Long-term efficiency impacts of KERS in fleet vehicles

AUG 15, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

KERS Evolution & Goals

Kinetic Energy Recovery Systems (KERS) have evolved significantly since their inception in the automotive industry. Initially developed for Formula 1 racing in the late 2000s, KERS technology has gradually transitioned into mainstream vehicle applications, including fleet vehicles. The primary goal of KERS is to capture and store kinetic energy that would otherwise be lost during braking, and then use this energy to boost acceleration or power auxiliary systems.

The evolution of KERS in fleet vehicles has been driven by the increasing demand for fuel efficiency and reduced emissions in commercial transportation. Early KERS systems were primarily mechanical, using flywheels to store energy. However, as technology advanced, electric and hydraulic KERS variants emerged, offering improved efficiency and integration with vehicle systems.

A key milestone in KERS development was the shift from purely performance-oriented applications to those focused on long-term efficiency gains. This transition aligned with the growing emphasis on sustainable transportation solutions and the need to optimize fleet operations. As a result, KERS technology has been adapted to meet the specific requirements of various fleet vehicle types, including delivery vans, buses, and long-haul trucks.

The goals of KERS implementation in fleet vehicles have expanded beyond simple energy recovery. Modern systems aim to provide a holistic approach to vehicle efficiency, integrating with other technologies such as regenerative braking, start-stop systems, and intelligent power management. The long-term objectives include significant reductions in fuel consumption, lower maintenance costs, and extended vehicle lifespan through reduced wear on conventional braking systems.

Another important goal in the evolution of KERS for fleet vehicles is the optimization of system weight and packaging. As fleets prioritize payload capacity and vehicle versatility, KERS developers have focused on creating more compact and lightweight solutions that do not compromise cargo space or vehicle dynamics. This has led to innovations in energy storage technologies, such as high-power density batteries and ultra-capacitors, which offer rapid charge and discharge capabilities crucial for the stop-start nature of many fleet operations.

Looking forward, the evolution of KERS in fleet vehicles is expected to continue, with a focus on seamless integration with electric and hybrid powertrains. The goal is to create synergistic systems that maximize energy efficiency across all aspects of vehicle operation. Additionally, there is a growing interest in developing KERS solutions that can be retrofitted to existing fleet vehicles, allowing for broader adoption and immediate efficiency gains without the need for complete fleet replacement.

The evolution of KERS in fleet vehicles has been driven by the increasing demand for fuel efficiency and reduced emissions in commercial transportation. Early KERS systems were primarily mechanical, using flywheels to store energy. However, as technology advanced, electric and hydraulic KERS variants emerged, offering improved efficiency and integration with vehicle systems.

A key milestone in KERS development was the shift from purely performance-oriented applications to those focused on long-term efficiency gains. This transition aligned with the growing emphasis on sustainable transportation solutions and the need to optimize fleet operations. As a result, KERS technology has been adapted to meet the specific requirements of various fleet vehicle types, including delivery vans, buses, and long-haul trucks.

The goals of KERS implementation in fleet vehicles have expanded beyond simple energy recovery. Modern systems aim to provide a holistic approach to vehicle efficiency, integrating with other technologies such as regenerative braking, start-stop systems, and intelligent power management. The long-term objectives include significant reductions in fuel consumption, lower maintenance costs, and extended vehicle lifespan through reduced wear on conventional braking systems.

Another important goal in the evolution of KERS for fleet vehicles is the optimization of system weight and packaging. As fleets prioritize payload capacity and vehicle versatility, KERS developers have focused on creating more compact and lightweight solutions that do not compromise cargo space or vehicle dynamics. This has led to innovations in energy storage technologies, such as high-power density batteries and ultra-capacitors, which offer rapid charge and discharge capabilities crucial for the stop-start nature of many fleet operations.

Looking forward, the evolution of KERS in fleet vehicles is expected to continue, with a focus on seamless integration with electric and hybrid powertrains. The goal is to create synergistic systems that maximize energy efficiency across all aspects of vehicle operation. Additionally, there is a growing interest in developing KERS solutions that can be retrofitted to existing fleet vehicles, allowing for broader adoption and immediate efficiency gains without the need for complete fleet replacement.

Fleet Vehicle Market

The fleet vehicle market has experienced significant growth and transformation in recent years, driven by technological advancements, changing business models, and increasing focus on sustainability. This market segment encompasses a wide range of vehicles used for commercial purposes, including delivery vans, trucks, buses, and service vehicles.

The global fleet vehicle market size was valued at approximately $700 billion in 2020 and is projected to reach over $1 trillion by 2028, growing at a CAGR of around 5-6% during the forecast period. This growth is primarily attributed to the rising demand for efficient transportation solutions, the expansion of e-commerce and last-mile delivery services, and the increasing adoption of advanced technologies in fleet management.

One of the key trends shaping the fleet vehicle market is the shift towards electrification and alternative fuel vehicles. As governments worldwide implement stricter emissions regulations and offer incentives for clean energy adoption, fleet operators are increasingly investing in electric and hybrid vehicles to reduce their carbon footprint and operational costs. This transition is particularly evident in urban areas, where concerns about air quality and noise pollution are driving the adoption of zero-emission vehicles for last-mile deliveries and public transportation.

Another significant factor influencing the fleet vehicle market is the integration of telematics and connected vehicle technologies. These solutions enable fleet managers to optimize route planning, monitor vehicle performance, and improve driver behavior, resulting in enhanced operational efficiency and reduced fuel consumption. The adoption of advanced analytics and artificial intelligence is further revolutionizing fleet management practices, allowing for predictive maintenance and real-time decision-making.

The market is also witnessing a growing interest in mobility-as-a-service (MaaS) solutions, with some fleet operators exploring new business models such as vehicle sharing and flexible leasing options. This trend is particularly prevalent in urban areas, where businesses are seeking more cost-effective and adaptable transportation solutions to meet their evolving needs.

Geographically, North America and Europe currently dominate the fleet vehicle market, owing to their well-established automotive industries and advanced infrastructure. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid urbanization, expanding e-commerce sectors, and increasing investments in transportation infrastructure.

The global fleet vehicle market size was valued at approximately $700 billion in 2020 and is projected to reach over $1 trillion by 2028, growing at a CAGR of around 5-6% during the forecast period. This growth is primarily attributed to the rising demand for efficient transportation solutions, the expansion of e-commerce and last-mile delivery services, and the increasing adoption of advanced technologies in fleet management.

One of the key trends shaping the fleet vehicle market is the shift towards electrification and alternative fuel vehicles. As governments worldwide implement stricter emissions regulations and offer incentives for clean energy adoption, fleet operators are increasingly investing in electric and hybrid vehicles to reduce their carbon footprint and operational costs. This transition is particularly evident in urban areas, where concerns about air quality and noise pollution are driving the adoption of zero-emission vehicles for last-mile deliveries and public transportation.

Another significant factor influencing the fleet vehicle market is the integration of telematics and connected vehicle technologies. These solutions enable fleet managers to optimize route planning, monitor vehicle performance, and improve driver behavior, resulting in enhanced operational efficiency and reduced fuel consumption. The adoption of advanced analytics and artificial intelligence is further revolutionizing fleet management practices, allowing for predictive maintenance and real-time decision-making.

The market is also witnessing a growing interest in mobility-as-a-service (MaaS) solutions, with some fleet operators exploring new business models such as vehicle sharing and flexible leasing options. This trend is particularly prevalent in urban areas, where businesses are seeking more cost-effective and adaptable transportation solutions to meet their evolving needs.

Geographically, North America and Europe currently dominate the fleet vehicle market, owing to their well-established automotive industries and advanced infrastructure. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid urbanization, expanding e-commerce sectors, and increasing investments in transportation infrastructure.

KERS Challenges

Kinetic Energy Recovery Systems (KERS) in fleet vehicles face several significant challenges that impact their long-term efficiency and widespread adoption. One of the primary obstacles is the system's weight and complexity, which can offset fuel savings, especially in lighter vehicles. The additional components required for KERS, such as flywheels or electric motors and batteries, increase the overall vehicle weight, potentially reducing fuel efficiency in certain driving conditions.

Durability and maintenance issues also pose substantial challenges for KERS in fleet applications. The frequent start-stop cycles and high-stress environments typical in fleet operations can lead to increased wear on KERS components. This results in higher maintenance costs and potential downtime, which can negate the efficiency gains and cost savings promised by the technology.

The integration of KERS with existing vehicle systems presents another hurdle. Retrofitting KERS to existing fleet vehicles can be complex and expensive, while designing new vehicles around KERS technology requires significant investment in research and development. This integration challenge extends to the need for specialized training for maintenance personnel and drivers to effectively operate and service KERS-equipped vehicles.

Cost remains a significant barrier to widespread KERS adoption in fleet vehicles. The initial investment for KERS technology can be substantial, and the return on investment period may be longer than fleet operators are willing to accept, especially for smaller operations with tighter budgets. This economic challenge is compounded by the uncertainty of long-term performance and the potential for unforeseen maintenance costs.

Energy storage limitations also present ongoing challenges for KERS efficiency. Current energy storage technologies, whether using flywheels, batteries, or hydraulic systems, have limitations in terms of capacity and efficiency. These limitations can restrict the amount of energy that can be recovered and reused, particularly in heavy-duty fleet applications where energy demands are high.

Environmental factors and driving conditions significantly impact KERS performance. The system's efficiency can vary greatly depending on the route profile, traffic conditions, and driving style. Urban environments with frequent stops may benefit more from KERS, while highway driving might see minimal gains, making it challenging to achieve consistent efficiency improvements across diverse fleet operations.

Regulatory and safety concerns add another layer of complexity to KERS implementation. Safety standards for high-speed rotating flywheels or high-voltage electrical systems must be rigorously addressed, potentially adding cost and complexity to vehicle design and maintenance procedures. Additionally, evolving emissions regulations and fuel efficiency standards may influence the cost-benefit analysis of KERS adoption in fleet vehicles.

Durability and maintenance issues also pose substantial challenges for KERS in fleet applications. The frequent start-stop cycles and high-stress environments typical in fleet operations can lead to increased wear on KERS components. This results in higher maintenance costs and potential downtime, which can negate the efficiency gains and cost savings promised by the technology.

The integration of KERS with existing vehicle systems presents another hurdle. Retrofitting KERS to existing fleet vehicles can be complex and expensive, while designing new vehicles around KERS technology requires significant investment in research and development. This integration challenge extends to the need for specialized training for maintenance personnel and drivers to effectively operate and service KERS-equipped vehicles.

Cost remains a significant barrier to widespread KERS adoption in fleet vehicles. The initial investment for KERS technology can be substantial, and the return on investment period may be longer than fleet operators are willing to accept, especially for smaller operations with tighter budgets. This economic challenge is compounded by the uncertainty of long-term performance and the potential for unforeseen maintenance costs.

Energy storage limitations also present ongoing challenges for KERS efficiency. Current energy storage technologies, whether using flywheels, batteries, or hydraulic systems, have limitations in terms of capacity and efficiency. These limitations can restrict the amount of energy that can be recovered and reused, particularly in heavy-duty fleet applications where energy demands are high.

Environmental factors and driving conditions significantly impact KERS performance. The system's efficiency can vary greatly depending on the route profile, traffic conditions, and driving style. Urban environments with frequent stops may benefit more from KERS, while highway driving might see minimal gains, making it challenging to achieve consistent efficiency improvements across diverse fleet operations.

Regulatory and safety concerns add another layer of complexity to KERS implementation. Safety standards for high-speed rotating flywheels or high-voltage electrical systems must be rigorously addressed, potentially adding cost and complexity to vehicle design and maintenance procedures. Additionally, evolving emissions regulations and fuel efficiency standards may influence the cost-benefit analysis of KERS adoption in fleet vehicles.

Current KERS Solutions

01 Energy storage and conversion efficiency

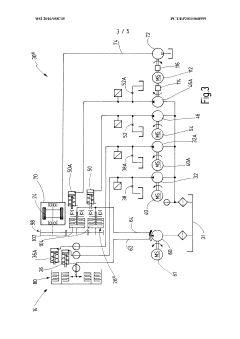

KERS efficiency is largely dependent on the system's ability to store and convert kinetic energy. This involves optimizing energy capture during braking, minimizing losses during energy conversion, and improving the efficiency of energy release during acceleration. Advanced storage technologies and high-efficiency power electronics play crucial roles in enhancing overall system performance.- Energy storage and conversion efficiency: KERS efficiency is largely dependent on the system's ability to store and convert kinetic energy. This involves optimizing energy capture during braking, minimizing losses during energy conversion, and improving the overall efficiency of energy storage devices such as flywheels or batteries. Advanced materials and designs are employed to reduce friction and heat losses, thereby increasing the system's overall efficiency.

- Integration with vehicle systems: Efficient KERS implementation requires seamless integration with other vehicle systems. This includes optimizing the interaction between KERS and the powertrain, braking system, and vehicle control units. Advanced control algorithms and sensors are used to manage energy flow, ensuring optimal energy recovery and deployment based on driving conditions and vehicle state.

- Hybrid and electric vehicle applications: KERS efficiency is particularly crucial in hybrid and electric vehicles. In these applications, the system is designed to work in conjunction with electric motors and batteries, maximizing energy recovery during deceleration and providing additional power during acceleration. This integration helps to extend the vehicle's range and improve overall energy efficiency.

- Mechanical KERS optimization: Mechanical KERS systems, often using flywheels, focus on improving efficiency through advanced materials, bearings, and vacuum technologies. These improvements aim to reduce energy losses due to friction and air resistance, allowing for higher energy storage capacities and faster energy transfer rates. The design of the flywheel and its housing is critical to achieving high efficiency in mechanical KERS.

- Control strategies for KERS efficiency: Sophisticated control strategies are employed to maximize KERS efficiency. These include predictive algorithms that anticipate braking events, adaptive systems that adjust energy recovery based on driving conditions, and intelligent power management systems that optimize energy distribution between KERS and other vehicle systems. Machine learning and AI techniques are increasingly used to refine these control strategies.

02 Hybrid and electric vehicle integration

Integrating KERS with hybrid and electric vehicle powertrains can significantly improve overall vehicle efficiency. This integration involves optimizing the interaction between the KERS, electric motors, and internal combustion engines to maximize energy recovery and utilization. Advanced control strategies and power management systems are key to achieving seamless integration and enhanced efficiency.Expand Specific Solutions03 Mechanical KERS designs

Mechanical KERS designs, such as flywheel-based systems, offer unique advantages in terms of energy density and rapid power transfer. Improving the efficiency of mechanical KERS involves optimizing flywheel design, reducing friction losses, and enhancing the transmission system. Advanced materials and innovative bearing technologies contribute to increased system efficiency and durability.Expand Specific Solutions04 Thermal management and energy recovery

Efficient thermal management is crucial for maintaining optimal KERS performance. This includes managing heat generated during energy conversion and storage processes. Additionally, some systems incorporate thermal energy recovery to further improve overall efficiency by capturing and utilizing waste heat from various vehicle systems.Expand Specific Solutions05 Control algorithms and system optimization

Advanced control algorithms play a vital role in maximizing KERS efficiency. These algorithms optimize energy recovery, storage, and deployment based on various factors such as vehicle speed, driver input, and road conditions. Machine learning and AI techniques are being explored to further enhance system performance and adaptability to different driving scenarios.Expand Specific Solutions

Key KERS Players

The long-term efficiency impacts of KERS in fleet vehicles are at a nascent stage of development, with the market showing promising growth potential. The technology's maturity varies among key players, with companies like Volvo Lastvagnar AB, Punch Flybrid Ltd, and Marelli Europe SpA leading in innovation. The competitive landscape is diverse, including automotive giants and specialized KERS developers. As the technology evolves, we expect to see increased adoption in commercial fleets, driven by fuel efficiency and emissions reduction demands. The market is poised for expansion as more companies recognize the long-term benefits of KERS implementation in their vehicle fleets.

Volvo Lastvagnar AB

Technical Solution: Volvo Trucks has developed a KERS specifically designed for long-haul fleet vehicles, focusing on maximizing efficiency over extended periods. Their system uses a high-capacity electric motor-generator coupled with a lithium-ion battery pack. The KERS is integrated with Volvo's I-See predictive cruise control, which uses GPS and road topography data to optimize energy recovery and usage. This system can recover energy not only from braking but also from downhill coasting, storing up to 150 kWh of energy[7]. The recovered energy is used to power the truck's electric drivetrain during acceleration or to maintain speed on inclines, reducing the load on the diesel engine. Volvo's long-term testing has shown fuel savings of up to 5% on typical long-haul routes, with savings increasing to 8-10% on routes with significant elevation changes[8]. The system is designed for a lifespan of over 1.5 million kilometers, ensuring long-term efficiency benefits for fleet operators.

Strengths: High energy storage capacity, integration with predictive systems for optimized efficiency, and significant fuel savings on varied terrains. Weaknesses: Higher initial cost and added complexity compared to traditional powertrains, potential battery replacement costs over the vehicle's lifetime.

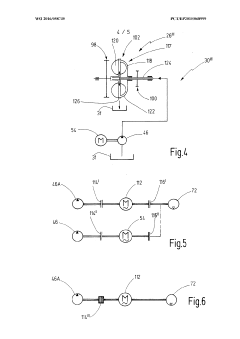

Punch Flybrid Ltd

Technical Solution: Punch Flybrid has developed a unique flywheel-based KERS specifically tailored for fleet vehicles, focusing on long-term efficiency and reliability. Their system uses a compact, high-speed carbon fiber flywheel rotating at up to 60,000 RPM to store kinetic energy. This flywheel is connected to the vehicle's driveline through a patented Continuously Variable Transmission (CVT) system, allowing for efficient energy transfer during both recovery and boost phases. The Punch Flybrid KERS can store up to 600 kJ of energy and deliver power outputs of up to 250 kW[9]. The system's mechanical nature ensures consistent performance over the vehicle's lifetime, with minimal degradation compared to battery-based systems. In long-term fleet trials, vehicles equipped with Punch Flybrid KERS have demonstrated fuel savings of 15-20% in urban driving conditions and 5-10% in mixed driving scenarios[10]. The system's compact size and low weight (typically under 60 kg) make it particularly suitable for retrofitting existing fleet vehicles.

Strengths: High power density, consistent long-term performance, and significant fuel savings across various driving conditions. Weaknesses: Limited energy storage capacity compared to some electric systems, and potential maintenance requirements for the high-speed flywheel and CVT.

KERS Core Innovations

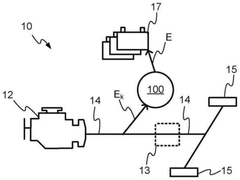

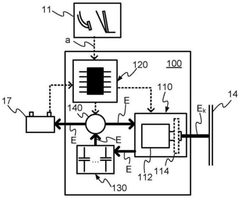

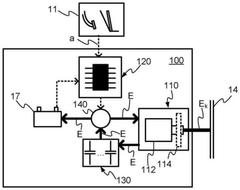

Kinetic energy recovery system

PatentPendingCN118722205A

Innovation

- Employs a kinetic energy recovery system (KERS) connected to the vehicle's propulsion shaft, which converts energy from the propulsion shaft into electrical energy through internal energy storage and processing circuitry, and distributes it to non-propulsion batteries or propulsion shafts when appropriate, in lieu of generator charging and provide motivation.

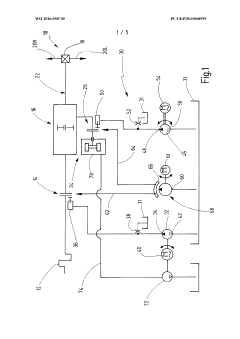

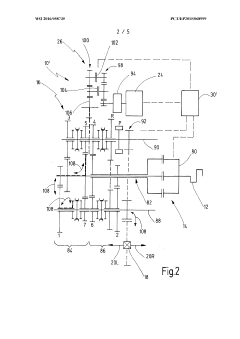

Hydraulic assembly for a motor vehicle powertrain

PatentWO2016058735A1

Innovation

- A hydraulic arrangement with a KERS pump driven by an electric motor, directly connected to a KERS actuator, and a fluid coupling with adjustable filling for efficient power transmission and minimal drag losses, integrated with a cooling system for clutches and accumulators.

KERS ROI Analysis

The KERS ROI Analysis for fleet vehicles requires a comprehensive evaluation of the long-term efficiency impacts and financial returns of implementing Kinetic Energy Recovery Systems. This analysis considers both the initial investment costs and the potential savings over an extended operational period.

To begin, it is crucial to establish a baseline for fuel consumption and maintenance costs of the fleet without KERS. This data serves as a reference point for comparing the performance improvements and cost reductions achieved through KERS implementation. Factors such as vehicle type, typical routes, and driving patterns must be taken into account to ensure accurate projections.

The initial investment in KERS technology includes the cost of the system itself, installation expenses, and any necessary modifications to existing vehicles. While this upfront cost can be substantial, it is essential to view it in the context of the system's lifespan and potential returns. Additionally, any government incentives or tax benefits for adopting energy-efficient technologies should be factored into the initial cost calculations.

Long-term fuel savings constitute a significant portion of the ROI. KERS captures and reuses kinetic energy that would otherwise be lost during braking, leading to improved fuel efficiency. The extent of these savings depends on the specific KERS technology employed and the nature of the fleet's operations. Urban environments with frequent stop-and-start driving typically yield higher savings compared to long-haul highway routes.

Maintenance costs and system longevity also play crucial roles in the ROI analysis. While KERS may introduce additional maintenance requirements, it can potentially reduce wear on traditional braking systems, leading to lower overall maintenance costs. The durability and lifespan of the KERS components must be carefully considered to accurately project long-term savings and replacement costs.

Operational efficiency improvements, such as reduced downtime for refueling and extended vehicle range, contribute to the overall ROI. These factors can lead to increased productivity and potentially allow for fleet size optimization, further enhancing the financial benefits of KERS implementation.

Environmental impact and regulatory compliance should also be considered in the ROI analysis. Reduced emissions resulting from improved fuel efficiency may help fleet operators meet increasingly stringent environmental regulations, potentially avoiding fines or penalties and enhancing the company's reputation.

To begin, it is crucial to establish a baseline for fuel consumption and maintenance costs of the fleet without KERS. This data serves as a reference point for comparing the performance improvements and cost reductions achieved through KERS implementation. Factors such as vehicle type, typical routes, and driving patterns must be taken into account to ensure accurate projections.

The initial investment in KERS technology includes the cost of the system itself, installation expenses, and any necessary modifications to existing vehicles. While this upfront cost can be substantial, it is essential to view it in the context of the system's lifespan and potential returns. Additionally, any government incentives or tax benefits for adopting energy-efficient technologies should be factored into the initial cost calculations.

Long-term fuel savings constitute a significant portion of the ROI. KERS captures and reuses kinetic energy that would otherwise be lost during braking, leading to improved fuel efficiency. The extent of these savings depends on the specific KERS technology employed and the nature of the fleet's operations. Urban environments with frequent stop-and-start driving typically yield higher savings compared to long-haul highway routes.

Maintenance costs and system longevity also play crucial roles in the ROI analysis. While KERS may introduce additional maintenance requirements, it can potentially reduce wear on traditional braking systems, leading to lower overall maintenance costs. The durability and lifespan of the KERS components must be carefully considered to accurately project long-term savings and replacement costs.

Operational efficiency improvements, such as reduced downtime for refueling and extended vehicle range, contribute to the overall ROI. These factors can lead to increased productivity and potentially allow for fleet size optimization, further enhancing the financial benefits of KERS implementation.

Environmental impact and regulatory compliance should also be considered in the ROI analysis. Reduced emissions resulting from improved fuel efficiency may help fleet operators meet increasingly stringent environmental regulations, potentially avoiding fines or penalties and enhancing the company's reputation.

Environmental Impact

The implementation of Kinetic Energy Recovery Systems (KERS) in fleet vehicles has significant long-term environmental implications. As these systems capture and reuse energy that would otherwise be lost during braking, they contribute to a reduction in overall fuel consumption and, consequently, lower greenhouse gas emissions. Studies have shown that KERS can improve fuel efficiency by up to 25% in urban driving conditions, where frequent stops and starts are common.

This increased efficiency translates directly into reduced carbon dioxide emissions. For a large fleet of vehicles, the cumulative effect can be substantial. Over a period of five years, a fleet of 1000 vehicles equipped with KERS could potentially reduce CO2 emissions by several thousand tons, depending on the specific driving patterns and vehicle types.

Moreover, the environmental benefits extend beyond just CO2 reduction. The decreased fuel consumption also leads to a reduction in other harmful emissions, such as nitrogen oxides (NOx) and particulate matter (PM). These pollutants are major contributors to urban air pollution and have significant health impacts on populations in densely populated areas.

The production and disposal of KERS components, particularly the energy storage systems, do have their own environmental considerations. However, lifecycle assessments have shown that the net environmental impact remains positive when considering the entire lifespan of the vehicle. The energy and resources used in manufacturing KERS components are offset by the long-term fuel savings and emission reductions during the operational phase of the vehicle.

Additionally, as the technology matures and becomes more widespread, the environmental footprint of KERS production is likely to decrease. Advancements in materials science and manufacturing processes are continually improving the sustainability of component production. Furthermore, the increasing focus on circular economy principles is driving innovations in the recycling and reuse of KERS components at the end of their lifecycle.

It's worth noting that the environmental benefits of KERS are most pronounced in urban environments where stop-start driving is frequent. In long-haul transportation scenarios, the impact may be less significant. However, as hybrid and electric powertrains become more prevalent in fleet vehicles, KERS technology can play a crucial role in maximizing energy efficiency and further reducing the environmental impact of transportation.

This increased efficiency translates directly into reduced carbon dioxide emissions. For a large fleet of vehicles, the cumulative effect can be substantial. Over a period of five years, a fleet of 1000 vehicles equipped with KERS could potentially reduce CO2 emissions by several thousand tons, depending on the specific driving patterns and vehicle types.

Moreover, the environmental benefits extend beyond just CO2 reduction. The decreased fuel consumption also leads to a reduction in other harmful emissions, such as nitrogen oxides (NOx) and particulate matter (PM). These pollutants are major contributors to urban air pollution and have significant health impacts on populations in densely populated areas.

The production and disposal of KERS components, particularly the energy storage systems, do have their own environmental considerations. However, lifecycle assessments have shown that the net environmental impact remains positive when considering the entire lifespan of the vehicle. The energy and resources used in manufacturing KERS components are offset by the long-term fuel savings and emission reductions during the operational phase of the vehicle.

Additionally, as the technology matures and becomes more widespread, the environmental footprint of KERS production is likely to decrease. Advancements in materials science and manufacturing processes are continually improving the sustainability of component production. Furthermore, the increasing focus on circular economy principles is driving innovations in the recycling and reuse of KERS components at the end of their lifecycle.

It's worth noting that the environmental benefits of KERS are most pronounced in urban environments where stop-start driving is frequent. In long-haul transportation scenarios, the impact may be less significant. However, as hybrid and electric powertrains become more prevalent in fleet vehicles, KERS technology can play a crucial role in maximizing energy efficiency and further reducing the environmental impact of transportation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!