Study of Heat-Affected Zone in 4140 Steel Welds

JUL 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

4140 Steel Welding Background and Objectives

The study of the heat-affected zone (HAZ) in 4140 steel welds is a critical area of research in materials science and engineering. 4140 steel, a medium carbon low alloy steel, is widely used in various industries due to its excellent combination of strength, toughness, and wear resistance. However, welding this material presents unique challenges, particularly in managing the heat-affected zone.

The development of welding techniques for 4140 steel can be traced back to the mid-20th century when the demand for high-strength steels in industrial applications began to surge. As manufacturing processes evolved, the need for reliable joining methods for these alloys became increasingly apparent. The heat-affected zone, a region adjacent to the weld that experiences significant microstructural changes due to the thermal cycle of welding, emerged as a critical area of concern.

Over the years, researchers and engineers have made significant strides in understanding the behavior of 4140 steel during welding. The focus has shifted from merely achieving a sound weld to optimizing the properties of the heat-affected zone. This evolution in approach has been driven by the growing demands of industries such as automotive, aerospace, and oil and gas, where the performance of welded components under extreme conditions is paramount.

The technological trajectory in this field has been marked by advancements in both welding processes and material characterization techniques. From traditional arc welding methods to more sophisticated processes like laser and electron beam welding, each development has brought new insights into HAZ formation and control. Concurrently, the advent of advanced microscopy and spectroscopy techniques has enabled researchers to delve deeper into the microstructural changes occurring within the HAZ.

The primary objectives of studying the heat-affected zone in 4140 steel welds are multifaceted. Firstly, there is a need to comprehensively understand the phase transformations and microstructural evolution within the HAZ during the welding thermal cycle. This understanding is crucial for predicting and controlling the mechanical properties of the welded joint. Secondly, researchers aim to develop strategies to mitigate the negative effects of welding on the HAZ, such as hardness variations, residual stresses, and potential for cracking.

Another key objective is to establish robust welding parameters and procedures that consistently produce high-quality welds with optimized HAZ properties. This involves exploring various pre-heating and post-weld heat treatment regimes, as well as investigating the effects of different welding processes on HAZ characteristics. Additionally, there is a growing emphasis on developing computational models that can accurately simulate HAZ formation and properties, thereby reducing the need for extensive experimental trials.

The development of welding techniques for 4140 steel can be traced back to the mid-20th century when the demand for high-strength steels in industrial applications began to surge. As manufacturing processes evolved, the need for reliable joining methods for these alloys became increasingly apparent. The heat-affected zone, a region adjacent to the weld that experiences significant microstructural changes due to the thermal cycle of welding, emerged as a critical area of concern.

Over the years, researchers and engineers have made significant strides in understanding the behavior of 4140 steel during welding. The focus has shifted from merely achieving a sound weld to optimizing the properties of the heat-affected zone. This evolution in approach has been driven by the growing demands of industries such as automotive, aerospace, and oil and gas, where the performance of welded components under extreme conditions is paramount.

The technological trajectory in this field has been marked by advancements in both welding processes and material characterization techniques. From traditional arc welding methods to more sophisticated processes like laser and electron beam welding, each development has brought new insights into HAZ formation and control. Concurrently, the advent of advanced microscopy and spectroscopy techniques has enabled researchers to delve deeper into the microstructural changes occurring within the HAZ.

The primary objectives of studying the heat-affected zone in 4140 steel welds are multifaceted. Firstly, there is a need to comprehensively understand the phase transformations and microstructural evolution within the HAZ during the welding thermal cycle. This understanding is crucial for predicting and controlling the mechanical properties of the welded joint. Secondly, researchers aim to develop strategies to mitigate the negative effects of welding on the HAZ, such as hardness variations, residual stresses, and potential for cracking.

Another key objective is to establish robust welding parameters and procedures that consistently produce high-quality welds with optimized HAZ properties. This involves exploring various pre-heating and post-weld heat treatment regimes, as well as investigating the effects of different welding processes on HAZ characteristics. Additionally, there is a growing emphasis on developing computational models that can accurately simulate HAZ formation and properties, thereby reducing the need for extensive experimental trials.

Industrial Demand for 4140 Steel Welding

The industrial demand for 4140 steel welding has been steadily increasing due to the material's exceptional mechanical properties and versatility across various sectors. This high-strength, low-alloy steel is widely used in manufacturing critical components that require both strength and toughness, making it indispensable in industries such as automotive, aerospace, oil and gas, and heavy machinery.

In the automotive industry, 4140 steel is extensively used for manufacturing drivetrain components, including crankshafts, connecting rods, and gears. The welding of these parts is crucial for producing high-performance vehicles that can withstand extreme conditions. As the automotive sector continues to evolve with the rise of electric and hybrid vehicles, the demand for 4140 steel welding is expected to remain strong, particularly in the production of robust chassis and suspension components.

The aerospace industry relies heavily on 4140 steel for manufacturing landing gear components, fasteners, and structural elements of aircraft. The welding of these parts requires precision and reliability to ensure the safety and performance of aircraft. With the projected growth in air travel and the increasing demand for new aircraft, the need for skilled 4140 steel welding in this sector is anticipated to grow significantly.

In the oil and gas industry, 4140 steel is a preferred material for downhole tools, drill collars, and other equipment exposed to harsh environments. The welding of these components is critical for maintaining the integrity of drilling operations and ensuring the longevity of equipment in corrosive and high-pressure conditions. As exploration and production activities continue to expand into more challenging environments, the demand for 4140 steel welding expertise is expected to rise.

The heavy machinery sector, including construction and mining equipment, also heavily relies on 4140 steel for manufacturing components such as axles, shafts, and hydraulic cylinders. The welding of these parts is essential for producing durable and reliable machinery capable of withstanding heavy loads and harsh operating conditions. With ongoing infrastructure development projects worldwide, the demand for 4140 steel welding in this sector remains robust.

As industries continue to push the boundaries of performance and durability, the need for advanced welding techniques and expertise in 4140 steel is becoming increasingly critical. This has led to a growing emphasis on research and development in welding technologies, particularly in areas such as heat-affected zone control and optimization of welding parameters. The industrial demand for skilled welders and engineers specializing in 4140 steel welding is expected to remain strong, driven by the material's unique properties and its crucial role in manufacturing high-performance components across multiple sectors.

In the automotive industry, 4140 steel is extensively used for manufacturing drivetrain components, including crankshafts, connecting rods, and gears. The welding of these parts is crucial for producing high-performance vehicles that can withstand extreme conditions. As the automotive sector continues to evolve with the rise of electric and hybrid vehicles, the demand for 4140 steel welding is expected to remain strong, particularly in the production of robust chassis and suspension components.

The aerospace industry relies heavily on 4140 steel for manufacturing landing gear components, fasteners, and structural elements of aircraft. The welding of these parts requires precision and reliability to ensure the safety and performance of aircraft. With the projected growth in air travel and the increasing demand for new aircraft, the need for skilled 4140 steel welding in this sector is anticipated to grow significantly.

In the oil and gas industry, 4140 steel is a preferred material for downhole tools, drill collars, and other equipment exposed to harsh environments. The welding of these components is critical for maintaining the integrity of drilling operations and ensuring the longevity of equipment in corrosive and high-pressure conditions. As exploration and production activities continue to expand into more challenging environments, the demand for 4140 steel welding expertise is expected to rise.

The heavy machinery sector, including construction and mining equipment, also heavily relies on 4140 steel for manufacturing components such as axles, shafts, and hydraulic cylinders. The welding of these parts is essential for producing durable and reliable machinery capable of withstanding heavy loads and harsh operating conditions. With ongoing infrastructure development projects worldwide, the demand for 4140 steel welding in this sector remains robust.

As industries continue to push the boundaries of performance and durability, the need for advanced welding techniques and expertise in 4140 steel is becoming increasingly critical. This has led to a growing emphasis on research and development in welding technologies, particularly in areas such as heat-affected zone control and optimization of welding parameters. The industrial demand for skilled welders and engineers specializing in 4140 steel welding is expected to remain strong, driven by the material's unique properties and its crucial role in manufacturing high-performance components across multiple sectors.

HAZ Challenges in 4140 Steel Welding

The heat-affected zone (HAZ) in 4140 steel welds presents several significant challenges that require careful consideration and management. One of the primary issues is the formation of hard and brittle microstructures in the HAZ, particularly martensite, which can lead to reduced ductility and increased susceptibility to cracking.

The rapid heating and cooling cycles during welding can cause uneven temperature distribution across the HAZ, resulting in varying microstructures and mechanical properties. This heterogeneity can create stress concentrations and potential weak points in the welded joint, compromising its overall integrity and performance.

Another critical challenge is the potential for hydrogen-induced cracking (HIC) in the HAZ of 4140 steel welds. The high hardenability of 4140 steel makes it particularly susceptible to hydrogen embrittlement, especially in the presence of residual stresses from welding. Controlling hydrogen content and managing cooling rates are essential to mitigate this risk.

The formation of carbides in the HAZ is also a concern, as it can lead to reduced toughness and impact strength. The dissolution and reprecipitation of carbides during the welding thermal cycle can result in coarse carbide structures that act as stress concentrators and potential crack initiation sites.

Residual stresses induced by the welding process pose another significant challenge in the HAZ of 4140 steel welds. These stresses can contribute to distortion, fatigue failure, and stress corrosion cracking, particularly in high-stress applications or corrosive environments.

The thickness of the material being welded also plays a crucial role in HAZ challenges. Thicker sections of 4140 steel are more prone to rapid cooling rates, which can exacerbate the formation of hard and brittle microstructures in the HAZ. This necessitates careful control of preheating and post-weld heat treatment processes to manage cooling rates effectively.

Achieving consistent mechanical properties across the weld joint, including the HAZ, is a persistent challenge. The variations in microstructure and hardness between the base metal, HAZ, and weld metal can create stress concentrations and potential failure points, particularly under cyclic loading conditions.

To address these challenges, welding engineers must carefully control welding parameters, including heat input, travel speed, and interpass temperature. Additionally, the implementation of appropriate pre-heating, post-weld heat treatment, and controlled cooling strategies is crucial to optimize the HAZ microstructure and properties in 4140 steel welds.

The rapid heating and cooling cycles during welding can cause uneven temperature distribution across the HAZ, resulting in varying microstructures and mechanical properties. This heterogeneity can create stress concentrations and potential weak points in the welded joint, compromising its overall integrity and performance.

Another critical challenge is the potential for hydrogen-induced cracking (HIC) in the HAZ of 4140 steel welds. The high hardenability of 4140 steel makes it particularly susceptible to hydrogen embrittlement, especially in the presence of residual stresses from welding. Controlling hydrogen content and managing cooling rates are essential to mitigate this risk.

The formation of carbides in the HAZ is also a concern, as it can lead to reduced toughness and impact strength. The dissolution and reprecipitation of carbides during the welding thermal cycle can result in coarse carbide structures that act as stress concentrators and potential crack initiation sites.

Residual stresses induced by the welding process pose another significant challenge in the HAZ of 4140 steel welds. These stresses can contribute to distortion, fatigue failure, and stress corrosion cracking, particularly in high-stress applications or corrosive environments.

The thickness of the material being welded also plays a crucial role in HAZ challenges. Thicker sections of 4140 steel are more prone to rapid cooling rates, which can exacerbate the formation of hard and brittle microstructures in the HAZ. This necessitates careful control of preheating and post-weld heat treatment processes to manage cooling rates effectively.

Achieving consistent mechanical properties across the weld joint, including the HAZ, is a persistent challenge. The variations in microstructure and hardness between the base metal, HAZ, and weld metal can create stress concentrations and potential failure points, particularly under cyclic loading conditions.

To address these challenges, welding engineers must carefully control welding parameters, including heat input, travel speed, and interpass temperature. Additionally, the implementation of appropriate pre-heating, post-weld heat treatment, and controlled cooling strategies is crucial to optimize the HAZ microstructure and properties in 4140 steel welds.

Current HAZ Mitigation Strategies

01 Composition and properties of 4140 steel heat-affected zone

The heat-affected zone (HAZ) of 4140 steel welds exhibits unique microstructural changes and mechanical properties due to the welding process. This zone experiences thermal cycles that alter its composition and characteristics, potentially affecting the overall weld integrity. Understanding the composition and properties of the HAZ is crucial for optimizing welding parameters and ensuring weld quality.- Composition and properties of 4140 steel heat-affected zone: The heat-affected zone (HAZ) of 4140 steel welds exhibits unique microstructural changes and mechanical properties due to the welding process. This zone experiences thermal cycles that alter its composition and characteristics, potentially affecting the overall weld integrity. Understanding the composition and properties of the HAZ is crucial for optimizing welding parameters and ensuring the quality of the welded joint.

- Heat treatment techniques for 4140 steel welds: Various heat treatment techniques can be applied to 4140 steel welds to improve the properties of the heat-affected zone. These may include pre-heating, post-weld heat treatment (PWHT), and controlled cooling processes. Such treatments aim to reduce residual stresses, refine grain structure, and enhance the overall mechanical properties of the welded joint, particularly in the HAZ region.

- Microstructure analysis of 4140 steel weld HAZ: Detailed microstructure analysis of the heat-affected zone in 4140 steel welds is essential for understanding the material's behavior and properties. This may involve techniques such as optical microscopy, scanning electron microscopy (SEM), and X-ray diffraction to examine grain size, phase transformations, and potential defects in the HAZ. Such analysis helps in predicting the weld performance and optimizing welding parameters.

- Mechanical testing of 4140 steel weld HAZ: Various mechanical tests are employed to evaluate the properties of the heat-affected zone in 4140 steel welds. These may include hardness testing, tensile testing, impact testing, and fatigue testing. The results of these tests provide valuable information about the strength, ductility, and toughness of the HAZ, which are crucial for assessing the overall quality and performance of the welded joint.

- Welding process optimization for 4140 steel: Optimizing the welding process for 4140 steel involves careful control of various parameters to minimize the negative effects on the heat-affected zone. This may include selecting appropriate welding techniques, controlling heat input, adjusting welding speed, and implementing proper shielding gas mixtures. The goal is to achieve a balance between weld quality, productivity, and the desired properties of the HAZ.

02 Heat treatment techniques for 4140 steel welds

Various heat treatment techniques can be applied to 4140 steel welds to improve the properties of the heat-affected zone. These may include pre-heating, post-weld heat treatment (PWHT), and controlled cooling rates. Such treatments aim to reduce residual stresses, refine grain structure, and enhance the overall mechanical properties of the welded joint, particularly in the HAZ region.Expand Specific Solutions03 Microstructure analysis of 4140 steel weld HAZ

Detailed microstructure analysis of the heat-affected zone in 4140 steel welds is essential for understanding its behavior and properties. This may involve techniques such as optical microscopy, electron microscopy, and X-ray diffraction to examine grain size, phase transformations, and potential defects in the HAZ. Such analysis helps in predicting the performance of the welded joint and optimizing welding processes.Expand Specific Solutions04 Mechanical testing of 4140 steel weld HAZ

Various mechanical tests are employed to evaluate the properties of the heat-affected zone in 4140 steel welds. These may include hardness testing, tensile testing, impact testing, and fatigue testing. Such tests provide crucial information about the strength, ductility, and toughness of the HAZ, helping to assess the overall quality and performance of the welded joint.Expand Specific Solutions05 Welding process optimization for 4140 steel

Optimizing the welding process parameters is crucial for controlling the properties of the heat-affected zone in 4140 steel welds. This may involve adjusting factors such as heat input, welding speed, electrode type, and shielding gas composition. By fine-tuning these parameters, it is possible to minimize the negative effects of welding on the HAZ and improve the overall quality of the welded joint.Expand Specific Solutions

Key Players in 4140 Steel Welding Industry

The study of heat-affected zones in 4140 steel welds is in a mature stage of development, with significant research and industrial applications. The market for this technology is substantial, driven by the widespread use of 4140 steel in various industries, including automotive, aerospace, and manufacturing. Major players like POSCO Holdings, Nippon Steel, and JFE Steel are at the forefront of research and development in this field. These companies, along with others such as Baoshan Iron & Steel and ArcelorMittal, have invested heavily in advanced welding technologies and heat treatment processes to optimize the properties of 4140 steel welds. The technology's maturity is evident in the sophisticated analysis techniques and equipment used by research institutions like Wuhan University of Science & Technology and the Electric Power Research Institute, contributing to a deep understanding of heat-affected zone characteristics in 4140 steel welds.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL CORP. has developed advanced techniques for studying the heat-affected zone (HAZ) in 4140 steel welds. They utilize high-resolution electron microscopy and in-situ thermal analysis to characterize microstructural changes in the HAZ[1]. Their approach involves precise control of welding parameters, including heat input and cooling rates, to optimize the HAZ properties. They have implemented a multi-pass welding technique that refines the grain structure in the HAZ, improving its toughness and fatigue resistance[3]. Additionally, NIPPON STEEL has developed a proprietary post-weld heat treatment process specifically tailored for 4140 steel, which helps to relieve residual stresses and temper the martensite formed in the HAZ[5].

Strengths: Advanced characterization techniques, precise control of welding parameters, and proprietary post-weld heat treatment. Weaknesses: Potentially higher production costs due to specialized processes and equipment requirements.

JFE Steel Corp.

Technical Solution: JFE Steel Corp. has pioneered a comprehensive approach to studying the HAZ in 4140 steel welds. They employ a combination of experimental and computational methods to predict and control HAZ properties. Their research includes the use of Gleeble thermal-mechanical simulators to recreate HAZ conditions and study phase transformations[2]. JFE Steel has developed a sophisticated finite element model that accurately predicts temperature distributions and microstructural evolution in the HAZ during welding[4]. They have also implemented advanced non-destructive testing techniques, such as phased array ultrasonic testing, to evaluate the integrity of the HAZ in real-time during welding processes[6].

Strengths: Integrated experimental and computational approach, advanced simulation capabilities, and real-time monitoring techniques. Weaknesses: High initial investment in research and development, and potential complexity in implementing the advanced techniques in production environments.

Innovations in HAZ Control for 4140 Steel

Method for manufacturing steel plate having superior toughness in weld heat-affected zone

PatentInactiveUS7396423B2

Innovation

- A welding structural steel product with uniformly dispersed TiN precipitates exhibiting high-temperature stability, manufactured by controlling the composition and processing conditions to maintain a fine ferrite and pearlite microstructure, reducing the grain size of austenite in the heat-affected zone, and optimizing the Ti/N ratio to enhance the toughness of the heat-affected zone.

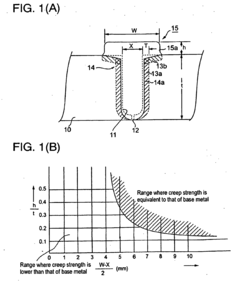

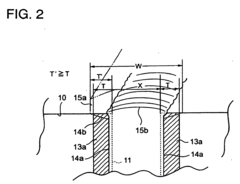

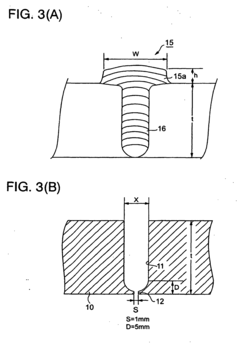

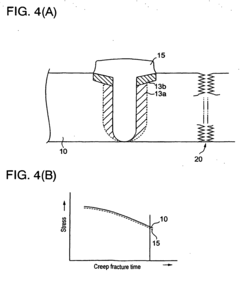

Welding method for a welded joint in high strength, ferrite type heat resistant steels

PatentInactiveEP1256411B1

Innovation

- A multi-pass buildup welding method that extends the welding line from the toe of the groove over the heat affected area to form a multi-layered weld cap, absorbing residual stress and maintaining the same creep strength as the base metal by adjusting the fusion area based on the relationship between groove width and base metal thickness.

Metallurgical Analysis of 4140 Steel HAZ

The metallurgical analysis of the heat-affected zone (HAZ) in 4140 steel welds is crucial for understanding the microstructural changes and their impact on the mechanical properties of the welded joint. 4140 steel, a medium carbon low alloy steel, is widely used in various industrial applications due to its excellent combination of strength and toughness. However, the welding process introduces significant thermal cycles that alter the microstructure of the base metal in the HAZ.

The HAZ in 4140 steel welds can be divided into several distinct regions, each with unique microstructural characteristics. The coarse-grained HAZ, adjacent to the fusion line, experiences peak temperatures well above the austenitization temperature, resulting in significant grain growth. This region is often characterized by a predominantly martensitic structure, which can lead to increased hardness but reduced toughness.

Moving away from the fusion line, the fine-grained HAZ undergoes complete austenitization but with limited grain growth. This region typically exhibits a refined martensitic structure, potentially offering a better balance of strength and toughness compared to the coarse-grained HAZ. Further from the weld, the intercritical HAZ experiences partial austenitization, resulting in a complex mixture of newly formed martensite and tempered original microstructure.

The subcritical HAZ, the outermost region of the HAZ, does not reach austenitization temperatures but undergoes tempering of the original microstructure. This can lead to a slight reduction in hardness compared to the base metal. The extent and characteristics of these HAZ regions depend on various factors, including the heat input during welding, cooling rate, and the initial microstructure of the base metal.

Microstructural analysis techniques such as optical microscopy, scanning electron microscopy (SEM), and transmission electron microscopy (TEM) are commonly employed to characterize the HAZ. These methods allow for detailed examination of grain size, phase distribution, and the presence of any detrimental features such as carbide precipitation or segregation at grain boundaries.

Hardness mapping across the HAZ provides valuable information about the local mechanical properties and can help identify potential weak points in the welded joint. Typically, a hardness gradient is observed from the fusion line to the base metal, reflecting the varying microstructural changes in different HAZ regions.

The presence of residual stresses in the HAZ is another critical aspect of the metallurgical analysis. These stresses, resulting from thermal gradients and phase transformations during welding, can significantly affect the mechanical behavior and service performance of the welded component. X-ray diffraction and neutron diffraction techniques are often used to measure and map residual stresses across the HAZ.

The HAZ in 4140 steel welds can be divided into several distinct regions, each with unique microstructural characteristics. The coarse-grained HAZ, adjacent to the fusion line, experiences peak temperatures well above the austenitization temperature, resulting in significant grain growth. This region is often characterized by a predominantly martensitic structure, which can lead to increased hardness but reduced toughness.

Moving away from the fusion line, the fine-grained HAZ undergoes complete austenitization but with limited grain growth. This region typically exhibits a refined martensitic structure, potentially offering a better balance of strength and toughness compared to the coarse-grained HAZ. Further from the weld, the intercritical HAZ experiences partial austenitization, resulting in a complex mixture of newly formed martensite and tempered original microstructure.

The subcritical HAZ, the outermost region of the HAZ, does not reach austenitization temperatures but undergoes tempering of the original microstructure. This can lead to a slight reduction in hardness compared to the base metal. The extent and characteristics of these HAZ regions depend on various factors, including the heat input during welding, cooling rate, and the initial microstructure of the base metal.

Microstructural analysis techniques such as optical microscopy, scanning electron microscopy (SEM), and transmission electron microscopy (TEM) are commonly employed to characterize the HAZ. These methods allow for detailed examination of grain size, phase distribution, and the presence of any detrimental features such as carbide precipitation or segregation at grain boundaries.

Hardness mapping across the HAZ provides valuable information about the local mechanical properties and can help identify potential weak points in the welded joint. Typically, a hardness gradient is observed from the fusion line to the base metal, reflecting the varying microstructural changes in different HAZ regions.

The presence of residual stresses in the HAZ is another critical aspect of the metallurgical analysis. These stresses, resulting from thermal gradients and phase transformations during welding, can significantly affect the mechanical behavior and service performance of the welded component. X-ray diffraction and neutron diffraction techniques are often used to measure and map residual stresses across the HAZ.

Welding Process Optimization for 4140 Steel

Welding process optimization for 4140 steel requires a comprehensive understanding of the material properties and the specific challenges associated with welding this high-strength alloy. The primary focus of optimization is to minimize the negative effects of the heat-affected zone (HAZ) while maintaining the desired mechanical properties of the welded joint.

One of the key aspects of process optimization is the selection of appropriate welding parameters. This includes determining the optimal heat input, which directly influences the size and characteristics of the HAZ. Lower heat input generally results in a smaller HAZ and faster cooling rates, which can be beneficial for maintaining the strength and toughness of 4140 steel. However, excessively low heat input may lead to incomplete fusion or lack of penetration.

Preheating and post-weld heat treatment (PWHT) are critical steps in the welding process for 4140 steel. Preheating helps to reduce the cooling rate and minimize the risk of hydrogen-induced cracking. The preheating temperature typically ranges from 200°C to 350°C, depending on the section thickness and specific application requirements. PWHT is essential for stress relief and to achieve the desired microstructure in the weld and HAZ.

The choice of welding process also plays a significant role in optimization. Gas Tungsten Arc Welding (GTAW) and Gas Metal Arc Welding (GMAW) are commonly used for 4140 steel due to their ability to provide precise control over heat input and weld bead placement. Pulsed welding techniques can further enhance control over heat input and weld pool dynamics.

Filler metal selection is another critical factor. The filler metal should be compatible with the base metal and provide adequate strength and toughness. For 4140 steel, low hydrogen electrodes are typically recommended to minimize the risk of hydrogen embrittlement.

Shielding gas composition and flow rate optimization can improve arc stability and weld quality. A mixture of argon and carbon dioxide is often used for GMAW, while pure argon is common for GTAW. The flow rate should be adjusted to provide adequate coverage without causing turbulence in the weld pool.

Weld joint design optimization can help to minimize stress concentrations and improve overall weld quality. Proper joint preparation, including cleaning and beveling, is essential for achieving sound welds in 4140 steel.

Implementing advanced monitoring and control systems can further enhance the welding process. Real-time monitoring of parameters such as arc voltage, current, and heat input can help maintain consistency and detect potential issues during welding.

One of the key aspects of process optimization is the selection of appropriate welding parameters. This includes determining the optimal heat input, which directly influences the size and characteristics of the HAZ. Lower heat input generally results in a smaller HAZ and faster cooling rates, which can be beneficial for maintaining the strength and toughness of 4140 steel. However, excessively low heat input may lead to incomplete fusion or lack of penetration.

Preheating and post-weld heat treatment (PWHT) are critical steps in the welding process for 4140 steel. Preheating helps to reduce the cooling rate and minimize the risk of hydrogen-induced cracking. The preheating temperature typically ranges from 200°C to 350°C, depending on the section thickness and specific application requirements. PWHT is essential for stress relief and to achieve the desired microstructure in the weld and HAZ.

The choice of welding process also plays a significant role in optimization. Gas Tungsten Arc Welding (GTAW) and Gas Metal Arc Welding (GMAW) are commonly used for 4140 steel due to their ability to provide precise control over heat input and weld bead placement. Pulsed welding techniques can further enhance control over heat input and weld pool dynamics.

Filler metal selection is another critical factor. The filler metal should be compatible with the base metal and provide adequate strength and toughness. For 4140 steel, low hydrogen electrodes are typically recommended to minimize the risk of hydrogen embrittlement.

Shielding gas composition and flow rate optimization can improve arc stability and weld quality. A mixture of argon and carbon dioxide is often used for GMAW, while pure argon is common for GTAW. The flow rate should be adjusted to provide adequate coverage without causing turbulence in the weld pool.

Weld joint design optimization can help to minimize stress concentrations and improve overall weld quality. Proper joint preparation, including cleaning and beveling, is essential for achieving sound welds in 4140 steel.

Implementing advanced monitoring and control systems can further enhance the welding process. Real-time monitoring of parameters such as arc voltage, current, and heat input can help maintain consistency and detect potential issues during welding.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!