse energy typically lost during braking. This demand is further bolstered by government regulations and incentives aimed at reducing carbon emissions and promoting cleaner transportation technologies.

The commercial vehicle sector has also shown considerable interest in KERS integration. Fleet operators are keen on reducing fuel costs and meeting stringent emissions standards, making KERS an attractive option for trucks, buses, and delivery vehicles. The potential for significant fuel savings in stop-start urban driving conditions has been a key driver for adoption in this segment.

In the high-performance and luxury vehicle markets, KERS is viewed as a cutting-edge technology that enhances both performance and efficiency. Manufacturers in these segments are incorporating KERS to meet customer expectations for advanced technology while also addressing regulatory pressures for improved fuel economy.

The motorsport industry continues to be a significant driver of KERS development and adoption. Beyond Formula 1, other racing series are exploring or implementing KERS, creating a trickle-down effect that influences consumer vehicle technology and market demand.

Public transportation systems, particularly in urban areas, are showing increased interest in KERS technology. Bus manufacturers and transit authorities are exploring KERS as a means to reduce fuel consumption and emissions in city environments characterized by frequent stops and starts.

The market for KERS components and systems is also expanding, with suppliers reporting increased demand for energy storage solutions, power electronics, and control systems specific to KERS applications. This has led to the emergence of specialized KERS suppliers and has prompted traditional automotive component manufacturers to diversify their product offerings.

As the technology matures and becomes more cost-effective, industry analysts project a significant growth in the KERS market over the next decade. This growth is expected to be driven by continued advancements in energy storage technologies, increasing environmental regulations, and the ongoing push for improved vehicle efficiency across all segments of the automotive industry.

In the passenger vehicle market, there is a growing demand for KERS-equipped vehicles, particularly in hybrid and electric models. Consumers are increasingly conscious of fuel economy and environmental impact, leading to a surge in interest for vehicles that can capture and reuse energy typically lost during braking. This demand is further bolstered by government regulations and incentives aimed at reducing carbon emissions and promoting cleaner transportation technologies.

The commercial vehicle sector has also shown considerable interest in KERS integration. Fleet operators are keen on reducing fuel costs and meeting stringent emissions standards, making KERS an attractive option for trucks, buses, and delivery vehicles. The potential for significant fuel savings in stop-start urban driving conditions has been a key driver for adoption in this segment.

In the high-performance and luxury vehicle markets, KERS is viewed as a cutting-edge technology that enhances both performance and efficiency. Manufacturers in these segments are incorporating KERS to meet customer expectations for advanced technology while also addressing regulatory pressures for improved fuel economy.

The motorsport industry continues to be a significant driver of KERS development and adoption. Beyond Formula 1, other racing series are exploring or implementing KERS, creating a trickle-down effect that influences consumer vehicle technology and market demand.

Public transportation systems, particularly in urban areas, are showing increased interest in KERS technology. Bus manufacturers and transit authorities are exploring KERS as a means to reduce fuel consumption and emissions in city environments characterized by frequent stops and starts.

The market for KERS components and systems is also expanding, with suppliers reporting increased demand for energy storage solutions, power electronics, and control systems specific to KERS applications. This has led to the emergence of specialized KERS suppliers and has prompted traditional automotive component manufacturers to diversify their product offerings.

As the technology matures and becomes more cost-effective, industry analysts project a significant growth in the KERS market over the next decade. This growth is expected to be driven by continued advancements in energy storage technologies, increasing environmental regulations, and the ongoing push for improved vehicle efficiency across all segments of the automotive industry.

KERS Tech Challenges

The integration of Kinetic Energy Recovery Systems (KERS) into conventional drivetrain systems presents several significant technical challenges. One of the primary obstacles is the seamless integration of the KERS components with existing drivetrain architecture. This requires careful consideration of space constraints, weight distribution, and the overall vehicle dynamics.

A major challenge lies in the energy storage system. KERS typically utilizes either high-speed flywheels or advanced battery systems to store recovered energy. Flywheel-based systems face issues related to gyroscopic effects, which can impact vehicle handling, especially during cornering. Battery-based systems, on the other hand, must contend with thermal management issues, as rapid charge and discharge cycles generate significant heat.

The control system for KERS integration poses another substantial challenge. Developing algorithms that can efficiently manage energy recovery, storage, and deployment while maintaining optimal vehicle performance and driver comfort is a complex task. This system must seamlessly coordinate with existing engine management and traction control systems, adding another layer of complexity to the drivetrain's electronic architecture.

Durability and reliability of KERS components in the harsh automotive environment present ongoing challenges. The system must withstand vibrations, temperature fluctuations, and potential impacts while maintaining consistent performance over the vehicle's lifetime. This necessitates robust design and extensive testing protocols.

Weight management is a critical concern in KERS integration. While the system offers energy recovery benefits, it also adds mass to the vehicle. Engineers must carefully balance the weight of KERS components against the energy efficiency gains to ensure a net positive impact on vehicle performance and fuel economy.

Another significant challenge is the cost-effectiveness of KERS integration. The additional components and complexity increase the overall cost of the drivetrain system. Manufacturers must find ways to optimize production processes and reduce costs to make KERS-equipped vehicles commercially viable for mass-market adoption.

Lastly, safety considerations present a unique set of challenges. High-speed flywheels pose potential risks in the event of a crash, requiring robust containment systems. For battery-based systems, electrical safety and the prevention of thermal runaway are paramount concerns that demand innovative solutions and rigorous safety protocols.

A major challenge lies in the energy storage system. KERS typically utilizes either high-speed flywheels or advanced battery systems to store recovered energy. Flywheel-based systems face issues related to gyroscopic effects, which can impact vehicle handling, especially during cornering. Battery-based systems, on the other hand, must contend with thermal management issues, as rapid charge and discharge cycles generate significant heat.

The control system for KERS integration poses another substantial challenge. Developing algorithms that can efficiently manage energy recovery, storage, and deployment while maintaining optimal vehicle performance and driver comfort is a complex task. This system must seamlessly coordinate with existing engine management and traction control systems, adding another layer of complexity to the drivetrain's electronic architecture.

Durability and reliability of KERS components in the harsh automotive environment present ongoing challenges. The system must withstand vibrations, temperature fluctuations, and potential impacts while maintaining consistent performance over the vehicle's lifetime. This necessitates robust design and extensive testing protocols.

Weight management is a critical concern in KERS integration. While the system offers energy recovery benefits, it also adds mass to the vehicle. Engineers must carefully balance the weight of KERS components against the energy efficiency gains to ensure a net positive impact on vehicle performance and fuel economy.

Another significant challenge is the cost-effectiveness of KERS integration. The additional components and complexity increase the overall cost of the drivetrain system. Manufacturers must find ways to optimize production processes and reduce costs to make KERS-equipped vehicles commercially viable for mass-market adoption.

Lastly, safety considerations present a unique set of challenges. High-speed flywheels pose potential risks in the event of a crash, requiring robust containment systems. For battery-based systems, electrical safety and the prevention of thermal runaway are paramount concerns that demand innovative solutions and rigorous safety protocols.

Current KERS Solutions

01 KERS integration in vehicle drivetrains

KERS systems are integrated into vehicle drivetrains to recover and store kinetic energy during braking, which can then be used to boost acceleration or improve fuel efficiency. These systems typically involve a motor-generator unit, energy storage device, and control systems to manage energy flow between the drivetrain and storage.- KERS integration in hybrid drivetrains: KERS is integrated into hybrid drivetrain systems to recover and store kinetic energy during braking. This energy is then used to assist acceleration, improving overall vehicle efficiency. The system typically includes an energy storage device, such as a flywheel or battery, and a mechanism to transfer energy between the drivetrain and storage device.

- Flywheel-based KERS systems: Flywheel-based KERS systems use a high-speed rotating mass to store kinetic energy. These systems offer rapid energy storage and release, making them particularly suitable for applications requiring frequent acceleration and deceleration. The flywheel is typically connected to the drivetrain through a continuously variable transmission or electric motor-generator.

- Electric KERS systems: Electric KERS systems use electric motor-generators to convert kinetic energy into electrical energy during braking. This energy is stored in batteries or supercapacitors and later used for propulsion. These systems are often integrated with existing electric or hybrid powertrains, offering seamless energy recovery and deployment.

- KERS control strategies: Advanced control strategies are employed to optimize KERS performance in various driving conditions. These strategies manage energy flow between the KERS, drivetrain, and other vehicle systems. They consider factors such as vehicle speed, battery state of charge, and driver input to maximize efficiency and performance while ensuring smooth operation.

- KERS applications in heavy vehicles: KERS technology is being adapted for use in heavy vehicles such as trucks and buses. These applications often involve larger energy storage capacities and more robust components to handle the increased loads. The systems are designed to recover significant amounts of energy during frequent stops or downhill operations, leading to substantial fuel savings in urban or hilly environments.

02 Energy storage technologies for KERS

Various energy storage technologies are employed in KERS drivetrain systems, including high-power batteries, supercapacitors, and flywheels. Each technology offers different characteristics in terms of power density, energy density, and response time, allowing for optimization based on specific vehicle requirements and applications.Expand Specific Solutions03 Control strategies for KERS drivetrains

Advanced control strategies are developed to optimize the performance of KERS drivetrain systems. These strategies focus on managing energy recuperation, storage, and deployment to maximize efficiency and performance. They often involve predictive algorithms, real-time adaptation, and integration with other vehicle systems.Expand Specific Solutions04 KERS applications in hybrid and electric vehicles

KERS drivetrain systems are particularly relevant in hybrid and electric vehicle architectures. They complement traditional powertrains by providing additional power for acceleration, enabling engine downsizing, and improving overall vehicle efficiency. Integration challenges include packaging, weight distribution, and thermal management.Expand Specific Solutions05 Innovative KERS designs for specific applications

Novel KERS drivetrain designs are developed for specific vehicle types or operating conditions. These may include systems optimized for heavy-duty vehicles, high-performance sports cars, or off-road applications. Innovations focus on improving power density, reducing system complexity, and enhancing durability.Expand Specific Solutions

Key KERS Manufacturers

The integration of Kinetic Energy Recovery Systems (KERS) into conventional drivetrain systems is currently in a transitional phase, with the market showing significant growth potential. The technology's maturity varies across different applications, ranging from Formula 1 racing to commercial vehicles. Companies like Punch Flybrid Ltd, Brembo SpA, and Hyliion, Inc. are at the forefront of KERS development, while established automotive giants such as Volvo Lastvagnar AB and ZF Friedrichshafen AG are incorporating KERS into their existing drivetrain systems. The market is characterized by a mix of specialized KERS developers and traditional automotive manufacturers, indicating a competitive landscape that balances innovation with established industry expertise.

Punch Flybrid Ltd

Technical Solution: Punch Flybrid Ltd has developed an advanced KERS (Kinetic Energy Recovery System) that integrates seamlessly with conventional drivetrain systems. Their technology utilizes a high-speed flywheel to store and release energy, providing significant improvements in fuel efficiency and performance. The system can capture up to 70% of the vehicle's kinetic energy during braking[1], which is then stored in a carbon fiber flywheel spinning at up to 60,000 RPM[2]. This stored energy can be rapidly deployed to boost acceleration or power auxiliary systems, reducing the load on the main engine. Punch Flybrid's KERS can be adapted to various vehicle types, from passenger cars to commercial vehicles and even off-highway equipment[3].

Strengths: High energy storage capacity, rapid power delivery, and adaptability to various vehicle types. Weaknesses: Complexity of integration with existing drivetrains and potential safety concerns with high-speed rotating components.

ZF Friedrichshafen AG

Technical Solution: ZF Friedrichshafen AG has developed an innovative KERS solution that integrates with conventional drivetrain systems, focusing on commercial vehicles and buses. Their system, known as ZF EcoLife 2, combines a hybrid module with an automatic transmission, allowing for energy recovery during braking and coasting. The recovered energy is stored in a compact, high-performance battery system. ZF's KERS can provide an electric boost of up to 120 kW, significantly reducing fuel consumption and emissions[4]. The system also enables electric-only operation for short distances, making it ideal for urban environments. ZF's technology seamlessly switches between combustion engine and electric motor, optimizing efficiency across various driving conditions[5].

Strengths: Seamless integration with existing transmissions, high power output, and suitability for commercial vehicles. Weaknesses: Limited electric-only range and potential complexity in maintenance.

KERS Patent Innovations

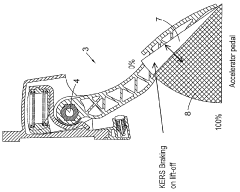

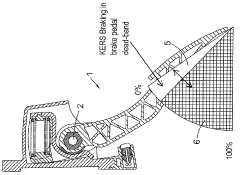

Driver interface for a kinetic energy recovery system

PatentActiveGB2530841A

Innovation

- A driver interface with dual operating zones on the brake and accelerator pedals allows for progressive control of KERS braking and power transfer, enabling intuitive energy harvesting and reuse, prioritizing KERS braking at the top pedal positions and incorporating engine and foundation braking for enhanced control.

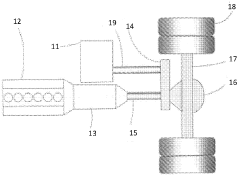

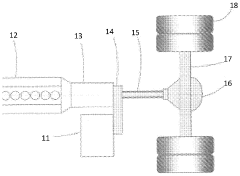

Kinetic energy recovery system for a vehicle

PatentInactiveGB2559203A

Innovation

- A KERS with a power-split arrangement using a hydrostatic continuously variable transmission (CVT) and an epicyclic gearset, which includes both a variable and fixed ratio path in parallel, allowing for increased efficiency and flexibility by minimizing power loss through a torque summing junction, enabling energy recovery even when the vehicle is stationary without the need for a clutch or disconnect.

Drivetrain Modification

The integration of Kinetic Energy Recovery Systems (KERS) into conventional drivetrain systems represents a significant shift in automotive engineering, necessitating substantial modifications to traditional powertrain configurations. This integration primarily affects the mechanical and electrical components of the drivetrain, requiring careful redesign and optimization to accommodate the new energy recovery and deployment mechanisms.

In conventional drivetrains, the power flow is typically unidirectional, moving from the engine through the transmission to the wheels. With KERS integration, this flow becomes bidirectional, allowing energy to be captured during deceleration and redeployed during acceleration. This fundamental change requires the addition of new components and the modification of existing ones.

One of the most significant alterations is the integration of an electric motor-generator unit. This component is typically coupled to the drivetrain, often at the transmission input or output shaft. The placement of this unit is crucial, as it affects the system's efficiency and the vehicle's weight distribution. In some designs, multiple motor-generator units may be employed, further complicating the drivetrain layout.

The transmission itself often requires modification to accommodate the additional torque input from the KERS. This may involve strengthening certain components, redesigning gear ratios, or even developing entirely new transmission types optimized for hybrid powertrains. Continuously Variable Transmissions (CVTs) have gained popularity in KERS-equipped vehicles due to their ability to maintain optimal engine speeds during energy recovery and deployment.

Power electronics and control systems are another critical area of modification. These systems manage the flow of electrical energy between the motor-generator, energy storage system (typically a battery or supercapacitor), and the vehicle's electrical systems. The integration of these components requires careful consideration of packaging, cooling, and electromagnetic compatibility.

The drivetrain's cooling system also requires significant modification to handle the additional heat generated by the KERS components, particularly the motor-generator and power electronics. This often involves the addition of separate cooling circuits or the expansion of existing ones.

Furthermore, the integration of KERS necessitates changes to the vehicle's braking system. Regenerative braking, a key feature of KERS, requires a blending system that seamlessly transitions between electrical and mechanical braking. This system must be carefully calibrated to ensure optimal energy recovery without compromising braking performance or driver feel.

Lastly, the drivetrain's mounting and support structures often require reinforcement or redesign to accommodate the additional weight and altered load paths introduced by the KERS components. This may involve changes to subframes, engine mounts, and other structural elements of the vehicle.

In conventional drivetrains, the power flow is typically unidirectional, moving from the engine through the transmission to the wheels. With KERS integration, this flow becomes bidirectional, allowing energy to be captured during deceleration and redeployed during acceleration. This fundamental change requires the addition of new components and the modification of existing ones.

One of the most significant alterations is the integration of an electric motor-generator unit. This component is typically coupled to the drivetrain, often at the transmission input or output shaft. The placement of this unit is crucial, as it affects the system's efficiency and the vehicle's weight distribution. In some designs, multiple motor-generator units may be employed, further complicating the drivetrain layout.

The transmission itself often requires modification to accommodate the additional torque input from the KERS. This may involve strengthening certain components, redesigning gear ratios, or even developing entirely new transmission types optimized for hybrid powertrains. Continuously Variable Transmissions (CVTs) have gained popularity in KERS-equipped vehicles due to their ability to maintain optimal engine speeds during energy recovery and deployment.

Power electronics and control systems are another critical area of modification. These systems manage the flow of electrical energy between the motor-generator, energy storage system (typically a battery or supercapacitor), and the vehicle's electrical systems. The integration of these components requires careful consideration of packaging, cooling, and electromagnetic compatibility.

The drivetrain's cooling system also requires significant modification to handle the additional heat generated by the KERS components, particularly the motor-generator and power electronics. This often involves the addition of separate cooling circuits or the expansion of existing ones.

Furthermore, the integration of KERS necessitates changes to the vehicle's braking system. Regenerative braking, a key feature of KERS, requires a blending system that seamlessly transitions between electrical and mechanical braking. This system must be carefully calibrated to ensure optimal energy recovery without compromising braking performance or driver feel.

Lastly, the drivetrain's mounting and support structures often require reinforcement or redesign to accommodate the additional weight and altered load paths introduced by the KERS components. This may involve changes to subframes, engine mounts, and other structural elements of the vehicle.

Energy Efficiency Impact

The integration of Kinetic Energy Recovery Systems (KERS) into conventional drivetrain systems has a significant impact on energy efficiency in vehicles. KERS technology captures and stores kinetic energy that would otherwise be lost during braking, allowing it to be redeployed to boost acceleration or reduce fuel consumption. This innovative approach to energy management has led to substantial improvements in overall vehicle efficiency.

One of the primary benefits of KERS integration is the reduction in fuel consumption. By harnessing energy that would typically be dissipated as heat during braking, KERS enables vehicles to utilize this recovered energy for propulsion. This results in less reliance on the internal combustion engine, particularly during acceleration phases, which are typically the most fuel-intensive. Studies have shown that KERS can contribute to fuel savings of up to 25% in urban driving conditions, where frequent braking and acceleration occur.

The energy efficiency impact of KERS extends beyond fuel savings to overall powertrain optimization. By providing an additional source of power, KERS allows for downsizing of the main engine without compromising performance. This reduction in engine size leads to decreased weight and improved aerodynamics, further enhancing the vehicle's efficiency. Additionally, the integration of KERS enables more precise control over power delivery, allowing for smoother and more efficient acceleration profiles.

In hybrid and electric vehicles, KERS integration plays a crucial role in extending the range and improving overall energy management. The system's ability to capture and store energy during deceleration complements the regenerative braking capabilities of electric motors, maximizing the amount of energy that can be recovered. This synergy between KERS and electric powertrains contributes to increased efficiency and reduced reliance on external charging, particularly in urban environments.

The impact of KERS on energy efficiency is not limited to passenger vehicles. In motorsports, particularly Formula 1, KERS has demonstrated its ability to significantly enhance performance while adhering to strict fuel consumption regulations. The technology's success in high-performance applications has driven further development and refinement, leading to more efficient and compact systems that are increasingly viable for mass-market vehicles.

As KERS technology continues to evolve, its integration with conventional drivetrain systems is expected to yield even greater energy efficiency gains. Advancements in energy storage technologies, such as high-performance capacitors and improved battery systems, will enhance the capacity and effectiveness of KERS. Furthermore, the development of more sophisticated control algorithms will optimize the interplay between KERS and other drivetrain components, maximizing energy recovery and utilization across various driving conditions.

One of the primary benefits of KERS integration is the reduction in fuel consumption. By harnessing energy that would typically be dissipated as heat during braking, KERS enables vehicles to utilize this recovered energy for propulsion. This results in less reliance on the internal combustion engine, particularly during acceleration phases, which are typically the most fuel-intensive. Studies have shown that KERS can contribute to fuel savings of up to 25% in urban driving conditions, where frequent braking and acceleration occur.

The energy efficiency impact of KERS extends beyond fuel savings to overall powertrain optimization. By providing an additional source of power, KERS allows for downsizing of the main engine without compromising performance. This reduction in engine size leads to decreased weight and improved aerodynamics, further enhancing the vehicle's efficiency. Additionally, the integration of KERS enables more precise control over power delivery, allowing for smoother and more efficient acceleration profiles.

In hybrid and electric vehicles, KERS integration plays a crucial role in extending the range and improving overall energy management. The system's ability to capture and store energy during deceleration complements the regenerative braking capabilities of electric motors, maximizing the amount of energy that can be recovered. This synergy between KERS and electric powertrains contributes to increased efficiency and reduced reliance on external charging, particularly in urban environments.

The impact of KERS on energy efficiency is not limited to passenger vehicles. In motorsports, particularly Formula 1, KERS has demonstrated its ability to significantly enhance performance while adhering to strict fuel consumption regulations. The technology's success in high-performance applications has driven further development and refinement, leading to more efficient and compact systems that are increasingly viable for mass-market vehicles.

As KERS technology continues to evolve, its integration with conventional drivetrain systems is expected to yield even greater energy efficiency gains. Advancements in energy storage technologies, such as high-performance capacitors and improved battery systems, will enhance the capacity and effectiveness of KERS. Furthermore, the development of more sophisticated control algorithms will optimize the interplay between KERS and other drivetrain components, maximizing energy recovery and utilization across various driving conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!