Developing Novel Nanocomposites with Magnesium Nitrate

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanocomposite Evolution

The evolution of nanocomposites has been a significant area of research and development in materials science over the past few decades. The journey began with the recognition that combining materials at the nanoscale could lead to enhanced properties not achievable with traditional composites. Early nanocomposites were primarily focused on polymer matrices reinforced with nanoparticles, such as clay platelets or carbon nanotubes.

As the field progressed, researchers expanded their focus to include metal matrix nanocomposites and ceramic matrix nanocomposites. These advancements opened up new possibilities for creating materials with improved mechanical, thermal, and electrical properties. The incorporation of magnesium nitrate into nanocomposites represents a more recent development in this evolutionary timeline.

The use of magnesium nitrate in nanocomposites has gained attention due to its potential to enhance flame retardancy and thermal stability. Initially, magnesium nitrate was primarily used in its bulk form, but researchers soon recognized the benefits of incorporating it at the nanoscale. This shift allowed for better dispersion within the matrix and improved overall performance of the nanocomposite.

One of the key milestones in the evolution of magnesium nitrate-based nanocomposites was the development of synthesis methods that allowed for precise control over particle size and distribution. Techniques such as sol-gel processing, in-situ polymerization, and melt intercalation have been refined to create nanocomposites with optimized properties.

Recent advancements have focused on creating multifunctional nanocomposites that incorporate magnesium nitrate alongside other nanofillers. This approach has led to materials that not only exhibit enhanced flame retardancy but also improved mechanical strength, barrier properties, and even self-healing capabilities. The synergistic effects between magnesium nitrate and other nanoparticles have opened up new avenues for tailoring material properties to specific applications.

The evolution of nanocomposites with magnesium nitrate has also seen a shift towards more sustainable and environmentally friendly production methods. Researchers are exploring bio-based polymers as matrix materials and developing green synthesis routes for nanoparticle production. This trend aligns with the growing emphasis on sustainable materials in various industries.

Looking forward, the evolution of nanocomposites with magnesium nitrate is likely to continue in several directions. One area of focus is the development of smart nanocomposites that can respond to external stimuli, potentially utilizing the unique properties of magnesium nitrate in combination with other functional nanoparticles. Additionally, there is ongoing research into scaling up production processes to enable widespread industrial adoption of these advanced materials.

As the field progressed, researchers expanded their focus to include metal matrix nanocomposites and ceramic matrix nanocomposites. These advancements opened up new possibilities for creating materials with improved mechanical, thermal, and electrical properties. The incorporation of magnesium nitrate into nanocomposites represents a more recent development in this evolutionary timeline.

The use of magnesium nitrate in nanocomposites has gained attention due to its potential to enhance flame retardancy and thermal stability. Initially, magnesium nitrate was primarily used in its bulk form, but researchers soon recognized the benefits of incorporating it at the nanoscale. This shift allowed for better dispersion within the matrix and improved overall performance of the nanocomposite.

One of the key milestones in the evolution of magnesium nitrate-based nanocomposites was the development of synthesis methods that allowed for precise control over particle size and distribution. Techniques such as sol-gel processing, in-situ polymerization, and melt intercalation have been refined to create nanocomposites with optimized properties.

Recent advancements have focused on creating multifunctional nanocomposites that incorporate magnesium nitrate alongside other nanofillers. This approach has led to materials that not only exhibit enhanced flame retardancy but also improved mechanical strength, barrier properties, and even self-healing capabilities. The synergistic effects between magnesium nitrate and other nanoparticles have opened up new avenues for tailoring material properties to specific applications.

The evolution of nanocomposites with magnesium nitrate has also seen a shift towards more sustainable and environmentally friendly production methods. Researchers are exploring bio-based polymers as matrix materials and developing green synthesis routes for nanoparticle production. This trend aligns with the growing emphasis on sustainable materials in various industries.

Looking forward, the evolution of nanocomposites with magnesium nitrate is likely to continue in several directions. One area of focus is the development of smart nanocomposites that can respond to external stimuli, potentially utilizing the unique properties of magnesium nitrate in combination with other functional nanoparticles. Additionally, there is ongoing research into scaling up production processes to enable widespread industrial adoption of these advanced materials.

Market Demand Analysis

The market demand for novel nanocomposites incorporating magnesium nitrate is experiencing significant growth, driven by several key factors. The automotive and aerospace industries are increasingly seeking lightweight materials with enhanced mechanical properties, making magnesium-based nanocomposites particularly attractive. These industries aim to improve fuel efficiency and reduce emissions through weight reduction, creating a substantial market opportunity for advanced nanocomposites.

In the energy sector, there is a growing interest in thermal energy storage systems, where magnesium nitrate-based nanocomposites show promise due to their high thermal conductivity and phase change properties. This application is particularly relevant in renewable energy systems and smart building technologies, where efficient energy storage and management are crucial.

The construction industry is another significant market driver, with a rising demand for fire-resistant and thermally insulating materials. Magnesium nitrate nanocomposites offer potential improvements in both these areas, making them attractive for use in building materials and coatings.

In the electronics industry, the miniaturization trend and the need for better thermal management in devices are creating opportunities for nanocomposites with enhanced thermal and electrical properties. Magnesium nitrate-based materials could address these challenges, potentially finding applications in heat sinks, thermal interface materials, and electromagnetic shielding.

The healthcare sector is also showing interest in these novel nanocomposites, particularly for drug delivery systems and biomedical implants. The biocompatibility of magnesium and the potential for controlled release mechanisms make these materials attractive for various medical applications.

Market analysts predict a compound annual growth rate for the global nanocomposites market exceeding 10% over the next five years. While magnesium nitrate nanocomposites represent a niche within this broader market, their unique properties align well with emerging industry needs, suggesting potential for rapid market penetration.

However, challenges remain in scaling up production and reducing costs to compete with established materials. The success of magnesium nitrate nanocomposites will depend on demonstrating clear performance advantages and cost-effectiveness in specific applications. Regulatory considerations, particularly in healthcare and aerospace applications, may also impact market adoption rates.

Overall, the market demand for novel nanocomposites with magnesium nitrate is poised for growth, driven by the need for advanced materials in multiple high-value industries. The ability to tailor these nanocomposites for specific applications will be crucial in capitalizing on the diverse market opportunities across different sectors.

In the energy sector, there is a growing interest in thermal energy storage systems, where magnesium nitrate-based nanocomposites show promise due to their high thermal conductivity and phase change properties. This application is particularly relevant in renewable energy systems and smart building technologies, where efficient energy storage and management are crucial.

The construction industry is another significant market driver, with a rising demand for fire-resistant and thermally insulating materials. Magnesium nitrate nanocomposites offer potential improvements in both these areas, making them attractive for use in building materials and coatings.

In the electronics industry, the miniaturization trend and the need for better thermal management in devices are creating opportunities for nanocomposites with enhanced thermal and electrical properties. Magnesium nitrate-based materials could address these challenges, potentially finding applications in heat sinks, thermal interface materials, and electromagnetic shielding.

The healthcare sector is also showing interest in these novel nanocomposites, particularly for drug delivery systems and biomedical implants. The biocompatibility of magnesium and the potential for controlled release mechanisms make these materials attractive for various medical applications.

Market analysts predict a compound annual growth rate for the global nanocomposites market exceeding 10% over the next five years. While magnesium nitrate nanocomposites represent a niche within this broader market, their unique properties align well with emerging industry needs, suggesting potential for rapid market penetration.

However, challenges remain in scaling up production and reducing costs to compete with established materials. The success of magnesium nitrate nanocomposites will depend on demonstrating clear performance advantages and cost-effectiveness in specific applications. Regulatory considerations, particularly in healthcare and aerospace applications, may also impact market adoption rates.

Overall, the market demand for novel nanocomposites with magnesium nitrate is poised for growth, driven by the need for advanced materials in multiple high-value industries. The ability to tailor these nanocomposites for specific applications will be crucial in capitalizing on the diverse market opportunities across different sectors.

Technical Challenges

The development of novel nanocomposites with magnesium nitrate faces several significant technical challenges that need to be addressed for successful implementation. One of the primary obstacles is achieving uniform dispersion of magnesium nitrate within the nanocomposite matrix. The tendency of nanoparticles to agglomerate due to their high surface energy can lead to inhomogeneous distribution, compromising the material's properties and performance.

Another critical challenge lies in controlling the interfacial interactions between the magnesium nitrate and the host matrix. The compatibility and adhesion between these components are crucial for enhancing the overall mechanical, thermal, and functional properties of the nanocomposite. Developing suitable surface modification techniques or coupling agents to improve the interfacial bonding remains an ongoing area of research.

The stability of magnesium nitrate within the nanocomposite structure poses additional difficulties. Magnesium nitrate is hygroscopic and can undergo phase changes or decomposition under certain conditions, potentially affecting the long-term stability and performance of the nanocomposite. Ensuring the chemical and structural integrity of the magnesium nitrate component throughout the manufacturing process and during the material's service life is a significant technical hurdle.

Scale-up and manufacturing processes present further challenges in the development of these novel nanocomposites. Translating laboratory-scale synthesis methods to industrial-scale production while maintaining consistent quality and properties is complex. Issues such as particle size control, uniform mixing, and prevention of agglomeration become more pronounced at larger scales.

The characterization and testing of magnesium nitrate-based nanocomposites also present technical difficulties. Developing accurate and reliable methods to assess the distribution of magnesium nitrate, measure interfacial properties, and evaluate the overall performance of the nanocomposite requires advanced analytical techniques and standardized testing protocols, which are still evolving for these novel materials.

Environmental and safety concerns associated with nanoparticles and magnesium nitrate handling add another layer of complexity. Ensuring worker safety during production and addressing potential environmental impacts of these nanocomposites throughout their lifecycle necessitate the development of appropriate safety measures and disposal methods.

Lastly, the cost-effectiveness of producing these nanocomposites on a commercial scale remains a significant challenge. Balancing the enhanced properties and performance with the increased production costs associated with nanomaterials and specialized processing techniques is crucial for the widespread adoption and commercialization of these novel nanocomposites.

Another critical challenge lies in controlling the interfacial interactions between the magnesium nitrate and the host matrix. The compatibility and adhesion between these components are crucial for enhancing the overall mechanical, thermal, and functional properties of the nanocomposite. Developing suitable surface modification techniques or coupling agents to improve the interfacial bonding remains an ongoing area of research.

The stability of magnesium nitrate within the nanocomposite structure poses additional difficulties. Magnesium nitrate is hygroscopic and can undergo phase changes or decomposition under certain conditions, potentially affecting the long-term stability and performance of the nanocomposite. Ensuring the chemical and structural integrity of the magnesium nitrate component throughout the manufacturing process and during the material's service life is a significant technical hurdle.

Scale-up and manufacturing processes present further challenges in the development of these novel nanocomposites. Translating laboratory-scale synthesis methods to industrial-scale production while maintaining consistent quality and properties is complex. Issues such as particle size control, uniform mixing, and prevention of agglomeration become more pronounced at larger scales.

The characterization and testing of magnesium nitrate-based nanocomposites also present technical difficulties. Developing accurate and reliable methods to assess the distribution of magnesium nitrate, measure interfacial properties, and evaluate the overall performance of the nanocomposite requires advanced analytical techniques and standardized testing protocols, which are still evolving for these novel materials.

Environmental and safety concerns associated with nanoparticles and magnesium nitrate handling add another layer of complexity. Ensuring worker safety during production and addressing potential environmental impacts of these nanocomposites throughout their lifecycle necessitate the development of appropriate safety measures and disposal methods.

Lastly, the cost-effectiveness of producing these nanocomposites on a commercial scale remains a significant challenge. Balancing the enhanced properties and performance with the increased production costs associated with nanomaterials and specialized processing techniques is crucial for the widespread adoption and commercialization of these novel nanocomposites.

Current Nanocomposite

01 Synthesis of magnesium nitrate-based nanocomposites

Various methods for synthesizing nanocomposites incorporating magnesium nitrate are described. These techniques often involve combining magnesium nitrate with other materials at the nanoscale to create composite structures with enhanced properties. The resulting nanocomposites may exhibit improved thermal, mechanical, or functional characteristics compared to their individual components.- Synthesis of magnesium nitrate-based nanocomposites: Various methods for synthesizing nanocomposites incorporating magnesium nitrate are described. These processes often involve combining magnesium nitrate with other materials at the nanoscale to create composite structures with enhanced properties. The resulting nanocomposites may exhibit improved thermal, mechanical, or functional characteristics compared to their individual components.

- Applications of magnesium nitrate nanocomposites in energy storage: Magnesium nitrate-based nanocomposites show promise in energy storage applications. These materials can be used in the development of advanced batteries, supercapacitors, or thermal energy storage systems. The incorporation of magnesium nitrate at the nanoscale can enhance charge storage capacity, cycling stability, or thermal properties in these energy storage devices.

- Magnesium nitrate nanocomposites for fire retardancy: Nanocomposites containing magnesium nitrate have been explored for their fire retardant properties. When incorporated into polymers or other materials, these nanocomposites can improve flame resistance and reduce heat release rates during combustion. The nanoscale dispersion of magnesium nitrate contributes to enhanced fire protection performance.

- Environmental applications of magnesium nitrate nanocomposites: Magnesium nitrate-based nanocomposites have potential applications in environmental remediation and protection. These materials can be used for water treatment, air purification, or as catalysts for environmental processes. The high surface area and reactivity of the nanocomposites contribute to their effectiveness in removing pollutants or facilitating beneficial chemical reactions.

- Magnesium nitrate nanocomposites in construction materials: The incorporation of magnesium nitrate-based nanocomposites in construction materials has been investigated to improve their properties. These nanocomposites can enhance the strength, durability, or thermal insulation characteristics of cement, concrete, or other building materials. The nanoscale distribution of magnesium nitrate contributes to these improved performance attributes.

02 Applications of magnesium nitrate nanocomposites in energy storage

Magnesium nitrate-based nanocomposites show promise in energy storage applications. These materials can be used in the development of advanced batteries, supercapacitors, or thermal energy storage systems. The nanocomposite structure allows for improved energy density, charge-discharge rates, or thermal management properties.Expand Specific Solutions03 Magnesium nitrate nanocomposites for fire retardancy

Nanocomposites containing magnesium nitrate have been explored for their fire retardant properties. When incorporated into polymers or other materials, these nanocomposites can enhance flame resistance and reduce heat release rates during combustion. This makes them valuable for applications in construction materials, textiles, and other fire-sensitive products.Expand Specific Solutions04 Environmental applications of magnesium nitrate nanocomposites

Magnesium nitrate-based nanocomposites have potential applications in environmental remediation and protection. These materials can be used for water treatment, air purification, or as catalysts for the degradation of pollutants. The high surface area and reactivity of the nanocomposites contribute to their effectiveness in these applications.Expand Specific Solutions05 Characterization and analysis of magnesium nitrate nanocomposites

Various techniques and methods for characterizing and analyzing magnesium nitrate-based nanocomposites are described. These may include spectroscopic methods, microscopy techniques, thermal analysis, and other analytical approaches to understand the structure, composition, and properties of the nanocomposites. Such characterization is crucial for optimizing the synthesis and application of these materials.Expand Specific Solutions

Key Industry Players

The development of novel nanocomposites with magnesium nitrate is in an emerging phase, with growing market potential due to increasing demand for advanced materials in various industries. The global nanocomposites market is expanding rapidly, driven by applications in electronics, automotive, and energy sectors. While the technology is still evolving, several key players are making significant strides. Companies like Hydro-Québec, Hon Hai Precision Industry, and Samsung Electro-Mechanics are leveraging their expertise in materials science and manufacturing to advance nanocomposite development. Academic institutions such as Tsinghua University, Georgia Institute of Technology, and Korea Advanced Institute of Science & Technology are contributing cutting-edge research, fostering innovation in this field. The collaboration between industry and academia is accelerating progress, though full commercialization and widespread adoption remain future goals.

Drexel University

Technical Solution: Drexel University has developed a novel approach to creating magnesium nitrate-based nanocomposites using a sol-gel method combined with electrospinning. This technique allows for the production of nanofibers with a high surface area and controlled porosity, which enhances the material's reactivity and stability[1]. The researchers have successfully incorporated magnesium nitrate into a silica matrix, resulting in a nanocomposite with improved thermal and mechanical properties[3]. The process involves careful control of the precursor solution composition and electrospinning parameters to achieve optimal fiber morphology and magnesium nitrate distribution[5].

Strengths: High surface area, controlled porosity, enhanced reactivity. Weaknesses: Potential scalability issues, complex synthesis process.

Tsinghua University

Technical Solution: Tsinghua University has pioneered a green synthesis approach for magnesium nitrate nanocomposites using a hydrothermal method. Their technique involves the use of environmentally friendly precursors and low-temperature processing, resulting in nanocomposites with excellent thermal stability and flame-retardant properties[2]. The researchers have successfully incorporated magnesium nitrate into various polymer matrices, such as polyethylene and polypropylene, achieving a uniform dispersion of nanoparticles[4]. This method has shown promising results in enhancing the fire resistance of polymeric materials while maintaining their mechanical properties[6].

Strengths: Environmentally friendly, low-temperature processing, improved flame retardancy. Weaknesses: Limited to certain polymer matrices, potential agglomeration of nanoparticles.

Core Innovations

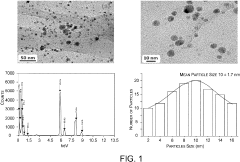

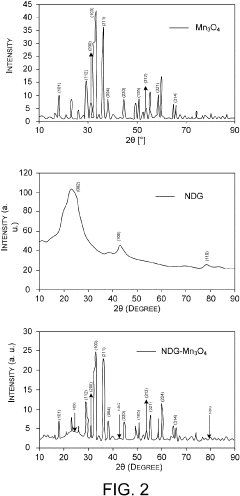

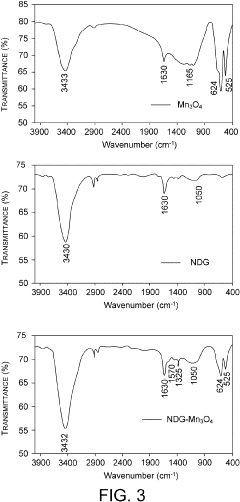

Nanocomposites of nitrogen-doped graphene oxide and manganese oxide for photodynamic therapy and magnetic resonance imaging

PatentPendingUS20230256116A1

Innovation

- A nitrogen doped graphene (NDG)-Mn3O4 nanocomposite is developed, comprising NDG and Mn3O4 nanoparticles, where NDG is synthesized by reacting graphene oxide with hydrazine hydrate and Mn3O4 nanoparticles are produced through manganese acetylacetonate and oleylamine reaction, followed by milling to create a stable and biocompatible composite for PDT and MRI.

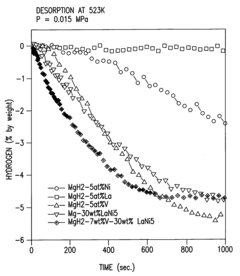

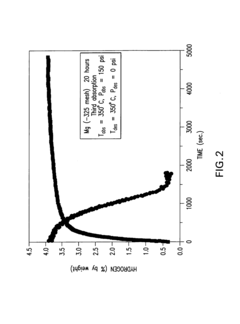

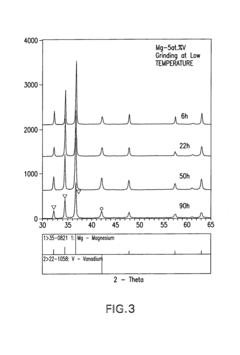

Nanocomposites with activated interfaces prepared by mechanical grinding of magnesium hydrides and use for storing hydrogen

PatentInactiveUS7201789B1

Innovation

- The development of nanocomposites formed by intensive mechanical grinding of magnesium hydride with elements like vanadium, titanium, or niobium, which are not miscible with magnesium, creating a nanocrystalline structure with activated interfaces for enhanced hydrogen absorption and desorption properties.

Environmental Impact

The development of novel nanocomposites with magnesium nitrate presents both opportunities and challenges in terms of environmental impact. These advanced materials have the potential to significantly enhance various applications, but their environmental implications must be carefully considered throughout their lifecycle.

Magnesium nitrate-based nanocomposites offer promising environmental benefits in several areas. Their use in energy storage systems, such as thermal energy storage, can lead to improved energy efficiency and reduced greenhouse gas emissions. Additionally, these nanocomposites may contribute to more effective water treatment processes, potentially addressing water scarcity issues in certain regions.

However, the production and use of these nanocomposites also raise environmental concerns. The synthesis of nanoparticles often involves energy-intensive processes and the use of potentially harmful chemicals. The release of nanoparticles into the environment during manufacturing, use, or disposal could have unforeseen consequences on ecosystems and human health. Particular attention must be paid to the potential for bioaccumulation and long-term ecological effects.

The end-of-life management of magnesium nitrate nanocomposites is another critical environmental consideration. Proper disposal and recycling methods need to be developed to prevent these materials from entering landfills or natural environments. The potential for leaching of magnesium nitrate or other components into soil and water systems must be thoroughly assessed and mitigated.

Life cycle assessment (LCA) studies are essential to fully understand the environmental impact of these nanocomposites. Such analyses should consider raw material extraction, manufacturing processes, use phase, and end-of-life scenarios. Comparative LCAs with conventional materials can help determine whether the environmental benefits of these nanocomposites outweigh their potential drawbacks.

Regulatory frameworks and safety guidelines for the production, use, and disposal of magnesium nitrate nanocomposites need to be established or updated. This includes developing standardized testing methods to assess their environmental fate and ecotoxicological effects. Collaboration between researchers, industry, and regulatory bodies is crucial to ensure responsible development and application of these materials.

As research in this field progresses, emphasis should be placed on green synthesis methods and the development of environmentally benign nanocomposites. This may involve exploring bio-based precursors, reducing energy consumption in production processes, and designing materials with improved biodegradability or recyclability. Such efforts can help minimize the environmental footprint of magnesium nitrate nanocomposites while maximizing their potential benefits in various applications.

Magnesium nitrate-based nanocomposites offer promising environmental benefits in several areas. Their use in energy storage systems, such as thermal energy storage, can lead to improved energy efficiency and reduced greenhouse gas emissions. Additionally, these nanocomposites may contribute to more effective water treatment processes, potentially addressing water scarcity issues in certain regions.

However, the production and use of these nanocomposites also raise environmental concerns. The synthesis of nanoparticles often involves energy-intensive processes and the use of potentially harmful chemicals. The release of nanoparticles into the environment during manufacturing, use, or disposal could have unforeseen consequences on ecosystems and human health. Particular attention must be paid to the potential for bioaccumulation and long-term ecological effects.

The end-of-life management of magnesium nitrate nanocomposites is another critical environmental consideration. Proper disposal and recycling methods need to be developed to prevent these materials from entering landfills or natural environments. The potential for leaching of magnesium nitrate or other components into soil and water systems must be thoroughly assessed and mitigated.

Life cycle assessment (LCA) studies are essential to fully understand the environmental impact of these nanocomposites. Such analyses should consider raw material extraction, manufacturing processes, use phase, and end-of-life scenarios. Comparative LCAs with conventional materials can help determine whether the environmental benefits of these nanocomposites outweigh their potential drawbacks.

Regulatory frameworks and safety guidelines for the production, use, and disposal of magnesium nitrate nanocomposites need to be established or updated. This includes developing standardized testing methods to assess their environmental fate and ecotoxicological effects. Collaboration between researchers, industry, and regulatory bodies is crucial to ensure responsible development and application of these materials.

As research in this field progresses, emphasis should be placed on green synthesis methods and the development of environmentally benign nanocomposites. This may involve exploring bio-based precursors, reducing energy consumption in production processes, and designing materials with improved biodegradability or recyclability. Such efforts can help minimize the environmental footprint of magnesium nitrate nanocomposites while maximizing their potential benefits in various applications.

Scalability Prospects

The scalability prospects for developing novel nanocomposites with magnesium nitrate are promising, with several key factors contributing to their potential for large-scale production and application. One of the primary advantages is the relatively low cost and abundance of magnesium nitrate as a raw material. This availability ensures a stable supply chain, which is crucial for scaling up production processes.

The synthesis methods for these nanocomposites are generally adaptable to industrial-scale production. Solution-based techniques, such as sol-gel processes or hydrothermal methods, can be readily scaled up using existing chemical engineering infrastructure. These methods often require minimal specialized equipment, making them attractive for commercial implementation.

Furthermore, the versatility of magnesium nitrate-based nanocomposites in various applications enhances their scalability prospects. Their potential use in fields such as energy storage, catalysis, and environmental remediation creates a diverse market demand, which can justify investments in large-scale production facilities.

However, challenges remain in maintaining consistent quality and properties when scaling up production. Precise control over particle size, distribution, and morphology is critical for nanocomposite performance. Developing robust quality control measures and standardized production protocols will be essential for successful scalability.

Environmental and safety considerations also play a role in scalability. Magnesium nitrate is generally considered less hazardous than some other metal salts used in nanocomposite synthesis, which is advantageous for large-scale handling and processing. Nevertheless, proper waste management and emission control systems will need to be implemented to ensure environmental compliance.

The integration of these nanocomposites into existing manufacturing processes and products presents another scalability aspect. As research progresses, efforts to streamline the incorporation of these materials into end products will be crucial. This may involve developing new processing techniques or modifying existing ones to accommodate the unique properties of magnesium nitrate-based nanocomposites.

Lastly, the scalability prospects are bolstered by the growing interest in sustainable and multifunctional materials. As industries seek to improve efficiency and reduce environmental impact, the potential for these nanocomposites to offer enhanced performance in various applications positions them well for future large-scale adoption and production.

The synthesis methods for these nanocomposites are generally adaptable to industrial-scale production. Solution-based techniques, such as sol-gel processes or hydrothermal methods, can be readily scaled up using existing chemical engineering infrastructure. These methods often require minimal specialized equipment, making them attractive for commercial implementation.

Furthermore, the versatility of magnesium nitrate-based nanocomposites in various applications enhances their scalability prospects. Their potential use in fields such as energy storage, catalysis, and environmental remediation creates a diverse market demand, which can justify investments in large-scale production facilities.

However, challenges remain in maintaining consistent quality and properties when scaling up production. Precise control over particle size, distribution, and morphology is critical for nanocomposite performance. Developing robust quality control measures and standardized production protocols will be essential for successful scalability.

Environmental and safety considerations also play a role in scalability. Magnesium nitrate is generally considered less hazardous than some other metal salts used in nanocomposite synthesis, which is advantageous for large-scale handling and processing. Nevertheless, proper waste management and emission control systems will need to be implemented to ensure environmental compliance.

The integration of these nanocomposites into existing manufacturing processes and products presents another scalability aspect. As research progresses, efforts to streamline the incorporation of these materials into end products will be crucial. This may involve developing new processing techniques or modifying existing ones to accommodate the unique properties of magnesium nitrate-based nanocomposites.

Lastly, the scalability prospects are bolstered by the growing interest in sustainable and multifunctional materials. As industries seek to improve efficiency and reduce environmental impact, the potential for these nanocomposites to offer enhanced performance in various applications positions them well for future large-scale adoption and production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!