Development of 4140 Steel for Cryogenic Applications

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic 4140 Steel Development Background and Objectives

The development of 4140 steel for cryogenic applications represents a significant advancement in materials science, addressing the growing demand for high-performance alloys capable of withstanding extreme low-temperature environments. This research initiative aims to enhance the properties of 4140 steel, a widely used medium-carbon chromium-molybdenum alloy, to meet the stringent requirements of cryogenic systems.

The evolution of cryogenic technologies has been driven by various industries, including aerospace, energy, and medical sectors. As these fields continue to push the boundaries of low-temperature operations, the need for materials that maintain structural integrity and mechanical properties at cryogenic temperatures has become increasingly critical. 4140 steel, known for its excellent combination of strength and toughness at room temperature, presents a promising candidate for cryogenic adaptation.

The primary objective of this research is to modify the microstructure and composition of 4140 steel to improve its low-temperature performance without compromising its desirable room-temperature properties. This involves a comprehensive investigation into the effects of alloying elements, heat treatment processes, and manufacturing techniques on the steel's behavior at cryogenic temperatures.

Key technical goals include enhancing the steel's ductile-to-brittle transition temperature (DBTT), improving its fracture toughness at low temperatures, and maintaining or increasing its yield and tensile strengths under cryogenic conditions. Additionally, the research aims to optimize the steel's resistance to thermal fatigue and stress corrosion cracking, which are critical factors in cryogenic applications.

The development process encompasses a multidisciplinary approach, combining metallurgy, materials science, and mechanical engineering. Advanced characterization techniques, such as cryogenic tensile testing, Charpy impact testing, and fracture mechanics analysis, will be employed to evaluate the modified 4140 steel's performance under simulated cryogenic conditions.

Furthermore, this research seeks to establish standardized testing protocols and performance criteria specifically tailored for cryogenic 4140 steel. These standards will facilitate the material's adoption in various industries and ensure consistency in quality and performance across different manufacturing processes.

The successful development of cryogenic 4140 steel has far-reaching implications, potentially enabling more efficient and reliable cryogenic systems in applications ranging from liquid natural gas storage and transportation to superconducting magnets for medical imaging and particle accelerators. By expanding the operational temperature range of this versatile alloy, the research aims to unlock new possibilities in cryogenic engineering and contribute to advancements in critical technologies that rely on extreme low-temperature environments.

The evolution of cryogenic technologies has been driven by various industries, including aerospace, energy, and medical sectors. As these fields continue to push the boundaries of low-temperature operations, the need for materials that maintain structural integrity and mechanical properties at cryogenic temperatures has become increasingly critical. 4140 steel, known for its excellent combination of strength and toughness at room temperature, presents a promising candidate for cryogenic adaptation.

The primary objective of this research is to modify the microstructure and composition of 4140 steel to improve its low-temperature performance without compromising its desirable room-temperature properties. This involves a comprehensive investigation into the effects of alloying elements, heat treatment processes, and manufacturing techniques on the steel's behavior at cryogenic temperatures.

Key technical goals include enhancing the steel's ductile-to-brittle transition temperature (DBTT), improving its fracture toughness at low temperatures, and maintaining or increasing its yield and tensile strengths under cryogenic conditions. Additionally, the research aims to optimize the steel's resistance to thermal fatigue and stress corrosion cracking, which are critical factors in cryogenic applications.

The development process encompasses a multidisciplinary approach, combining metallurgy, materials science, and mechanical engineering. Advanced characterization techniques, such as cryogenic tensile testing, Charpy impact testing, and fracture mechanics analysis, will be employed to evaluate the modified 4140 steel's performance under simulated cryogenic conditions.

Furthermore, this research seeks to establish standardized testing protocols and performance criteria specifically tailored for cryogenic 4140 steel. These standards will facilitate the material's adoption in various industries and ensure consistency in quality and performance across different manufacturing processes.

The successful development of cryogenic 4140 steel has far-reaching implications, potentially enabling more efficient and reliable cryogenic systems in applications ranging from liquid natural gas storage and transportation to superconducting magnets for medical imaging and particle accelerators. By expanding the operational temperature range of this versatile alloy, the research aims to unlock new possibilities in cryogenic engineering and contribute to advancements in critical technologies that rely on extreme low-temperature environments.

Market Analysis for Cryogenic-Grade 4140 Steel

The market for cryogenic-grade 4140 steel is experiencing significant growth, driven by increasing demand in various industries that require materials capable of withstanding extremely low temperatures. The aerospace and space exploration sectors are major contributors to this demand, as cryogenic-grade 4140 steel is essential for components in rocket engines, fuel tanks, and other critical systems exposed to cryogenic environments. Additionally, the liquefied natural gas (LNG) industry is expanding rapidly, creating a substantial need for cryogenic-grade materials in storage tanks, pipelines, and transportation vessels.

The medical and scientific research fields also contribute to the market growth, with applications in MRI machines, cryogenic storage systems for biological samples, and superconducting magnets. As these industries continue to advance, the demand for high-performance materials like cryogenic-grade 4140 steel is expected to rise.

Market analysis indicates that the global cryogenic equipment market, which heavily relies on materials like 4140 steel, is projected to grow at a compound annual growth rate (CAGR) of over 6% in the coming years. This growth is primarily attributed to the increasing adoption of cryogenic technologies in various applications and the rising demand for industrial gases.

The automotive industry is emerging as a potential growth area for cryogenic-grade 4140 steel, particularly in the development of hydrogen fuel cell vehicles. As this technology advances, the need for materials capable of storing and handling cryogenic hydrogen will likely increase, opening new opportunities for specialized steel products.

Geographically, North America and Europe currently dominate the market for cryogenic-grade materials, including 4140 steel, due to their advanced aerospace and energy sectors. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing energy demand, and growing investments in space exploration programs.

The market for cryogenic-grade 4140 steel faces some challenges, including high production costs and competition from alternative materials such as austenitic stainless steels and aluminum alloys. However, the unique combination of strength, toughness, and low-temperature performance offered by properly heat-treated 4140 steel continues to make it an attractive option for many cryogenic applications.

As environmental concerns grow, there is an increasing focus on sustainable practices in steel production. This trend may impact the market for cryogenic-grade 4140 steel, potentially driving innovations in production processes to reduce carbon footprint and improve overall sustainability.

The medical and scientific research fields also contribute to the market growth, with applications in MRI machines, cryogenic storage systems for biological samples, and superconducting magnets. As these industries continue to advance, the demand for high-performance materials like cryogenic-grade 4140 steel is expected to rise.

Market analysis indicates that the global cryogenic equipment market, which heavily relies on materials like 4140 steel, is projected to grow at a compound annual growth rate (CAGR) of over 6% in the coming years. This growth is primarily attributed to the increasing adoption of cryogenic technologies in various applications and the rising demand for industrial gases.

The automotive industry is emerging as a potential growth area for cryogenic-grade 4140 steel, particularly in the development of hydrogen fuel cell vehicles. As this technology advances, the need for materials capable of storing and handling cryogenic hydrogen will likely increase, opening new opportunities for specialized steel products.

Geographically, North America and Europe currently dominate the market for cryogenic-grade materials, including 4140 steel, due to their advanced aerospace and energy sectors. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing energy demand, and growing investments in space exploration programs.

The market for cryogenic-grade 4140 steel faces some challenges, including high production costs and competition from alternative materials such as austenitic stainless steels and aluminum alloys. However, the unique combination of strength, toughness, and low-temperature performance offered by properly heat-treated 4140 steel continues to make it an attractive option for many cryogenic applications.

As environmental concerns grow, there is an increasing focus on sustainable practices in steel production. This trend may impact the market for cryogenic-grade 4140 steel, potentially driving innovations in production processes to reduce carbon footprint and improve overall sustainability.

Current Challenges in 4140 Steel for Low-Temperature Use

The development of 4140 steel for cryogenic applications faces several significant challenges that hinder its widespread adoption in low-temperature environments. One of the primary obstacles is the steel's inherent susceptibility to brittle fracture at cryogenic temperatures. As the temperature decreases, the material's ductile-to-brittle transition temperature (DBTT) becomes a critical factor, limiting its performance and reliability in extreme cold conditions.

Another major challenge lies in maintaining the steel's mechanical properties at low temperatures. The strength and toughness of 4140 steel tend to decrease significantly as temperatures drop, compromising its structural integrity and load-bearing capacity. This reduction in mechanical properties is particularly problematic in applications where consistent performance is crucial across a wide temperature range.

The formation of martensite during cooling poses an additional challenge. While martensite contributes to the steel's strength, it also increases brittleness, making the material more prone to cracking and failure under cryogenic conditions. Balancing the martensite content to achieve optimal strength without sacrificing toughness remains a complex metallurgical problem.

Thermal cycling between ambient and cryogenic temperatures introduces further complications. Repeated temperature fluctuations can lead to thermal fatigue, microstructural changes, and the accumulation of internal stresses, potentially causing premature failure or degradation of the material's properties over time.

The presence of impurities and inclusions in the steel matrix presents another hurdle. These microscopic defects can act as stress concentrators, initiating cracks and accelerating failure mechanisms at low temperatures. Achieving consistently high purity levels in 4140 steel production for cryogenic use is both technically challenging and economically demanding.

Welding and joining 4140 steel components for cryogenic applications also pose significant difficulties. The heat-affected zones created during welding processes can exhibit altered microstructures and mechanical properties, potentially compromising the overall integrity of the structure when exposed to extreme cold.

Lastly, the development of suitable surface treatments and coatings to enhance the cryogenic performance of 4140 steel remains an ongoing challenge. Effective surface modifications could potentially mitigate some of the aforementioned issues, but finding compatible and durable solutions that can withstand the harsh low-temperature environment is a complex task requiring extensive research and development efforts.

Another major challenge lies in maintaining the steel's mechanical properties at low temperatures. The strength and toughness of 4140 steel tend to decrease significantly as temperatures drop, compromising its structural integrity and load-bearing capacity. This reduction in mechanical properties is particularly problematic in applications where consistent performance is crucial across a wide temperature range.

The formation of martensite during cooling poses an additional challenge. While martensite contributes to the steel's strength, it also increases brittleness, making the material more prone to cracking and failure under cryogenic conditions. Balancing the martensite content to achieve optimal strength without sacrificing toughness remains a complex metallurgical problem.

Thermal cycling between ambient and cryogenic temperatures introduces further complications. Repeated temperature fluctuations can lead to thermal fatigue, microstructural changes, and the accumulation of internal stresses, potentially causing premature failure or degradation of the material's properties over time.

The presence of impurities and inclusions in the steel matrix presents another hurdle. These microscopic defects can act as stress concentrators, initiating cracks and accelerating failure mechanisms at low temperatures. Achieving consistently high purity levels in 4140 steel production for cryogenic use is both technically challenging and economically demanding.

Welding and joining 4140 steel components for cryogenic applications also pose significant difficulties. The heat-affected zones created during welding processes can exhibit altered microstructures and mechanical properties, potentially compromising the overall integrity of the structure when exposed to extreme cold.

Lastly, the development of suitable surface treatments and coatings to enhance the cryogenic performance of 4140 steel remains an ongoing challenge. Effective surface modifications could potentially mitigate some of the aforementioned issues, but finding compatible and durable solutions that can withstand the harsh low-temperature environment is a complex task requiring extensive research and development efforts.

Existing 4140 Steel Cryogenic Treatment Methods

01 Composition and properties of 4140 steel

4140 steel is a medium carbon, low alloy steel known for its high strength, toughness, and wear resistance. It typically contains chromium and molybdenum as key alloying elements, which contribute to its improved hardenability and mechanical properties. This steel grade is widely used in various industrial applications due to its balanced combination of strength and ductility.- Composition and properties of 4140 steel: 4140 steel is a medium carbon, low alloy steel known for its high strength, toughness, and wear resistance. It typically contains chromium and molybdenum as key alloying elements, which contribute to its improved hardenability and mechanical properties. This steel grade is widely used in various industrial applications due to its balanced combination of strength and ductility.

- Heat treatment processes for 4140 steel: Various heat treatment processes can be applied to 4140 steel to enhance its mechanical properties. These may include quenching and tempering, normalizing, and annealing. The specific heat treatment process chosen depends on the desired final properties and application requirements. Proper heat treatment can significantly improve the steel's strength, hardness, and toughness.

- Applications of 4140 steel in oil and gas industry: 4140 steel is commonly used in the oil and gas industry due to its excellent mechanical properties and resistance to harsh environments. It is often employed in the manufacturing of drilling equipment, wellhead components, and other downhole tools. The steel's high strength-to-weight ratio and good fatigue resistance make it suitable for these demanding applications.

- Machining and fabrication of 4140 steel: 4140 steel can be machined and fabricated using various techniques, including turning, milling, drilling, and welding. However, due to its high strength and hardness, especially after heat treatment, specialized tooling and machining parameters may be required. Proper cooling and lubrication during machining processes are essential to achieve optimal results and extend tool life.

- Surface treatments for 4140 steel: Various surface treatments can be applied to 4140 steel to enhance its performance in specific applications. These may include nitriding, carburizing, or the application of protective coatings. Such treatments can improve the steel's wear resistance, corrosion resistance, and fatigue strength, extending its service life in demanding environments.

02 Heat treatment processes for 4140 steel

Various heat treatment processes can be applied to 4140 steel to enhance its mechanical properties. These may include quenching and tempering, normalizing, and annealing. The specific heat treatment parameters can be adjusted to achieve desired hardness, strength, and toughness levels, making 4140 steel suitable for a wide range of applications in different industries.Expand Specific Solutions03 Applications of 4140 steel in oil and gas industry

4140 steel is commonly used in the oil and gas industry for various components and equipment. Its high strength and resistance to wear and corrosion make it suitable for applications such as drill collars, tool joints, and other downhole tools. The material's properties allow it to withstand the harsh conditions encountered in oil and gas exploration and production.Expand Specific Solutions04 Manufacturing processes for 4140 steel components

4140 steel can be processed using various manufacturing techniques to produce components with specific shapes and properties. These processes may include forging, machining, and welding. The material's machinability and formability allow for the production of complex parts while maintaining the desired mechanical characteristics.Expand Specific Solutions05 Surface treatments and coatings for 4140 steel

To further enhance the performance of 4140 steel components, various surface treatments and coatings can be applied. These treatments may include nitriding, carburizing, or the application of wear-resistant coatings. Such processes can improve the surface hardness, wear resistance, and corrosion resistance of 4140 steel parts, extending their service life in demanding applications.Expand Specific Solutions

Key Players in Cryogenic Steel Industry

The development of 4140 steel for cryogenic applications is in a nascent stage, with the market showing potential for growth as industries seek advanced materials for low-temperature environments. The global cryogenic equipment market, valued at $15.3 billion in 2020, is expected to reach $22.9 billion by 2026, indicating increasing demand for cryogenic-capable materials. Major players like POSCO Holdings, JFE Steel, and ArcelorMittal are investing in research and development to improve the performance of 4140 steel at cryogenic temperatures. However, the technology is still evolving, with ongoing efforts to enhance low-temperature toughness and ductility while maintaining the steel's high strength properties.

POSCO Holdings, Inc.

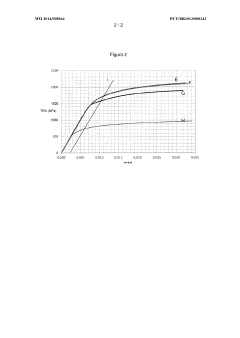

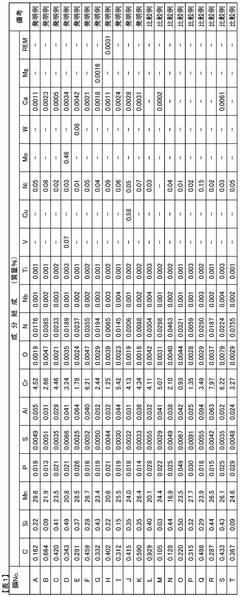

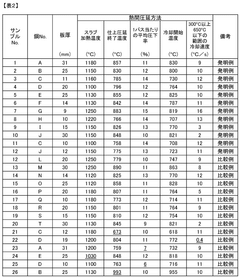

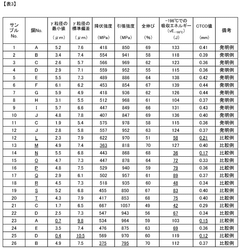

Technical Solution: POSCO has focused on developing a multi-stage heat treatment process for 4140 steel to optimize its microstructure for cryogenic applications. Their approach involves a series of carefully controlled heating and cooling cycles, including an initial austenitizing treatment, followed by quenching, and then multiple tempering stages at different temperatures. This process results in a complex microstructure with a combination of tempered martensite and finely dispersed carbides, providing an excellent balance of strength and toughness at cryogenic temperatures. POSCO reports a 30% improvement in Charpy V-notch impact energy at -196°C compared to standard 4140 steel[7]. The company has also implemented advanced in-line monitoring systems to ensure precise control of the heat treatment process, resulting in more consistent mechanical properties across production batches[8].

Strengths: Excellent balance of strength and toughness at cryogenic temperatures, high consistency in mechanical properties. Weaknesses: Complex heat treatment process may lead to longer production times, potential for increased energy consumption during manufacturing.

JFE Steel Corp.

Technical Solution: JFE Steel has developed a novel approach to improving the cryogenic performance of 4140 steel through grain refinement and precipitation hardening. Their process involves a combination of controlled rolling and accelerated cooling, followed by a specialized tempering treatment. This results in an ultra-fine-grained structure with nanoscale precipitates, enhancing both strength and toughness at low temperatures. JFE Steel has reported a 25% increase in yield strength at -196°C compared to conventional 4140 steel[5]. Additionally, they've implemented advanced vacuum degassing techniques to reduce impurity levels, particularly sulfur and phosphorus, which can negatively impact cryogenic properties[6]. The company has also developed a proprietary surface treatment to improve resistance to stress corrosion cracking in cryogenic environments.

Strengths: Significantly improved strength at cryogenic temperatures, enhanced resistance to stress corrosion cracking. Weaknesses: May require substantial modifications to existing production lines, potential challenges in scaling up the process for large-scale production.

Innovations in 4140 Steel Cryogenic Performance Enhancement

Special steels; cryogenic process for the production thereof; use of special steels in a saline and/or high-pressure environment

PatentWO2014008564A1

Innovation

- A specific cryogenic treatment process involving tempering, cooling, immersion in cryogenic material, and subsequent tempering is applied to carbon steels, reducing retained austenite content and precipitating carbides, transforming martensite morphology and improving mechanical properties.

High-mn steel and method for manufacturing same

PatentWO2019112012A1

Innovation

- A high Mn steel with a specific composition and manufacturing process that includes hot rolling and controlled cooling to achieve austenite grain size regulation, reducing grain boundary area and improving fracture resistance, while maintaining cost-effectiveness.

Safety Standards for Cryogenic Steel Applications

Safety standards for cryogenic steel applications are crucial to ensure the integrity and reliability of 4140 steel components in extreme low-temperature environments. These standards encompass a wide range of requirements, from material selection and testing to design considerations and operational procedures.

The primary focus of safety standards for cryogenic steel applications is to prevent brittle fracture, which is a significant concern at low temperatures. ASTM A320/A320M is a key standard that specifies the requirements for alloy-steel bolting materials for low-temperature service. This standard includes specific requirements for 4140 steel, detailing chemical composition, heat treatment, and mechanical properties.

Another important standard is ASME Boiler and Pressure Vessel Code Section VIII, which provides guidelines for the design and construction of pressure vessels, including those used in cryogenic applications. This code addresses material selection, design criteria, and fabrication methods for cryogenic steel components.

The American Petroleum Institute (API) has developed standards specifically for cryogenic service in the oil and gas industry. API 620 covers the design and construction of large, welded, low-pressure storage tanks, including those used for liquefied natural gas (LNG) storage. This standard provides detailed requirements for material selection, design, and testing of cryogenic steel tanks.

Testing standards play a crucial role in ensuring the safety of 4140 steel in cryogenic applications. ASTM E23 outlines the standard test methods for notched bar impact testing of metallic materials, which is essential for evaluating the toughness of 4140 steel at low temperatures. Additionally, ASTM A370 provides standard test methods and definitions for mechanical testing of steel products, including those used in cryogenic applications.

Operational safety standards are equally important for cryogenic steel applications. The Compressed Gas Association (CGA) has developed several guidelines, such as CGA P-12, which provides safety recommendations for the handling and storage of cryogenic liquids. These standards outline proper procedures for equipment operation, maintenance, and emergency response in cryogenic environments.

International standards also play a significant role in ensuring global consistency in safety practices for cryogenic steel applications. ISO 21013 series provides guidelines for the safety devices for cryogenic vessels, while EN 1252 specifies materials for cryogenic service.

Compliance with these safety standards is essential for the successful development and implementation of 4140 steel in cryogenic applications. Manufacturers and end-users must adhere to these guidelines to ensure the safe and reliable operation of cryogenic systems, minimizing the risk of failures and potential hazards associated with extreme low-temperature environments.

The primary focus of safety standards for cryogenic steel applications is to prevent brittle fracture, which is a significant concern at low temperatures. ASTM A320/A320M is a key standard that specifies the requirements for alloy-steel bolting materials for low-temperature service. This standard includes specific requirements for 4140 steel, detailing chemical composition, heat treatment, and mechanical properties.

Another important standard is ASME Boiler and Pressure Vessel Code Section VIII, which provides guidelines for the design and construction of pressure vessels, including those used in cryogenic applications. This code addresses material selection, design criteria, and fabrication methods for cryogenic steel components.

The American Petroleum Institute (API) has developed standards specifically for cryogenic service in the oil and gas industry. API 620 covers the design and construction of large, welded, low-pressure storage tanks, including those used for liquefied natural gas (LNG) storage. This standard provides detailed requirements for material selection, design, and testing of cryogenic steel tanks.

Testing standards play a crucial role in ensuring the safety of 4140 steel in cryogenic applications. ASTM E23 outlines the standard test methods for notched bar impact testing of metallic materials, which is essential for evaluating the toughness of 4140 steel at low temperatures. Additionally, ASTM A370 provides standard test methods and definitions for mechanical testing of steel products, including those used in cryogenic applications.

Operational safety standards are equally important for cryogenic steel applications. The Compressed Gas Association (CGA) has developed several guidelines, such as CGA P-12, which provides safety recommendations for the handling and storage of cryogenic liquids. These standards outline proper procedures for equipment operation, maintenance, and emergency response in cryogenic environments.

International standards also play a significant role in ensuring global consistency in safety practices for cryogenic steel applications. ISO 21013 series provides guidelines for the safety devices for cryogenic vessels, while EN 1252 specifies materials for cryogenic service.

Compliance with these safety standards is essential for the successful development and implementation of 4140 steel in cryogenic applications. Manufacturers and end-users must adhere to these guidelines to ensure the safe and reliable operation of cryogenic systems, minimizing the risk of failures and potential hazards associated with extreme low-temperature environments.

Environmental Impact of Cryogenic Steel Production

The production of cryogenic steel, particularly 4140 steel for low-temperature applications, has significant environmental implications that warrant careful consideration. The manufacturing process involves energy-intensive operations, including mining, smelting, and heat treatment, which contribute to greenhouse gas emissions and resource depletion. The extraction of alloying elements such as chromium and molybdenum, essential for 4140 steel's composition, can lead to habitat disruption and soil contamination in mining areas.

During the steel production phase, the use of blast furnaces and electric arc furnaces generates substantial carbon dioxide emissions. The subsequent heat treatment processes, crucial for achieving the desired microstructure and properties for cryogenic applications, further increase the carbon footprint. Additionally, the quenching and tempering stages often involve the use of oil-based quenchants, which can pose risks of soil and water pollution if not properly managed.

The cryogenic treatment of 4140 steel, while enhancing its mechanical properties, requires significant energy input to maintain extremely low temperatures. This process typically utilizes liquid nitrogen or helium, both of which have their own environmental considerations in terms of production and transportation. The disposal or recycling of cryogenic fluids used in the treatment process also presents environmental challenges.

Water consumption is another critical environmental factor in cryogenic steel production. Large volumes of water are required for cooling and cleaning processes, potentially straining local water resources. The wastewater generated may contain heavy metals and other contaminants, necessitating thorough treatment before release to prevent ecosystem damage.

On a positive note, the development of 4140 steel for cryogenic applications can contribute to more efficient and durable equipment in industries such as energy, aerospace, and scientific research. This improved performance and longevity may offset some of the environmental impacts of production by reducing the frequency of replacement and maintenance.

Efforts to mitigate the environmental impact of cryogenic steel production include the implementation of more efficient furnaces, waste heat recovery systems, and the use of renewable energy sources in manufacturing facilities. Advanced recycling technologies for steel scrap and alloying elements are also being developed to reduce the reliance on primary raw materials and minimize waste.

As the demand for cryogenic-grade 4140 steel grows, there is an increasing focus on life cycle assessment and sustainable production methods. This includes exploring alternative alloying elements with lower environmental footprints and optimizing heat treatment processes to reduce energy consumption without compromising the steel's cryogenic performance.

During the steel production phase, the use of blast furnaces and electric arc furnaces generates substantial carbon dioxide emissions. The subsequent heat treatment processes, crucial for achieving the desired microstructure and properties for cryogenic applications, further increase the carbon footprint. Additionally, the quenching and tempering stages often involve the use of oil-based quenchants, which can pose risks of soil and water pollution if not properly managed.

The cryogenic treatment of 4140 steel, while enhancing its mechanical properties, requires significant energy input to maintain extremely low temperatures. This process typically utilizes liquid nitrogen or helium, both of which have their own environmental considerations in terms of production and transportation. The disposal or recycling of cryogenic fluids used in the treatment process also presents environmental challenges.

Water consumption is another critical environmental factor in cryogenic steel production. Large volumes of water are required for cooling and cleaning processes, potentially straining local water resources. The wastewater generated may contain heavy metals and other contaminants, necessitating thorough treatment before release to prevent ecosystem damage.

On a positive note, the development of 4140 steel for cryogenic applications can contribute to more efficient and durable equipment in industries such as energy, aerospace, and scientific research. This improved performance and longevity may offset some of the environmental impacts of production by reducing the frequency of replacement and maintenance.

Efforts to mitigate the environmental impact of cryogenic steel production include the implementation of more efficient furnaces, waste heat recovery systems, and the use of renewable energy sources in manufacturing facilities. Advanced recycling technologies for steel scrap and alloying elements are also being developed to reduce the reliance on primary raw materials and minimize waste.

As the demand for cryogenic-grade 4140 steel grows, there is an increasing focus on life cycle assessment and sustainable production methods. This includes exploring alternative alloying elements with lower environmental footprints and optimizing heat treatment processes to reduce energy consumption without compromising the steel's cryogenic performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!