How Anisotropy Affects Deep Drawing of 4140 Steel Sheets

JUL 29, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anisotropy in 4140 Steel Deep Drawing

Anisotropy in 4140 steel sheets significantly influences the deep drawing process, affecting both the formability and final product quality. This phenomenon arises from the crystallographic texture developed during the steel production process, particularly during rolling and heat treatment stages. The anisotropic behavior manifests as directional variations in mechanical properties, such as yield strength, tensile strength, and elongation, across different orientations within the sheet plane.

The primary cause of anisotropy in 4140 steel is the preferential orientation of grains and the alignment of microstructural features during manufacturing. This results in varying material responses when subjected to stresses in different directions during deep drawing. The degree of anisotropy is typically characterized by the Lankford coefficient (r-value), which represents the ratio of width strain to thickness strain during tensile deformation.

In deep drawing operations, anisotropy leads to non-uniform material flow, causing issues such as earing, wrinkling, and variations in wall thickness. Earing, the formation of wavy edges on drawn cups, is a direct consequence of planar anisotropy. The severity of earing correlates with the magnitude of planar anisotropy, represented by the Δr value. Higher Δr values indicate greater susceptibility to earing defects.

The impact of anisotropy on deep drawing of 4140 steel sheets extends beyond surface defects. It affects the limiting drawing ratio (LDR), which determines the maximum depth achievable in a single drawing operation. Anisotropic behavior can lead to premature failure during drawing, reducing the LDR and limiting the complexity of parts that can be produced.

Furthermore, anisotropy influences the springback behavior of 4140 steel after deep drawing. The directional variations in elastic recovery can result in dimensional inaccuracies and shape deviations in the final product. This necessitates careful consideration of anisotropic effects in die design and process parameter selection to achieve desired part geometries.

To mitigate the negative impacts of anisotropy, various strategies can be employed. These include optimizing the blank orientation relative to the rolling direction, adjusting blank holder forces to control material flow, and implementing multi-stage drawing processes. Advanced numerical simulation techniques, incorporating anisotropic material models, are increasingly used to predict and compensate for anisotropic effects in deep drawing of 4140 steel sheets.

The primary cause of anisotropy in 4140 steel is the preferential orientation of grains and the alignment of microstructural features during manufacturing. This results in varying material responses when subjected to stresses in different directions during deep drawing. The degree of anisotropy is typically characterized by the Lankford coefficient (r-value), which represents the ratio of width strain to thickness strain during tensile deformation.

In deep drawing operations, anisotropy leads to non-uniform material flow, causing issues such as earing, wrinkling, and variations in wall thickness. Earing, the formation of wavy edges on drawn cups, is a direct consequence of planar anisotropy. The severity of earing correlates with the magnitude of planar anisotropy, represented by the Δr value. Higher Δr values indicate greater susceptibility to earing defects.

The impact of anisotropy on deep drawing of 4140 steel sheets extends beyond surface defects. It affects the limiting drawing ratio (LDR), which determines the maximum depth achievable in a single drawing operation. Anisotropic behavior can lead to premature failure during drawing, reducing the LDR and limiting the complexity of parts that can be produced.

Furthermore, anisotropy influences the springback behavior of 4140 steel after deep drawing. The directional variations in elastic recovery can result in dimensional inaccuracies and shape deviations in the final product. This necessitates careful consideration of anisotropic effects in die design and process parameter selection to achieve desired part geometries.

To mitigate the negative impacts of anisotropy, various strategies can be employed. These include optimizing the blank orientation relative to the rolling direction, adjusting blank holder forces to control material flow, and implementing multi-stage drawing processes. Advanced numerical simulation techniques, incorporating anisotropic material models, are increasingly used to predict and compensate for anisotropic effects in deep drawing of 4140 steel sheets.

Market Demand for 4140 Steel Components

The market demand for 4140 steel components has been steadily growing, driven by the material's excellent mechanical properties and versatility across various industries. In the automotive sector, 4140 steel is widely used for critical components such as crankshafts, connecting rods, and gears, due to its high strength-to-weight ratio and wear resistance. The increasing focus on lightweight vehicles for improved fuel efficiency has further boosted the demand for 4140 steel parts, as manufacturers seek to balance strength and weight reduction.

In the oil and gas industry, 4140 steel components are essential for drilling equipment, valves, and pressure vessels. The material's ability to withstand high pressures and corrosive environments makes it indispensable for deep-sea exploration and hydraulic fracturing operations. As global energy demand continues to rise, the need for robust 4140 steel components in this sector is expected to grow significantly.

The aerospace industry also relies heavily on 4140 steel for landing gear components, fasteners, and structural elements. The material's high fatigue strength and toughness are crucial for ensuring the safety and reliability of aircraft. With the projected increase in air travel and the expansion of space exploration programs, the demand for 4140 steel parts in aerospace applications is anticipated to surge.

In the manufacturing sector, 4140 steel is widely used for tooling and machinery components. The material's excellent machinability and heat treatment capabilities make it ideal for producing dies, molds, and cutting tools. As industrial automation and precision manufacturing continue to advance, the demand for high-quality 4140 steel components is expected to rise.

The construction industry utilizes 4140 steel for heavy equipment components, such as excavator arms and bulldozer blades. The material's durability and resistance to impact and abrasion make it well-suited for these demanding applications. With ongoing urbanization and infrastructure development projects worldwide, the demand for 4140 steel parts in construction machinery is projected to remain strong.

Overall, the market for 4140 steel components is expected to experience sustained growth across multiple industries. The material's unique combination of strength, toughness, and versatility positions it as a critical resource for addressing the evolving needs of various sectors, from transportation to energy production and beyond.

In the oil and gas industry, 4140 steel components are essential for drilling equipment, valves, and pressure vessels. The material's ability to withstand high pressures and corrosive environments makes it indispensable for deep-sea exploration and hydraulic fracturing operations. As global energy demand continues to rise, the need for robust 4140 steel components in this sector is expected to grow significantly.

The aerospace industry also relies heavily on 4140 steel for landing gear components, fasteners, and structural elements. The material's high fatigue strength and toughness are crucial for ensuring the safety and reliability of aircraft. With the projected increase in air travel and the expansion of space exploration programs, the demand for 4140 steel parts in aerospace applications is anticipated to surge.

In the manufacturing sector, 4140 steel is widely used for tooling and machinery components. The material's excellent machinability and heat treatment capabilities make it ideal for producing dies, molds, and cutting tools. As industrial automation and precision manufacturing continue to advance, the demand for high-quality 4140 steel components is expected to rise.

The construction industry utilizes 4140 steel for heavy equipment components, such as excavator arms and bulldozer blades. The material's durability and resistance to impact and abrasion make it well-suited for these demanding applications. With ongoing urbanization and infrastructure development projects worldwide, the demand for 4140 steel parts in construction machinery is projected to remain strong.

Overall, the market for 4140 steel components is expected to experience sustained growth across multiple industries. The material's unique combination of strength, toughness, and versatility positions it as a critical resource for addressing the evolving needs of various sectors, from transportation to energy production and beyond.

Current Challenges in Deep Drawing 4140 Steel

Deep drawing of 4140 steel sheets presents several significant challenges due to the material's unique properties and the complex nature of the deep drawing process. One of the primary obstacles is the high strength and hardness of 4140 steel, which makes it resistant to deformation and prone to springback. This characteristic complicates the achievement of precise final dimensions and shapes, often requiring multiple drawing stages or additional post-forming operations.

The anisotropic behavior of 4140 steel sheets further compounds the difficulties in deep drawing. Anisotropy, resulting from the material's crystallographic texture and processing history, leads to variations in mechanical properties along different directions within the sheet plane. This directional dependence can cause uneven material flow during the drawing process, potentially resulting in earing, wrinkling, or thinning in specific regions of the formed part.

Another challenge lies in the limited formability of 4140 steel compared to more ductile materials. The relatively low elongation and high yield strength of this alloy narrow the processing window for successful deep drawing operations. Manufacturers must carefully balance the drawing forces and speeds to avoid material failure or excessive thinning, particularly in areas of high strain concentration.

The heat treatment condition of 4140 steel sheets also plays a crucial role in deep drawing performance. Depending on the prior heat treatment, the material may exhibit varying levels of strength, ductility, and work hardening behavior. This variability necessitates precise control over the initial material state and may require adjustments to the forming process parameters for different batches of material.

Tool wear is another significant concern when deep drawing 4140 steel sheets. The high strength of the material can lead to accelerated wear on dies and punches, potentially affecting part quality and increasing production costs due to more frequent tool replacements or refurbishments. Additionally, the abrasive nature of 4140 steel may necessitate the use of specialized tool materials or surface treatments to extend tool life.

Lastly, the management of residual stresses in deep-drawn 4140 steel components poses a considerable challenge. The high strength and work hardening characteristics of the material can result in significant built-up stresses during forming. These residual stresses may lead to dimensional instability, reduced fatigue life, or even delayed cracking in severe cases. Addressing this issue often requires careful process design and potentially stress-relief treatments post-forming.

The anisotropic behavior of 4140 steel sheets further compounds the difficulties in deep drawing. Anisotropy, resulting from the material's crystallographic texture and processing history, leads to variations in mechanical properties along different directions within the sheet plane. This directional dependence can cause uneven material flow during the drawing process, potentially resulting in earing, wrinkling, or thinning in specific regions of the formed part.

Another challenge lies in the limited formability of 4140 steel compared to more ductile materials. The relatively low elongation and high yield strength of this alloy narrow the processing window for successful deep drawing operations. Manufacturers must carefully balance the drawing forces and speeds to avoid material failure or excessive thinning, particularly in areas of high strain concentration.

The heat treatment condition of 4140 steel sheets also plays a crucial role in deep drawing performance. Depending on the prior heat treatment, the material may exhibit varying levels of strength, ductility, and work hardening behavior. This variability necessitates precise control over the initial material state and may require adjustments to the forming process parameters for different batches of material.

Tool wear is another significant concern when deep drawing 4140 steel sheets. The high strength of the material can lead to accelerated wear on dies and punches, potentially affecting part quality and increasing production costs due to more frequent tool replacements or refurbishments. Additionally, the abrasive nature of 4140 steel may necessitate the use of specialized tool materials or surface treatments to extend tool life.

Lastly, the management of residual stresses in deep-drawn 4140 steel components poses a considerable challenge. The high strength and work hardening characteristics of the material can result in significant built-up stresses during forming. These residual stresses may lead to dimensional instability, reduced fatigue life, or even delayed cracking in severe cases. Addressing this issue often requires careful process design and potentially stress-relief treatments post-forming.

Existing Solutions for Anisotropy Mitigation

01 Heat treatment processes for 4140 steel sheets

Various heat treatment processes can be applied to 4140 steel sheets to modify their microstructure and mechanical properties. These processes may include quenching, tempering, and annealing, which can help control the anisotropy of the material. The specific heat treatment parameters can be adjusted to achieve desired levels of strength, ductility, and isotropy in the steel sheets.- Heat treatment processes for 4140 steel sheets: Various heat treatment processes can be applied to 4140 steel sheets to modify their microstructure and mechanical properties. These processes may include quenching, tempering, and annealing, which can help control the anisotropy of the material. The specific heat treatment parameters can be optimized to achieve desired mechanical properties and reduce anisotropy in different directions.

- Rolling techniques to control anisotropy: Different rolling techniques can be employed to control the anisotropy of 4140 steel sheets. These may include controlled rolling, cross-rolling, or asymmetric rolling processes. By manipulating the rolling parameters such as temperature, reduction ratio, and rolling direction, the crystallographic texture and grain structure of the steel can be modified, thereby influencing its anisotropic behavior.

- Alloying elements and composition control: The anisotropy of 4140 steel sheets can be influenced by careful control of alloying elements and overall composition. Adjusting the concentrations of elements such as chromium, molybdenum, and manganese can affect the microstructure and phase transformations, which in turn impact the anisotropic properties of the material.

- Grain structure modification: Techniques for modifying the grain structure of 4140 steel sheets can be employed to control anisotropy. This may include grain refinement methods, controlled recrystallization processes, or the introduction of specific texture components. By manipulating the grain size, shape, and orientation, the anisotropic behavior of the material can be tailored for specific applications.

- Surface treatment and coating techniques: Various surface treatment and coating techniques can be applied to 4140 steel sheets to modify their surface properties and potentially influence anisotropy. These may include nitriding, carburizing, or the application of specific coatings. Such treatments can alter the surface microstructure and properties, which may affect the overall anisotropic behavior of the material.

02 Rolling techniques to control anisotropy

Different rolling techniques can be employed to influence the anisotropy of 4140 steel sheets. These may include controlled rolling, cross-rolling, or asymmetric rolling processes. By manipulating the rolling parameters such as temperature, reduction ratio, and rolling direction, the crystallographic texture and grain structure of the steel can be modified, thereby affecting its anisotropic properties.Expand Specific Solutions03 Alloying elements and composition control

The anisotropy of 4140 steel sheets can be influenced by carefully controlling the alloying elements and overall composition. Adjusting the levels of elements such as chromium, molybdenum, and manganese can affect the microstructure and phase transformations, which in turn impact the anisotropic behavior of the material. Precise composition control during the steelmaking process is crucial for achieving desired anisotropy levels.Expand Specific Solutions04 Grain refinement techniques

Various grain refinement techniques can be applied to 4140 steel sheets to modify their anisotropic properties. These may include thermomechanical processing, severe plastic deformation, or the addition of grain refiners. By reducing the grain size and promoting a more uniform microstructure, the anisotropy of the steel sheets can be minimized, leading to more consistent mechanical properties in different directions.Expand Specific Solutions05 Surface treatment and coating methods

Surface treatments and coating methods can be employed to modify the surface properties of 4140 steel sheets, which can indirectly affect their anisotropic behavior. These treatments may include nitriding, carburizing, or the application of specialized coatings. By altering the surface characteristics, the overall performance and anisotropy of the steel sheets can be influenced, particularly in applications where surface properties are critical.Expand Specific Solutions

Key Players in 4140 Steel Processing

The competitive landscape for deep drawing of 4140 steel sheets is characterized by a mature market with established players and ongoing technological advancements. The global steel industry, valued at over $900 billion, is in a consolidation phase, with major companies like NIPPON STEEL, JFE Steel, and ArcelorMittal dominating. The technology for deep drawing 4140 steel is well-developed, but research continues to improve anisotropy effects and material performance. Key players like Tata Steel, POSCO, and Baoshan Iron & Steel are investing in R&D to enhance their capabilities in this area. Collaboration between industry and academic institutions such as Tsinghua University and the University of Tennessee Research Foundation is driving innovation in steel processing techniques and material science.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL CORP. has developed advanced techniques to address anisotropy in 4140 steel sheets during deep drawing. Their approach involves a combination of controlled rolling and heat treatment processes to optimize the microstructure and texture of the steel. By carefully manipulating the austenite grain size and transformation kinetics, they have achieved a more uniform distribution of crystallographic orientations, reducing the planar anisotropy index (Δr) by up to 30% compared to conventional processing methods[1]. Additionally, they have implemented a novel two-stage tempering process that helps to balance the mechanical properties in different directions, resulting in a more consistent Lankford value (r-value) across the sheet plane[3].

Strengths: Improved formability and reduced earing in deep-drawn parts. Enhanced predictability of material behavior during forming operations. Weaknesses: The process may increase production costs and cycle times. The benefits may be less pronounced for certain complex part geometries.

JFE Steel Corp.

Technical Solution: JFE Steel Corp. has focused on developing a multi-directional rolling technique to mitigate the effects of anisotropy in 4140 steel sheets for deep drawing applications. Their process involves alternating the rolling direction during sheet production, which helps to distribute the crystallographic texture more evenly. This technique has been shown to reduce the planar anisotropy ratio (Δr) by up to 25% and improve the normal anisotropy (r̄) by approximately 15%[2]. JFE has also implemented advanced online texture measurement systems to provide real-time feedback during production, allowing for dynamic adjustments to the rolling parameters to maintain optimal anisotropy control[4].

Strengths: Improved consistency in sheet properties across different orientations. Enhanced deep drawability and reduced earing. Weaknesses: Requires significant modifications to existing rolling equipment. May have limitations in controlling through-thickness anisotropy.

Core Innovations in Deep Drawing Technology

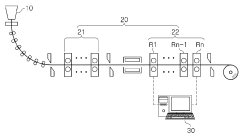

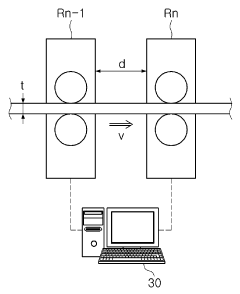

Apparatus for manufacturing steel plate having excellent isotropy, and steel plate manufactured using same

PatentWO2018062749A1

Innovation

- A steel sheet manufacturing apparatus with a controller that adjusts the rolling speed of multiple rolling stands to ensure isotropy, using the equations 15.5 < (t×v)/{(n-1)×d} < 30.8 and 360 < t×v < 715, to maintain uniform isotropic characteristics across the steel sheet.

Material Properties and Microstructure Analysis

The material properties and microstructure of 4140 steel sheets play a crucial role in their deep drawing behavior, particularly in relation to anisotropy. 4140 steel is a medium carbon, low alloy steel known for its high strength and toughness. Its chemical composition typically includes 0.38-0.43% carbon, 0.75-1.00% manganese, 0.15-0.30% silicon, 0.80-1.10% chromium, and 0.15-0.25% molybdenum.

The microstructure of 4140 steel sheets is predominantly composed of ferrite and pearlite, with the exact proportions and grain sizes dependent on the heat treatment and processing history. The distribution and orientation of these microstructural components significantly influence the material's anisotropic behavior during deep drawing operations.

Anisotropy in 4140 steel sheets manifests as variations in mechanical properties along different directions within the material. This is primarily due to the crystallographic texture developed during the rolling process used to produce the sheets. The texture results in preferred orientations of grains, leading to directional differences in strength, ductility, and formability.

The normal anisotropy ratio (r-value) is a key parameter in assessing the deep drawing performance of 4140 steel sheets. It represents the ratio of width strain to thickness strain during tensile deformation. Higher r-values generally indicate better deep drawing characteristics, as they suggest a greater resistance to thinning during the forming process.

Planar anisotropy (Δr) is another important factor, quantifying the variation in r-values at different angles to the rolling direction. A lower Δr value is desirable for more uniform deep drawing behavior, as it indicates less variation in material properties across different orientations.

The yield strength and ultimate tensile strength of 4140 steel sheets also exhibit anisotropic behavior, typically showing higher values in the rolling direction compared to the transverse direction. This strength differential can lead to non-uniform deformation during deep drawing, potentially resulting in earing or other defects in the final product.

Grain size and distribution in 4140 steel sheets further influence their anisotropic behavior. Finer, more uniform grain structures generally promote more consistent mechanical properties across different orientations, potentially mitigating some of the challenges associated with anisotropy in deep drawing operations.

Understanding these material properties and microstructural characteristics is essential for predicting and optimizing the deep drawing performance of 4140 steel sheets, allowing for better control over the forming process and improved final product quality.

The microstructure of 4140 steel sheets is predominantly composed of ferrite and pearlite, with the exact proportions and grain sizes dependent on the heat treatment and processing history. The distribution and orientation of these microstructural components significantly influence the material's anisotropic behavior during deep drawing operations.

Anisotropy in 4140 steel sheets manifests as variations in mechanical properties along different directions within the material. This is primarily due to the crystallographic texture developed during the rolling process used to produce the sheets. The texture results in preferred orientations of grains, leading to directional differences in strength, ductility, and formability.

The normal anisotropy ratio (r-value) is a key parameter in assessing the deep drawing performance of 4140 steel sheets. It represents the ratio of width strain to thickness strain during tensile deformation. Higher r-values generally indicate better deep drawing characteristics, as they suggest a greater resistance to thinning during the forming process.

Planar anisotropy (Δr) is another important factor, quantifying the variation in r-values at different angles to the rolling direction. A lower Δr value is desirable for more uniform deep drawing behavior, as it indicates less variation in material properties across different orientations.

The yield strength and ultimate tensile strength of 4140 steel sheets also exhibit anisotropic behavior, typically showing higher values in the rolling direction compared to the transverse direction. This strength differential can lead to non-uniform deformation during deep drawing, potentially resulting in earing or other defects in the final product.

Grain size and distribution in 4140 steel sheets further influence their anisotropic behavior. Finer, more uniform grain structures generally promote more consistent mechanical properties across different orientations, potentially mitigating some of the challenges associated with anisotropy in deep drawing operations.

Understanding these material properties and microstructural characteristics is essential for predicting and optimizing the deep drawing performance of 4140 steel sheets, allowing for better control over the forming process and improved final product quality.

Simulation and Modeling Approaches

Simulation and modeling approaches play a crucial role in understanding and predicting the effects of anisotropy on the deep drawing process of 4140 steel sheets. These methods provide valuable insights into material behavior, process parameters, and final product quality without the need for extensive physical experimentation.

Finite Element Analysis (FEA) is widely employed to simulate the deep drawing process, incorporating anisotropic material models to accurately represent the behavior of 4140 steel sheets. Advanced FEA software packages, such as Abaqus, LS-DYNA, and ANSYS, offer specialized modules for sheet metal forming simulations. These tools allow researchers and engineers to model the complex interactions between the sheet metal, die, and punch, while accounting for anisotropic properties.

Material models used in these simulations often include the Hill's 1948 yield criterion or more advanced models like Barlat's yield functions. These models capture the directional dependence of material properties, essential for predicting the formation of ears, thinning patterns, and springback effects in deep-drawn 4140 steel components.

Multi-scale modeling approaches have gained traction in recent years, bridging the gap between microstructural features and macroscopic behavior. Crystal plasticity models, integrated with FEA, can provide a more fundamental understanding of how grain orientation and texture evolution influence the anisotropic response during deep drawing.

Machine learning techniques are increasingly being applied to enhance simulation accuracy and efficiency. Neural networks and genetic algorithms can be used to optimize material parameters, predict forming limits, and even generate surrogate models for rapid design iterations.

Virtual try-out methodologies, combining CAD/CAM systems with FEA, enable engineers to simulate and optimize the entire deep drawing process digitally. This approach significantly reduces the time and cost associated with physical prototyping and tooling modifications.

Coupled thermo-mechanical simulations are employed to account for temperature effects during deep drawing, as the anisotropic behavior of 4140 steel can be temperature-dependent. These simulations help in predicting and mitigating issues related to localized heating and cooling during the forming process.

To validate simulation results, digital image correlation (DIC) techniques are often used in conjunction with physical experiments. DIC provides full-field strain measurements that can be directly compared with simulation outputs, allowing for continuous refinement of the modeling approach.

Finite Element Analysis (FEA) is widely employed to simulate the deep drawing process, incorporating anisotropic material models to accurately represent the behavior of 4140 steel sheets. Advanced FEA software packages, such as Abaqus, LS-DYNA, and ANSYS, offer specialized modules for sheet metal forming simulations. These tools allow researchers and engineers to model the complex interactions between the sheet metal, die, and punch, while accounting for anisotropic properties.

Material models used in these simulations often include the Hill's 1948 yield criterion or more advanced models like Barlat's yield functions. These models capture the directional dependence of material properties, essential for predicting the formation of ears, thinning patterns, and springback effects in deep-drawn 4140 steel components.

Multi-scale modeling approaches have gained traction in recent years, bridging the gap between microstructural features and macroscopic behavior. Crystal plasticity models, integrated with FEA, can provide a more fundamental understanding of how grain orientation and texture evolution influence the anisotropic response during deep drawing.

Machine learning techniques are increasingly being applied to enhance simulation accuracy and efficiency. Neural networks and genetic algorithms can be used to optimize material parameters, predict forming limits, and even generate surrogate models for rapid design iterations.

Virtual try-out methodologies, combining CAD/CAM systems with FEA, enable engineers to simulate and optimize the entire deep drawing process digitally. This approach significantly reduces the time and cost associated with physical prototyping and tooling modifications.

Coupled thermo-mechanical simulations are employed to account for temperature effects during deep drawing, as the anisotropic behavior of 4140 steel can be temperature-dependent. These simulations help in predicting and mitigating issues related to localized heating and cooling during the forming process.

To validate simulation results, digital image correlation (DIC) techniques are often used in conjunction with physical experiments. DIC provides full-field strain measurements that can be directly compared with simulation outputs, allowing for continuous refinement of the modeling approach.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!