Enhancing Filtration Systems with Magnesium Nitrate Additives

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Nitrate Filtration Enhancement: Background and Objectives

Filtration systems have been a cornerstone of industrial processes and environmental protection for decades. The quest for more efficient and effective filtration methods has led to continuous innovation in this field. Recently, the use of magnesium nitrate as an additive in filtration systems has emerged as a promising avenue for enhancing filtration performance. This technological advancement builds upon the established principles of chemical and physical filtration while introducing novel approaches to improve efficiency and effectiveness.

The evolution of filtration technology has seen significant milestones, from simple mechanical straining to advanced membrane technologies. The introduction of chemical additives to enhance filtration processes represents the next logical step in this progression. Magnesium nitrate, a compound well-known for its diverse applications in agriculture and industry, is now being explored for its potential to revolutionize filtration systems.

The primary objective of incorporating magnesium nitrate into filtration systems is to address several key challenges faced by conventional filtration methods. These include improving the removal of specific contaminants, enhancing the longevity of filter media, and increasing the overall efficiency of the filtration process. By leveraging the unique properties of magnesium nitrate, researchers and engineers aim to develop more robust and versatile filtration solutions capable of meeting increasingly stringent environmental regulations and industrial demands.

The integration of magnesium nitrate into filtration systems is expected to have far-reaching implications across various sectors. In water treatment, it could lead to more effective removal of pollutants and microorganisms. In industrial processes, it may result in more efficient separation of materials and improved product quality. Environmental applications could benefit from enhanced air and water purification capabilities, contributing to broader efforts in pollution control and environmental protection.

As we delve deeper into this technological frontier, it is crucial to understand the fundamental principles underlying the interaction between magnesium nitrate and various filtration media. This understanding will guide the development of optimized formulations and application methods, paving the way for next-generation filtration systems that are more effective, efficient, and sustainable.

The exploration of magnesium nitrate as a filtration enhancer represents a convergence of chemical engineering, materials science, and environmental technology. It exemplifies the interdisciplinary nature of modern technological advancements and underscores the importance of continuous innovation in addressing global challenges related to resource management and environmental stewardship.

The evolution of filtration technology has seen significant milestones, from simple mechanical straining to advanced membrane technologies. The introduction of chemical additives to enhance filtration processes represents the next logical step in this progression. Magnesium nitrate, a compound well-known for its diverse applications in agriculture and industry, is now being explored for its potential to revolutionize filtration systems.

The primary objective of incorporating magnesium nitrate into filtration systems is to address several key challenges faced by conventional filtration methods. These include improving the removal of specific contaminants, enhancing the longevity of filter media, and increasing the overall efficiency of the filtration process. By leveraging the unique properties of magnesium nitrate, researchers and engineers aim to develop more robust and versatile filtration solutions capable of meeting increasingly stringent environmental regulations and industrial demands.

The integration of magnesium nitrate into filtration systems is expected to have far-reaching implications across various sectors. In water treatment, it could lead to more effective removal of pollutants and microorganisms. In industrial processes, it may result in more efficient separation of materials and improved product quality. Environmental applications could benefit from enhanced air and water purification capabilities, contributing to broader efforts in pollution control and environmental protection.

As we delve deeper into this technological frontier, it is crucial to understand the fundamental principles underlying the interaction between magnesium nitrate and various filtration media. This understanding will guide the development of optimized formulations and application methods, paving the way for next-generation filtration systems that are more effective, efficient, and sustainable.

The exploration of magnesium nitrate as a filtration enhancer represents a convergence of chemical engineering, materials science, and environmental technology. It exemplifies the interdisciplinary nature of modern technological advancements and underscores the importance of continuous innovation in addressing global challenges related to resource management and environmental stewardship.

Market Analysis for Advanced Filtration Systems

The global market for advanced filtration systems has been experiencing significant growth, driven by increasing environmental concerns, stringent regulations, and the need for improved water and air quality across various industries. The integration of magnesium nitrate additives into filtration systems represents a promising innovation that could potentially reshape the market landscape.

The filtration systems market is projected to expand at a steady rate over the next five years, with a particular focus on water treatment, air purification, and industrial process filtration. The water treatment segment, in particular, is expected to dominate the market due to growing water scarcity issues and the need for clean drinking water in developing regions. Industries such as pharmaceuticals, food and beverage, and electronics are also contributing to the increased demand for advanced filtration solutions.

The introduction of magnesium nitrate additives in filtration systems addresses several key market needs. These additives have shown potential to enhance filtration efficiency, reduce energy consumption, and extend the lifespan of filtration media. This aligns well with the market's growing emphasis on sustainability and cost-effectiveness in filtration processes.

Geographically, North America and Europe currently lead the advanced filtration systems market, owing to strict environmental regulations and high adoption rates of innovative technologies. However, the Asia-Pacific region is anticipated to witness the fastest growth, driven by rapid industrialization, urbanization, and increasing awareness of environmental issues.

The competitive landscape of the filtration systems market is characterized by the presence of both large multinational corporations and specialized niche players. Key market players are investing heavily in research and development to introduce novel filtration technologies and gain a competitive edge. The potential of magnesium nitrate additives has attracted attention from several industry leaders, who are exploring ways to incorporate this technology into their product offerings.

Consumer trends indicate a growing preference for multi-functional filtration systems that can address multiple contaminants simultaneously. This trend aligns well with the capabilities of magnesium nitrate-enhanced filtration systems, which have demonstrated effectiveness against a wide range of pollutants.

The market for advanced filtration systems faces some challenges, including high initial costs and the need for specialized maintenance. However, the long-term benefits of improved efficiency and reduced operational costs offered by magnesium nitrate additives could help overcome these barriers and drive market growth.

The filtration systems market is projected to expand at a steady rate over the next five years, with a particular focus on water treatment, air purification, and industrial process filtration. The water treatment segment, in particular, is expected to dominate the market due to growing water scarcity issues and the need for clean drinking water in developing regions. Industries such as pharmaceuticals, food and beverage, and electronics are also contributing to the increased demand for advanced filtration solutions.

The introduction of magnesium nitrate additives in filtration systems addresses several key market needs. These additives have shown potential to enhance filtration efficiency, reduce energy consumption, and extend the lifespan of filtration media. This aligns well with the market's growing emphasis on sustainability and cost-effectiveness in filtration processes.

Geographically, North America and Europe currently lead the advanced filtration systems market, owing to strict environmental regulations and high adoption rates of innovative technologies. However, the Asia-Pacific region is anticipated to witness the fastest growth, driven by rapid industrialization, urbanization, and increasing awareness of environmental issues.

The competitive landscape of the filtration systems market is characterized by the presence of both large multinational corporations and specialized niche players. Key market players are investing heavily in research and development to introduce novel filtration technologies and gain a competitive edge. The potential of magnesium nitrate additives has attracted attention from several industry leaders, who are exploring ways to incorporate this technology into their product offerings.

Consumer trends indicate a growing preference for multi-functional filtration systems that can address multiple contaminants simultaneously. This trend aligns well with the capabilities of magnesium nitrate-enhanced filtration systems, which have demonstrated effectiveness against a wide range of pollutants.

The market for advanced filtration systems faces some challenges, including high initial costs and the need for specialized maintenance. However, the long-term benefits of improved efficiency and reduced operational costs offered by magnesium nitrate additives could help overcome these barriers and drive market growth.

Current Challenges in Filtration Technology

Filtration technology, while advanced, still faces significant challenges in meeting the ever-increasing demands for efficiency, sustainability, and performance across various industries. One of the primary issues is the gradual decline in filtration efficiency over time due to the accumulation of particles and contaminants on filter surfaces. This phenomenon, known as filter fouling, leads to increased pressure drop and reduced flow rates, ultimately compromising the overall system performance.

Another critical challenge is the trade-off between filtration efficiency and energy consumption. As filters become more efficient at capturing smaller particles, they often require higher pressure differentials, resulting in increased energy usage. This balance becomes particularly crucial in industries where energy costs significantly impact operational expenses.

The need for more sustainable filtration solutions presents another hurdle. Many current filtration systems rely on disposable filter media, contributing to waste generation and environmental concerns. Developing eco-friendly, reusable, or biodegradable filter materials without compromising performance remains a significant challenge for researchers and manufacturers alike.

In specialized applications, such as water treatment and air purification, the removal of emerging contaminants poses new challenges. Micropollutants, including pharmaceuticals, personal care products, and industrial chemicals, often pass through conventional filtration systems unaffected. Addressing these contaminants requires innovative approaches and materials that can selectively target and remove these substances at the molecular level.

The variability in filtration requirements across different industries further complicates the development of universal solutions. For instance, the food and beverage industry demands filters that maintain product quality without altering taste or composition, while industrial processes may prioritize durability and resistance to harsh chemicals. This diversity necessitates tailored approaches and materials for each specific application.

Nanotechnology and advanced materials offer promising avenues for addressing these challenges, but they also introduce new complexities. The potential health and environmental impacts of nanoparticles used in filtration systems require careful consideration and extensive testing before widespread adoption.

Lastly, the integration of smart technologies and real-time monitoring systems into filtration processes presents both opportunities and challenges. While these advancements can optimize performance and predict maintenance needs, they also increase system complexity and require new skill sets for operation and maintenance.

Another critical challenge is the trade-off between filtration efficiency and energy consumption. As filters become more efficient at capturing smaller particles, they often require higher pressure differentials, resulting in increased energy usage. This balance becomes particularly crucial in industries where energy costs significantly impact operational expenses.

The need for more sustainable filtration solutions presents another hurdle. Many current filtration systems rely on disposable filter media, contributing to waste generation and environmental concerns. Developing eco-friendly, reusable, or biodegradable filter materials without compromising performance remains a significant challenge for researchers and manufacturers alike.

In specialized applications, such as water treatment and air purification, the removal of emerging contaminants poses new challenges. Micropollutants, including pharmaceuticals, personal care products, and industrial chemicals, often pass through conventional filtration systems unaffected. Addressing these contaminants requires innovative approaches and materials that can selectively target and remove these substances at the molecular level.

The variability in filtration requirements across different industries further complicates the development of universal solutions. For instance, the food and beverage industry demands filters that maintain product quality without altering taste or composition, while industrial processes may prioritize durability and resistance to harsh chemicals. This diversity necessitates tailored approaches and materials for each specific application.

Nanotechnology and advanced materials offer promising avenues for addressing these challenges, but they also introduce new complexities. The potential health and environmental impacts of nanoparticles used in filtration systems require careful consideration and extensive testing before widespread adoption.

Lastly, the integration of smart technologies and real-time monitoring systems into filtration processes presents both opportunities and challenges. While these advancements can optimize performance and predict maintenance needs, they also increase system complexity and require new skill sets for operation and maintenance.

Existing Magnesium Nitrate Additive Solutions

01 Membrane filtration systems

Membrane filtration systems are widely used for their high efficiency in separating particles and contaminants from fluids. These systems utilize various types of membranes, such as microfiltration, ultrafiltration, and nanofiltration, to achieve different levels of filtration. The efficiency of these systems can be improved by optimizing membrane properties, pore size, and operating conditions.- Advanced filtration media and materials: Utilization of innovative filtration media and materials to enhance filtration efficiency. This includes the development of novel filter materials, nanofiber-based filters, and composite materials that can capture smaller particles and improve overall filtration performance.

- Multi-stage filtration systems: Implementation of multi-stage filtration systems that combine different filtration mechanisms to achieve higher overall efficiency. These systems may incorporate a series of filters with varying pore sizes or utilize different filtration technologies in sequence to capture a wider range of contaminants.

- Electrostatic filtration techniques: Integration of electrostatic filtration techniques to enhance particle capture efficiency. This approach involves using electrically charged filter media or introducing an electric field within the filtration system to attract and trap charged particles more effectively.

- Optimized filter design and configuration: Improvement of filter design and configuration to maximize filtration efficiency. This includes optimizing filter geometry, pleating patterns, and flow dynamics to increase the effective filtration area and reduce pressure drop across the filter.

- Smart filtration systems with real-time monitoring: Development of smart filtration systems that incorporate sensors and real-time monitoring capabilities to assess and maintain filtration efficiency. These systems can adjust operating parameters based on current conditions and provide predictive maintenance alerts to ensure optimal performance.

02 Particle filtration and separation techniques

Advanced particle filtration and separation techniques are employed to enhance filtration efficiency. These methods include cyclonic separation, centrifugal filtration, and electrostatic precipitation. By combining multiple separation mechanisms, these systems can effectively remove a wide range of particle sizes and types, improving overall filtration performance.Expand Specific Solutions03 Filter media optimization

Optimizing filter media is crucial for improving filtration efficiency. This involves developing advanced materials with enhanced porosity, surface area, and chemical properties. Nanofiber-based filter media, composite materials, and functionalized surfaces are some examples of innovations in this area. These advancements lead to higher particle capture rates and lower pressure drops across the filter.Expand Specific Solutions04 Smart filtration systems and monitoring

Smart filtration systems incorporate sensors and real-time monitoring capabilities to optimize filtration efficiency. These systems can adjust operating parameters based on incoming fluid quality, filter condition, and desired output. Continuous monitoring allows for predictive maintenance and ensures consistent filtration performance over time.Expand Specific Solutions05 Hybrid and multi-stage filtration systems

Hybrid and multi-stage filtration systems combine different filtration technologies to achieve higher overall efficiency. These systems may incorporate a series of filters with decreasing pore sizes or combine various filtration mechanisms such as depth filtration, surface filtration, and adsorption. This approach allows for the removal of a broader range of contaminants and improves the overall filtration efficiency.Expand Specific Solutions

Key Players in Filtration Industry

The market for enhancing filtration systems with magnesium nitrate additives is in an early growth stage, characterized by increasing research and development activities. While the market size is still relatively small, it shows potential for expansion as environmental concerns drive demand for advanced filtration technologies. The technology's maturity is evolving, with academic institutions like Zhejiang University, Harbin Institute of Technology, and Nanjing University leading research efforts. Companies such as GreenTech Environmental Co., Ltd. and Evoqua Water Technologies LLC are actively developing commercial applications, indicating a gradual transition from laboratory to industrial scale. The competitive landscape is diverse, with both specialized environmental firms and large chemical corporations like China Petroleum & Chemical Corp. showing interest in this emerging field.

Zhejiang University

Technical Solution: Zhejiang University has developed an innovative filtration system enhanced with magnesium nitrate additives. Their approach involves incorporating magnesium nitrate into a composite membrane structure, which significantly improves the membrane's hydrophilicity and anti-fouling properties[1]. The researchers have demonstrated that this modification enhances the membrane's permeability and selectivity, particularly for water treatment applications[2]. The magnesium nitrate additives create a more porous structure within the membrane, allowing for higher flux rates while maintaining excellent rejection of contaminants[3]. Additionally, the university's team has explored the use of magnesium nitrate in combination with other materials to create synergistic effects, further improving the overall filtration performance[4].

Strengths: Enhanced hydrophilicity, improved anti-fouling properties, increased permeability and selectivity. Weaknesses: Potential cost increase due to additives, possible long-term stability issues in certain environments.

Harbin Institute of Technology

Technical Solution: Harbin Institute of Technology has developed a novel approach to enhancing filtration systems using magnesium nitrate additives. Their research focuses on incorporating magnesium nitrate into nanofiber membranes through electrospinning techniques[1]. This method results in a highly porous and interconnected membrane structure with enhanced mechanical strength and chemical stability[2]. The magnesium nitrate additives contribute to improved ion exchange capabilities, making the filtration system particularly effective for removing heavy metals and other ionic contaminants from water[3]. The institute has also explored the use of magnesium nitrate in combination with other nanomaterials to create multifunctional filtration membranes with additional properties such as antimicrobial activity[4]. Their technology has shown promising results in both laboratory and pilot-scale tests, demonstrating significant improvements in filtration efficiency and longevity compared to conventional systems[5].

Strengths: Enhanced mechanical strength, improved ion exchange capabilities, multifunctional properties. Weaknesses: Potentially complex manufacturing process, higher initial costs compared to traditional filtration systems.

Innovative Approaches in Magnesium Nitrate Application

Method for increasing the magnesium ion concentration in feed water

PatentWO2019011796A1

Innovation

- The method involves increasing the carbon dioxide concentration in feed water and passing it through a solid bed containing poorly water-soluble magnesium ion sources, such as brucite or hydromagnesite, to rapidly and effectively replenish magnesium ions, avoiding the use of highly soluble salts and allowing for precise dosage and reduced installation size.

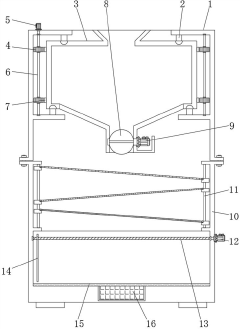

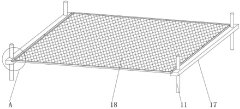

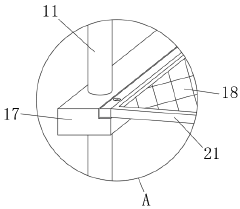

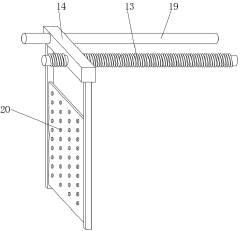

Magnesium nitrate production filtering device

PatentActiveCN218188154U

Innovation

- The melting box can rotate smoothly through the meshing of tooth block and gear, allowing for thorough melting and filtering of magnesium nitrate solution.

- The threaded connection between the swing frame and threaded rod enables left-right sliding, facilitating paddling of the magnesium nitrate solution.

- Integration of a heater for drying and heating the solution promotes rapid crystallization.

Environmental Impact Assessment

The incorporation of magnesium nitrate additives in filtration systems presents both potential benefits and environmental concerns that require careful assessment. These additives can significantly enhance the efficiency of filtration processes, particularly in water treatment applications. However, their use also raises questions about their impact on ecosystems and long-term environmental sustainability.

One of the primary environmental considerations is the potential for increased nitrate levels in treated water and surrounding water bodies. While magnesium nitrate can improve filtration performance, excessive nitrate concentrations in water can lead to eutrophication, causing algal blooms and disrupting aquatic ecosystems. This necessitates stringent monitoring and control measures to ensure that nitrate levels remain within acceptable limits.

The production and disposal of magnesium nitrate additives also warrant attention from an environmental perspective. The manufacturing process may involve energy-intensive steps and the use of chemical precursors, contributing to carbon emissions and potential chemical waste. Proper disposal protocols must be established to prevent the release of unused or spent additives into the environment, as this could lead to soil and groundwater contamination.

On the positive side, the enhanced filtration efficiency achieved through magnesium nitrate additives could result in reduced energy consumption and chemical usage in water treatment processes. This may lead to a net positive environmental impact by decreasing the overall carbon footprint of filtration systems. Additionally, improved water quality could have cascading benefits for aquatic ecosystems and human health.

The potential for magnesium accumulation in treated water and its effects on soil chemistry when used for irrigation purposes should also be considered. While magnesium is an essential nutrient, excessive levels could alter soil pH and affect plant growth. Long-term studies are needed to assess the cumulative impact of magnesium nitrate additives on soil ecosystems and agricultural productivity.

Regulatory compliance is another crucial aspect of the environmental impact assessment. The use of magnesium nitrate additives must align with existing water quality standards and environmental regulations. This may require extensive testing and documentation to demonstrate that the additives do not introduce harmful contaminants or compromise water safety.

In conclusion, while magnesium nitrate additives show promise for enhancing filtration systems, their environmental impact must be thoroughly evaluated. A comprehensive life cycle assessment, considering production, use, and disposal, is essential to fully understand and mitigate potential environmental risks. Balancing the benefits of improved filtration against potential ecological consequences will be crucial in determining the overall sustainability of this technology.

One of the primary environmental considerations is the potential for increased nitrate levels in treated water and surrounding water bodies. While magnesium nitrate can improve filtration performance, excessive nitrate concentrations in water can lead to eutrophication, causing algal blooms and disrupting aquatic ecosystems. This necessitates stringent monitoring and control measures to ensure that nitrate levels remain within acceptable limits.

The production and disposal of magnesium nitrate additives also warrant attention from an environmental perspective. The manufacturing process may involve energy-intensive steps and the use of chemical precursors, contributing to carbon emissions and potential chemical waste. Proper disposal protocols must be established to prevent the release of unused or spent additives into the environment, as this could lead to soil and groundwater contamination.

On the positive side, the enhanced filtration efficiency achieved through magnesium nitrate additives could result in reduced energy consumption and chemical usage in water treatment processes. This may lead to a net positive environmental impact by decreasing the overall carbon footprint of filtration systems. Additionally, improved water quality could have cascading benefits for aquatic ecosystems and human health.

The potential for magnesium accumulation in treated water and its effects on soil chemistry when used for irrigation purposes should also be considered. While magnesium is an essential nutrient, excessive levels could alter soil pH and affect plant growth. Long-term studies are needed to assess the cumulative impact of magnesium nitrate additives on soil ecosystems and agricultural productivity.

Regulatory compliance is another crucial aspect of the environmental impact assessment. The use of magnesium nitrate additives must align with existing water quality standards and environmental regulations. This may require extensive testing and documentation to demonstrate that the additives do not introduce harmful contaminants or compromise water safety.

In conclusion, while magnesium nitrate additives show promise for enhancing filtration systems, their environmental impact must be thoroughly evaluated. A comprehensive life cycle assessment, considering production, use, and disposal, is essential to fully understand and mitigate potential environmental risks. Balancing the benefits of improved filtration against potential ecological consequences will be crucial in determining the overall sustainability of this technology.

Regulatory Compliance for Chemical Additives

The regulatory landscape for chemical additives in filtration systems is complex and multifaceted, requiring careful consideration and compliance. When incorporating magnesium nitrate additives into filtration systems, manufacturers must adhere to a range of regulations and standards set by various governing bodies. In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating chemical additives under the Toxic Substances Control Act (TSCA). This act requires manufacturers to submit premanufacture notices for new chemical substances and maintain comprehensive records of chemical production and use.

Additionally, the Occupational Safety and Health Administration (OSHA) sets standards for workplace safety, including the handling and use of chemical additives like magnesium nitrate. Compliance with OSHA regulations involves proper labeling, safety data sheets, and employee training on handling hazardous materials. The Food and Drug Administration (FDA) may also have jurisdiction if the filtration systems are used in food processing or pharmaceutical applications, necessitating compliance with Good Manufacturing Practices (GMP) and specific food contact regulations.

On an international level, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation imposes strict requirements on chemical substances used in products sold within the EU market. Manufacturers must register their substances with the European Chemicals Agency (ECHA) and provide detailed information on the properties, uses, and potential risks associated with the chemical additives.

Compliance with these regulations often requires extensive testing and documentation. For magnesium nitrate additives, this may include toxicological studies, environmental impact assessments, and detailed chemical analysis. Manufacturers must also consider local and state regulations, which can vary significantly and may impose additional requirements or restrictions on chemical use.

To ensure ongoing compliance, companies must implement robust quality management systems and maintain up-to-date knowledge of regulatory changes. This often involves regular audits, employee training programs, and partnerships with regulatory experts. Furthermore, as environmental concerns grow, many regions are implementing stricter regulations on chemical additives, particularly those that may impact water quality or contribute to environmental pollution.

In conclusion, regulatory compliance for chemical additives like magnesium nitrate in filtration systems demands a comprehensive approach. Manufacturers must navigate a complex web of national and international regulations, balancing innovation with safety and environmental responsibility. Staying abreast of regulatory changes and maintaining open communication with regulatory bodies is crucial for long-term success in this field.

Additionally, the Occupational Safety and Health Administration (OSHA) sets standards for workplace safety, including the handling and use of chemical additives like magnesium nitrate. Compliance with OSHA regulations involves proper labeling, safety data sheets, and employee training on handling hazardous materials. The Food and Drug Administration (FDA) may also have jurisdiction if the filtration systems are used in food processing or pharmaceutical applications, necessitating compliance with Good Manufacturing Practices (GMP) and specific food contact regulations.

On an international level, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation imposes strict requirements on chemical substances used in products sold within the EU market. Manufacturers must register their substances with the European Chemicals Agency (ECHA) and provide detailed information on the properties, uses, and potential risks associated with the chemical additives.

Compliance with these regulations often requires extensive testing and documentation. For magnesium nitrate additives, this may include toxicological studies, environmental impact assessments, and detailed chemical analysis. Manufacturers must also consider local and state regulations, which can vary significantly and may impose additional requirements or restrictions on chemical use.

To ensure ongoing compliance, companies must implement robust quality management systems and maintain up-to-date knowledge of regulatory changes. This often involves regular audits, employee training programs, and partnerships with regulatory experts. Furthermore, as environmental concerns grow, many regions are implementing stricter regulations on chemical additives, particularly those that may impact water quality or contribute to environmental pollution.

In conclusion, regulatory compliance for chemical additives like magnesium nitrate in filtration systems demands a comprehensive approach. Manufacturers must navigate a complex web of national and international regulations, balancing innovation with safety and environmental responsibility. Staying abreast of regulatory changes and maintaining open communication with regulatory bodies is crucial for long-term success in this field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!