Comparative Study of Piezoelectric vs. Triboelectric Sensors

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezo vs Tribo Sensors: Background and Objectives

Piezoelectric and triboelectric sensors represent two significant advancements in the field of energy harvesting and sensing technologies. These sensors have gained considerable attention in recent years due to their ability to convert mechanical energy into electrical signals, offering promising applications in various domains such as wearable electronics, environmental monitoring, and smart infrastructure.

The development of piezoelectric sensors can be traced back to the discovery of the piezoelectric effect by Jacques and Pierre Curie in 1880. This effect describes the ability of certain materials to generate an electric charge in response to applied mechanical stress. Over the decades, piezoelectric sensors have evolved from simple quartz crystals to sophisticated multi-layered devices incorporating advanced materials like lead zirconate titanate (PZT) and polyvinylidene fluoride (PVDF).

In contrast, triboelectric sensors are a more recent innovation, emerging from the field of nanogenerators in the early 2010s. These sensors operate on the principle of contact electrification and electrostatic induction, where two dissimilar materials are brought into contact and then separated, generating an electrical potential difference. The development of triboelectric nanogenerators (TENGs) has opened up new possibilities for energy harvesting from ambient mechanical energy sources.

The primary objective of this comparative study is to provide a comprehensive analysis of piezoelectric and triboelectric sensors, examining their fundamental principles, technological advancements, and potential applications. By exploring the strengths and limitations of each technology, we aim to identify their respective niches in the sensor market and predict future trends in their development and adoption.

Key areas of focus include the sensitivity, power output, durability, and scalability of both sensor types. Additionally, we will investigate the materials used in their construction, manufacturing processes, and integration challenges in various applications. The study will also consider the environmental impact and sustainability aspects of these technologies, as well as their potential for integration with other emerging technologies such as Internet of Things (IoT) and artificial intelligence.

By conducting this comparative analysis, we seek to provide valuable insights for researchers, engineers, and industry stakeholders involved in sensor development and implementation. The findings of this study will contribute to informed decision-making regarding the selection and application of these sensor technologies in diverse fields, ranging from consumer electronics to industrial automation and healthcare.

The development of piezoelectric sensors can be traced back to the discovery of the piezoelectric effect by Jacques and Pierre Curie in 1880. This effect describes the ability of certain materials to generate an electric charge in response to applied mechanical stress. Over the decades, piezoelectric sensors have evolved from simple quartz crystals to sophisticated multi-layered devices incorporating advanced materials like lead zirconate titanate (PZT) and polyvinylidene fluoride (PVDF).

In contrast, triboelectric sensors are a more recent innovation, emerging from the field of nanogenerators in the early 2010s. These sensors operate on the principle of contact electrification and electrostatic induction, where two dissimilar materials are brought into contact and then separated, generating an electrical potential difference. The development of triboelectric nanogenerators (TENGs) has opened up new possibilities for energy harvesting from ambient mechanical energy sources.

The primary objective of this comparative study is to provide a comprehensive analysis of piezoelectric and triboelectric sensors, examining their fundamental principles, technological advancements, and potential applications. By exploring the strengths and limitations of each technology, we aim to identify their respective niches in the sensor market and predict future trends in their development and adoption.

Key areas of focus include the sensitivity, power output, durability, and scalability of both sensor types. Additionally, we will investigate the materials used in their construction, manufacturing processes, and integration challenges in various applications. The study will also consider the environmental impact and sustainability aspects of these technologies, as well as their potential for integration with other emerging technologies such as Internet of Things (IoT) and artificial intelligence.

By conducting this comparative analysis, we seek to provide valuable insights for researchers, engineers, and industry stakeholders involved in sensor development and implementation. The findings of this study will contribute to informed decision-making regarding the selection and application of these sensor technologies in diverse fields, ranging from consumer electronics to industrial automation and healthcare.

Market Analysis for Energy Harvesting Sensors

The energy harvesting sensor market is experiencing significant growth, driven by the increasing demand for self-powered and sustainable sensing solutions across various industries. This market segment encompasses both piezoelectric and triboelectric sensors, which are gaining traction due to their ability to convert ambient energy into usable electrical power.

The global energy harvesting sensor market is projected to expand at a compound annual growth rate (CAGR) of over 10% in the coming years. This growth is fueled by the rising adoption of Internet of Things (IoT) devices, smart wearables, and industrial automation systems that require long-lasting, maintenance-free power sources. The automotive sector, in particular, is showing strong interest in energy harvesting sensors for applications such as tire pressure monitoring systems and structural health monitoring.

Piezoelectric sensors currently dominate the market, accounting for a larger share due to their established technology and wider range of applications. These sensors are widely used in industrial machinery, aerospace, and consumer electronics. However, triboelectric sensors are rapidly gaining market share, especially in emerging applications such as smart textiles and human-machine interfaces.

The Asia-Pacific region is expected to witness the highest growth rate in the energy harvesting sensor market, driven by the rapid industrialization and increasing investments in IoT infrastructure in countries like China, Japan, and South Korea. North America and Europe are also significant markets, with a focus on advanced applications in healthcare, aerospace, and automotive industries.

Key market drivers include the growing need for energy-efficient and battery-less sensors in remote and hard-to-reach locations, as well as the increasing emphasis on sustainable and green technologies. The miniaturization of sensors and improvements in energy conversion efficiency are also contributing to market expansion.

However, the market faces challenges such as the relatively high initial costs of energy harvesting sensors compared to traditional battery-powered sensors, and the need for further improvements in energy conversion efficiency. Additionally, the lack of standardization in energy harvesting technologies may hinder widespread adoption in some industries.

Looking ahead, the integration of energy harvesting sensors with artificial intelligence and machine learning algorithms is expected to open up new opportunities, particularly in predictive maintenance and smart infrastructure applications. The development of hybrid energy harvesting systems, combining multiple harvesting technologies, is also a promising trend that could further boost market growth.

The global energy harvesting sensor market is projected to expand at a compound annual growth rate (CAGR) of over 10% in the coming years. This growth is fueled by the rising adoption of Internet of Things (IoT) devices, smart wearables, and industrial automation systems that require long-lasting, maintenance-free power sources. The automotive sector, in particular, is showing strong interest in energy harvesting sensors for applications such as tire pressure monitoring systems and structural health monitoring.

Piezoelectric sensors currently dominate the market, accounting for a larger share due to their established technology and wider range of applications. These sensors are widely used in industrial machinery, aerospace, and consumer electronics. However, triboelectric sensors are rapidly gaining market share, especially in emerging applications such as smart textiles and human-machine interfaces.

The Asia-Pacific region is expected to witness the highest growth rate in the energy harvesting sensor market, driven by the rapid industrialization and increasing investments in IoT infrastructure in countries like China, Japan, and South Korea. North America and Europe are also significant markets, with a focus on advanced applications in healthcare, aerospace, and automotive industries.

Key market drivers include the growing need for energy-efficient and battery-less sensors in remote and hard-to-reach locations, as well as the increasing emphasis on sustainable and green technologies. The miniaturization of sensors and improvements in energy conversion efficiency are also contributing to market expansion.

However, the market faces challenges such as the relatively high initial costs of energy harvesting sensors compared to traditional battery-powered sensors, and the need for further improvements in energy conversion efficiency. Additionally, the lack of standardization in energy harvesting technologies may hinder widespread adoption in some industries.

Looking ahead, the integration of energy harvesting sensors with artificial intelligence and machine learning algorithms is expected to open up new opportunities, particularly in predictive maintenance and smart infrastructure applications. The development of hybrid energy harvesting systems, combining multiple harvesting technologies, is also a promising trend that could further boost market growth.

Current Challenges in Piezo and Tribo Technologies

Despite significant advancements in both piezoelectric and triboelectric sensor technologies, several challenges persist that hinder their widespread adoption and optimal performance. For piezoelectric sensors, one of the primary challenges is the inherent limitation in low-frequency response. These sensors struggle to accurately detect and measure slow-changing or static forces, which restricts their application in certain fields requiring constant pressure monitoring.

Another significant challenge for piezoelectric sensors is their susceptibility to temperature fluctuations. Changes in ambient temperature can affect the piezoelectric material's properties, leading to measurement inaccuracies and reduced reliability in environments with varying thermal conditions. This temperature sensitivity necessitates complex compensation mechanisms, increasing system complexity and cost.

Triboelectric sensors, while promising in many aspects, face their own set of challenges. One of the most pressing issues is the lack of standardization in materials and fabrication processes. The performance of triboelectric sensors heavily depends on the selection of triboelectric materials and their surface properties, but there is currently no universally accepted standard for material selection or device construction.

Durability and long-term stability remain concerns for both technologies. Piezoelectric materials can suffer from aging effects and degradation over time, potentially altering their sensitivity and output characteristics. Triboelectric sensors, particularly those relying on surface contact, may experience wear and tear that affects their performance and lifespan.

For triboelectric sensors, environmental factors such as humidity and air pressure can significantly impact their output. These external influences can lead to inconsistent results and reduced reliability in real-world applications, necessitating additional environmental control or compensation strategies.

Both technologies face challenges in miniaturization and integration with other electronic components. As devices become smaller and more complex, maintaining sensor performance while reducing size and power consumption becomes increasingly difficult. This is particularly challenging for triboelectric sensors, which often require specific mechanical designs to optimize charge separation and collection.

Signal processing and noise reduction present ongoing challenges for both piezoelectric and triboelectric sensors. Piezoelectric sensors often produce high-impedance signals that are susceptible to electromagnetic interference, while triboelectric sensors can generate noisy outputs due to their inherent working principle based on intermittent contact and separation.

Lastly, the cost-effectiveness of these sensors, especially for large-scale production and integration into consumer products, remains a hurdle. While both technologies offer unique advantages, the materials and manufacturing processes required can be expensive, limiting their adoption in price-sensitive markets.

Addressing these challenges requires interdisciplinary research efforts, combining materials science, electrical engineering, and manufacturing technologies to develop more robust, reliable, and cost-effective sensor solutions.

Another significant challenge for piezoelectric sensors is their susceptibility to temperature fluctuations. Changes in ambient temperature can affect the piezoelectric material's properties, leading to measurement inaccuracies and reduced reliability in environments with varying thermal conditions. This temperature sensitivity necessitates complex compensation mechanisms, increasing system complexity and cost.

Triboelectric sensors, while promising in many aspects, face their own set of challenges. One of the most pressing issues is the lack of standardization in materials and fabrication processes. The performance of triboelectric sensors heavily depends on the selection of triboelectric materials and their surface properties, but there is currently no universally accepted standard for material selection or device construction.

Durability and long-term stability remain concerns for both technologies. Piezoelectric materials can suffer from aging effects and degradation over time, potentially altering their sensitivity and output characteristics. Triboelectric sensors, particularly those relying on surface contact, may experience wear and tear that affects their performance and lifespan.

For triboelectric sensors, environmental factors such as humidity and air pressure can significantly impact their output. These external influences can lead to inconsistent results and reduced reliability in real-world applications, necessitating additional environmental control or compensation strategies.

Both technologies face challenges in miniaturization and integration with other electronic components. As devices become smaller and more complex, maintaining sensor performance while reducing size and power consumption becomes increasingly difficult. This is particularly challenging for triboelectric sensors, which often require specific mechanical designs to optimize charge separation and collection.

Signal processing and noise reduction present ongoing challenges for both piezoelectric and triboelectric sensors. Piezoelectric sensors often produce high-impedance signals that are susceptible to electromagnetic interference, while triboelectric sensors can generate noisy outputs due to their inherent working principle based on intermittent contact and separation.

Lastly, the cost-effectiveness of these sensors, especially for large-scale production and integration into consumer products, remains a hurdle. While both technologies offer unique advantages, the materials and manufacturing processes required can be expensive, limiting their adoption in price-sensitive markets.

Addressing these challenges requires interdisciplinary research efforts, combining materials science, electrical engineering, and manufacturing technologies to develop more robust, reliable, and cost-effective sensor solutions.

Existing Piezo and Tribo Sensor Solutions

01 Piezoelectric sensor design and applications

Piezoelectric sensors are designed to convert mechanical stress or vibration into electrical signals. These sensors are widely used in various applications including pressure measurement, acceleration detection, and energy harvesting. The design often involves optimizing the piezoelectric material selection and structural configuration to enhance sensitivity and performance.- Piezoelectric sensor design and applications: Piezoelectric sensors are designed to convert mechanical stress into electrical signals. They are used in various applications including pressure sensing, vibration detection, and energy harvesting. These sensors can be optimized for sensitivity, frequency response, and durability depending on the specific application requirements.

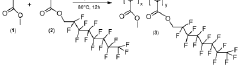

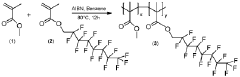

- Triboelectric sensor development and uses: Triboelectric sensors utilize the triboelectric effect to generate electrical signals from mechanical motion or contact-separation. They are employed in touch sensing, motion detection, and energy harvesting applications. Recent developments focus on improving their sensitivity, flexibility, and integration with other electronic components.

- Hybrid piezoelectric-triboelectric sensor systems: Hybrid systems combining piezoelectric and triboelectric sensors leverage the advantages of both technologies. These integrated sensors offer enhanced sensitivity, broader detection range, and improved energy harvesting capabilities. They are particularly useful in wearable electronics, smart textiles, and IoT devices.

- Nanomaterial-based piezoelectric and triboelectric sensors: Nanomaterials such as nanofibers, nanoparticles, and 2D materials are being incorporated into piezoelectric and triboelectric sensors. These nanomaterial-based sensors exhibit improved performance characteristics including higher sensitivity, flexibility, and durability. They enable the development of ultra-thin and conformable sensor devices.

- Signal processing and readout circuits for piezoelectric and triboelectric sensors: Advanced signal processing techniques and specialized readout circuits are being developed to enhance the performance of piezoelectric and triboelectric sensors. These include noise reduction algorithms, charge amplification circuits, and integrated sensor-processor units. Such developments improve sensor accuracy, response time, and power efficiency.

02 Triboelectric sensor development and uses

Triboelectric sensors utilize the triboelectric effect to generate electrical signals from mechanical motion or contact-separation. These sensors are being developed for applications such as touch sensing, motion detection, and energy harvesting from ambient mechanical energy. Research focuses on improving material combinations and surface structures to enhance charge generation efficiency.Expand Specific Solutions03 Hybrid piezoelectric-triboelectric sensor systems

Hybrid systems combining both piezoelectric and triboelectric sensing mechanisms are being developed to leverage the advantages of both technologies. These hybrid sensors can offer improved sensitivity, broader sensing range, and enhanced energy harvesting capabilities. Integration strategies and signal processing techniques are key areas of focus in hybrid sensor development.Expand Specific Solutions04 Flexible and wearable piezoelectric/triboelectric sensors

Advancements in flexible electronics and nanomaterials have enabled the development of flexible and wearable piezoelectric and triboelectric sensors. These sensors can conform to curved surfaces or be integrated into textiles, opening up applications in health monitoring, human-machine interfaces, and smart clothing. Research focuses on improving durability, stretchability, and signal quality in these flexible sensor designs.Expand Specific Solutions05 Nanomaterial-enhanced piezoelectric and triboelectric sensors

Incorporation of nanomaterials such as nanoparticles, nanowires, and nanocomposites is being explored to enhance the performance of piezoelectric and triboelectric sensors. These nanomaterials can improve charge generation efficiency, increase surface area for triboelectric effects, and enhance overall sensor sensitivity. Research in this area focuses on optimizing nanomaterial synthesis, integration, and characterization techniques.Expand Specific Solutions

Key Players in Piezoelectric and Triboelectric Industry

The competitive landscape for piezoelectric vs. triboelectric sensors is evolving rapidly as the technology matures. The market is in a growth phase, with increasing adoption across industries like automotive, consumer electronics, and industrial applications. Key players include established companies like TDK Electronics and Robert Bosch, as well as emerging specialists like Ionix Advanced Technologies. Universities and research institutes like Tsinghua University and the Beijing Institute of Nanoenergy & Nanosystems are driving innovation. The technology is advancing from basic research to commercial applications, with companies developing novel materials, fabrication techniques, and integrated solutions to improve sensor performance and expand use cases.

Beijing Institute of Nanoenergy & Nanosystems

Technical Solution: The Beijing Institute of Nanoenergy & Nanosystems has developed advanced triboelectric nanogenerators (TENGs) for self-powered sensing applications. Their technology utilizes the coupling of triboelectrification and electrostatic induction to convert mechanical energy into electricity. They have demonstrated TENGs with power density up to 500 W/m2 and conversion efficiency over 70%[1]. The institute has also created flexible and stretchable TENG sensors that can be integrated into wearable devices for health monitoring and human-machine interfaces[2]. Their recent work focuses on improving the durability and output stability of TENGs through novel material designs and surface modifications[3].

Strengths: High power density, flexibility for wearable applications, and ongoing improvements in durability. Weaknesses: May be sensitive to environmental conditions like humidity, and mass production challenges for some designs.

Tsinghua University

Technical Solution: Tsinghua University has made significant advancements in both piezoelectric and triboelectric sensor technologies. For piezoelectric sensors, they have developed nanostructured piezoelectric materials with enhanced sensitivity and flexibility, suitable for pressure and strain sensing in soft robotics and biomedical devices[4]. Their work on triboelectric sensors includes the creation of self-powered, highly sensitive touch sensors using micro-patterned surfaces to enhance triboelectric charge generation[5]. The university has also pioneered hybrid piezo-triboelectric systems that combine the advantages of both mechanisms, achieving higher output and broader frequency response for energy harvesting and sensing applications[6].

Strengths: Innovative hybrid systems, high sensitivity in both piezo and tribo sensors. Weaknesses: Some designs may have complex fabrication processes, potentially limiting large-scale production.

Core Innovations in Energy Harvesting Mechanisms

Triboelectric sensors

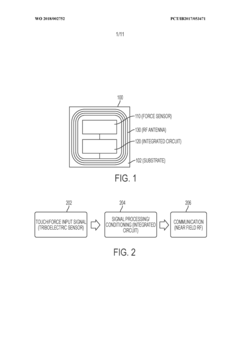

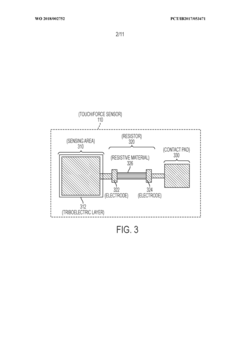

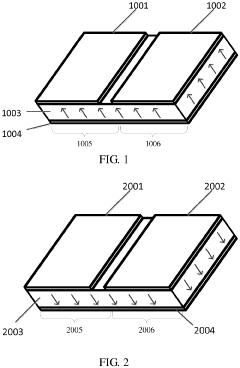

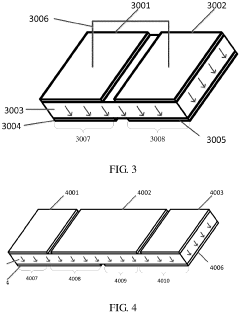

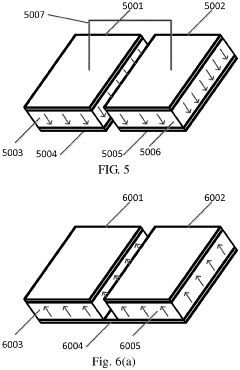

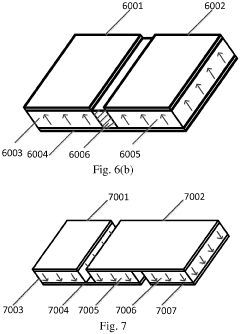

PatentWO2018002752A1

Innovation

- The integration of triboelectric sensors that convert applied force into electrical signals for wireless communication, allowing for power generation and input transmission without an external power supply, enabling flexible installation and diverse applications such as smart switches and control devices.

Piezoelectric sensing device and application

PatentActiveEP3534418A1

Innovation

- A piezoelectric sensing apparatus is designed with multiple piezoelectric regions connected such that same-polarity surfaces are connected in series, allowing for the boosting of high-frequency signals and weakening of low-frequency signals, enhancing positioning accuracy by amplifying high-frequency signals and attenuating low-frequency signals.

Environmental Impact of Piezo and Tribo Sensors

The environmental impact of piezoelectric and triboelectric sensors is an increasingly important consideration as these technologies become more widespread. Both types of sensors offer advantages in terms of energy harvesting and self-powered operation, which can reduce overall energy consumption and battery waste. However, their manufacturing processes and materials used have different environmental implications.

Piezoelectric sensors typically utilize materials such as lead zirconate titanate (PZT), which contains lead, a toxic heavy metal. The production and disposal of lead-based piezoelectric materials pose significant environmental concerns. Efforts are being made to develop lead-free alternatives, such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT), but these are not yet as widely adopted or efficient.

Triboelectric sensors, on the other hand, often use more environmentally friendly materials such as polymers, textiles, and metals. The manufacturing processes for triboelectric devices generally have a lower environmental impact compared to piezoelectric sensors. Additionally, many triboelectric materials are flexible and can be produced using additive manufacturing techniques, potentially reducing material waste.

In terms of lifecycle analysis, both sensor types have the potential to reduce overall environmental impact by enabling more efficient energy use in various applications. For instance, in structural health monitoring, these sensors can help prevent catastrophic failures and extend the lifespan of infrastructure, thereby reducing resource consumption and waste.

The recyclability of these sensors is another crucial factor. Piezoelectric sensors, especially those containing lead, require careful handling and specialized recycling processes. Triboelectric sensors, composed of more common materials, may be easier to recycle or repurpose at the end of their life cycle.

Energy efficiency during operation is a key advantage for both sensor types. Their ability to generate electricity from ambient mechanical energy reduces the need for external power sources, potentially lowering the carbon footprint of sensor networks and IoT devices.

As research progresses, the environmental impact of both piezoelectric and triboelectric sensors is likely to improve. Developments in green manufacturing processes, the use of sustainable materials, and improved recycling techniques will contribute to making these technologies more environmentally friendly. Future innovations may also focus on enhancing the biodegradability of sensor components, further reducing their long-term environmental impact.

Piezoelectric sensors typically utilize materials such as lead zirconate titanate (PZT), which contains lead, a toxic heavy metal. The production and disposal of lead-based piezoelectric materials pose significant environmental concerns. Efforts are being made to develop lead-free alternatives, such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT), but these are not yet as widely adopted or efficient.

Triboelectric sensors, on the other hand, often use more environmentally friendly materials such as polymers, textiles, and metals. The manufacturing processes for triboelectric devices generally have a lower environmental impact compared to piezoelectric sensors. Additionally, many triboelectric materials are flexible and can be produced using additive manufacturing techniques, potentially reducing material waste.

In terms of lifecycle analysis, both sensor types have the potential to reduce overall environmental impact by enabling more efficient energy use in various applications. For instance, in structural health monitoring, these sensors can help prevent catastrophic failures and extend the lifespan of infrastructure, thereby reducing resource consumption and waste.

The recyclability of these sensors is another crucial factor. Piezoelectric sensors, especially those containing lead, require careful handling and specialized recycling processes. Triboelectric sensors, composed of more common materials, may be easier to recycle or repurpose at the end of their life cycle.

Energy efficiency during operation is a key advantage for both sensor types. Their ability to generate electricity from ambient mechanical energy reduces the need for external power sources, potentially lowering the carbon footprint of sensor networks and IoT devices.

As research progresses, the environmental impact of both piezoelectric and triboelectric sensors is likely to improve. Developments in green manufacturing processes, the use of sustainable materials, and improved recycling techniques will contribute to making these technologies more environmentally friendly. Future innovations may also focus on enhancing the biodegradability of sensor components, further reducing their long-term environmental impact.

Standardization Efforts for Energy Harvesting Sensors

The standardization of energy harvesting sensors, particularly in the context of piezoelectric and triboelectric technologies, has become increasingly important as these devices gain traction in various applications. Efforts to establish uniform standards are crucial for ensuring interoperability, reliability, and performance consistency across different manufacturers and implementations.

Several international organizations are at the forefront of these standardization efforts. The Institute of Electrical and Electronics Engineers (IEEE) has been actively developing standards for energy harvesting devices, including the IEEE 1789-2015 standard for LED current ripple. This standard, while not directly related to piezoelectric or triboelectric sensors, provides a framework for addressing electromagnetic compatibility issues in energy harvesting systems.

The International Electrotechnical Commission (IEC) has also been instrumental in this area. The IEC Technical Committee 47 (Semiconductor devices) has been working on standards for energy harvesting devices, including piezoelectric and triboelectric sensors. Their efforts aim to establish common terminology, testing methods, and performance metrics for these technologies.

In the specific realm of piezoelectric and triboelectric sensors, standardization efforts are focusing on several key areas. These include defining standard measurement protocols for energy output, establishing uniform methods for characterizing sensor performance under various environmental conditions, and creating guidelines for integrating these sensors into larger systems.

One significant challenge in standardization is the diverse range of applications for energy harvesting sensors. Piezoelectric and triboelectric devices can be used in wearable technology, structural health monitoring, and even in biomedical implants. Each application domain may require specific standards tailored to its unique requirements and constraints.

To address this, working groups within standardization bodies are collaborating with industry experts and academic researchers to develop application-specific guidelines. These efforts aim to create a hierarchical structure of standards, with overarching principles applicable to all energy harvesting sensors, supplemented by more detailed specifications for particular use cases.

Another critical aspect of standardization is the development of reference materials and calibration procedures. This is particularly important for comparing the performance of different sensor designs and ensuring consistency in measurements across various research and industrial settings. Efforts are underway to establish standardized test benches and reference samples that can serve as benchmarks for evaluating new sensor designs and materials.

As the field of energy harvesting sensors continues to evolve rapidly, standardization efforts must remain flexible and adaptable. Regular reviews and updates to existing standards will be necessary to keep pace with technological advancements and emerging applications. This ongoing process will require continued collaboration between researchers, industry stakeholders, and standardization bodies to ensure that standards remain relevant and beneficial to the broader community.

Several international organizations are at the forefront of these standardization efforts. The Institute of Electrical and Electronics Engineers (IEEE) has been actively developing standards for energy harvesting devices, including the IEEE 1789-2015 standard for LED current ripple. This standard, while not directly related to piezoelectric or triboelectric sensors, provides a framework for addressing electromagnetic compatibility issues in energy harvesting systems.

The International Electrotechnical Commission (IEC) has also been instrumental in this area. The IEC Technical Committee 47 (Semiconductor devices) has been working on standards for energy harvesting devices, including piezoelectric and triboelectric sensors. Their efforts aim to establish common terminology, testing methods, and performance metrics for these technologies.

In the specific realm of piezoelectric and triboelectric sensors, standardization efforts are focusing on several key areas. These include defining standard measurement protocols for energy output, establishing uniform methods for characterizing sensor performance under various environmental conditions, and creating guidelines for integrating these sensors into larger systems.

One significant challenge in standardization is the diverse range of applications for energy harvesting sensors. Piezoelectric and triboelectric devices can be used in wearable technology, structural health monitoring, and even in biomedical implants. Each application domain may require specific standards tailored to its unique requirements and constraints.

To address this, working groups within standardization bodies are collaborating with industry experts and academic researchers to develop application-specific guidelines. These efforts aim to create a hierarchical structure of standards, with overarching principles applicable to all energy harvesting sensors, supplemented by more detailed specifications for particular use cases.

Another critical aspect of standardization is the development of reference materials and calibration procedures. This is particularly important for comparing the performance of different sensor designs and ensuring consistency in measurements across various research and industrial settings. Efforts are underway to establish standardized test benches and reference samples that can serve as benchmarks for evaluating new sensor designs and materials.

As the field of energy harvesting sensors continues to evolve rapidly, standardization efforts must remain flexible and adaptable. Regular reviews and updates to existing standards will be necessary to keep pace with technological advancements and emerging applications. This ongoing process will require continued collaboration between researchers, industry stakeholders, and standardization bodies to ensure that standards remain relevant and beneficial to the broader community.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!