Ultrasonic Inspection Techniques for Quality Assurance in 4140 Steel

JUL 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrasonic NDT Evolution

Ultrasonic non-destructive testing (NDT) has undergone significant evolution since its inception in the mid-20th century. Initially developed for industrial applications in the 1940s, ultrasonic inspection techniques have continuously improved, driven by advancements in technology and the growing demand for more accurate and efficient quality assurance methods.

In the early stages, ultrasonic NDT relied on simple A-scan displays, which provided limited information about material defects. The 1960s and 1970s saw the introduction of more sophisticated equipment, including B-scan and C-scan imaging techniques, which allowed for better visualization of flaws within materials. This period also marked the beginning of automated ultrasonic testing systems, enhancing the speed and reliability of inspections.

The 1980s and 1990s brought about significant improvements in transducer technology and signal processing capabilities. Phased array ultrasonic testing (PAUT) emerged as a powerful technique, offering enhanced detection and characterization of defects. PAUT systems allowed for electronic beam steering and focusing, providing more comprehensive inspections and improved defect sizing capabilities.

The turn of the millennium saw the integration of computer technology and advanced software algorithms into ultrasonic NDT systems. This led to the development of more sophisticated data analysis tools, 3D imaging capabilities, and real-time defect characterization. The advent of portable, handheld ultrasonic devices also increased the accessibility and versatility of ultrasonic inspections in various industrial settings.

In recent years, the evolution of ultrasonic NDT has been marked by the incorporation of artificial intelligence and machine learning algorithms. These technologies have significantly enhanced defect detection accuracy, automated data interpretation, and improved the overall reliability of ultrasonic inspections. Additionally, the development of advanced materials and manufacturing techniques has led to the creation of more sensitive and specialized ultrasonic transducers.

For 4140 steel quality assurance, the evolution of ultrasonic NDT has been particularly impactful. Modern ultrasonic inspection techniques now offer high-resolution imaging of internal structures, precise defect sizing, and the ability to detect subtle material property variations. This has greatly improved the ability to ensure the integrity and quality of 4140 steel components, which are widely used in critical applications such as automotive, aerospace, and oil and gas industries.

Looking ahead, the future of ultrasonic NDT for 4140 steel quality assurance is likely to involve further integration of IoT technologies, enabling real-time monitoring and predictive maintenance strategies. Additionally, advancements in materials science may lead to the development of even more sensitive and specialized ultrasonic inspection techniques tailored specifically for high-strength steels like 4140.

In the early stages, ultrasonic NDT relied on simple A-scan displays, which provided limited information about material defects. The 1960s and 1970s saw the introduction of more sophisticated equipment, including B-scan and C-scan imaging techniques, which allowed for better visualization of flaws within materials. This period also marked the beginning of automated ultrasonic testing systems, enhancing the speed and reliability of inspections.

The 1980s and 1990s brought about significant improvements in transducer technology and signal processing capabilities. Phased array ultrasonic testing (PAUT) emerged as a powerful technique, offering enhanced detection and characterization of defects. PAUT systems allowed for electronic beam steering and focusing, providing more comprehensive inspections and improved defect sizing capabilities.

The turn of the millennium saw the integration of computer technology and advanced software algorithms into ultrasonic NDT systems. This led to the development of more sophisticated data analysis tools, 3D imaging capabilities, and real-time defect characterization. The advent of portable, handheld ultrasonic devices also increased the accessibility and versatility of ultrasonic inspections in various industrial settings.

In recent years, the evolution of ultrasonic NDT has been marked by the incorporation of artificial intelligence and machine learning algorithms. These technologies have significantly enhanced defect detection accuracy, automated data interpretation, and improved the overall reliability of ultrasonic inspections. Additionally, the development of advanced materials and manufacturing techniques has led to the creation of more sensitive and specialized ultrasonic transducers.

For 4140 steel quality assurance, the evolution of ultrasonic NDT has been particularly impactful. Modern ultrasonic inspection techniques now offer high-resolution imaging of internal structures, precise defect sizing, and the ability to detect subtle material property variations. This has greatly improved the ability to ensure the integrity and quality of 4140 steel components, which are widely used in critical applications such as automotive, aerospace, and oil and gas industries.

Looking ahead, the future of ultrasonic NDT for 4140 steel quality assurance is likely to involve further integration of IoT technologies, enabling real-time monitoring and predictive maintenance strategies. Additionally, advancements in materials science may lead to the development of even more sensitive and specialized ultrasonic inspection techniques tailored specifically for high-strength steels like 4140.

4140 Steel QA Demand

The demand for quality assurance in 4140 steel production has been steadily increasing due to its widespread use in critical applications across various industries. This high-strength, low-alloy steel is extensively utilized in the automotive, aerospace, and oil and gas sectors, where component reliability is paramount. The automotive industry, in particular, has seen a surge in demand for 4140 steel in the manufacturing of crankshafts, connecting rods, and other high-stress engine parts. This trend is driven by the need for lighter yet stronger materials to improve fuel efficiency and overall vehicle performance.

In the aerospace sector, 4140 steel finds applications in landing gear components, fasteners, and structural elements, where stringent quality standards are essential for safety and regulatory compliance. The oil and gas industry relies on 4140 steel for drilling equipment, valves, and pressure vessels, which must withstand extreme conditions and maintain integrity over extended periods. As these industries continue to evolve and face new challenges, the demand for more sophisticated quality assurance techniques has grown proportionally.

The market for ultrasonic inspection techniques in 4140 steel quality assurance has expanded significantly in recent years. This growth is attributed to the increasing awareness of the limitations of traditional inspection methods and the need for more accurate, non-destructive testing solutions. Ultrasonic inspection offers the advantage of detecting internal flaws and inconsistencies that may not be visible through surface inspection or other conventional methods.

The global non-destructive testing market, which includes ultrasonic inspection techniques, has been experiencing robust growth. This trend is expected to continue as industries seek to minimize material waste, reduce production costs, and enhance product reliability. The adoption of advanced ultrasonic inspection techniques for 4140 steel is also driven by regulatory pressures and industry standards that mandate more stringent quality control measures.

Furthermore, the push towards Industry 4.0 and smart manufacturing has created a demand for integrated quality assurance systems that can provide real-time data and analytics. This has led to the development of automated ultrasonic inspection systems that can be seamlessly incorporated into production lines, offering continuous monitoring and quality control for 4140 steel components. As a result, manufacturers are increasingly investing in these technologies to maintain a competitive edge and meet the evolving demands of their customers.

In the aerospace sector, 4140 steel finds applications in landing gear components, fasteners, and structural elements, where stringent quality standards are essential for safety and regulatory compliance. The oil and gas industry relies on 4140 steel for drilling equipment, valves, and pressure vessels, which must withstand extreme conditions and maintain integrity over extended periods. As these industries continue to evolve and face new challenges, the demand for more sophisticated quality assurance techniques has grown proportionally.

The market for ultrasonic inspection techniques in 4140 steel quality assurance has expanded significantly in recent years. This growth is attributed to the increasing awareness of the limitations of traditional inspection methods and the need for more accurate, non-destructive testing solutions. Ultrasonic inspection offers the advantage of detecting internal flaws and inconsistencies that may not be visible through surface inspection or other conventional methods.

The global non-destructive testing market, which includes ultrasonic inspection techniques, has been experiencing robust growth. This trend is expected to continue as industries seek to minimize material waste, reduce production costs, and enhance product reliability. The adoption of advanced ultrasonic inspection techniques for 4140 steel is also driven by regulatory pressures and industry standards that mandate more stringent quality control measures.

Furthermore, the push towards Industry 4.0 and smart manufacturing has created a demand for integrated quality assurance systems that can provide real-time data and analytics. This has led to the development of automated ultrasonic inspection systems that can be seamlessly incorporated into production lines, offering continuous monitoring and quality control for 4140 steel components. As a result, manufacturers are increasingly investing in these technologies to maintain a competitive edge and meet the evolving demands of their customers.

Ultrasonic Challenges

Ultrasonic inspection of 4140 steel presents several significant challenges that impact the accuracy and reliability of quality assurance processes. One of the primary difficulties lies in the material's microstructure. 4140 steel, being a medium carbon alloy steel, possesses a complex grain structure that can interfere with ultrasonic wave propagation. This interference can lead to signal attenuation and scattering, potentially masking critical defects or creating false indications.

The heat treatment processes commonly applied to 4140 steel further complicate ultrasonic testing. Quenching and tempering, which are often used to enhance the steel's mechanical properties, can introduce residual stresses and microstructural variations throughout the material. These variations can cause inconsistencies in ultrasonic wave velocity and attenuation, making it challenging to achieve uniform and reliable inspection results across the entire component.

Another significant challenge is the detection of small defects in 4140 steel components. The high strength and toughness of this material often require the identification of very small flaws that could potentially lead to failure under high-stress conditions. Achieving the necessary resolution and sensitivity to detect these minute defects while maintaining a practical inspection speed is a delicate balance that inspectors must strike.

The geometry of 4140 steel components can also pose difficulties for ultrasonic inspection. Complex shapes, varying thicknesses, and hard-to-reach areas can create acoustic shadows or result in multiple reflections that complicate signal interpretation. This is particularly problematic in components with intricate designs or those that have undergone extensive machining processes.

Surface conditions of 4140 steel parts present another hurdle for ultrasonic testing. Rough surfaces, which are common in as-forged or as-cast components, can significantly reduce the coupling efficiency between the ultrasonic transducer and the material. This poor coupling can lead to reduced signal strength and increased noise, potentially obscuring important defect indications.

The high attenuation characteristics of 4140 steel, especially in thicker sections, limit the penetration depth of ultrasonic waves. This limitation can necessitate the use of lower frequency transducers to achieve adequate penetration, which in turn reduces the resolution and sensitivity of the inspection. Balancing penetration depth with detection capability is a constant challenge for inspectors working with this material.

Lastly, the interpretation of ultrasonic data for 4140 steel requires considerable expertise. The complex interplay between material properties, heat treatment effects, and potential defects demands a high level of skill and experience from technicians. Misinterpretation of signals can lead to false acceptances or rejections, both of which can have serious consequences in critical applications where 4140 steel is commonly used.

The heat treatment processes commonly applied to 4140 steel further complicate ultrasonic testing. Quenching and tempering, which are often used to enhance the steel's mechanical properties, can introduce residual stresses and microstructural variations throughout the material. These variations can cause inconsistencies in ultrasonic wave velocity and attenuation, making it challenging to achieve uniform and reliable inspection results across the entire component.

Another significant challenge is the detection of small defects in 4140 steel components. The high strength and toughness of this material often require the identification of very small flaws that could potentially lead to failure under high-stress conditions. Achieving the necessary resolution and sensitivity to detect these minute defects while maintaining a practical inspection speed is a delicate balance that inspectors must strike.

The geometry of 4140 steel components can also pose difficulties for ultrasonic inspection. Complex shapes, varying thicknesses, and hard-to-reach areas can create acoustic shadows or result in multiple reflections that complicate signal interpretation. This is particularly problematic in components with intricate designs or those that have undergone extensive machining processes.

Surface conditions of 4140 steel parts present another hurdle for ultrasonic testing. Rough surfaces, which are common in as-forged or as-cast components, can significantly reduce the coupling efficiency between the ultrasonic transducer and the material. This poor coupling can lead to reduced signal strength and increased noise, potentially obscuring important defect indications.

The high attenuation characteristics of 4140 steel, especially in thicker sections, limit the penetration depth of ultrasonic waves. This limitation can necessitate the use of lower frequency transducers to achieve adequate penetration, which in turn reduces the resolution and sensitivity of the inspection. Balancing penetration depth with detection capability is a constant challenge for inspectors working with this material.

Lastly, the interpretation of ultrasonic data for 4140 steel requires considerable expertise. The complex interplay between material properties, heat treatment effects, and potential defects demands a high level of skill and experience from technicians. Misinterpretation of signals can lead to false acceptances or rejections, both of which can have serious consequences in critical applications where 4140 steel is commonly used.

Current UT Solutions

01 Advanced ultrasonic inspection systems

Modern ultrasonic inspection systems incorporate advanced technologies for improved quality assurance. These systems may include features such as automated scanning, real-time data processing, and high-resolution imaging capabilities. They are designed to enhance the accuracy and efficiency of non-destructive testing in various industrial applications.- Advanced ultrasonic inspection systems: Modern ultrasonic inspection techniques utilize advanced systems for quality assurance in various industries. These systems incorporate sophisticated sensors, data processing algorithms, and imaging technologies to detect defects, measure thickness, and assess material integrity with high precision and reliability.

- Automated defect detection and classification: Ultrasonic inspection techniques employ automated defect detection and classification methods to enhance quality assurance processes. These methods use machine learning algorithms and pattern recognition techniques to identify and categorize defects in materials and components, improving inspection accuracy and efficiency.

- Integration with other NDT methods: Quality assurance in ultrasonic inspection often involves integration with other non-destructive testing (NDT) methods. This multi-modal approach combines ultrasonic techniques with methods such as radiography, eddy current testing, or thermography to provide comprehensive material evaluation and defect detection capabilities.

- Real-time monitoring and analysis: Ultrasonic inspection techniques for quality assurance incorporate real-time monitoring and analysis capabilities. These systems provide immediate feedback on material conditions, allowing for rapid decision-making and process adjustments in manufacturing and maintenance applications.

- Customized ultrasonic transducers and probes: Quality assurance in ultrasonic inspection relies on specialized transducers and probes designed for specific applications. These customized components optimize signal generation, reception, and resolution for various materials, geometries, and inspection requirements, enhancing the overall effectiveness of the inspection process.

02 Data analysis and interpretation techniques

Sophisticated data analysis and interpretation techniques are crucial for effective ultrasonic inspection quality assurance. These methods may involve machine learning algorithms, pattern recognition, and signal processing to accurately identify defects and anomalies in inspected materials. Advanced software tools are often employed to assist in the analysis and visualization of inspection results.Expand Specific Solutions03 Calibration and standardization procedures

Proper calibration and standardization procedures are essential for maintaining the reliability and consistency of ultrasonic inspection techniques. This includes the use of reference standards, regular equipment calibration, and adherence to industry-specific guidelines. These procedures help ensure the accuracy of measurements and facilitate comparisons across different inspection systems and operators.Expand Specific Solutions04 Integration with other NDT methods

Ultrasonic inspection techniques are often integrated with other non-destructive testing (NDT) methods to provide comprehensive quality assurance. This may include combining ultrasonic testing with visual inspection, radiography, or eddy current testing. The integration of multiple NDT methods can enhance defect detection capabilities and provide more robust quality assurance solutions.Expand Specific Solutions05 Training and certification for operators

Effective implementation of ultrasonic inspection techniques for quality assurance requires properly trained and certified operators. Training programs focus on equipment operation, data interpretation, and adherence to industry standards. Certification processes ensure that operators possess the necessary skills and knowledge to perform reliable inspections and maintain quality assurance standards.Expand Specific Solutions

NDT Industry Leaders

The ultrasonic inspection techniques for quality assurance in 4140 steel market is in a mature growth stage, with established players and proven technologies. The global non-destructive testing market, which includes ultrasonic inspection, is projected to reach $12.6 billion by 2024, growing at a CAGR of 7.2%. Key players like JFE Steel Corp., Sanyo Special Steel Co., Ltd., and Howmet Aerospace, Inc. have developed advanced ultrasonic inspection capabilities for 4140 steel. These companies leverage their expertise in materials science and NDT to offer comprehensive quality assurance solutions. The technology's maturity is evident in its widespread adoption across industries like aerospace, automotive, and energy, where 4140 steel is commonly used.

JFE Steel Corp.

Technical Solution: JFE Steel Corp. has developed advanced ultrasonic inspection techniques for quality assurance in 4140 steel. Their approach utilizes phased array ultrasonic testing (PAUT) technology, which allows for improved detection of defects in complex geometries. The company has implemented a multi-angle inspection system that can detect both surface and subsurface flaws with high accuracy. JFE Steel's method incorporates real-time data analysis and machine learning algorithms to enhance defect characterization and reduce false positives[1][3]. They have also developed custom transducers optimized for 4140 steel's acoustic properties, improving signal-to-noise ratios and overall inspection reliability[2].

Strengths: High accuracy in defect detection, adaptability to complex geometries, and integration of advanced data analysis. Weaknesses: Potentially higher initial implementation costs and the need for specialized operator training.

POSCO Holdings, Inc.

Technical Solution: POSCO Holdings has innovated in ultrasonic inspection for 4140 steel quality assurance by developing a dual-frequency ultrasonic testing system. This system combines high and low-frequency ultrasonic waves to achieve both penetration depth and resolution. POSCO's approach includes the use of focused beam transducers to improve sensitivity in detecting small defects, particularly in heat-affected zones of welded 4140 steel components[4]. They have also implemented an automated scanning system with robotic arms for consistent and repeatable inspections, reducing human error. POSCO's method incorporates advanced signal processing techniques, including wavelet analysis, to enhance defect detection in noisy environments[5].

Strengths: Improved detection of small defects, automation for consistency, and advanced signal processing. Weaknesses: Complexity of the dual-frequency system may require more maintenance and calibration.

Key UT Innovations

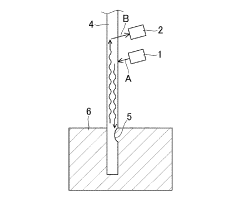

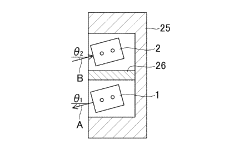

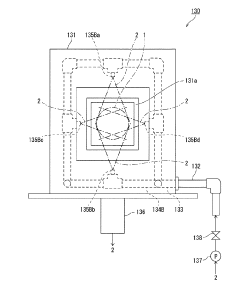

Method and device for ultrasound inspection

PatentActiveJP2018179751A

Innovation

- An ultrasonic inspection method using airborne probes arranged on the same side of the steel surface, inclined in the same direction, employs plate and surface waves to detect defects without direct contact, allowing for rapid and wide-range detection of corrosion position and depth.

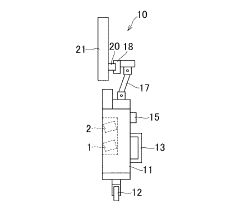

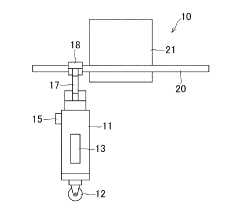

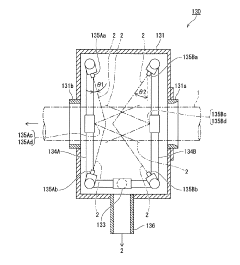

Flaw inspection method and device of steel material and manufacturing method of steel material

PatentActiveJP2021099247A

Innovation

- A method and apparatus that includes a cleaning step using high-pressure water spray to remove surface contaminants and scale, followed by ultrasonic flaw detection in a controlled water environment to eliminate noise interference.

Material Science Impact

The impact of ultrasonic inspection techniques for quality assurance in 4140 steel extends far beyond the realm of non-destructive testing, significantly influencing the field of material science. This advanced inspection method has revolutionized our understanding of material properties and behavior, particularly in high-strength alloy steels like 4140.

Ultrasonic inspection has enabled researchers to gain deeper insights into the microstructure of 4140 steel, revealing critical information about grain size, distribution, and orientation. This enhanced understanding has led to improvements in heat treatment processes, allowing for more precise control over the material's mechanical properties. As a result, manufacturers can now tailor the steel's characteristics to meet specific application requirements with greater accuracy.

The application of ultrasonic techniques has also contributed to the development of new alloy compositions. By providing real-time data on material homogeneity and defect distribution, researchers can more effectively evaluate the performance of experimental alloys. This has accelerated the pace of innovation in steel metallurgy, leading to the creation of advanced materials with superior strength, toughness, and corrosion resistance.

Furthermore, ultrasonic inspection has played a crucial role in advancing our knowledge of material fatigue and failure mechanisms. By detecting and characterizing subsurface defects and microstructural changes over time, researchers can better understand how 4140 steel behaves under various loading conditions and environmental factors. This information has been instrumental in developing more accurate predictive models for material lifespan and performance, enhancing the reliability and safety of critical components in industries such as aerospace and automotive.

The integration of ultrasonic inspection techniques with other material characterization methods has opened new avenues for interdisciplinary research. For instance, combining ultrasonic data with electron microscopy and X-ray diffraction results has provided a more comprehensive view of material properties at multiple scales. This holistic approach has led to breakthroughs in understanding the relationship between microstructure and macroscopic behavior, fostering the development of novel materials with tailored properties.

In the realm of materials processing, ultrasonic inspection has enabled the optimization of manufacturing techniques for 4140 steel. By providing real-time feedback on material quality during production, manufacturers can fine-tune parameters such as cooling rates and deformation processes to achieve desired material properties consistently. This has not only improved product quality but also reduced waste and energy consumption in steel production.

Ultrasonic inspection has enabled researchers to gain deeper insights into the microstructure of 4140 steel, revealing critical information about grain size, distribution, and orientation. This enhanced understanding has led to improvements in heat treatment processes, allowing for more precise control over the material's mechanical properties. As a result, manufacturers can now tailor the steel's characteristics to meet specific application requirements with greater accuracy.

The application of ultrasonic techniques has also contributed to the development of new alloy compositions. By providing real-time data on material homogeneity and defect distribution, researchers can more effectively evaluate the performance of experimental alloys. This has accelerated the pace of innovation in steel metallurgy, leading to the creation of advanced materials with superior strength, toughness, and corrosion resistance.

Furthermore, ultrasonic inspection has played a crucial role in advancing our knowledge of material fatigue and failure mechanisms. By detecting and characterizing subsurface defects and microstructural changes over time, researchers can better understand how 4140 steel behaves under various loading conditions and environmental factors. This information has been instrumental in developing more accurate predictive models for material lifespan and performance, enhancing the reliability and safety of critical components in industries such as aerospace and automotive.

The integration of ultrasonic inspection techniques with other material characterization methods has opened new avenues for interdisciplinary research. For instance, combining ultrasonic data with electron microscopy and X-ray diffraction results has provided a more comprehensive view of material properties at multiple scales. This holistic approach has led to breakthroughs in understanding the relationship between microstructure and macroscopic behavior, fostering the development of novel materials with tailored properties.

In the realm of materials processing, ultrasonic inspection has enabled the optimization of manufacturing techniques for 4140 steel. By providing real-time feedback on material quality during production, manufacturers can fine-tune parameters such as cooling rates and deformation processes to achieve desired material properties consistently. This has not only improved product quality but also reduced waste and energy consumption in steel production.

UT Data Analytics

Ultrasonic testing (UT) data analytics has emerged as a crucial component in the quality assurance of 4140 steel, offering advanced capabilities for defect detection, characterization, and material property evaluation. The integration of sophisticated data analysis techniques with ultrasonic inspection methods has significantly enhanced the accuracy and reliability of quality control processes in steel manufacturing and fabrication.

One of the key advancements in UT data analytics is the application of machine learning algorithms for automated defect classification. These algorithms can be trained on large datasets of ultrasonic signals corresponding to various types of defects, enabling rapid and accurate identification of flaws in 4140 steel components. This approach not only improves the speed of inspection but also reduces the reliance on human interpretation, minimizing the potential for errors and inconsistencies.

Signal processing techniques play a vital role in UT data analytics, allowing for the extraction of meaningful information from raw ultrasonic data. Advanced filtering methods, such as wavelet transforms and adaptive noise reduction algorithms, help to enhance signal quality and isolate relevant features. These techniques are particularly valuable when dealing with the complex microstructure of 4140 steel, which can produce challenging ultrasonic responses.

The development of 3D imaging and visualization tools has revolutionized the way UT data is analyzed and interpreted. By combining multiple ultrasonic scans and employing sophisticated reconstruction algorithms, it is possible to create detailed three-dimensional representations of internal structures and defects within 4140 steel components. This capability greatly enhances the ability to assess the size, shape, and orientation of flaws, leading to more informed decisions regarding the acceptability of parts.

Statistical analysis methods are increasingly being applied to UT data to quantify material properties and assess the overall quality of 4140 steel products. Techniques such as probability of detection (POD) analysis help to establish the reliability of inspection procedures and determine the minimum detectable flaw size. Additionally, correlation studies between ultrasonic parameters and mechanical properties offer insights into the material's microstructure and performance characteristics.

The integration of UT data analytics with other non-destructive testing (NDT) methods, such as eddy current testing and radiography, has led to the development of multi-modal inspection systems. These systems leverage the strengths of different NDT techniques to provide a more comprehensive assessment of 4140 steel components. Data fusion algorithms play a crucial role in combining and interpreting information from multiple sources, resulting in improved defect detection capabilities and reduced false alarm rates.

As the field of UT data analytics continues to evolve, emerging technologies such as artificial intelligence and deep learning are expected to further enhance the capabilities of ultrasonic inspection for 4140 steel. These advancements promise to deliver more sophisticated defect recognition, predictive maintenance strategies, and real-time quality control solutions, ultimately contributing to improved product reliability and manufacturing efficiency in the steel industry.

One of the key advancements in UT data analytics is the application of machine learning algorithms for automated defect classification. These algorithms can be trained on large datasets of ultrasonic signals corresponding to various types of defects, enabling rapid and accurate identification of flaws in 4140 steel components. This approach not only improves the speed of inspection but also reduces the reliance on human interpretation, minimizing the potential for errors and inconsistencies.

Signal processing techniques play a vital role in UT data analytics, allowing for the extraction of meaningful information from raw ultrasonic data. Advanced filtering methods, such as wavelet transforms and adaptive noise reduction algorithms, help to enhance signal quality and isolate relevant features. These techniques are particularly valuable when dealing with the complex microstructure of 4140 steel, which can produce challenging ultrasonic responses.

The development of 3D imaging and visualization tools has revolutionized the way UT data is analyzed and interpreted. By combining multiple ultrasonic scans and employing sophisticated reconstruction algorithms, it is possible to create detailed three-dimensional representations of internal structures and defects within 4140 steel components. This capability greatly enhances the ability to assess the size, shape, and orientation of flaws, leading to more informed decisions regarding the acceptability of parts.

Statistical analysis methods are increasingly being applied to UT data to quantify material properties and assess the overall quality of 4140 steel products. Techniques such as probability of detection (POD) analysis help to establish the reliability of inspection procedures and determine the minimum detectable flaw size. Additionally, correlation studies between ultrasonic parameters and mechanical properties offer insights into the material's microstructure and performance characteristics.

The integration of UT data analytics with other non-destructive testing (NDT) methods, such as eddy current testing and radiography, has led to the development of multi-modal inspection systems. These systems leverage the strengths of different NDT techniques to provide a more comprehensive assessment of 4140 steel components. Data fusion algorithms play a crucial role in combining and interpreting information from multiple sources, resulting in improved defect detection capabilities and reduced false alarm rates.

As the field of UT data analytics continues to evolve, emerging technologies such as artificial intelligence and deep learning are expected to further enhance the capabilities of ultrasonic inspection for 4140 steel. These advancements promise to deliver more sophisticated defect recognition, predictive maintenance strategies, and real-time quality control solutions, ultimately contributing to improved product reliability and manufacturing efficiency in the steel industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!