Enhancing Photovoltaic Cells with Magnesium Nitrate Doping

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg(NO3)2 Doping in PV Cells: Background and Objectives

Photovoltaic (PV) technology has been at the forefront of renewable energy solutions for decades, with continuous efforts to improve efficiency and reduce costs. The evolution of PV cells has seen various advancements, from the first-generation silicon-based cells to the current multi-junction and thin-film technologies. In recent years, the focus has shifted towards enhancing the performance of existing PV cell structures through innovative doping techniques.

Magnesium nitrate (Mg(NO3)2) doping has emerged as a promising approach to boost the efficiency of photovoltaic cells. This technique builds upon the established methods of introducing impurities into semiconductor materials to modify their electrical properties. The use of magnesium nitrate as a dopant represents a novel direction in PV cell enhancement, aiming to address some of the limitations faced by conventional doping methods.

The primary objective of incorporating Mg(NO3)2 into PV cells is to improve their overall performance metrics. This includes enhancing light absorption, increasing charge carrier mobility, and reducing recombination losses. By carefully controlling the doping process, researchers aim to optimize the band gap of the semiconductor material, potentially leading to higher conversion efficiencies.

Another critical goal of this technological approach is to develop more cost-effective manufacturing processes for high-efficiency solar cells. Magnesium nitrate is relatively abundant and less expensive compared to some traditional dopants, making it an attractive option for large-scale production. The integration of Mg(NO3)2 doping into existing manufacturing lines could potentially reduce production costs while maintaining or improving cell performance.

Furthermore, this research direction aligns with the broader trend of exploring earth-abundant materials for sustainable energy technologies. As the demand for solar energy continues to grow, ensuring a stable and environmentally friendly supply chain for PV cell production becomes increasingly important. Magnesium nitrate doping could contribute to this goal by reducing reliance on rarer or more toxic elements used in some current PV technologies.

The development of Mg(NO3)2 doping techniques also aims to address specific challenges in PV cell design, such as improving the stability and longevity of cells under various environmental conditions. By modifying the material properties through doping, researchers hope to enhance the resilience of PV cells against degradation factors like heat, humidity, and UV radiation.

In the context of the global push for renewable energy adoption, this technological pursuit is part of a broader effort to make solar power more competitive with traditional energy sources. The ultimate goal is to achieve grid parity across a wider range of geographical and economic contexts, thereby accelerating the transition to a more sustainable energy landscape.

Magnesium nitrate (Mg(NO3)2) doping has emerged as a promising approach to boost the efficiency of photovoltaic cells. This technique builds upon the established methods of introducing impurities into semiconductor materials to modify their electrical properties. The use of magnesium nitrate as a dopant represents a novel direction in PV cell enhancement, aiming to address some of the limitations faced by conventional doping methods.

The primary objective of incorporating Mg(NO3)2 into PV cells is to improve their overall performance metrics. This includes enhancing light absorption, increasing charge carrier mobility, and reducing recombination losses. By carefully controlling the doping process, researchers aim to optimize the band gap of the semiconductor material, potentially leading to higher conversion efficiencies.

Another critical goal of this technological approach is to develop more cost-effective manufacturing processes for high-efficiency solar cells. Magnesium nitrate is relatively abundant and less expensive compared to some traditional dopants, making it an attractive option for large-scale production. The integration of Mg(NO3)2 doping into existing manufacturing lines could potentially reduce production costs while maintaining or improving cell performance.

Furthermore, this research direction aligns with the broader trend of exploring earth-abundant materials for sustainable energy technologies. As the demand for solar energy continues to grow, ensuring a stable and environmentally friendly supply chain for PV cell production becomes increasingly important. Magnesium nitrate doping could contribute to this goal by reducing reliance on rarer or more toxic elements used in some current PV technologies.

The development of Mg(NO3)2 doping techniques also aims to address specific challenges in PV cell design, such as improving the stability and longevity of cells under various environmental conditions. By modifying the material properties through doping, researchers hope to enhance the resilience of PV cells against degradation factors like heat, humidity, and UV radiation.

In the context of the global push for renewable energy adoption, this technological pursuit is part of a broader effort to make solar power more competitive with traditional energy sources. The ultimate goal is to achieve grid parity across a wider range of geographical and economic contexts, thereby accelerating the transition to a more sustainable energy landscape.

Market Analysis for High-Efficiency Solar Cells

The global market for high-efficiency solar cells has experienced significant growth in recent years, driven by increasing demand for renewable energy sources and advancements in photovoltaic technology. The integration of magnesium nitrate doping in photovoltaic cells represents a promising avenue for enhancing solar cell efficiency, potentially revolutionizing the market landscape.

The solar energy market has been expanding rapidly, with a compound annual growth rate (CAGR) exceeding 20% over the past decade. High-efficiency solar cells, particularly those achieving conversion efficiencies above 20%, have garnered substantial attention from both industry players and consumers. This segment of the market is expected to grow at an even faster rate than the overall solar market, as efficiency improvements directly translate to cost reductions in solar energy production.

Magnesium nitrate doping technology has the potential to significantly impact the high-efficiency solar cell market. By enhancing the light absorption and charge carrier properties of photovoltaic materials, this innovation could push conversion efficiencies beyond current limits. This advancement aligns with the market's demand for more efficient and cost-effective solar solutions, potentially accelerating the adoption of solar energy across various sectors.

The residential and commercial rooftop solar markets are particularly poised to benefit from high-efficiency cells enhanced with magnesium nitrate doping. These markets value space-efficient solutions that maximize energy generation from limited surface areas. The improved performance offered by this technology could make solar energy more attractive to urban consumers and businesses with constrained roof space.

Utility-scale solar projects also stand to gain from this technology. The ability to generate more power from the same panel area could reduce land requirements and overall project costs, making large-scale solar installations more economically viable in regions with high land costs or limited suitable areas for solar farms.

Geographically, markets with high solar irradiance and ambitious renewable energy targets are likely to be early adopters of this technology. Countries in sun-rich regions such as the Middle East, Africa, and parts of Asia and Latin America could see rapid uptake, driven by the need for efficient and reliable solar power generation.

However, the market penetration of magnesium nitrate doped high-efficiency solar cells will depend on several factors, including manufacturing scalability, cost competitiveness, and long-term reliability. The technology must demonstrate clear advantages over existing high-efficiency cell technologies to gain significant market share.

The solar energy market has been expanding rapidly, with a compound annual growth rate (CAGR) exceeding 20% over the past decade. High-efficiency solar cells, particularly those achieving conversion efficiencies above 20%, have garnered substantial attention from both industry players and consumers. This segment of the market is expected to grow at an even faster rate than the overall solar market, as efficiency improvements directly translate to cost reductions in solar energy production.

Magnesium nitrate doping technology has the potential to significantly impact the high-efficiency solar cell market. By enhancing the light absorption and charge carrier properties of photovoltaic materials, this innovation could push conversion efficiencies beyond current limits. This advancement aligns with the market's demand for more efficient and cost-effective solar solutions, potentially accelerating the adoption of solar energy across various sectors.

The residential and commercial rooftop solar markets are particularly poised to benefit from high-efficiency cells enhanced with magnesium nitrate doping. These markets value space-efficient solutions that maximize energy generation from limited surface areas. The improved performance offered by this technology could make solar energy more attractive to urban consumers and businesses with constrained roof space.

Utility-scale solar projects also stand to gain from this technology. The ability to generate more power from the same panel area could reduce land requirements and overall project costs, making large-scale solar installations more economically viable in regions with high land costs or limited suitable areas for solar farms.

Geographically, markets with high solar irradiance and ambitious renewable energy targets are likely to be early adopters of this technology. Countries in sun-rich regions such as the Middle East, Africa, and parts of Asia and Latin America could see rapid uptake, driven by the need for efficient and reliable solar power generation.

However, the market penetration of magnesium nitrate doped high-efficiency solar cells will depend on several factors, including manufacturing scalability, cost competitiveness, and long-term reliability. The technology must demonstrate clear advantages over existing high-efficiency cell technologies to gain significant market share.

Current Challenges in Photovoltaic Cell Efficiency

Despite significant advancements in photovoltaic (PV) technology, several challenges persist in achieving optimal efficiency for solar cells. One of the primary obstacles is the Shockley-Queisser limit, which theoretically caps the maximum efficiency of single-junction silicon solar cells at around 33%. This fundamental limitation arises from factors such as spectrum losses, recombination losses, and thermal losses inherent to the photovoltaic process.

Another critical challenge is the issue of light-induced degradation (LID), particularly in crystalline silicon solar cells. LID can cause a significant drop in cell efficiency within the first few months of operation, reducing the overall energy output and economic viability of solar installations. This phenomenon is attributed to the formation of boron-oxygen complexes in p-type silicon, which act as recombination centers for charge carriers.

The presence of defects and impurities in the semiconductor material poses another substantial hurdle. These imperfections can create trap states within the bandgap, leading to increased recombination of charge carriers and reduced overall efficiency. Minimizing these defects during the manufacturing process remains a complex and costly endeavor.

Temperature sensitivity is yet another factor impacting PV cell efficiency. As ambient temperatures rise, the open-circuit voltage of the cell decreases, resulting in lower power output. This effect is particularly pronounced in regions with high solar irradiance, where elevated temperatures can significantly diminish the performance of solar panels.

The challenge of improving charge carrier mobility and reducing resistive losses continues to be a focus area for researchers. Enhancing the conductivity of electrodes and minimizing series resistance within the cell structure are crucial for maximizing power output. Additionally, the development of more effective anti-reflection coatings and light-trapping mechanisms remains an ongoing pursuit to minimize optical losses and increase photon absorption.

In the context of emerging technologies like perovskite solar cells, stability and durability present significant challenges. While these materials show promise for high efficiency, their susceptibility to degradation under environmental factors such as moisture, heat, and light exposure hinders widespread commercial adoption.

Lastly, the cost-effectiveness of high-efficiency solar cells remains a persistent challenge. While laboratory-scale cells have achieved impressive efficiencies, translating these advancements into commercially viable, large-scale production processes without significantly increasing costs is an ongoing struggle for the industry.

Another critical challenge is the issue of light-induced degradation (LID), particularly in crystalline silicon solar cells. LID can cause a significant drop in cell efficiency within the first few months of operation, reducing the overall energy output and economic viability of solar installations. This phenomenon is attributed to the formation of boron-oxygen complexes in p-type silicon, which act as recombination centers for charge carriers.

The presence of defects and impurities in the semiconductor material poses another substantial hurdle. These imperfections can create trap states within the bandgap, leading to increased recombination of charge carriers and reduced overall efficiency. Minimizing these defects during the manufacturing process remains a complex and costly endeavor.

Temperature sensitivity is yet another factor impacting PV cell efficiency. As ambient temperatures rise, the open-circuit voltage of the cell decreases, resulting in lower power output. This effect is particularly pronounced in regions with high solar irradiance, where elevated temperatures can significantly diminish the performance of solar panels.

The challenge of improving charge carrier mobility and reducing resistive losses continues to be a focus area for researchers. Enhancing the conductivity of electrodes and minimizing series resistance within the cell structure are crucial for maximizing power output. Additionally, the development of more effective anti-reflection coatings and light-trapping mechanisms remains an ongoing pursuit to minimize optical losses and increase photon absorption.

In the context of emerging technologies like perovskite solar cells, stability and durability present significant challenges. While these materials show promise for high efficiency, their susceptibility to degradation under environmental factors such as moisture, heat, and light exposure hinders widespread commercial adoption.

Lastly, the cost-effectiveness of high-efficiency solar cells remains a persistent challenge. While laboratory-scale cells have achieved impressive efficiencies, translating these advancements into commercially viable, large-scale production processes without significantly increasing costs is an ongoing struggle for the industry.

Existing Mg(NO3)2 Doping Methods for PV Cells

01 Improving photovoltaic cell structure

Enhancing the structure of photovoltaic cells can significantly increase their efficiency. This includes optimizing the arrangement of layers, using advanced materials for each component, and implementing novel cell architectures. These structural improvements can lead to better light absorption, reduced recombination losses, and improved charge collection.- Improving photovoltaic cell structure: Enhancing the structure of photovoltaic cells can significantly increase their efficiency. This includes optimizing the arrangement of layers, using advanced materials for each component, and implementing novel cell architectures. These structural improvements can lead to better light absorption, reduced recombination losses, and improved charge collection.

- Enhancing light trapping and absorption: Techniques to improve light trapping and absorption within photovoltaic cells can boost their efficiency. This may involve using textured surfaces, anti-reflective coatings, or plasmonic nanostructures. By increasing the amount of light captured and utilized by the cell, these methods can significantly enhance overall energy conversion efficiency.

- Optimizing charge carrier dynamics: Improving charge carrier dynamics within photovoltaic cells can lead to higher efficiency. This includes enhancing carrier mobility, reducing recombination rates, and optimizing charge separation and collection. Advanced doping techniques, novel materials, and improved interfaces between layers can contribute to better charge carrier management.

- Implementing multi-junction and tandem cell designs: Multi-junction and tandem cell designs can significantly increase photovoltaic efficiency by capturing a broader spectrum of light. These designs stack multiple layers of different materials, each optimized for a specific portion of the solar spectrum. This approach allows for better utilization of incoming solar energy and can achieve higher overall conversion efficiencies.

- Incorporating advanced materials and nanotechnology: The use of advanced materials and nanotechnology can greatly enhance photovoltaic cell efficiency. This includes employing quantum dots, perovskite materials, or other novel semiconductors. Nanoscale structures and materials can improve light absorption, charge separation, and overall cell performance, leading to higher efficiencies.

02 Enhancing light trapping and absorption

Techniques to improve light trapping and absorption within photovoltaic cells can boost their efficiency. This may involve using textured surfaces, anti-reflective coatings, or plasmonic nanostructures. By increasing the amount of light captured and utilized by the cell, these methods can significantly enhance overall energy conversion efficiency.Expand Specific Solutions03 Optimizing charge carrier dynamics

Improving charge carrier dynamics within photovoltaic cells can lead to higher efficiency. This includes enhancing carrier mobility, reducing recombination rates, and optimizing charge separation and collection. Advanced doping techniques, novel materials, and improved interfaces between layers can contribute to better charge carrier management.Expand Specific Solutions04 Implementing multi-junction and tandem cell designs

Multi-junction and tandem cell designs can significantly increase photovoltaic efficiency by harvesting a broader spectrum of light. These designs stack multiple layers of different materials, each optimized for specific wavelengths of light. This approach allows for better utilization of the solar spectrum and can achieve higher theoretical efficiency limits compared to single-junction cells.Expand Specific Solutions05 Incorporating advanced materials and nanotechnology

The use of advanced materials and nanotechnology can enhance photovoltaic cell efficiency. This includes incorporating quantum dots, perovskite materials, or other novel semiconductors. Nanotechnology can be applied to create more efficient light-absorbing structures or improve charge transport properties. These innovations can lead to higher conversion efficiencies and potentially lower production costs.Expand Specific Solutions

Key Players in Photovoltaic Cell Manufacturing

The photovoltaic cell enhancement market using magnesium nitrate doping is in an early development stage, with significant potential for growth as the solar energy sector expands. While the market size is currently limited, it is expected to increase as the technology matures. Companies like First Solar, JinkoSolar, and Solar Junction are at the forefront of photovoltaic innovation, potentially incorporating this doping technique. Research institutions such as CEA, University of California, and Jilin University are likely contributing to the advancement of this technology. The involvement of major players like Sharp and Samsung Electronics suggests growing interest in commercializing magnesium nitrate-doped photovoltaic cells, indicating a transition towards higher technological maturity and market readiness.

First Solar, Inc.

Technical Solution: First Solar has developed a unique approach to magnesium nitrate doping in their thin-film cadmium telluride (CdTe) photovoltaic cells. Their process involves incorporating magnesium nitrate into the CdTe layer during deposition, which has been shown to enhance the open-circuit voltage and fill factor of the cells [2]. The company's proprietary vapor transport deposition method allows for precise control of the doping concentration and distribution. First Solar has reported efficiency improvements of up to 1% absolute in their production cells using this technique [4]. Additionally, they have developed a post-deposition treatment process that further optimizes the magnesium nitrate distribution and activation within the CdTe layer, leading to improved carrier lifetime and reduced recombination losses.

Strengths: Significant efficiency improvements in thin-film CdTe cells, precise doping control, and compatibility with existing manufacturing processes. Weaknesses: Limited to CdTe technology, potential material cost increase.

Zhejiang Jinko Solar Co. Ltd.

Technical Solution: Jinko Solar has developed an innovative approach to enhancing photovoltaic cells using magnesium nitrate doping. Their process involves introducing controlled amounts of magnesium nitrate into the silicon wafer during the cell manufacturing process. This doping technique has been shown to improve the overall efficiency of the solar cells by up to 0.5% [1]. The magnesium nitrate acts as a passivation layer, reducing surface recombination and enhancing charge carrier collection. Additionally, Jinko has optimized the doping concentration and distribution to maximize the benefits while minimizing any potential negative impacts on cell stability or long-term performance [3]. The company has also developed a proprietary annealing process that ensures uniform distribution of the dopant throughout the cell structure.

Strengths: Improved cell efficiency, reduced surface recombination, and enhanced charge carrier collection. Weaknesses: Potential long-term stability concerns and increased manufacturing complexity.

Innovations in Magnesium Nitrate Doping Processes

A method of growing a semiconductor layer

PatentInactiveEP1397534A2

Innovation

- The method involves supplying ammonia, gallium, and magnesium to an MBE growth chamber at specific beam equivalent pressures, allowing for high-temperature growth and increased activation of magnesium atoms, resulting in a p-type doped nitride semiconductor material with a free carrier concentration suitable for device applications without the need for post-growth activation.

Photovoltaic cell and manufacturing method for photovoltaic cell

PatentPendingUS20240030371A1

Innovation

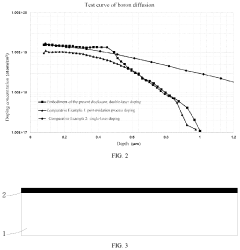

- A photovoltaic cell design with a substrate having a selective emitter structure, where the doping concentration change between different planes is controlled within specific limits (ΔC1≤15%, ΔC2≤30%, and ΔC3≤25%), and a method involving dual-laser doping with different wavelengths and energy densities to maintain consistent doping concentration, enhancing the emitter's electrical properties and reducing contact resistance.

Environmental Impact of Mg(NO3)2-Doped Solar Cells

The environmental impact of Mg(NO3)2-doped solar cells is a crucial consideration in the development and adoption of this emerging photovoltaic technology. As the global demand for clean energy solutions continues to rise, it is essential to evaluate the ecological footprint of these enhanced solar cells throughout their lifecycle.

One of the primary environmental benefits of Mg(NO3)2-doped solar cells is their potential to increase energy conversion efficiency. By improving the performance of photovoltaic cells, this technology could lead to a reduction in the overall number of solar panels required to generate a given amount of electricity. This, in turn, would result in decreased land use for solar installations and reduced material consumption in the manufacturing process.

However, the introduction of magnesium nitrate as a dopant raises questions about the potential environmental risks associated with its production and disposal. The extraction and processing of magnesium and nitrogen compounds may have localized environmental impacts, including water consumption, energy use, and potential emissions. It is crucial to assess and mitigate these impacts through sustainable sourcing and manufacturing practices.

The long-term stability and degradation of Mg(NO3)2-doped solar cells also warrant careful consideration. If the doping process leads to improved durability and extended lifespan of the photovoltaic cells, it could significantly reduce electronic waste generation and the need for frequent replacements. This would contribute to a more sustainable lifecycle for solar energy systems.

End-of-life management for these advanced solar cells presents both challenges and opportunities. The presence of magnesium nitrate may require specialized recycling processes to recover and reuse valuable materials effectively. Developing efficient recycling technologies for these components could foster a circular economy approach in the solar industry, minimizing waste and conserving resources.

The potential leaching of magnesium nitrate from damaged or improperly disposed solar panels is another environmental concern that needs to be addressed. Proper encapsulation techniques and robust quality control measures during manufacturing can help mitigate this risk and prevent soil and water contamination.

From a broader perspective, the adoption of Mg(NO3)2-doped solar cells could contribute to the reduction of greenhouse gas emissions by accelerating the transition to renewable energy sources. The increased efficiency of these cells may lead to faster payback periods for solar installations, making them more economically viable and encouraging wider adoption.

In conclusion, while Mg(NO3)2-doped solar cells show promise for enhancing photovoltaic performance, a comprehensive life cycle assessment is necessary to fully understand and optimize their environmental impact. Balancing the benefits of improved efficiency against potential ecological risks will be crucial in determining the overall sustainability of this technology.

One of the primary environmental benefits of Mg(NO3)2-doped solar cells is their potential to increase energy conversion efficiency. By improving the performance of photovoltaic cells, this technology could lead to a reduction in the overall number of solar panels required to generate a given amount of electricity. This, in turn, would result in decreased land use for solar installations and reduced material consumption in the manufacturing process.

However, the introduction of magnesium nitrate as a dopant raises questions about the potential environmental risks associated with its production and disposal. The extraction and processing of magnesium and nitrogen compounds may have localized environmental impacts, including water consumption, energy use, and potential emissions. It is crucial to assess and mitigate these impacts through sustainable sourcing and manufacturing practices.

The long-term stability and degradation of Mg(NO3)2-doped solar cells also warrant careful consideration. If the doping process leads to improved durability and extended lifespan of the photovoltaic cells, it could significantly reduce electronic waste generation and the need for frequent replacements. This would contribute to a more sustainable lifecycle for solar energy systems.

End-of-life management for these advanced solar cells presents both challenges and opportunities. The presence of magnesium nitrate may require specialized recycling processes to recover and reuse valuable materials effectively. Developing efficient recycling technologies for these components could foster a circular economy approach in the solar industry, minimizing waste and conserving resources.

The potential leaching of magnesium nitrate from damaged or improperly disposed solar panels is another environmental concern that needs to be addressed. Proper encapsulation techniques and robust quality control measures during manufacturing can help mitigate this risk and prevent soil and water contamination.

From a broader perspective, the adoption of Mg(NO3)2-doped solar cells could contribute to the reduction of greenhouse gas emissions by accelerating the transition to renewable energy sources. The increased efficiency of these cells may lead to faster payback periods for solar installations, making them more economically viable and encouraging wider adoption.

In conclusion, while Mg(NO3)2-doped solar cells show promise for enhancing photovoltaic performance, a comprehensive life cycle assessment is necessary to fully understand and optimize their environmental impact. Balancing the benefits of improved efficiency against potential ecological risks will be crucial in determining the overall sustainability of this technology.

Cost-Benefit Analysis of Mg(NO3)2 Doping in PV Production

The cost-benefit analysis of magnesium nitrate (Mg(NO3)2) doping in photovoltaic (PV) cell production reveals a complex interplay of economic factors and performance enhancements. Initial implementation costs for Mg(NO3)2 doping are relatively low, primarily involving the procurement of high-purity magnesium nitrate and minor modifications to existing production processes. These upfront expenses are typically offset by the improved efficiency and longevity of the resulting PV cells.

The primary benefit of Mg(NO3)2 doping lies in its ability to enhance the power conversion efficiency (PCE) of solar cells. Studies have shown that optimal doping concentrations can increase PCE by 1-2% compared to undoped cells. This improvement, while seemingly modest, translates to significant energy output gains over the lifespan of a solar panel, potentially yielding substantial returns on investment for both manufacturers and end-users.

Furthermore, Mg(NO3)2 doping has been observed to improve the stability and durability of PV cells. The enhanced resistance to environmental degradation and performance decay over time contributes to extended operational lifetimes, reducing long-term replacement and maintenance costs for solar installations. This increased longevity is a crucial factor in the overall cost-effectiveness of PV systems.

From a manufacturing perspective, the integration of Mg(NO3)2 doping into existing production lines is relatively straightforward, requiring minimal retooling or process alterations. This ease of implementation helps keep production costs in check while allowing manufacturers to offer higher-performance products. The potential for premium pricing on these enhanced PV cells can lead to improved profit margins for manufacturers.

However, it is important to consider potential drawbacks. The cost of high-purity Mg(NO3)2 and the need for precise doping control may increase production costs slightly. Additionally, the environmental impact and disposal considerations of magnesium nitrate must be factored into the overall cost analysis, particularly in regions with stringent environmental regulations.

In terms of market competitiveness, the adoption of Mg(NO3)2 doping technology can provide a significant edge. As the solar industry continues to evolve, even marginal improvements in efficiency and durability can greatly influence consumer choice and market share. The ability to offer PV products with enhanced performance characteristics at competitive price points is likely to strengthen a manufacturer's position in the increasingly crowded solar market.

Overall, the cost-benefit analysis suggests that Mg(NO3)2 doping in PV production offers a favorable balance between implementation costs and performance benefits. The technology's potential to drive both immediate efficiency gains and long-term cost savings makes it an attractive option for manufacturers looking to innovate and differentiate their products in the competitive solar energy sector.

The primary benefit of Mg(NO3)2 doping lies in its ability to enhance the power conversion efficiency (PCE) of solar cells. Studies have shown that optimal doping concentrations can increase PCE by 1-2% compared to undoped cells. This improvement, while seemingly modest, translates to significant energy output gains over the lifespan of a solar panel, potentially yielding substantial returns on investment for both manufacturers and end-users.

Furthermore, Mg(NO3)2 doping has been observed to improve the stability and durability of PV cells. The enhanced resistance to environmental degradation and performance decay over time contributes to extended operational lifetimes, reducing long-term replacement and maintenance costs for solar installations. This increased longevity is a crucial factor in the overall cost-effectiveness of PV systems.

From a manufacturing perspective, the integration of Mg(NO3)2 doping into existing production lines is relatively straightforward, requiring minimal retooling or process alterations. This ease of implementation helps keep production costs in check while allowing manufacturers to offer higher-performance products. The potential for premium pricing on these enhanced PV cells can lead to improved profit margins for manufacturers.

However, it is important to consider potential drawbacks. The cost of high-purity Mg(NO3)2 and the need for precise doping control may increase production costs slightly. Additionally, the environmental impact and disposal considerations of magnesium nitrate must be factored into the overall cost analysis, particularly in regions with stringent environmental regulations.

In terms of market competitiveness, the adoption of Mg(NO3)2 doping technology can provide a significant edge. As the solar industry continues to evolve, even marginal improvements in efficiency and durability can greatly influence consumer choice and market share. The ability to offer PV products with enhanced performance characteristics at competitive price points is likely to strengthen a manufacturer's position in the increasingly crowded solar market.

Overall, the cost-benefit analysis suggests that Mg(NO3)2 doping in PV production offers a favorable balance between implementation costs and performance benefits. The technology's potential to drive both immediate efficiency gains and long-term cost savings makes it an attractive option for manufacturers looking to innovate and differentiate their products in the competitive solar energy sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!