Design of Flexible Piezoelectric Sensors for Wearable Technology

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Piezo Sensor Tech Background and Objectives

Flexible piezoelectric sensors have emerged as a groundbreaking technology in the field of wearable devices, marking a significant milestone in the evolution of human-machine interfaces. The development of these sensors can be traced back to the discovery of the piezoelectric effect in the late 19th century, which laid the foundation for their modern applications. Over the past few decades, advancements in materials science and nanotechnology have propelled the miniaturization and flexibility of piezoelectric sensors, making them ideal for integration into wearable technology.

The primary objective of designing flexible piezoelectric sensors for wearable technology is to create highly sensitive, durable, and comfortable devices that can seamlessly interface with the human body. These sensors aim to accurately detect and measure various physiological parameters, such as heart rate, blood pressure, and muscle movements, while maintaining user comfort and mobility. The ultimate goal is to enable continuous, real-time health monitoring and enhance the overall user experience in wearable devices.

The technological trajectory of flexible piezoelectric sensors has been characterized by a shift from rigid, bulky designs to ultra-thin, conformable structures. This evolution has been driven by the need for sensors that can adapt to the complex contours of the human body without compromising functionality. Recent research has focused on developing novel piezoelectric materials and fabrication techniques that can achieve high sensitivity and flexibility simultaneously.

One of the key trends in this field is the exploration of organic and composite piezoelectric materials, which offer superior flexibility and biocompatibility compared to traditional ceramic-based sensors. Additionally, there is a growing emphasis on developing self-powered sensors that can harvest energy from body movements, potentially eliminating the need for external power sources in wearable devices.

The future of flexible piezoelectric sensors in wearable technology is poised for significant advancements. Researchers are working towards achieving higher sensitivity, improved durability, and enhanced integration with other electronic components. There is also a focus on developing multi-functional sensors that can simultaneously measure multiple parameters, thereby reducing the overall size and complexity of wearable devices.

As the technology continues to mature, we can expect to see a wider range of applications beyond health monitoring, including gesture recognition, human-computer interaction, and smart textiles. The convergence of flexible piezoelectric sensors with other emerging technologies, such as artificial intelligence and 5G connectivity, is likely to unlock new possibilities in personalized healthcare and immersive user experiences.

The primary objective of designing flexible piezoelectric sensors for wearable technology is to create highly sensitive, durable, and comfortable devices that can seamlessly interface with the human body. These sensors aim to accurately detect and measure various physiological parameters, such as heart rate, blood pressure, and muscle movements, while maintaining user comfort and mobility. The ultimate goal is to enable continuous, real-time health monitoring and enhance the overall user experience in wearable devices.

The technological trajectory of flexible piezoelectric sensors has been characterized by a shift from rigid, bulky designs to ultra-thin, conformable structures. This evolution has been driven by the need for sensors that can adapt to the complex contours of the human body without compromising functionality. Recent research has focused on developing novel piezoelectric materials and fabrication techniques that can achieve high sensitivity and flexibility simultaneously.

One of the key trends in this field is the exploration of organic and composite piezoelectric materials, which offer superior flexibility and biocompatibility compared to traditional ceramic-based sensors. Additionally, there is a growing emphasis on developing self-powered sensors that can harvest energy from body movements, potentially eliminating the need for external power sources in wearable devices.

The future of flexible piezoelectric sensors in wearable technology is poised for significant advancements. Researchers are working towards achieving higher sensitivity, improved durability, and enhanced integration with other electronic components. There is also a focus on developing multi-functional sensors that can simultaneously measure multiple parameters, thereby reducing the overall size and complexity of wearable devices.

As the technology continues to mature, we can expect to see a wider range of applications beyond health monitoring, including gesture recognition, human-computer interaction, and smart textiles. The convergence of flexible piezoelectric sensors with other emerging technologies, such as artificial intelligence and 5G connectivity, is likely to unlock new possibilities in personalized healthcare and immersive user experiences.

Wearable Tech Market Demand Analysis

The wearable technology market has experienced significant growth in recent years, driven by increasing consumer demand for smart, connected devices that can monitor health, fitness, and daily activities. The global wearable technology market size was valued at $61.30 billion in 2022 and is projected to reach $184.40 billion by 2030, growing at a CAGR of 14.8% from 2023 to 2030.

Flexible piezoelectric sensors play a crucial role in this expanding market, as they offer unique advantages for wearable applications. These sensors can detect and measure pressure, strain, and motion, making them ideal for a wide range of wearable devices. The demand for such sensors is particularly strong in the healthcare and fitness sectors, where continuous monitoring of vital signs and body movements is essential.

In the healthcare industry, there is a growing need for non-invasive, comfortable, and accurate monitoring devices. Flexible piezoelectric sensors can be integrated into clothing or attached directly to the skin, allowing for long-term, unobtrusive monitoring of patients' vital signs, such as heart rate, respiratory rate, and blood pressure. This technology is especially valuable for remote patient monitoring and telemedicine applications, which have seen accelerated adoption due to the COVID-19 pandemic.

The fitness and sports industry is another key driver of demand for flexible piezoelectric sensors in wearable technology. Consumers are increasingly interested in tracking their physical performance and health metrics during exercise. Wearable devices equipped with these sensors can provide real-time feedback on posture, gait analysis, and muscle activity, helping athletes and fitness enthusiasts optimize their training and prevent injuries.

The consumer electronics sector is also contributing to the growing demand for flexible piezoelectric sensors. Smartwatches, fitness bands, and other wearable devices are incorporating these sensors to enhance user experience and functionality. For example, gesture recognition and touch-sensitive interfaces powered by piezoelectric sensors are becoming more common in wearable devices, offering intuitive and seamless interaction.

As the Internet of Things (IoT) continues to expand, there is an increasing demand for wearable devices that can seamlessly integrate with smart home systems and other connected devices. Flexible piezoelectric sensors enable the development of more sophisticated and responsive wearable technology, capable of interacting with the user's environment and other smart devices.

The automotive industry is emerging as a potential growth area for wearable technology incorporating flexible piezoelectric sensors. Driver monitoring systems and smart textiles in car seats can utilize these sensors to enhance safety and comfort. Additionally, the growing focus on autonomous vehicles is creating new opportunities for wearable devices that can interface with vehicle systems.

Flexible piezoelectric sensors play a crucial role in this expanding market, as they offer unique advantages for wearable applications. These sensors can detect and measure pressure, strain, and motion, making them ideal for a wide range of wearable devices. The demand for such sensors is particularly strong in the healthcare and fitness sectors, where continuous monitoring of vital signs and body movements is essential.

In the healthcare industry, there is a growing need for non-invasive, comfortable, and accurate monitoring devices. Flexible piezoelectric sensors can be integrated into clothing or attached directly to the skin, allowing for long-term, unobtrusive monitoring of patients' vital signs, such as heart rate, respiratory rate, and blood pressure. This technology is especially valuable for remote patient monitoring and telemedicine applications, which have seen accelerated adoption due to the COVID-19 pandemic.

The fitness and sports industry is another key driver of demand for flexible piezoelectric sensors in wearable technology. Consumers are increasingly interested in tracking their physical performance and health metrics during exercise. Wearable devices equipped with these sensors can provide real-time feedback on posture, gait analysis, and muscle activity, helping athletes and fitness enthusiasts optimize their training and prevent injuries.

The consumer electronics sector is also contributing to the growing demand for flexible piezoelectric sensors. Smartwatches, fitness bands, and other wearable devices are incorporating these sensors to enhance user experience and functionality. For example, gesture recognition and touch-sensitive interfaces powered by piezoelectric sensors are becoming more common in wearable devices, offering intuitive and seamless interaction.

As the Internet of Things (IoT) continues to expand, there is an increasing demand for wearable devices that can seamlessly integrate with smart home systems and other connected devices. Flexible piezoelectric sensors enable the development of more sophisticated and responsive wearable technology, capable of interacting with the user's environment and other smart devices.

The automotive industry is emerging as a potential growth area for wearable technology incorporating flexible piezoelectric sensors. Driver monitoring systems and smart textiles in car seats can utilize these sensors to enhance safety and comfort. Additionally, the growing focus on autonomous vehicles is creating new opportunities for wearable devices that can interface with vehicle systems.

Flexible Piezo Sensor Challenges

The development of flexible piezoelectric sensors for wearable technology faces several significant challenges that researchers and engineers must overcome. One of the primary obstacles is achieving a balance between flexibility and performance. While traditional piezoelectric materials like lead zirconate titanate (PZT) offer excellent sensing capabilities, they are inherently rigid and brittle, making them unsuitable for wearable applications. The quest for materials that can maintain high piezoelectric coefficients while being bendable and stretchable is ongoing.

Another major challenge lies in the integration of these sensors into wearable devices. The sensors must be able to withstand repeated bending, stretching, and twisting without degradation in performance or physical damage. This requires innovative design approaches and novel fabrication techniques to ensure durability and reliability under various mechanical stresses.

The miniaturization of flexible piezoelectric sensors presents another hurdle. As wearable devices become increasingly compact and unobtrusive, the sensors must follow suit without compromising their sensitivity or output. This miniaturization effort often leads to reduced signal-to-noise ratios, necessitating advanced signal processing techniques to extract meaningful data from weaker electrical outputs.

Power management is a critical issue in the design of flexible piezoelectric sensors for wearables. While these sensors can generate electricity from mechanical deformation, the amount of power produced is typically very low. Developing efficient energy harvesting and storage systems that can operate on such small power outputs remains a significant challenge. This is particularly important for self-powered wearable devices that aim to eliminate the need for external power sources or frequent charging.

Environmental factors pose additional challenges to the implementation of flexible piezoelectric sensors in wearable technology. These sensors must be able to function reliably across a range of temperatures, humidity levels, and exposure to various chemicals such as sweat or cleaning agents. Ensuring consistent performance and longevity under these diverse conditions requires careful material selection and protective packaging strategies.

The manufacturing scalability of flexible piezoelectric sensors is another area of concern. Current fabrication methods for high-performance flexible piezoelectric materials often involve complex processes that are difficult to scale up for mass production. Developing cost-effective, large-scale manufacturing techniques that maintain the quality and consistency of these sensors is crucial for their widespread adoption in consumer wearable devices.

Lastly, biocompatibility and safety considerations present unique challenges, especially for wearable devices that come into direct contact with the skin. Ensuring that the materials used in flexible piezoelectric sensors do not cause allergic reactions or other adverse effects, while also meeting regulatory standards for wearable electronics, adds another layer of complexity to their design and development.

Another major challenge lies in the integration of these sensors into wearable devices. The sensors must be able to withstand repeated bending, stretching, and twisting without degradation in performance or physical damage. This requires innovative design approaches and novel fabrication techniques to ensure durability and reliability under various mechanical stresses.

The miniaturization of flexible piezoelectric sensors presents another hurdle. As wearable devices become increasingly compact and unobtrusive, the sensors must follow suit without compromising their sensitivity or output. This miniaturization effort often leads to reduced signal-to-noise ratios, necessitating advanced signal processing techniques to extract meaningful data from weaker electrical outputs.

Power management is a critical issue in the design of flexible piezoelectric sensors for wearables. While these sensors can generate electricity from mechanical deformation, the amount of power produced is typically very low. Developing efficient energy harvesting and storage systems that can operate on such small power outputs remains a significant challenge. This is particularly important for self-powered wearable devices that aim to eliminate the need for external power sources or frequent charging.

Environmental factors pose additional challenges to the implementation of flexible piezoelectric sensors in wearable technology. These sensors must be able to function reliably across a range of temperatures, humidity levels, and exposure to various chemicals such as sweat or cleaning agents. Ensuring consistent performance and longevity under these diverse conditions requires careful material selection and protective packaging strategies.

The manufacturing scalability of flexible piezoelectric sensors is another area of concern. Current fabrication methods for high-performance flexible piezoelectric materials often involve complex processes that are difficult to scale up for mass production. Developing cost-effective, large-scale manufacturing techniques that maintain the quality and consistency of these sensors is crucial for their widespread adoption in consumer wearable devices.

Lastly, biocompatibility and safety considerations present unique challenges, especially for wearable devices that come into direct contact with the skin. Ensuring that the materials used in flexible piezoelectric sensors do not cause allergic reactions or other adverse effects, while also meeting regulatory standards for wearable electronics, adds another layer of complexity to their design and development.

Current Flexible Piezo Sensor Design Solutions

01 Flexible piezoelectric materials

Development of flexible piezoelectric materials that can maintain their performance under bending or stretching conditions. These materials often include polymers or composite structures that combine flexibility with piezoelectric properties, enabling the creation of sensors that can conform to various shapes and surfaces.- Flexible piezoelectric materials: Development of flexible piezoelectric materials that can maintain their piezoelectric properties while being bendable or stretchable. These materials often include polymers or composite structures that allow for greater flexibility compared to traditional rigid piezoelectric ceramics.

- Substrate and electrode design: Innovative designs for flexible substrates and electrodes that can accommodate bending and stretching without compromising the sensor's performance. This may involve using stretchable conductive materials or patterned structures that allow for deformation.

- Nanostructure integration: Incorporation of nanostructures such as nanowires, nanofibers, or nanoparticles to enhance the flexibility and sensitivity of piezoelectric sensors. These nanostructures can improve the mechanical properties and increase the active surface area of the sensor.

- Encapsulation techniques: Development of encapsulation methods to protect flexible piezoelectric sensors from environmental factors while maintaining their flexibility. This may include the use of soft polymers or elastomeric materials as protective layers.

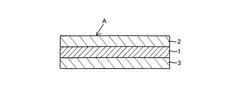

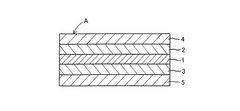

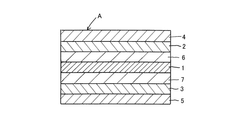

- Multi-layer and composite structures: Design of multi-layer or composite structures that combine different materials to achieve both flexibility and optimal piezoelectric performance. This approach can involve alternating layers of piezoelectric materials with flexible substrates or creating composite materials with embedded piezoelectric elements.

02 Nanostructured piezoelectric sensors

Utilization of nanostructures such as nanowires, nanofibers, or nanoparticles to enhance the flexibility and sensitivity of piezoelectric sensors. These nanostructures can be incorporated into flexible substrates or formed into arrays, allowing for improved mechanical compliance and increased active surface area.Expand Specific Solutions03 Substrate and electrode design

Innovative designs for flexible substrates and electrodes that can withstand repeated bending or stretching without compromising the sensor's performance. This includes the use of stretchable electrodes, serpentine patterns, or mesh structures to maintain electrical connectivity during deformation.Expand Specific Solutions04 Encapsulation and protection

Development of flexible encapsulation methods to protect the piezoelectric sensors from environmental factors while maintaining their flexibility. This may involve the use of soft polymers or elastomeric materials that can seal the sensor components without restricting their movement or sensitivity.Expand Specific Solutions05 Integration with flexible electronics

Techniques for integrating flexible piezoelectric sensors with other flexible electronic components to create complete sensing systems. This includes the development of flexible circuits, interconnects, and signal processing elements that can work in conjunction with the flexible sensors without compromising overall system flexibility.Expand Specific Solutions

Key Players in Flexible Piezo Sensor Industry

The flexible piezoelectric sensor market for wearable technology is in a growth phase, driven by increasing demand for smart wearables and healthcare monitoring devices. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, while piezoelectric sensors are well-established, their flexible integration into wearables is still evolving. Companies like Sumitomo Riko, Sekisui Chemical, and TDK Electronics are at the forefront, developing advanced materials and manufacturing processes. Academic institutions such as the National University of Singapore and Xi'an Jiaotong University are contributing cutting-edge research, pushing the boundaries of sensor flexibility, sensitivity, and durability for wearable applications.

Sumitomo Riko Co. Ltd.

Technical Solution: Sumitomo Riko Co. Ltd. has developed an innovative approach to flexible piezoelectric sensors for wearable technology, leveraging their expertise in automotive and industrial rubber products. Their technology is based on a unique composite material that combines piezoelectric ceramics with highly elastic polymers, resulting in sensors that can withstand large deformations while maintaining high sensitivity[13]. Sumitomo Riko's sensors feature a multi-layer structure that enhances both flexibility and durability, addressing common issues in wearable sensor longevity. The company has also developed a proprietary electrode design that minimizes signal loss and improves overall sensor performance. Their sensors have demonstrated excellent response to both static and dynamic forces, making them suitable for a wide range of wearable applications, from health monitoring to sports performance analysis[14]. Additionally, Sumitomo Riko has implemented advanced manufacturing techniques to ensure consistent quality and scalability of their flexible piezoelectric sensors[15].

Strengths: High durability, excellent performance under large deformations, and scalable manufacturing process. Weaknesses: Potentially higher cost due to complex material composition and manufacturing process.

Sekisui Chemical Co., Ltd.

Technical Solution: Sekisui Chemical Co., Ltd. has developed a novel approach to flexible piezoelectric sensors using their expertise in materials science. Their technology is based on a composite material that combines piezoelectric ceramic particles with a flexible polymer matrix[7]. This allows for the creation of sensors that are both highly sensitive and mechanically robust. Sekisui's sensors can be molded into various shapes and thicknesses, making them adaptable to different wearable form factors. The company has also developed a proprietary electrode design that enhances the charge collection efficiency, resulting in improved signal-to-noise ratios compared to conventional flexible piezoelectric sensors[8]. Sekisui's sensors have shown promise in applications ranging from sports performance monitoring to medical diagnostics, with the ability to detect both large motions and subtle vibrations[9].

Strengths: Customizable form factors, high sensitivity, and mechanical robustness. Weaknesses: Potential limitations in extreme bending scenarios due to the ceramic component.

Core Innovations in Flexible Piezo Materials

Piezoelectric sensor

PatentWO2018047878A1

Innovation

- A piezoelectric sensor is designed with a porous synthetic resin sheet, a signal electrode layer, and a ground electrode layer, both containing conductive fine particles and stretchable binder resins, allowing for elasticity and accurate movement detection even when the surface expands or contracts.

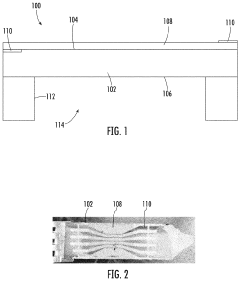

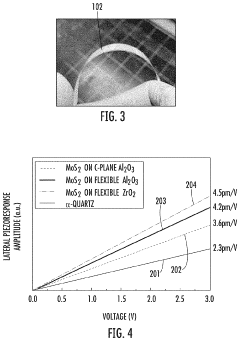

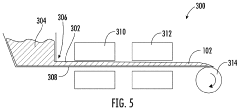

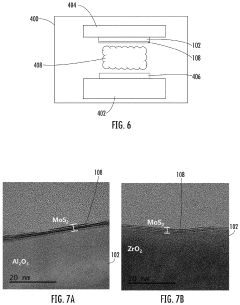

Flexible-piezoelectric sensors made with thin ribbon ceramics and transition metal dichalcogenides

PatentPendingUS20230337543A1

Innovation

- A flexible piezoelectric sensor is developed using a thin piezoelectric layer, typically a transition metal dichalcogenide (TMD) material, deposited on a ribbon ceramic substrate with a thickness between 10 μm to 200 μm, and electrical contacts are strategically placed to enhance sensitivity and conformality.

Biocompatibility and Safety Considerations

The integration of flexible piezoelectric sensors into wearable technology necessitates a thorough examination of biocompatibility and safety considerations. These factors are paramount in ensuring the widespread adoption and long-term viability of such devices in direct contact with human skin.

Biocompatibility is a critical aspect of wearable sensor design, as these devices are intended for prolonged contact with the user's body. The materials used in flexible piezoelectric sensors must not cause adverse reactions, such as skin irritation, allergic responses, or toxicity. Commonly used piezoelectric materials, including polyvinylidene fluoride (PVDF) and its copolymers, have shown promising biocompatibility profiles. However, ongoing research is essential to evaluate the long-term effects of continuous exposure to these materials.

The encapsulation of piezoelectric sensors plays a crucial role in enhancing biocompatibility. Biocompatible polymers, such as polydimethylsiloxane (PDMS) or medical-grade silicone, are often employed as protective layers. These materials not only isolate the active sensing components from direct skin contact but also provide flexibility and comfort to the wearer.

Safety considerations extend beyond biocompatibility to encompass electrical safety, mechanical reliability, and potential electromagnetic interference. The low voltage output of piezoelectric sensors generally poses minimal risk of electrical shock. However, proper insulation and grounding techniques must be implemented to prevent any potential electrical hazards, especially in scenarios where the sensor may be exposed to moisture or sweat.

Mechanical safety is another crucial aspect, particularly for flexible sensors that may undergo repeated bending or stretching. The design must ensure that the sensor maintains its structural integrity under various deformations without risking breakage or the release of potentially harmful components. This includes careful consideration of the adhesives and bonding methods used in sensor construction.

Electromagnetic compatibility (EMC) is an important safety consideration, especially as wearable devices often incorporate wireless communication capabilities. Piezoelectric sensors must be designed and shielded to prevent interference with other electronic devices, including medical implants such as pacemakers.

Long-term durability and degradation characteristics of the sensor materials must also be evaluated from a safety perspective. This includes assessing the potential for material breakdown over time and ensuring that any degradation products do not pose health risks to the user.

Regulatory compliance is a critical aspect of safety considerations for wearable piezoelectric sensors. Adherence to standards set by organizations such as the FDA, CE, and ISO is essential for market approval and consumer trust. This involves rigorous testing and documentation of the sensor's safety profile under various conditions of use.

Biocompatibility is a critical aspect of wearable sensor design, as these devices are intended for prolonged contact with the user's body. The materials used in flexible piezoelectric sensors must not cause adverse reactions, such as skin irritation, allergic responses, or toxicity. Commonly used piezoelectric materials, including polyvinylidene fluoride (PVDF) and its copolymers, have shown promising biocompatibility profiles. However, ongoing research is essential to evaluate the long-term effects of continuous exposure to these materials.

The encapsulation of piezoelectric sensors plays a crucial role in enhancing biocompatibility. Biocompatible polymers, such as polydimethylsiloxane (PDMS) or medical-grade silicone, are often employed as protective layers. These materials not only isolate the active sensing components from direct skin contact but also provide flexibility and comfort to the wearer.

Safety considerations extend beyond biocompatibility to encompass electrical safety, mechanical reliability, and potential electromagnetic interference. The low voltage output of piezoelectric sensors generally poses minimal risk of electrical shock. However, proper insulation and grounding techniques must be implemented to prevent any potential electrical hazards, especially in scenarios where the sensor may be exposed to moisture or sweat.

Mechanical safety is another crucial aspect, particularly for flexible sensors that may undergo repeated bending or stretching. The design must ensure that the sensor maintains its structural integrity under various deformations without risking breakage or the release of potentially harmful components. This includes careful consideration of the adhesives and bonding methods used in sensor construction.

Electromagnetic compatibility (EMC) is an important safety consideration, especially as wearable devices often incorporate wireless communication capabilities. Piezoelectric sensors must be designed and shielded to prevent interference with other electronic devices, including medical implants such as pacemakers.

Long-term durability and degradation characteristics of the sensor materials must also be evaluated from a safety perspective. This includes assessing the potential for material breakdown over time and ensuring that any degradation products do not pose health risks to the user.

Regulatory compliance is a critical aspect of safety considerations for wearable piezoelectric sensors. Adherence to standards set by organizations such as the FDA, CE, and ISO is essential for market approval and consumer trust. This involves rigorous testing and documentation of the sensor's safety profile under various conditions of use.

Energy Harvesting Potential of Flexible Piezo Sensors

Flexible piezoelectric sensors in wearable technology possess significant potential for energy harvesting, offering a sustainable power source for various applications. These sensors can convert mechanical energy from body movements into electrical energy, providing a continuous and renewable power supply for wearable devices. The energy harvesting capabilities of flexible piezo sensors are particularly advantageous in scenarios where traditional battery power is impractical or insufficient.

The efficiency of energy harvesting in flexible piezoelectric sensors depends on several factors, including the material properties, device structure, and the nature of applied mechanical stress. Advanced piezoelectric materials, such as polyvinylidene fluoride (PVDF) and its copolymers, exhibit high piezoelectric coefficients and flexibility, making them ideal for wearable applications. These materials can be engineered into thin films or nanofibers, maximizing their surface area and energy conversion efficiency.

The integration of flexible piezo sensors into textiles and garments opens up new possibilities for energy harvesting in everyday wear. By strategically placing these sensors in areas of high movement, such as joints or chest regions, the energy generated from regular activities like walking, breathing, or arm movements can be captured and utilized. This approach not only provides a power source but also enables the development of self-powered wearable systems.

Recent advancements in nanogenerator technology have further enhanced the energy harvesting potential of flexible piezo sensors. Triboelectric nanogenerators (TENGs), which combine piezoelectric and triboelectric effects, have demonstrated improved energy conversion efficiencies. These hybrid systems can harness energy from various mechanical inputs, including friction, vibration, and pressure, expanding the range of harvestable energy sources in wearable applications.

The scalability of flexible piezoelectric energy harvesters presents both opportunities and challenges. While individual sensors may generate small amounts of power, arrays of these sensors can potentially produce sufficient energy to power low-consumption electronic devices. However, optimizing the power management and storage systems to effectively utilize the harvested energy remains a critical area of research.

As wearable technology continues to evolve, the energy harvesting potential of flexible piezo sensors is expected to play a crucial role in addressing power limitations. Future developments may focus on enhancing the energy conversion efficiency, improving the durability of flexible materials, and developing more sophisticated energy management systems. These advancements could lead to truly self-sustaining wearable devices, reducing reliance on external power sources and expanding the possibilities for long-term, continuous monitoring in healthcare, fitness, and other applications.

The efficiency of energy harvesting in flexible piezoelectric sensors depends on several factors, including the material properties, device structure, and the nature of applied mechanical stress. Advanced piezoelectric materials, such as polyvinylidene fluoride (PVDF) and its copolymers, exhibit high piezoelectric coefficients and flexibility, making them ideal for wearable applications. These materials can be engineered into thin films or nanofibers, maximizing their surface area and energy conversion efficiency.

The integration of flexible piezo sensors into textiles and garments opens up new possibilities for energy harvesting in everyday wear. By strategically placing these sensors in areas of high movement, such as joints or chest regions, the energy generated from regular activities like walking, breathing, or arm movements can be captured and utilized. This approach not only provides a power source but also enables the development of self-powered wearable systems.

Recent advancements in nanogenerator technology have further enhanced the energy harvesting potential of flexible piezo sensors. Triboelectric nanogenerators (TENGs), which combine piezoelectric and triboelectric effects, have demonstrated improved energy conversion efficiencies. These hybrid systems can harness energy from various mechanical inputs, including friction, vibration, and pressure, expanding the range of harvestable energy sources in wearable applications.

The scalability of flexible piezoelectric energy harvesters presents both opportunities and challenges. While individual sensors may generate small amounts of power, arrays of these sensors can potentially produce sufficient energy to power low-consumption electronic devices. However, optimizing the power management and storage systems to effectively utilize the harvested energy remains a critical area of research.

As wearable technology continues to evolve, the energy harvesting potential of flexible piezo sensors is expected to play a crucial role in addressing power limitations. Future developments may focus on enhancing the energy conversion efficiency, improving the durability of flexible materials, and developing more sophisticated energy management systems. These advancements could lead to truly self-sustaining wearable devices, reducing reliance on external power sources and expanding the possibilities for long-term, continuous monitoring in healthcare, fitness, and other applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!