Evaluating Magnesium Nitrate in Protective Metal Coatings

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Nitrate Coating Background and Objectives

Magnesium nitrate has emerged as a promising component in protective metal coatings, drawing significant attention from researchers and industry professionals alike. The development of this technology can be traced back to the early 2000s when the need for more effective and environmentally friendly corrosion protection methods became increasingly apparent. As traditional coating systems faced limitations in performance and sustainability, the exploration of alternative materials and approaches gained momentum.

The evolution of magnesium nitrate coatings has been driven by several key factors, including the growing demand for lightweight materials in various industries, the push for more sustainable and non-toxic coating solutions, and the need for enhanced corrosion resistance in harsh environments. Over the past two decades, researchers have made significant strides in understanding the unique properties of magnesium nitrate and its potential applications in protective coatings.

One of the primary objectives in the development of magnesium nitrate coatings has been to achieve superior corrosion protection for a wide range of metal substrates. This goal has been pursued through the optimization of coating formulations, application techniques, and curing processes. Researchers have focused on enhancing the adhesion, durability, and barrier properties of these coatings to provide long-lasting protection against environmental factors and chemical attacks.

Another crucial aim has been to improve the cost-effectiveness and scalability of magnesium nitrate coating technologies. This has involved efforts to streamline production processes, reduce material costs, and develop more efficient application methods. The ultimate goal is to make these advanced coatings commercially viable and accessible for widespread industrial use.

Environmental considerations have also played a significant role in shaping the trajectory of magnesium nitrate coating research. With increasing regulatory pressure and growing consumer awareness, there has been a concerted effort to develop coatings that are not only effective but also environmentally benign. This has led to the exploration of water-based formulations and the minimization of volatile organic compounds (VOCs) in coating systems.

As the technology continues to evolve, researchers are now focusing on expanding the functionality of magnesium nitrate coatings beyond mere corrosion protection. Current objectives include the development of self-healing properties, the incorporation of smart sensing capabilities, and the enhancement of wear resistance. These advancements aim to create multifunctional coatings that can adapt to changing environmental conditions and provide real-time monitoring of substrate integrity.

The ongoing research in magnesium nitrate coatings is expected to lead to breakthroughs in material science and surface engineering. By addressing current limitations and exploring new possibilities, scientists and engineers are working towards creating next-generation protective coatings that offer unprecedented levels of performance, durability, and sustainability.

The evolution of magnesium nitrate coatings has been driven by several key factors, including the growing demand for lightweight materials in various industries, the push for more sustainable and non-toxic coating solutions, and the need for enhanced corrosion resistance in harsh environments. Over the past two decades, researchers have made significant strides in understanding the unique properties of magnesium nitrate and its potential applications in protective coatings.

One of the primary objectives in the development of magnesium nitrate coatings has been to achieve superior corrosion protection for a wide range of metal substrates. This goal has been pursued through the optimization of coating formulations, application techniques, and curing processes. Researchers have focused on enhancing the adhesion, durability, and barrier properties of these coatings to provide long-lasting protection against environmental factors and chemical attacks.

Another crucial aim has been to improve the cost-effectiveness and scalability of magnesium nitrate coating technologies. This has involved efforts to streamline production processes, reduce material costs, and develop more efficient application methods. The ultimate goal is to make these advanced coatings commercially viable and accessible for widespread industrial use.

Environmental considerations have also played a significant role in shaping the trajectory of magnesium nitrate coating research. With increasing regulatory pressure and growing consumer awareness, there has been a concerted effort to develop coatings that are not only effective but also environmentally benign. This has led to the exploration of water-based formulations and the minimization of volatile organic compounds (VOCs) in coating systems.

As the technology continues to evolve, researchers are now focusing on expanding the functionality of magnesium nitrate coatings beyond mere corrosion protection. Current objectives include the development of self-healing properties, the incorporation of smart sensing capabilities, and the enhancement of wear resistance. These advancements aim to create multifunctional coatings that can adapt to changing environmental conditions and provide real-time monitoring of substrate integrity.

The ongoing research in magnesium nitrate coatings is expected to lead to breakthroughs in material science and surface engineering. By addressing current limitations and exploring new possibilities, scientists and engineers are working towards creating next-generation protective coatings that offer unprecedented levels of performance, durability, and sustainability.

Market Analysis for Protective Metal Coatings

The protective metal coatings market has been experiencing steady growth due to increasing demand across various industries, including automotive, aerospace, construction, and marine. This market is driven by the need to protect metal surfaces from corrosion, wear, and environmental factors, thereby extending the lifespan of metal components and structures.

In recent years, the global protective metal coatings market has shown a compound annual growth rate (CAGR) of around 5-6%. This growth is expected to continue in the coming years, with projections indicating a market value reaching several billion dollars by 2025. The Asia-Pacific region, particularly China and India, has emerged as a significant contributor to this growth, owing to rapid industrialization and infrastructure development.

The automotive sector remains a key driver for protective metal coatings, as manufacturers seek to enhance the durability and aesthetics of vehicle components. The aerospace industry also presents substantial opportunities, with increasing demand for high-performance coatings that can withstand extreme conditions. Additionally, the construction industry's focus on corrosion-resistant materials for buildings and infrastructure projects has further bolstered market growth.

Environmental regulations have played a crucial role in shaping market trends, with a growing emphasis on eco-friendly and low-VOC (volatile organic compound) coatings. This has led to increased research and development efforts in water-based and powder coatings, which are gaining traction in various applications.

The evaluation of magnesium nitrate in protective metal coatings represents a potential innovation in this market. Magnesium nitrate's properties, such as its ability to enhance corrosion resistance and improve adhesion, could address some of the existing challenges in metal protection. If proven effective, this technology could capture a significant market share, particularly in industries requiring high-performance coatings.

However, the adoption of new coating technologies like magnesium nitrate-based solutions would depend on factors such as cost-effectiveness, ease of application, and long-term performance. Market acceptance would require extensive testing and validation across different industrial applications. The success of such innovations could potentially disrupt the current market dynamics and create new opportunities for coating manufacturers and suppliers.

In conclusion, the protective metal coatings market shows promising growth prospects, driven by industrial expansion and technological advancements. The potential integration of magnesium nitrate in these coatings aligns with the market's demand for improved performance and durability. As the industry continues to evolve, innovations in coating technologies will play a crucial role in meeting the diverse needs of end-users across various sectors.

In recent years, the global protective metal coatings market has shown a compound annual growth rate (CAGR) of around 5-6%. This growth is expected to continue in the coming years, with projections indicating a market value reaching several billion dollars by 2025. The Asia-Pacific region, particularly China and India, has emerged as a significant contributor to this growth, owing to rapid industrialization and infrastructure development.

The automotive sector remains a key driver for protective metal coatings, as manufacturers seek to enhance the durability and aesthetics of vehicle components. The aerospace industry also presents substantial opportunities, with increasing demand for high-performance coatings that can withstand extreme conditions. Additionally, the construction industry's focus on corrosion-resistant materials for buildings and infrastructure projects has further bolstered market growth.

Environmental regulations have played a crucial role in shaping market trends, with a growing emphasis on eco-friendly and low-VOC (volatile organic compound) coatings. This has led to increased research and development efforts in water-based and powder coatings, which are gaining traction in various applications.

The evaluation of magnesium nitrate in protective metal coatings represents a potential innovation in this market. Magnesium nitrate's properties, such as its ability to enhance corrosion resistance and improve adhesion, could address some of the existing challenges in metal protection. If proven effective, this technology could capture a significant market share, particularly in industries requiring high-performance coatings.

However, the adoption of new coating technologies like magnesium nitrate-based solutions would depend on factors such as cost-effectiveness, ease of application, and long-term performance. Market acceptance would require extensive testing and validation across different industrial applications. The success of such innovations could potentially disrupt the current market dynamics and create new opportunities for coating manufacturers and suppliers.

In conclusion, the protective metal coatings market shows promising growth prospects, driven by industrial expansion and technological advancements. The potential integration of magnesium nitrate in these coatings aligns with the market's demand for improved performance and durability. As the industry continues to evolve, innovations in coating technologies will play a crucial role in meeting the diverse needs of end-users across various sectors.

Current Challenges in Magnesium Nitrate Coatings

Despite the promising potential of magnesium nitrate in protective metal coatings, several significant challenges currently hinder its widespread adoption and optimal performance. One of the primary issues is the high hygroscopicity of magnesium nitrate, which can lead to moisture absorption and subsequent degradation of the coating's protective properties. This tendency to attract water molecules from the environment can result in the formation of a wet film on the coated surface, potentially accelerating corrosion processes rather than preventing them.

Another challenge lies in the stability of magnesium nitrate coatings under varying environmental conditions. Temperature fluctuations and exposure to different pH levels can affect the coating's integrity and protective capabilities. The coating may experience phase changes or chemical reactions that alter its structure and effectiveness, particularly in extreme temperatures or highly acidic or alkaline environments.

The adhesion of magnesium nitrate coatings to various metal substrates presents another significant hurdle. Achieving strong and durable bonding between the coating and the underlying metal surface is crucial for long-term protection. However, the chemical nature of magnesium nitrate can sometimes lead to poor adhesion, resulting in coating delamination or flaking, especially under mechanical stress or thermal cycling.

Uniformity and thickness control in the application of magnesium nitrate coatings pose additional challenges. Ensuring an even distribution of the coating material across complex geometries and maintaining consistent thickness is essential for optimal performance. Variations in coating thickness can lead to weak points in the protective layer, compromising its overall effectiveness.

The long-term stability and durability of magnesium nitrate coatings are also areas of concern. Over time, these coatings may degrade due to environmental factors, UV exposure, or chemical interactions with the substrate or surrounding atmosphere. Understanding and mitigating these degradation mechanisms is crucial for developing coatings that can provide lasting protection in real-world applications.

Furthermore, the potential environmental impact of magnesium nitrate coatings needs to be carefully evaluated. While magnesium nitrate itself is generally considered environmentally friendly, the long-term effects of its use in large-scale coating applications, including its disposal and potential leaching into the environment, require thorough assessment to ensure sustainability and regulatory compliance.

Lastly, the cost-effectiveness of magnesium nitrate coatings compared to existing alternatives remains a challenge. While the material itself may be relatively inexpensive, the processing, application, and potential need for frequent reapplication or maintenance could impact its economic viability in various industrial settings. Balancing performance benefits with overall lifecycle costs is essential for the widespread adoption of this technology in protective metal coatings.

Another challenge lies in the stability of magnesium nitrate coatings under varying environmental conditions. Temperature fluctuations and exposure to different pH levels can affect the coating's integrity and protective capabilities. The coating may experience phase changes or chemical reactions that alter its structure and effectiveness, particularly in extreme temperatures or highly acidic or alkaline environments.

The adhesion of magnesium nitrate coatings to various metal substrates presents another significant hurdle. Achieving strong and durable bonding between the coating and the underlying metal surface is crucial for long-term protection. However, the chemical nature of magnesium nitrate can sometimes lead to poor adhesion, resulting in coating delamination or flaking, especially under mechanical stress or thermal cycling.

Uniformity and thickness control in the application of magnesium nitrate coatings pose additional challenges. Ensuring an even distribution of the coating material across complex geometries and maintaining consistent thickness is essential for optimal performance. Variations in coating thickness can lead to weak points in the protective layer, compromising its overall effectiveness.

The long-term stability and durability of magnesium nitrate coatings are also areas of concern. Over time, these coatings may degrade due to environmental factors, UV exposure, or chemical interactions with the substrate or surrounding atmosphere. Understanding and mitigating these degradation mechanisms is crucial for developing coatings that can provide lasting protection in real-world applications.

Furthermore, the potential environmental impact of magnesium nitrate coatings needs to be carefully evaluated. While magnesium nitrate itself is generally considered environmentally friendly, the long-term effects of its use in large-scale coating applications, including its disposal and potential leaching into the environment, require thorough assessment to ensure sustainability and regulatory compliance.

Lastly, the cost-effectiveness of magnesium nitrate coatings compared to existing alternatives remains a challenge. While the material itself may be relatively inexpensive, the processing, application, and potential need for frequent reapplication or maintenance could impact its economic viability in various industrial settings. Balancing performance benefits with overall lifecycle costs is essential for the widespread adoption of this technology in protective metal coatings.

Existing Magnesium Nitrate Coating Solutions

01 Corrosion protection for magnesium alloys

Magnesium nitrate is used in protective coatings for magnesium alloys to enhance corrosion resistance. These coatings can be applied through various methods such as anodizing or chemical conversion, forming a protective layer on the surface of the magnesium alloy.- Corrosion protection for magnesium alloys: Magnesium nitrate is used in protective coatings for magnesium alloys to enhance corrosion resistance. These coatings can be applied through various methods such as anodizing or chemical conversion, forming a protective layer on the surface of the alloy.

- Fire retardant applications: Magnesium nitrate is utilized in fire retardant formulations due to its ability to release nitrogen and form a protective char layer when exposed to high temperatures. This property makes it useful in various applications such as building materials and textiles.

- Agricultural use for plant protection: Magnesium nitrate is employed in agricultural applications as a fertilizer and plant protectant. It provides essential nutrients to plants while also offering some level of protection against certain pests and diseases.

- Water treatment and purification: Magnesium nitrate is used in water treatment processes for its ability to remove contaminants and improve water quality. It can help in the precipitation of certain pollutants and aid in the overall purification process.

- Protective coatings for metals: Magnesium nitrate is incorporated into protective coatings for various metals to enhance their resistance to corrosion and environmental degradation. These coatings can be applied through different methods and may include additional compounds for improved performance.

02 Fire retardant applications

Magnesium nitrate is utilized in fire retardant formulations due to its ability to release nitrogen and form a protective char layer when exposed to high temperatures. This property makes it useful in various applications such as building materials and textiles.Expand Specific Solutions03 Agricultural use for plant protection

Magnesium nitrate is employed in agricultural applications as a fertilizer and plant protectant. It provides essential nutrients to plants while also offering some level of protection against certain pests and diseases.Expand Specific Solutions04 Protective coatings for metal surfaces

Magnesium nitrate is incorporated into protective coatings for various metal surfaces beyond magnesium alloys. These coatings can provide corrosion resistance, improve durability, and enhance the overall lifespan of metal components.Expand Specific Solutions05 Environmental protection applications

Magnesium nitrate is used in environmental protection applications, such as wastewater treatment and air pollution control. It can help in the removal of contaminants and the neutralization of harmful substances in various environmental processes.Expand Specific Solutions

Key Players in Magnesium Nitrate Coating Industry

The evaluation of magnesium nitrate in protective metal coatings is currently in a developing stage, with the market showing potential for growth. The technology's maturity is progressing, as evidenced by the involvement of major players like Chemetall GmbH, PPG Industries Ohio, Inc., and BASF Corp. These companies are likely investing in research and development to enhance the effectiveness of magnesium nitrate-based coatings. The market size is expected to expand as industries seek more efficient and environmentally friendly corrosion protection solutions. However, the technology is still evolving, with ongoing research at institutions like Naval Research Laboratory and Nanjing University contributing to its advancement.

Chemetall GmbH

Technical Solution: Chemetall GmbH has developed an innovative magnesium nitrate-based coating system for metal protection. Their approach involves a multi-layer application process, where magnesium nitrate is incorporated into a primer layer, followed by a topcoat containing corrosion inhibitors. This system creates a synergistic effect, enhancing the overall corrosion resistance of the metal substrate. The magnesium nitrate acts as a sacrificial anode, preferentially corroding to protect the underlying metal[1]. Additionally, Chemetall's formulation includes nano-sized magnesium nitrate particles, which improve the coating's barrier properties and increase its durability[3]. The company has also integrated self-healing capabilities into their coating, where magnesium nitrate ions can migrate to damaged areas and form a protective layer[5].

Strengths: Excellent corrosion resistance, self-healing properties, and improved durability. Weaknesses: Potentially higher cost due to complex formulation and multi-layer application process.

PPG Industries Ohio, Inc.

Technical Solution: PPG Industries has developed a cutting-edge protective metal coating system incorporating magnesium nitrate. Their approach utilizes a sol-gel process to create a nanostructured coating matrix that encapsulates magnesium nitrate particles. This matrix allows for controlled release of magnesium ions, providing long-term corrosion protection[2]. The coating also incorporates smart release technology, where magnesium nitrate is released in response to environmental triggers such as pH changes or mechanical damage[4]. PPG's formulation includes additional corrosion inhibitors that work synergistically with magnesium nitrate, enhancing the overall protective performance. The company has also developed a single-layer application method, reducing application time and costs compared to traditional multi-layer systems[6].

Strengths: Advanced nanostructured coating, smart release technology, and simplified application process. Weaknesses: May have limitations in extreme environments or with certain metal substrates.

Core Innovations in Magnesium Nitrate Coatings

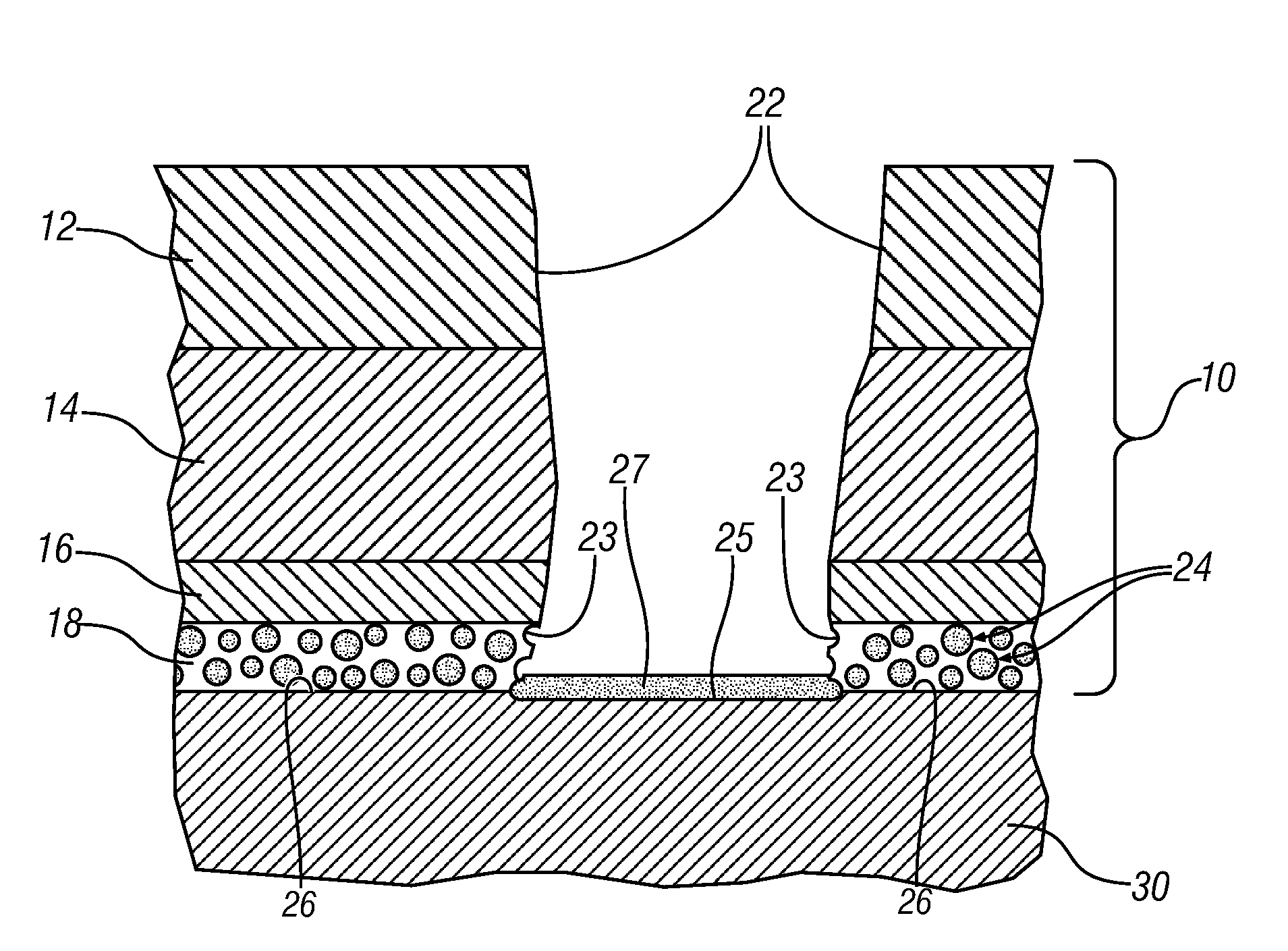

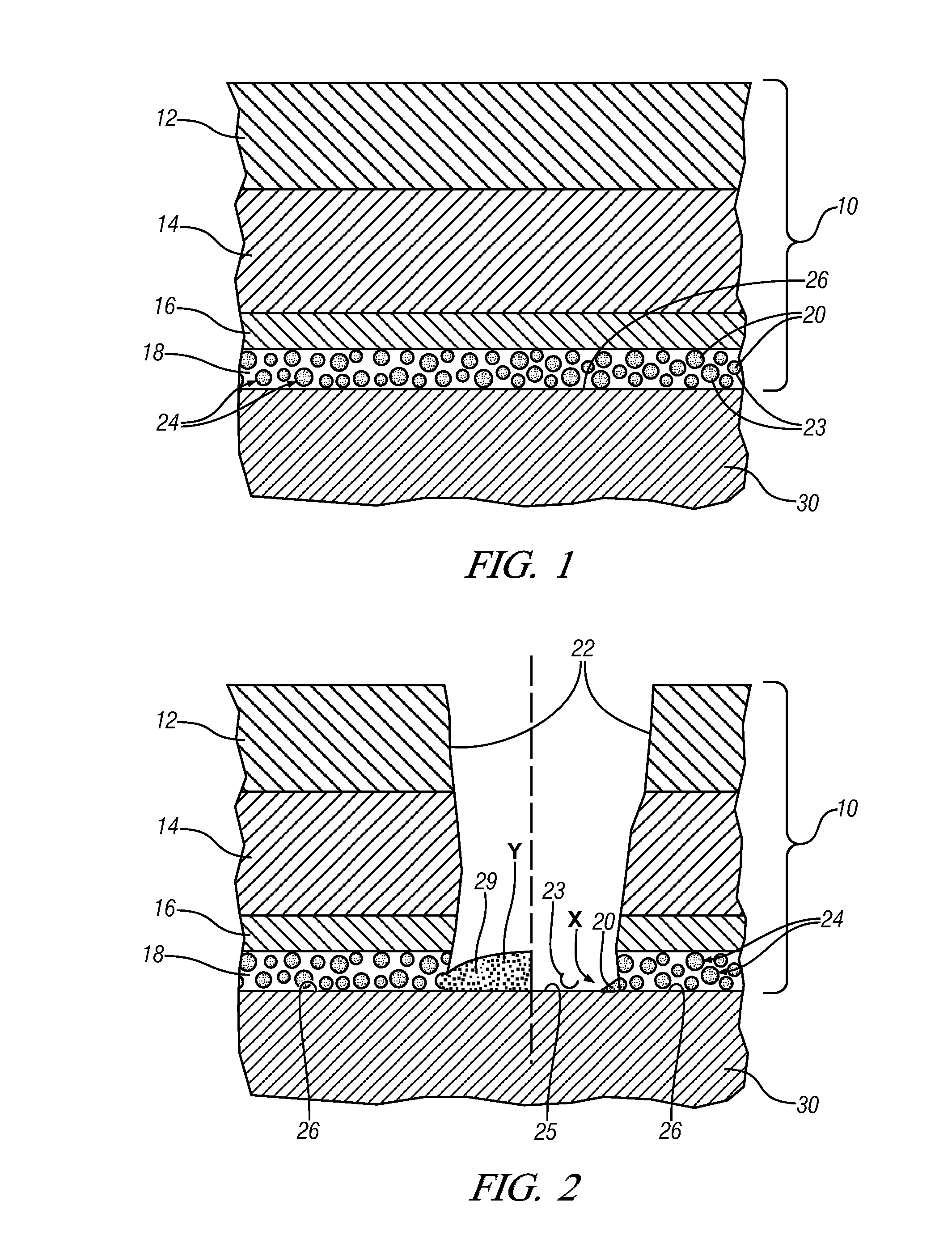

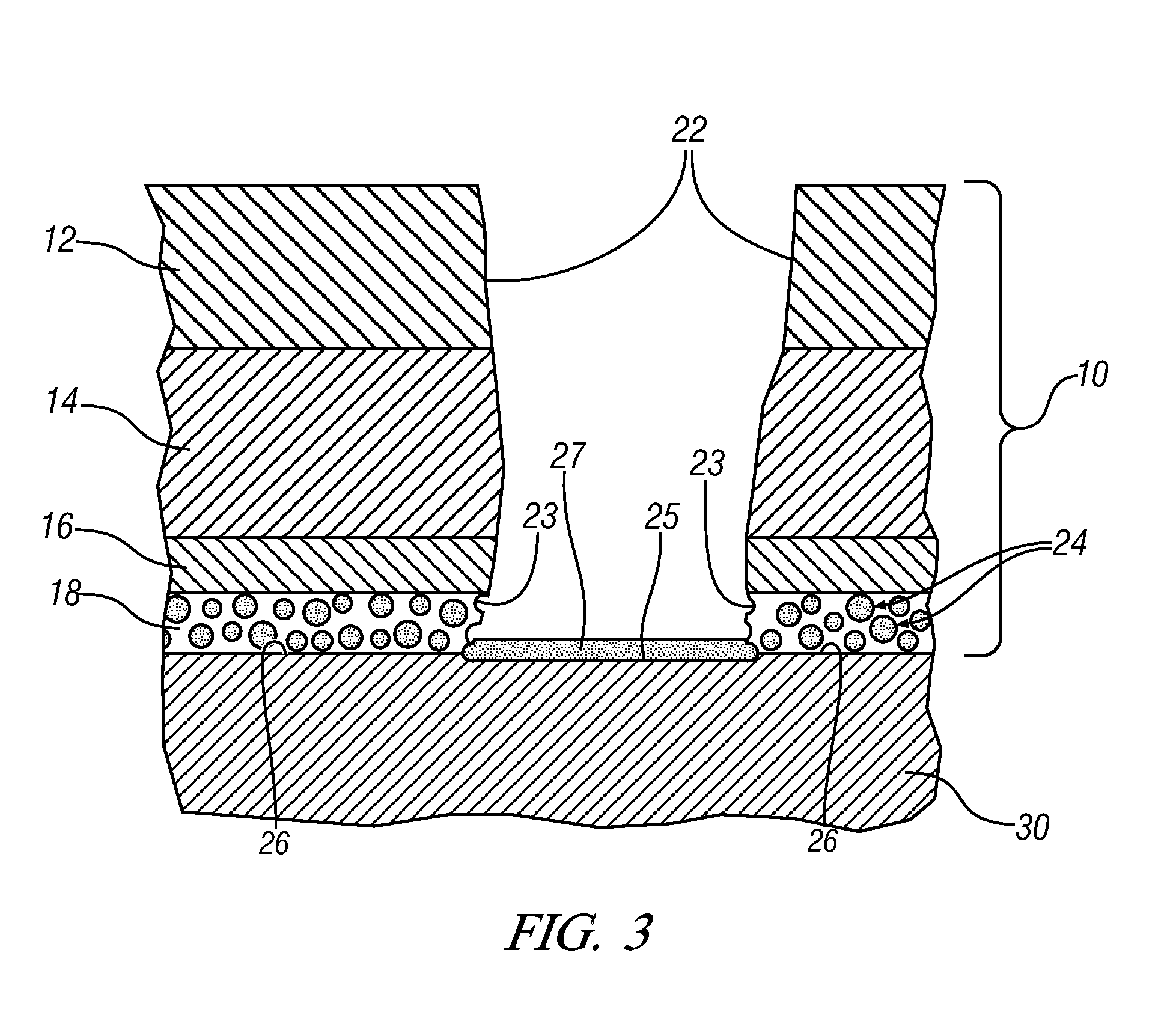

Corrosion inhibitors in breakable microcapsules to passivate scratched metals

PatentActiveUS20110064941A1

Innovation

- Incorporating water-soluble passivating chemicals in a paint layer, encapsulated in frangible microcapsules, which react with the magnesium surface upon exposure to water to form a protective film, even after the paint film is damaged.

Pretreatment of magnesium substrates

PatentWO2015127080A1

Innovation

- A composition comprising a compound with at least 4 phosphorus acid groups, such as phytic acid, and a soluble alkaline earth salt, along with optional fluoride, is used to pretreat magnesium substrates, forming a solution that promotes adhesion and corrosion resistance without the toxicity concerns of chromium.

Environmental Impact of Magnesium Nitrate Coatings

The environmental impact of magnesium nitrate coatings is a critical consideration in their application as protective metal coatings. These coatings offer significant benefits in terms of corrosion resistance and durability, but their potential effects on the environment must be carefully evaluated.

Magnesium nitrate, when used in protective coatings, can have both positive and negative environmental implications. On the positive side, these coatings can extend the lifespan of metal structures, reducing the need for frequent replacements and thereby conserving resources. This longevity can lead to a decrease in overall material consumption and waste generation associated with metal infrastructure maintenance.

However, the production and application of magnesium nitrate coatings may have environmental drawbacks. The manufacturing process of magnesium nitrate involves energy-intensive steps and potential chemical emissions. These factors contribute to the carbon footprint of the coating production and may have localized impacts on air and water quality near production facilities.

During the application of magnesium nitrate coatings, volatile organic compounds (VOCs) may be released into the atmosphere. These emissions can contribute to air pollution and potentially affect local ecosystems. Proper application techniques and containment measures are essential to minimize these environmental risks.

The long-term environmental impact of magnesium nitrate coatings also depends on their degradation and disposal. As these coatings wear off over time, particles may enter soil and water systems. The potential effects of these particles on aquatic and terrestrial ecosystems need to be thoroughly investigated to ensure they do not pose significant risks to flora and fauna.

Recycling and disposal of metal structures coated with magnesium nitrate present additional environmental challenges. The presence of the coating may complicate recycling processes, potentially reducing the recyclability of the metal substrate. Proper disposal methods must be developed to prevent the release of harmful substances into the environment during the end-of-life phase of coated products.

Research into more environmentally friendly formulations of magnesium nitrate coatings is ongoing. Efforts are being made to develop water-based alternatives and coatings with lower VOC content. These innovations aim to reduce the environmental impact while maintaining the protective properties of the coatings.

Overall, while magnesium nitrate coatings offer significant benefits in terms of metal protection, their environmental impact must be carefully managed throughout their lifecycle. Balancing the protective advantages with environmental considerations is crucial for the sustainable use of these coatings in various industries.

Magnesium nitrate, when used in protective coatings, can have both positive and negative environmental implications. On the positive side, these coatings can extend the lifespan of metal structures, reducing the need for frequent replacements and thereby conserving resources. This longevity can lead to a decrease in overall material consumption and waste generation associated with metal infrastructure maintenance.

However, the production and application of magnesium nitrate coatings may have environmental drawbacks. The manufacturing process of magnesium nitrate involves energy-intensive steps and potential chemical emissions. These factors contribute to the carbon footprint of the coating production and may have localized impacts on air and water quality near production facilities.

During the application of magnesium nitrate coatings, volatile organic compounds (VOCs) may be released into the atmosphere. These emissions can contribute to air pollution and potentially affect local ecosystems. Proper application techniques and containment measures are essential to minimize these environmental risks.

The long-term environmental impact of magnesium nitrate coatings also depends on their degradation and disposal. As these coatings wear off over time, particles may enter soil and water systems. The potential effects of these particles on aquatic and terrestrial ecosystems need to be thoroughly investigated to ensure they do not pose significant risks to flora and fauna.

Recycling and disposal of metal structures coated with magnesium nitrate present additional environmental challenges. The presence of the coating may complicate recycling processes, potentially reducing the recyclability of the metal substrate. Proper disposal methods must be developed to prevent the release of harmful substances into the environment during the end-of-life phase of coated products.

Research into more environmentally friendly formulations of magnesium nitrate coatings is ongoing. Efforts are being made to develop water-based alternatives and coatings with lower VOC content. These innovations aim to reduce the environmental impact while maintaining the protective properties of the coatings.

Overall, while magnesium nitrate coatings offer significant benefits in terms of metal protection, their environmental impact must be carefully managed throughout their lifecycle. Balancing the protective advantages with environmental considerations is crucial for the sustainable use of these coatings in various industries.

Regulatory Framework for Protective Coatings

The regulatory framework for protective coatings, particularly those incorporating magnesium nitrate, is a complex and evolving landscape. In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the use of chemicals in protective coatings. Under the Toxic Substances Control Act (TSCA), the EPA maintains an inventory of existing chemical substances and requires manufacturers to submit premanufacture notices for new chemical substances.

For protective coatings containing magnesium nitrate, compliance with the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation is essential in the European Union. REACH aims to improve the protection of human health and the environment through better and earlier identification of the intrinsic properties of chemical substances. Manufacturers and importers are required to gather information on the properties of their chemical substances and register the information in a central database.

In addition to chemical regulations, protective coatings must also adhere to various industry standards. The International Organization for Standardization (ISO) has developed several standards relevant to protective coatings, such as ISO 12944, which provides guidelines for corrosion protection of steel structures by protective paint systems. The American Society for Testing and Materials (ASTM) also offers numerous standards for testing and evaluating protective coatings, including ASTM D5894 for cyclic corrosion testing.

Occupational safety regulations also impact the use of protective coatings. The Occupational Safety and Health Administration (OSHA) in the United States sets standards for worker exposure to hazardous chemicals, including those used in protective coatings. Employers must provide appropriate personal protective equipment and ensure proper ventilation when applying these coatings.

Environmental regulations are becoming increasingly stringent, with a focus on reducing volatile organic compounds (VOCs) in coatings. Many jurisdictions have implemented limits on VOC content in protective coatings, driving the development of low-VOC and zero-VOC formulations. The use of magnesium nitrate in protective coatings must be evaluated in light of these environmental considerations.

As the regulatory landscape continues to evolve, manufacturers and users of protective coatings must stay informed of changes and ensure ongoing compliance. This may involve regular product testing, updating safety data sheets, and modifying formulations to meet new requirements. The global nature of the coatings industry also necessitates awareness of international regulations and standards to facilitate trade and ensure product acceptance across different markets.

For protective coatings containing magnesium nitrate, compliance with the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation is essential in the European Union. REACH aims to improve the protection of human health and the environment through better and earlier identification of the intrinsic properties of chemical substances. Manufacturers and importers are required to gather information on the properties of their chemical substances and register the information in a central database.

In addition to chemical regulations, protective coatings must also adhere to various industry standards. The International Organization for Standardization (ISO) has developed several standards relevant to protective coatings, such as ISO 12944, which provides guidelines for corrosion protection of steel structures by protective paint systems. The American Society for Testing and Materials (ASTM) also offers numerous standards for testing and evaluating protective coatings, including ASTM D5894 for cyclic corrosion testing.

Occupational safety regulations also impact the use of protective coatings. The Occupational Safety and Health Administration (OSHA) in the United States sets standards for worker exposure to hazardous chemicals, including those used in protective coatings. Employers must provide appropriate personal protective equipment and ensure proper ventilation when applying these coatings.

Environmental regulations are becoming increasingly stringent, with a focus on reducing volatile organic compounds (VOCs) in coatings. Many jurisdictions have implemented limits on VOC content in protective coatings, driving the development of low-VOC and zero-VOC formulations. The use of magnesium nitrate in protective coatings must be evaluated in light of these environmental considerations.

As the regulatory landscape continues to evolve, manufacturers and users of protective coatings must stay informed of changes and ensure ongoing compliance. This may involve regular product testing, updating safety data sheets, and modifying formulations to meet new requirements. The global nature of the coatings industry also necessitates awareness of international regulations and standards to facilitate trade and ensure product acceptance across different markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!