High-Precision Forming Techniques for 4140 Steel Parts

JUL 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

4140 Steel Forming Background and Objectives

The forming of 4140 steel parts has been a critical process in various industries, including automotive, aerospace, and manufacturing, for decades. This medium carbon, low alloy steel is known for its excellent combination of strength, toughness, and wear resistance, making it a preferred choice for high-stress applications. The evolution of forming techniques for 4140 steel has been driven by the increasing demand for higher precision, improved material utilization, and enhanced component performance.

Historically, traditional forming methods such as forging, rolling, and machining have been employed to shape 4140 steel parts. However, these conventional techniques often faced challenges in achieving tight tolerances, complex geometries, and consistent material properties throughout the formed part. As industries progressed, the need for more advanced forming techniques became apparent, leading to the development of high-precision forming methods specifically tailored for 4140 steel.

The primary objective of high-precision forming techniques for 4140 steel parts is to achieve superior dimensional accuracy, surface finish, and mechanical properties while minimizing material waste and production costs. This goal aligns with the broader industry trends of lightweighting, performance optimization, and sustainable manufacturing practices. By enhancing the precision of formed 4140 steel components, manufacturers can improve the overall quality and reliability of end products, reduce assembly issues, and extend the service life of critical parts.

Recent technological advancements have paved the way for innovative forming processes that address the unique challenges posed by 4140 steel. These include precision hot forging, near-net-shape forming, and advanced cold forming techniques. The integration of computer-aided design (CAD) and finite element analysis (FEA) has also played a crucial role in optimizing forming parameters and predicting material behavior during the forming process.

As the industry continues to evolve, the focus on high-precision forming techniques for 4140 steel parts is expected to intensify. Future objectives include further improving dimensional accuracy to micron-level tolerances, enhancing surface quality to reduce or eliminate post-forming operations, and developing forming processes that can maintain consistent mechanical properties throughout complex geometries. Additionally, there is a growing emphasis on developing forming techniques that can be easily integrated into smart manufacturing environments, leveraging real-time process monitoring and adaptive control systems.

Historically, traditional forming methods such as forging, rolling, and machining have been employed to shape 4140 steel parts. However, these conventional techniques often faced challenges in achieving tight tolerances, complex geometries, and consistent material properties throughout the formed part. As industries progressed, the need for more advanced forming techniques became apparent, leading to the development of high-precision forming methods specifically tailored for 4140 steel.

The primary objective of high-precision forming techniques for 4140 steel parts is to achieve superior dimensional accuracy, surface finish, and mechanical properties while minimizing material waste and production costs. This goal aligns with the broader industry trends of lightweighting, performance optimization, and sustainable manufacturing practices. By enhancing the precision of formed 4140 steel components, manufacturers can improve the overall quality and reliability of end products, reduce assembly issues, and extend the service life of critical parts.

Recent technological advancements have paved the way for innovative forming processes that address the unique challenges posed by 4140 steel. These include precision hot forging, near-net-shape forming, and advanced cold forming techniques. The integration of computer-aided design (CAD) and finite element analysis (FEA) has also played a crucial role in optimizing forming parameters and predicting material behavior during the forming process.

As the industry continues to evolve, the focus on high-precision forming techniques for 4140 steel parts is expected to intensify. Future objectives include further improving dimensional accuracy to micron-level tolerances, enhancing surface quality to reduce or eliminate post-forming operations, and developing forming processes that can maintain consistent mechanical properties throughout complex geometries. Additionally, there is a growing emphasis on developing forming techniques that can be easily integrated into smart manufacturing environments, leveraging real-time process monitoring and adaptive control systems.

Market Analysis for Precision 4140 Steel Components

The market for precision 4140 steel components is experiencing significant growth, driven by increasing demand across various industries. The automotive sector remains a primary consumer, with high-precision 4140 steel parts being crucial for engine components, transmission systems, and chassis elements. The aerospace industry also contributes substantially to market expansion, utilizing these components in landing gear assemblies and structural elements.

In the oil and gas sector, 4140 steel parts are essential for drilling equipment and pressure vessels, where high strength and durability are paramount. The renewable energy sector, particularly wind turbine manufacturing, has emerged as a new growth area for precision 4140 steel components, used in gearboxes and other critical mechanisms.

Market trends indicate a shift towards more complex geometries and tighter tolerances in 4140 steel parts, driven by the need for improved performance and efficiency in end-use applications. This trend is particularly evident in the automotive industry, where lightweight yet strong components are in high demand to meet fuel efficiency standards.

The global market for precision 4140 steel components is geographically diverse, with significant production centers in North America, Europe, and Asia. China has emerged as a major player in recent years, leveraging its manufacturing capabilities and cost advantages. However, concerns over quality control and intellectual property protection have led some industries to prefer suppliers from more established markets.

Technological advancements in forming techniques, such as precision forging and advanced machining processes, are expanding the capabilities of 4140 steel part production. This is opening up new application areas and allowing manufacturers to meet increasingly stringent performance requirements.

The market is characterized by a mix of large, integrated steel producers and specialized precision component manufacturers. There is a growing trend towards vertical integration, with some companies investing in advanced forming technologies to capture more value in the supply chain.

Pricing pressures remain a significant factor in the market, particularly in commodity-type components. However, high-value, precision-engineered parts maintain stronger profit margins due to their critical nature and the specialized skills required for their production.

Looking ahead, the market for precision 4140 steel components is expected to continue its growth trajectory, supported by ongoing industrialization in emerging economies and the constant drive for improved performance in established industries. The development of new forming techniques and surface treatment processes is likely to further expand the application range of 4140 steel, potentially opening up new market segments.

In the oil and gas sector, 4140 steel parts are essential for drilling equipment and pressure vessels, where high strength and durability are paramount. The renewable energy sector, particularly wind turbine manufacturing, has emerged as a new growth area for precision 4140 steel components, used in gearboxes and other critical mechanisms.

Market trends indicate a shift towards more complex geometries and tighter tolerances in 4140 steel parts, driven by the need for improved performance and efficiency in end-use applications. This trend is particularly evident in the automotive industry, where lightweight yet strong components are in high demand to meet fuel efficiency standards.

The global market for precision 4140 steel components is geographically diverse, with significant production centers in North America, Europe, and Asia. China has emerged as a major player in recent years, leveraging its manufacturing capabilities and cost advantages. However, concerns over quality control and intellectual property protection have led some industries to prefer suppliers from more established markets.

Technological advancements in forming techniques, such as precision forging and advanced machining processes, are expanding the capabilities of 4140 steel part production. This is opening up new application areas and allowing manufacturers to meet increasingly stringent performance requirements.

The market is characterized by a mix of large, integrated steel producers and specialized precision component manufacturers. There is a growing trend towards vertical integration, with some companies investing in advanced forming technologies to capture more value in the supply chain.

Pricing pressures remain a significant factor in the market, particularly in commodity-type components. However, high-value, precision-engineered parts maintain stronger profit margins due to their critical nature and the specialized skills required for their production.

Looking ahead, the market for precision 4140 steel components is expected to continue its growth trajectory, supported by ongoing industrialization in emerging economies and the constant drive for improved performance in established industries. The development of new forming techniques and surface treatment processes is likely to further expand the application range of 4140 steel, potentially opening up new market segments.

Current Challenges in High-Precision 4140 Steel Forming

The high-precision forming of 4140 steel parts presents several significant challenges that hinder the achievement of optimal results. One of the primary obstacles is the material's high strength and hardness, which make it resistant to deformation and difficult to shape with precision. This characteristic necessitates higher forming forces and more robust tooling, increasing the complexity and cost of the manufacturing process.

Temperature control during forming is another critical challenge. 4140 steel's properties are highly sensitive to temperature variations, and maintaining consistent heat distribution throughout the workpiece is crucial. Uneven heating can lead to localized stress concentrations, resulting in distortions or defects in the final product. Additionally, the rapid cooling rates associated with some forming processes can induce unwanted microstructural changes, affecting the part's mechanical properties.

Springback, the elastic recovery of the material after deformation, poses a significant challenge in achieving tight tolerances. 4140 steel's high yield strength contributes to substantial springback, making it difficult to predict and compensate for dimensional changes. This issue is particularly pronounced in complex geometries and can lead to costly rework or scrap.

Tool wear is another concern in high-precision forming of 4140 steel. The material's abrasive nature and high forming forces accelerate tool degradation, potentially compromising part quality and increasing production costs. Frequent tool replacement or reconditioning is often necessary, impacting overall process efficiency.

Surface finish requirements present additional challenges. Achieving the desired surface quality while maintaining dimensional accuracy can be problematic, especially in areas with complex contours or sharp edges. The high strength of 4140 steel can lead to surface defects such as orange peel or galling during forming operations.

Residual stresses induced during the forming process can cause distortion in the finished parts, particularly in thin-walled or asymmetrical components. Managing and minimizing these internal stresses is crucial for maintaining dimensional stability and preventing warpage or cracking in subsequent operations or during service.

Lastly, the optimization of process parameters for high-precision forming of 4140 steel remains a complex task. The interplay between material properties, forming conditions, and part geometry requires sophisticated modeling and simulation techniques. Developing accurate predictive models that account for all relevant variables is an ongoing challenge in the field.

Temperature control during forming is another critical challenge. 4140 steel's properties are highly sensitive to temperature variations, and maintaining consistent heat distribution throughout the workpiece is crucial. Uneven heating can lead to localized stress concentrations, resulting in distortions or defects in the final product. Additionally, the rapid cooling rates associated with some forming processes can induce unwanted microstructural changes, affecting the part's mechanical properties.

Springback, the elastic recovery of the material after deformation, poses a significant challenge in achieving tight tolerances. 4140 steel's high yield strength contributes to substantial springback, making it difficult to predict and compensate for dimensional changes. This issue is particularly pronounced in complex geometries and can lead to costly rework or scrap.

Tool wear is another concern in high-precision forming of 4140 steel. The material's abrasive nature and high forming forces accelerate tool degradation, potentially compromising part quality and increasing production costs. Frequent tool replacement or reconditioning is often necessary, impacting overall process efficiency.

Surface finish requirements present additional challenges. Achieving the desired surface quality while maintaining dimensional accuracy can be problematic, especially in areas with complex contours or sharp edges. The high strength of 4140 steel can lead to surface defects such as orange peel or galling during forming operations.

Residual stresses induced during the forming process can cause distortion in the finished parts, particularly in thin-walled or asymmetrical components. Managing and minimizing these internal stresses is crucial for maintaining dimensional stability and preventing warpage or cracking in subsequent operations or during service.

Lastly, the optimization of process parameters for high-precision forming of 4140 steel remains a complex task. The interplay between material properties, forming conditions, and part geometry requires sophisticated modeling and simulation techniques. Developing accurate predictive models that account for all relevant variables is an ongoing challenge in the field.

Existing High-Precision Forming Methods for 4140 Steel

01 Heat treatment processes for 4140 steel

Various heat treatment processes are employed to enhance the precision and mechanical properties of 4140 steel parts. These processes may include quenching, tempering, and annealing, which are carefully controlled to achieve desired hardness, strength, and dimensional stability.- Heat treatment processes for 4140 steel: Various heat treatment processes are employed to enhance the precision and mechanical properties of 4140 steel parts. These processes may include quenching, tempering, and annealing, which are carefully controlled to achieve the desired hardness, strength, and dimensional stability. The specific heat treatment parameters are optimized based on the part's intended application and required specifications.

- Precision machining techniques for 4140 steel: Advanced machining techniques are utilized to achieve high precision in 4140 steel parts. These may include CNC milling, turning, grinding, and EDM processes. The machining parameters, such as cutting speed, feed rate, and tool selection, are carefully optimized to ensure dimensional accuracy and surface finish. Specialized fixtures and tooling may be employed to maintain consistency across production runs.

- Quality control and inspection methods: Rigorous quality control and inspection procedures are implemented to ensure the precision of 4140 steel parts. This may involve the use of advanced measurement equipment such as coordinate measuring machines (CMMs), optical comparators, and 3D scanners. Statistical process control techniques are often employed to monitor and maintain consistent part quality throughout production.

- Surface treatment and finishing processes: Various surface treatment and finishing processes are applied to 4140 steel parts to enhance their precision, wear resistance, and corrosion resistance. These may include nitriding, carburizing, shot peening, and precision grinding. The selection of appropriate surface treatments depends on the specific requirements of the part and its intended application.

- Design considerations for precision 4140 steel parts: The design of precision 4140 steel parts takes into account factors such as material properties, manufacturing processes, and functional requirements. Design features may include stress-relieving techniques, optimal wall thicknesses, and strategic placement of critical dimensions. Advanced CAD/CAM software and simulation tools are often used to optimize part designs for manufacturability and precision.

02 Precision machining techniques

Advanced machining techniques are utilized to achieve high precision in 4140 steel parts. These may include CNC machining, grinding, and finishing processes that ensure tight tolerances and superior surface quality for critical components.Expand Specific Solutions03 Surface treatment and coating

Various surface treatments and coatings are applied to 4140 steel parts to improve wear resistance, corrosion protection, and overall performance. These treatments may include nitriding, carburizing, or the application of specialized coatings to enhance surface properties while maintaining dimensional precision.Expand Specific Solutions04 Quality control and inspection methods

Rigorous quality control and inspection methods are implemented to ensure the precision of 4140 steel parts. These may include advanced measurement techniques, non-destructive testing, and statistical process control to maintain consistent quality and dimensional accuracy throughout production.Expand Specific Solutions05 Specialized tooling and fixtures

Custom tooling and fixtures are designed and utilized to enhance the precision of 4140 steel parts during manufacturing processes. These may include specialized cutting tools, holding devices, and jigs that minimize deformation and ensure consistent results in machining and assembly operations.Expand Specific Solutions

Key Players in Precision Steel Forming Industry

The high-precision forming of 4140 steel parts is in a mature stage of development, with a substantial market size driven by automotive, aerospace, and industrial applications. The technology's maturity is evident from the involvement of major players across the steel and manufacturing sectors. Companies like POSCO Holdings, Mercedes-Benz Group, and Nippon Steel are leveraging their extensive R&D capabilities to advance forming techniques. Specialized firms such as Guizhou Aviation Technology and AVIC Shenyang Liming Aero-Engine are focusing on aerospace applications, while automotive giants like Hyundai Motor and Kia are integrating these techniques into their production processes. The competitive landscape is diverse, with both established steel producers and niche specialists contributing to ongoing technological advancements in this field.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL CORP. has developed advanced high-precision forming techniques for 4140 steel parts. Their approach involves a combination of controlled heating and cooling processes, precision forging, and advanced heat treatment methods. The company utilizes a proprietary hot working process that optimizes the microstructure of 4140 steel, resulting in improved mechanical properties and dimensional accuracy[1]. They have also implemented computer-aided simulation tools to predict and control material flow during forming, reducing defects and enhancing part quality[2]. Additionally, NIPPON STEEL has developed a specialized quenching and tempering process tailored for 4140 steel, which allows for precise control of hardness and strength distributions throughout the part[3].

Strengths: Superior microstructure control, reduced defects, and enhanced mechanical properties. Weaknesses: Potentially higher production costs and longer processing times compared to conventional methods.

HBIS Co., Ltd.

Technical Solution: HBIS Co., Ltd. has implemented an innovative approach to high-precision forming of 4140 steel parts. Their technique involves a multi-stage forming process that incorporates both hot and cold working methods. The company has developed a specialized pre-forming stage that optimizes the initial grain structure of the 4140 steel, enhancing its formability[4]. HBIS utilizes advanced die designs with precise temperature control systems, allowing for uniform heat distribution during the forming process[5]. They have also implemented in-line quality control measures, including real-time monitoring of forming parameters and non-destructive testing techniques, to ensure consistent part quality and dimensional accuracy[6].

Strengths: Improved formability, consistent part quality, and efficient production process. Weaknesses: May require significant initial investment in specialized equipment and tooling.

Innovative Technologies in 4140 Steel Forming

100-150mm alloy structural steel 4140 thick plate and production technique thereof

PatentActiveCN103725966A

Innovation

- KR hot metal pretreatment, converter smelting, argon blowing treatment, LF refining, VD refining, die casting, steel ingot slow cooling, steel ingot cleaning, heating, controlled rolling, stack cooling, heat treatment and slow cooling are used to strictly control the content of harmful elements in steel. And the rolling process, through multi-stage rolling and heat treatment, ensures that the internal residual stress of the steel plate is minimized and the performance indicators meet the standards.

Large-diameter round steel with high strength and high toughness and manufacturing method thereof

PatentActiveCN110284062A

Innovation

- By optimizing the chemical composition, including the content design of C, Si, Mn, Cr, Mo, Ni, Cu, V, Nb, Ti, and N, combined with the continuous casting and rolling process and high-temperature heat treatment, the hardenability and grain size of the steel are improved. Refinement and cost reduction.

Material Properties and Heat Treatment Considerations

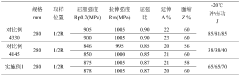

AISI 4140 steel is a medium carbon, low alloy steel known for its excellent combination of strength, toughness, and wear resistance. Its chemical composition typically includes 0.38-0.43% carbon, 0.75-1.00% manganese, 0.15-0.30% silicon, 0.80-1.10% chromium, and 0.15-0.25% molybdenum. These alloying elements contribute to the steel's unique properties and heat treatment response.

The material properties of 4140 steel are highly dependent on its heat treatment condition. In the annealed state, 4140 steel exhibits a tensile strength of approximately 655 MPa and a yield strength of 415 MPa. However, through proper heat treatment, these properties can be significantly enhanced. Quenching and tempering can increase the tensile strength to over 1,000 MPa while maintaining good ductility and impact resistance.

Heat treatment considerations for 4140 steel are crucial for achieving optimal mechanical properties. The typical heat treatment process involves austenitizing, quenching, and tempering. Austenitizing is typically performed at temperatures between 840-870°C, followed by rapid quenching in oil or polymer quenchants to form martensite. The subsequent tempering process, usually conducted between 200-650°C, allows for the precise control of strength and toughness.

The hardenability of 4140 steel is excellent due to its alloying elements, particularly chromium and molybdenum. This characteristic enables the formation of a uniform martensitic structure throughout thicker sections, making it suitable for larger components. However, care must be taken to avoid quench cracking, especially in complex geometries or parts with sharp corners.

For high-precision forming techniques, the dimensional stability of 4140 steel during heat treatment is a critical consideration. The material undergoes volumetric changes during phase transformations, which can lead to distortion. Minimizing these effects requires careful control of heating and cooling rates, as well as proper fixturing during heat treatment.

Surface treatments such as carburizing or nitriding can be applied to 4140 steel to enhance surface hardness and wear resistance while maintaining a tough core. These processes can be particularly beneficial for components subjected to high contact stresses or abrasive environments.

In conclusion, understanding the material properties and heat treatment considerations of 4140 steel is essential for developing high-precision forming techniques. The ability to tailor the microstructure and mechanical properties through controlled heat treatment processes allows for the optimization of component performance in various applications.

The material properties of 4140 steel are highly dependent on its heat treatment condition. In the annealed state, 4140 steel exhibits a tensile strength of approximately 655 MPa and a yield strength of 415 MPa. However, through proper heat treatment, these properties can be significantly enhanced. Quenching and tempering can increase the tensile strength to over 1,000 MPa while maintaining good ductility and impact resistance.

Heat treatment considerations for 4140 steel are crucial for achieving optimal mechanical properties. The typical heat treatment process involves austenitizing, quenching, and tempering. Austenitizing is typically performed at temperatures between 840-870°C, followed by rapid quenching in oil or polymer quenchants to form martensite. The subsequent tempering process, usually conducted between 200-650°C, allows for the precise control of strength and toughness.

The hardenability of 4140 steel is excellent due to its alloying elements, particularly chromium and molybdenum. This characteristic enables the formation of a uniform martensitic structure throughout thicker sections, making it suitable for larger components. However, care must be taken to avoid quench cracking, especially in complex geometries or parts with sharp corners.

For high-precision forming techniques, the dimensional stability of 4140 steel during heat treatment is a critical consideration. The material undergoes volumetric changes during phase transformations, which can lead to distortion. Minimizing these effects requires careful control of heating and cooling rates, as well as proper fixturing during heat treatment.

Surface treatments such as carburizing or nitriding can be applied to 4140 steel to enhance surface hardness and wear resistance while maintaining a tough core. These processes can be particularly beneficial for components subjected to high contact stresses or abrasive environments.

In conclusion, understanding the material properties and heat treatment considerations of 4140 steel is essential for developing high-precision forming techniques. The ability to tailor the microstructure and mechanical properties through controlled heat treatment processes allows for the optimization of component performance in various applications.

Quality Control and Inspection Methods for 4140 Steel Parts

Quality control and inspection methods play a crucial role in ensuring the precision and reliability of 4140 steel parts formed through high-precision techniques. The implementation of robust quality control measures is essential to maintain consistent product quality and meet stringent industry standards.

Non-destructive testing (NDT) methods are widely employed for inspecting 4140 steel parts. Ultrasonic testing is particularly effective for detecting internal defects, such as inclusions or voids, which may compromise the structural integrity of the formed parts. This method uses high-frequency sound waves to penetrate the material and identify anomalies based on the reflected signals.

Magnetic particle inspection is another valuable NDT technique for 4140 steel parts. This method is particularly useful for detecting surface and near-surface defects, such as cracks or seams. The process involves magnetizing the part and applying magnetic particles, which accumulate at discontinuities, making them visible under appropriate lighting conditions.

Dimensional inspection is critical for ensuring that formed 4140 steel parts meet specified tolerances. Coordinate measuring machines (CMMs) are commonly used for high-precision measurements. These automated systems can accurately measure complex geometries and provide detailed reports on dimensional compliance.

Surface roughness measurements are essential for evaluating the quality of finished surfaces on 4140 steel parts. Profilometers are typically used to quantify surface texture parameters, such as average roughness (Ra) and maximum peak-to-valley height (Rz). These measurements help ensure that the parts meet surface finish requirements for their intended applications.

Hardness testing is a crucial quality control measure for 4140 steel parts, as it directly relates to the material's strength and wear resistance. Rockwell and Brinell hardness tests are commonly employed to verify that the parts meet specified hardness ranges after heat treatment processes.

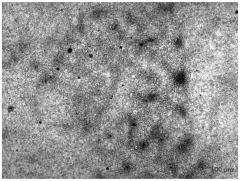

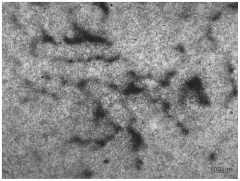

Metallographic examination is often conducted to assess the microstructure of 4140 steel parts. This involves preparing polished and etched samples for microscopic analysis. The examination can reveal important information about grain structure, phase distribution, and the presence of any undesirable microstructural features that may affect the part's performance.

Statistical process control (SPC) techniques are implemented to monitor and control the manufacturing process for 4140 steel parts. Key process parameters, such as forming pressure, temperature, and cycle time, are continuously tracked and analyzed to identify trends and potential issues before they result in non-conforming parts.

In-process inspection methods, such as automated vision systems, are increasingly being integrated into production lines for real-time quality monitoring. These systems can detect surface defects, verify dimensional accuracy, and ensure proper part orientation during the forming process.

Non-destructive testing (NDT) methods are widely employed for inspecting 4140 steel parts. Ultrasonic testing is particularly effective for detecting internal defects, such as inclusions or voids, which may compromise the structural integrity of the formed parts. This method uses high-frequency sound waves to penetrate the material and identify anomalies based on the reflected signals.

Magnetic particle inspection is another valuable NDT technique for 4140 steel parts. This method is particularly useful for detecting surface and near-surface defects, such as cracks or seams. The process involves magnetizing the part and applying magnetic particles, which accumulate at discontinuities, making them visible under appropriate lighting conditions.

Dimensional inspection is critical for ensuring that formed 4140 steel parts meet specified tolerances. Coordinate measuring machines (CMMs) are commonly used for high-precision measurements. These automated systems can accurately measure complex geometries and provide detailed reports on dimensional compliance.

Surface roughness measurements are essential for evaluating the quality of finished surfaces on 4140 steel parts. Profilometers are typically used to quantify surface texture parameters, such as average roughness (Ra) and maximum peak-to-valley height (Rz). These measurements help ensure that the parts meet surface finish requirements for their intended applications.

Hardness testing is a crucial quality control measure for 4140 steel parts, as it directly relates to the material's strength and wear resistance. Rockwell and Brinell hardness tests are commonly employed to verify that the parts meet specified hardness ranges after heat treatment processes.

Metallographic examination is often conducted to assess the microstructure of 4140 steel parts. This involves preparing polished and etched samples for microscopic analysis. The examination can reveal important information about grain structure, phase distribution, and the presence of any undesirable microstructural features that may affect the part's performance.

Statistical process control (SPC) techniques are implemented to monitor and control the manufacturing process for 4140 steel parts. Key process parameters, such as forming pressure, temperature, and cycle time, are continuously tracked and analyzed to identify trends and potential issues before they result in non-conforming parts.

In-process inspection methods, such as automated vision systems, are increasingly being integrated into production lines for real-time quality monitoring. These systems can detect surface defects, verify dimensional accuracy, and ensure proper part orientation during the forming process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!