High-Temperature Oxidation Resistance of 4140 Steel

JUL 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

4140 Steel Oxidation Background and Objectives

The high-temperature oxidation resistance of 4140 steel has been a critical area of research in materials science and engineering for decades. This medium-carbon, low-alloy steel, known for its excellent combination of strength and toughness, finds widespread applications in various industries, including automotive, aerospace, and oil and gas. However, its performance under elevated temperatures, particularly in oxidizing environments, has been a persistent challenge.

The evolution of 4140 steel's oxidation resistance can be traced back to the mid-20th century when the demand for high-performance materials in industrial applications began to surge. Initial studies focused on understanding the basic mechanisms of oxidation and the role of alloying elements in enhancing resistance. As industrial processes became more demanding, the need for improved oxidation resistance at higher temperatures became increasingly apparent.

Over the years, research efforts have been directed towards modifying the composition and microstructure of 4140 steel to enhance its oxidation resistance. The addition of chromium, silicon, and other alloying elements has been explored to form protective oxide scales. Surface treatment techniques, such as nitriding and carburizing, have also been investigated to create barrier layers against oxidation.

The primary objective of current research in this field is to develop strategies that can significantly improve the high-temperature oxidation resistance of 4140 steel without compromising its desirable mechanical properties. This involves a multifaceted approach, including optimizing alloy composition, exploring novel heat treatment processes, and developing advanced surface modification techniques.

Another crucial goal is to understand the oxidation kinetics and mechanisms at various temperatures and in different environments. This knowledge is essential for predicting the long-term performance of 4140 steel components in high-temperature applications and for developing more accurate life prediction models.

Furthermore, researchers aim to bridge the gap between laboratory findings and industrial applications. This includes scaling up successful experimental techniques to industrial processes and addressing the challenges associated with complex geometries and varying service conditions encountered in real-world applications.

The pursuit of enhanced oxidation resistance in 4140 steel is driven by the increasing demands of industries such as power generation, where components are exposed to ever-higher temperatures and more aggressive environments. As global energy needs continue to grow, the development of materials capable of withstanding extreme conditions becomes paramount, placing the improvement of 4140 steel's oxidation resistance at the forefront of materials research and development efforts.

The evolution of 4140 steel's oxidation resistance can be traced back to the mid-20th century when the demand for high-performance materials in industrial applications began to surge. Initial studies focused on understanding the basic mechanisms of oxidation and the role of alloying elements in enhancing resistance. As industrial processes became more demanding, the need for improved oxidation resistance at higher temperatures became increasingly apparent.

Over the years, research efforts have been directed towards modifying the composition and microstructure of 4140 steel to enhance its oxidation resistance. The addition of chromium, silicon, and other alloying elements has been explored to form protective oxide scales. Surface treatment techniques, such as nitriding and carburizing, have also been investigated to create barrier layers against oxidation.

The primary objective of current research in this field is to develop strategies that can significantly improve the high-temperature oxidation resistance of 4140 steel without compromising its desirable mechanical properties. This involves a multifaceted approach, including optimizing alloy composition, exploring novel heat treatment processes, and developing advanced surface modification techniques.

Another crucial goal is to understand the oxidation kinetics and mechanisms at various temperatures and in different environments. This knowledge is essential for predicting the long-term performance of 4140 steel components in high-temperature applications and for developing more accurate life prediction models.

Furthermore, researchers aim to bridge the gap between laboratory findings and industrial applications. This includes scaling up successful experimental techniques to industrial processes and addressing the challenges associated with complex geometries and varying service conditions encountered in real-world applications.

The pursuit of enhanced oxidation resistance in 4140 steel is driven by the increasing demands of industries such as power generation, where components are exposed to ever-higher temperatures and more aggressive environments. As global energy needs continue to grow, the development of materials capable of withstanding extreme conditions becomes paramount, placing the improvement of 4140 steel's oxidation resistance at the forefront of materials research and development efforts.

Market Analysis for Heat-Resistant Steel

The market for heat-resistant steel, particularly in the context of 4140 steel's high-temperature oxidation resistance, has shown significant growth and potential in recent years. This trend is driven by the increasing demand for materials capable of withstanding extreme temperatures in various industrial applications. The automotive sector, especially in high-performance engines and exhaust systems, represents a major market for heat-resistant steel. As automotive manufacturers strive for improved engine efficiency and reduced emissions, the need for materials that can maintain structural integrity under high-temperature conditions continues to rise.

In the oil and gas industry, heat-resistant steel plays a crucial role in drilling equipment, pipelines, and refinery components exposed to corrosive environments and high temperatures. The expansion of deep-sea drilling operations and the exploration of unconventional oil and gas reserves have further boosted the demand for advanced heat-resistant materials. The aerospace industry also contributes significantly to the market growth, with applications in jet engines, rocket propulsion systems, and spacecraft components that require exceptional heat resistance.

The power generation sector, particularly in thermal and nuclear power plants, represents another substantial market for heat-resistant steel. As the global energy demand increases and countries invest in upgrading their power infrastructure, the need for materials capable of withstanding high temperatures and pressures in turbines, boilers, and heat exchangers grows accordingly. The renewable energy sector, especially concentrated solar power plants, also requires heat-resistant materials for thermal storage systems and heat transfer components.

Geographically, the Asia-Pacific region leads the market for heat-resistant steel, driven by rapid industrialization, infrastructure development, and the growth of manufacturing sectors in countries like China and India. North America and Europe follow closely, with their established automotive, aerospace, and energy industries contributing to steady demand. The Middle East region shows promising growth potential, primarily due to its oil and gas sector and increasing investments in industrial diversification.

Market analysts project a compound annual growth rate (CAGR) for the heat-resistant steel market in the range of 5-7% over the next five years. This growth is attributed to ongoing technological advancements in steel manufacturing, increasing adoption of high-performance materials in critical applications, and the expansion of end-use industries in emerging economies. However, factors such as volatile raw material prices and the development of alternative materials like advanced ceramics and composites may pose challenges to market growth.

In the oil and gas industry, heat-resistant steel plays a crucial role in drilling equipment, pipelines, and refinery components exposed to corrosive environments and high temperatures. The expansion of deep-sea drilling operations and the exploration of unconventional oil and gas reserves have further boosted the demand for advanced heat-resistant materials. The aerospace industry also contributes significantly to the market growth, with applications in jet engines, rocket propulsion systems, and spacecraft components that require exceptional heat resistance.

The power generation sector, particularly in thermal and nuclear power plants, represents another substantial market for heat-resistant steel. As the global energy demand increases and countries invest in upgrading their power infrastructure, the need for materials capable of withstanding high temperatures and pressures in turbines, boilers, and heat exchangers grows accordingly. The renewable energy sector, especially concentrated solar power plants, also requires heat-resistant materials for thermal storage systems and heat transfer components.

Geographically, the Asia-Pacific region leads the market for heat-resistant steel, driven by rapid industrialization, infrastructure development, and the growth of manufacturing sectors in countries like China and India. North America and Europe follow closely, with their established automotive, aerospace, and energy industries contributing to steady demand. The Middle East region shows promising growth potential, primarily due to its oil and gas sector and increasing investments in industrial diversification.

Market analysts project a compound annual growth rate (CAGR) for the heat-resistant steel market in the range of 5-7% over the next five years. This growth is attributed to ongoing technological advancements in steel manufacturing, increasing adoption of high-performance materials in critical applications, and the expansion of end-use industries in emerging economies. However, factors such as volatile raw material prices and the development of alternative materials like advanced ceramics and composites may pose challenges to market growth.

Current Challenges in High-Temperature Oxidation Resistance

The high-temperature oxidation resistance of 4140 steel faces several significant challenges that hinder its performance in extreme environments. One of the primary issues is the formation and stability of protective oxide scales at elevated temperatures. While 4140 steel can form a chromium-rich oxide layer, this layer's effectiveness diminishes as temperatures increase, leading to accelerated oxidation rates and potential material degradation.

Another critical challenge is the adherence of the oxide scale to the steel substrate. At high temperatures, thermal stresses and differences in thermal expansion coefficients between the oxide layer and the base metal can cause spallation or cracking of the protective scale. This exposes fresh metal surfaces to oxidation, compromising the steel's long-term durability and performance.

The presence of alloying elements in 4140 steel, while beneficial for mechanical properties, can complicate its oxidation behavior. Elements such as chromium and molybdenum can form complex oxides with varying protective qualities. The interaction between these alloying elements and the oxidizing environment can lead to the formation of volatile species or less protective oxides, further challenging the material's resistance to high-temperature oxidation.

Cyclic oxidation conditions pose a particular challenge for 4140 steel. The repeated heating and cooling cycles experienced in many industrial applications can cause thermal fatigue and enhance oxide scale spallation. This cyclic behavior accelerates material loss and can lead to premature failure of components made from 4140 steel.

The influence of external contaminants and aggressive environments on the oxidation resistance of 4140 steel is also a significant concern. Sulfur, chlorine, and other corrosive species present in industrial atmospheres can penetrate the oxide scale or react with alloying elements, compromising the protective nature of the oxide layer and accelerating the oxidation process.

Furthermore, the microstructural stability of 4140 steel at high temperatures presents challenges for maintaining oxidation resistance. Prolonged exposure to elevated temperatures can lead to grain growth, phase transformations, and changes in the distribution of alloying elements. These microstructural changes can affect the formation and properties of the protective oxide scale, potentially reducing the steel's overall oxidation resistance.

Addressing these challenges requires a multifaceted approach, combining materials science, surface engineering, and process optimization. Developing advanced coatings, modifying the steel's composition, or implementing novel heat treatment processes are potential strategies to enhance the high-temperature oxidation resistance of 4140 steel. However, each of these approaches comes with its own set of technical and economic considerations, necessitating careful evaluation and research to find optimal solutions for specific applications.

Another critical challenge is the adherence of the oxide scale to the steel substrate. At high temperatures, thermal stresses and differences in thermal expansion coefficients between the oxide layer and the base metal can cause spallation or cracking of the protective scale. This exposes fresh metal surfaces to oxidation, compromising the steel's long-term durability and performance.

The presence of alloying elements in 4140 steel, while beneficial for mechanical properties, can complicate its oxidation behavior. Elements such as chromium and molybdenum can form complex oxides with varying protective qualities. The interaction between these alloying elements and the oxidizing environment can lead to the formation of volatile species or less protective oxides, further challenging the material's resistance to high-temperature oxidation.

Cyclic oxidation conditions pose a particular challenge for 4140 steel. The repeated heating and cooling cycles experienced in many industrial applications can cause thermal fatigue and enhance oxide scale spallation. This cyclic behavior accelerates material loss and can lead to premature failure of components made from 4140 steel.

The influence of external contaminants and aggressive environments on the oxidation resistance of 4140 steel is also a significant concern. Sulfur, chlorine, and other corrosive species present in industrial atmospheres can penetrate the oxide scale or react with alloying elements, compromising the protective nature of the oxide layer and accelerating the oxidation process.

Furthermore, the microstructural stability of 4140 steel at high temperatures presents challenges for maintaining oxidation resistance. Prolonged exposure to elevated temperatures can lead to grain growth, phase transformations, and changes in the distribution of alloying elements. These microstructural changes can affect the formation and properties of the protective oxide scale, potentially reducing the steel's overall oxidation resistance.

Addressing these challenges requires a multifaceted approach, combining materials science, surface engineering, and process optimization. Developing advanced coatings, modifying the steel's composition, or implementing novel heat treatment processes are potential strategies to enhance the high-temperature oxidation resistance of 4140 steel. However, each of these approaches comes with its own set of technical and economic considerations, necessitating careful evaluation and research to find optimal solutions for specific applications.

Existing Solutions for 4140 Steel Oxidation Resistance

01 Alloying elements for improved oxidation resistance

The addition of specific alloying elements to 4140 steel can significantly enhance its oxidation resistance. Elements such as chromium, nickel, and molybdenum are commonly used to form protective oxide layers on the steel surface, reducing the rate of oxidation at high temperatures.- Alloying elements for improved oxidation resistance: Adding specific alloying elements to 4140 steel can enhance its oxidation resistance. Elements such as chromium, nickel, and molybdenum are commonly used to form protective oxide layers on the steel surface, reducing the rate of oxidation at high temperatures.

- Heat treatment processes: Various heat treatment processes can be applied to 4140 steel to improve its oxidation resistance. These may include quenching, tempering, and annealing techniques that modify the microstructure of the steel, resulting in enhanced resistance to oxidation.

- Surface treatments and coatings: Applying surface treatments or protective coatings to 4140 steel can significantly improve its oxidation resistance. These may include nitriding, carburizing, or the application of ceramic or metallic coatings that act as barriers against oxidation.

- Controlled atmosphere processing: Processing 4140 steel in controlled atmospheres can enhance its oxidation resistance. This may involve heat treatment or other processing steps in inert gas environments or under vacuum conditions to minimize oxidation during manufacturing.

- Microstructure optimization: Optimizing the microstructure of 4140 steel through careful control of composition and processing parameters can lead to improved oxidation resistance. This may involve techniques to refine grain size, control precipitate formation, or modify phase distributions within the steel.

02 Heat treatment processes for oxidation resistance

Various heat treatment processes can be applied to 4140 steel to improve its oxidation resistance. These may include normalizing, quenching, and tempering treatments, which can alter the microstructure of the steel and enhance its ability to resist oxidation under high-temperature conditions.Expand Specific Solutions03 Surface treatments and coatings

Applying surface treatments or protective coatings to 4140 steel can significantly improve its oxidation resistance. These may include nitriding, carburizing, or the application of ceramic or metallic coatings that act as barriers against oxidation.Expand Specific Solutions04 Controlled atmosphere processing

Processing 4140 steel in controlled atmospheres can help prevent oxidation during manufacturing and heat treatment. This may involve the use of inert gases or reducing atmospheres to minimize oxygen exposure and prevent the formation of oxide layers on the steel surface.Expand Specific Solutions05 Microstructure optimization

Optimizing the microstructure of 4140 steel through careful control of composition and processing parameters can enhance its oxidation resistance. This may involve techniques such as grain refinement, precipitation hardening, or the formation of specific phases that improve the steel's resistance to high-temperature oxidation.Expand Specific Solutions

Key Players in High-Temperature Steel Industry

The high-temperature oxidation resistance of 4140 steel is a critical area of research in the advanced materials industry, currently in a growth phase. The market for heat-resistant steels is expanding, driven by increasing demand in aerospace, automotive, and energy sectors. Technologically, this field is moderately mature, with ongoing innovations focused on enhancing performance and durability. Key players like NIPPON STEEL CORP., JFE Steel Corp., and Mitsubishi Heavy Industries are at the forefront, leveraging their extensive R&D capabilities. Companies such as Angang Steel and Baoshan Iron & Steel are also making significant contributions, particularly in developing specialized alloys for high-temperature applications. The competitive landscape is characterized by a mix of established steel manufacturers and specialized materials research institutes, indicating a dynamic and evolving market.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL CORP. has developed advanced high-temperature oxidation resistant 4140 steel through innovative alloying and heat treatment processes. Their approach involves precise control of chromium, molybdenum, and silicon content to form protective oxide scales at elevated temperatures. The company utilizes a proprietary two-stage heat treatment process, including normalization and tempering, to optimize the microstructure for enhanced oxidation resistance[1]. Additionally, they have implemented surface modification techniques, such as Al-Si coatings, to further improve the steel's performance in high-temperature environments[3]. These advancements have resulted in 4140 steel variants capable of withstanding temperatures up to 650°C for extended periods without significant degradation[5].

Strengths: Superior oxidation resistance at high temperatures, improved longevity in harsh environments, and enhanced mechanical properties. Weaknesses: Potentially higher production costs due to specialized alloying and heat treatment processes, and limited applicability in ultra-high temperature applications beyond 650°C.

JFE Steel Corp.

Technical Solution: JFE Steel Corp. has developed a proprietary high-temperature oxidation resistant 4140 steel through a combination of advanced alloying techniques and surface treatments. Their approach involves carefully controlling the chromium and molybdenum content while adding small amounts of rare earth elements to enhance oxide scale adhesion[2]. The company employs a unique multi-stage heat treatment process that includes normalizing, quenching, and tempering to achieve an optimal microstructure for oxidation resistance[4]. JFE Steel has also implemented an innovative surface nitriding process that creates a nitrogen-rich layer on the steel surface, further improving its resistance to high-temperature oxidation[6]. These developments have resulted in 4140 steel variants that can maintain their integrity at temperatures up to 600°C for prolonged periods[8].

Strengths: Excellent oxidation resistance, improved mechanical properties at elevated temperatures, and enhanced surface protection. Weaknesses: Potentially higher production costs due to the use of rare earth elements and complex heat treatment processes, and limited effectiveness above 600°C.

Core Innovations in High-Temperature Steel Protection

COMPOSITION DESIGN AND PROCESSING METHODS OF HIGH STRENGTH, HIGH DUCTILITY, AND HIGH CORROSION RESISTANCE FeMnAlC ALLOYS

PatentActiveUS20170107588A1

Innovation

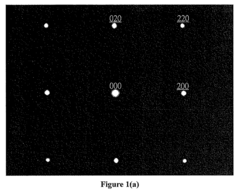

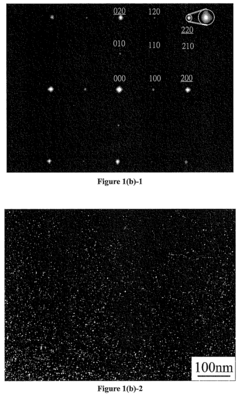

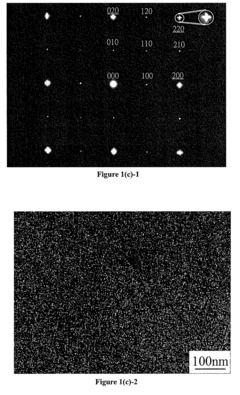

- The alloy composition is optimized with a carbon concentration between 1.4% and 2.2% to form a high density of fine κ′-carbides through spinodal decomposition during quenching, and nitriding treatments are applied at 450-550°C to enhance mechanical strength and corrosion resistance, resulting in a microstructure of austenite+fine κ′-carbides without grain boundary precipitates.

Environmental Impact of Heat-Resistant Steel Production

The production of heat-resistant steel, including 4140 steel with enhanced high-temperature oxidation resistance, has significant environmental implications. The manufacturing process involves energy-intensive operations and the use of various raw materials, which contribute to environmental concerns.

One of the primary environmental impacts is the high energy consumption associated with steel production. The furnaces used for melting and heat treatment require substantial amounts of electricity or fossil fuels, leading to increased greenhouse gas emissions. The production of heat-resistant steel often requires higher temperatures and longer processing times, further amplifying energy demands and carbon footprint.

Raw material extraction for heat-resistant steel production also poses environmental challenges. Mining activities for iron ore, chromium, and other alloying elements can result in habitat destruction, soil erosion, and water pollution. The transportation of these materials to production facilities adds to the overall carbon emissions associated with the steel industry.

The use of chemicals and additives in the production process can lead to air and water pollution if not properly managed. Emissions from steel plants may contain particulate matter, sulfur dioxide, and nitrogen oxides, which can contribute to air quality issues in surrounding areas. Wastewater from production processes may contain heavy metals and other contaminants, requiring careful treatment before discharge.

However, the development of more efficient production techniques and the implementation of environmental management systems have helped mitigate some of these impacts. Advanced furnace designs and energy recovery systems have improved energy efficiency in steel production. Additionally, the use of recycled steel as a raw material has gained traction, reducing the need for virgin ore extraction and lowering overall environmental impact.

The longevity and durability of heat-resistant steel products, such as those made from 4140 steel with improved oxidation resistance, can indirectly benefit the environment. These materials' extended lifespan reduces the frequency of replacement and, consequently, the demand for new production, potentially offsetting some of the environmental costs associated with their manufacture.

As environmental regulations become more stringent, steel producers are increasingly focusing on sustainable practices. This includes investing in cleaner technologies, implementing closed-loop water systems, and exploring alternative energy sources for production processes. The industry is also researching ways to reduce carbon emissions through carbon capture and storage technologies and the use of hydrogen as a reducing agent in steelmaking.

One of the primary environmental impacts is the high energy consumption associated with steel production. The furnaces used for melting and heat treatment require substantial amounts of electricity or fossil fuels, leading to increased greenhouse gas emissions. The production of heat-resistant steel often requires higher temperatures and longer processing times, further amplifying energy demands and carbon footprint.

Raw material extraction for heat-resistant steel production also poses environmental challenges. Mining activities for iron ore, chromium, and other alloying elements can result in habitat destruction, soil erosion, and water pollution. The transportation of these materials to production facilities adds to the overall carbon emissions associated with the steel industry.

The use of chemicals and additives in the production process can lead to air and water pollution if not properly managed. Emissions from steel plants may contain particulate matter, sulfur dioxide, and nitrogen oxides, which can contribute to air quality issues in surrounding areas. Wastewater from production processes may contain heavy metals and other contaminants, requiring careful treatment before discharge.

However, the development of more efficient production techniques and the implementation of environmental management systems have helped mitigate some of these impacts. Advanced furnace designs and energy recovery systems have improved energy efficiency in steel production. Additionally, the use of recycled steel as a raw material has gained traction, reducing the need for virgin ore extraction and lowering overall environmental impact.

The longevity and durability of heat-resistant steel products, such as those made from 4140 steel with improved oxidation resistance, can indirectly benefit the environment. These materials' extended lifespan reduces the frequency of replacement and, consequently, the demand for new production, potentially offsetting some of the environmental costs associated with their manufacture.

As environmental regulations become more stringent, steel producers are increasingly focusing on sustainable practices. This includes investing in cleaner technologies, implementing closed-loop water systems, and exploring alternative energy sources for production processes. The industry is also researching ways to reduce carbon emissions through carbon capture and storage technologies and the use of hydrogen as a reducing agent in steelmaking.

Cost-Benefit Analysis of Oxidation-Resistant 4140 Steel

The cost-benefit analysis of oxidation-resistant 4140 steel is a crucial consideration for industries operating in high-temperature environments. This analysis encompasses both the financial implications and the performance advantages of implementing oxidation-resistant treatments or modifications to 4140 steel.

From a cost perspective, the initial investment in oxidation-resistant 4140 steel is typically higher than that of standard 4140 steel. This increased cost is attributed to the additional processing steps, such as surface treatments, alloying elements, or coating applications, required to enhance the steel's oxidation resistance. However, it is essential to consider these upfront costs in the context of long-term benefits and potential savings.

The primary benefit of oxidation-resistant 4140 steel lies in its extended service life under high-temperature conditions. By mitigating oxidation-induced degradation, components made from this material can maintain their structural integrity and performance characteristics for longer periods. This longevity translates to reduced frequency of replacements, minimizing downtime and associated labor costs for maintenance and repairs.

Furthermore, the improved oxidation resistance contributes to enhanced reliability and safety in critical applications. This is particularly valuable in industries such as aerospace, power generation, and oil and gas, where component failure can lead to catastrophic consequences. The reduced risk of failure not only prevents potential accidents but also mitigates the financial risks associated with liability and insurance costs.

Another significant benefit is the potential for improved energy efficiency. Oxidation-resistant 4140 steel can maintain its properties at higher operating temperatures, allowing for more efficient processes in various industrial applications. This can lead to reduced energy consumption and associated cost savings over the long term.

However, it is important to note that the cost-benefit ratio may vary depending on the specific application and operating conditions. Factors such as the severity of the oxidative environment, the required service life, and the criticality of the component must be carefully evaluated. In some cases, the additional cost of oxidation-resistant 4140 steel may not be justified if the operating conditions do not pose a significant oxidation risk or if alternative materials offer a more cost-effective solution.

To accurately assess the cost-benefit ratio, a comprehensive life cycle cost analysis should be conducted. This analysis should consider not only the initial material and processing costs but also the long-term operational expenses, maintenance requirements, and potential savings from improved performance and reduced downtime. Additionally, the environmental impact and sustainability aspects of using oxidation-resistant 4140 steel should be factored into the analysis, as these considerations are becoming increasingly important in many industries.

From a cost perspective, the initial investment in oxidation-resistant 4140 steel is typically higher than that of standard 4140 steel. This increased cost is attributed to the additional processing steps, such as surface treatments, alloying elements, or coating applications, required to enhance the steel's oxidation resistance. However, it is essential to consider these upfront costs in the context of long-term benefits and potential savings.

The primary benefit of oxidation-resistant 4140 steel lies in its extended service life under high-temperature conditions. By mitigating oxidation-induced degradation, components made from this material can maintain their structural integrity and performance characteristics for longer periods. This longevity translates to reduced frequency of replacements, minimizing downtime and associated labor costs for maintenance and repairs.

Furthermore, the improved oxidation resistance contributes to enhanced reliability and safety in critical applications. This is particularly valuable in industries such as aerospace, power generation, and oil and gas, where component failure can lead to catastrophic consequences. The reduced risk of failure not only prevents potential accidents but also mitigates the financial risks associated with liability and insurance costs.

Another significant benefit is the potential for improved energy efficiency. Oxidation-resistant 4140 steel can maintain its properties at higher operating temperatures, allowing for more efficient processes in various industrial applications. This can lead to reduced energy consumption and associated cost savings over the long term.

However, it is important to note that the cost-benefit ratio may vary depending on the specific application and operating conditions. Factors such as the severity of the oxidative environment, the required service life, and the criticality of the component must be carefully evaluated. In some cases, the additional cost of oxidation-resistant 4140 steel may not be justified if the operating conditions do not pose a significant oxidation risk or if alternative materials offer a more cost-effective solution.

To accurately assess the cost-benefit ratio, a comprehensive life cycle cost analysis should be conducted. This analysis should consider not only the initial material and processing costs but also the long-term operational expenses, maintenance requirements, and potential savings from improved performance and reduced downtime. Additionally, the environmental impact and sustainability aspects of using oxidation-resistant 4140 steel should be factored into the analysis, as these considerations are becoming increasingly important in many industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!