Nichrome Wire: Expanding Applications in Alternative Energy

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Wire Evolution

Nichrome wire, an alloy primarily composed of nickel and chromium, has undergone significant evolution since its inception in the early 20th century. Initially developed for its high electrical resistance and heat-generating properties, nichrome wire has found extensive applications in heating elements and resistors across various industries.

The evolution of nichrome wire can be traced through several key stages. In its early days, the focus was on refining the composition to achieve optimal electrical and thermal properties. This led to the development of different grades of nichrome, each tailored for specific applications. As manufacturing techniques improved, the production of thinner and more uniform wire became possible, expanding its potential uses.

A significant milestone in nichrome wire evolution came with the advent of precision winding techniques. This allowed for the creation of tightly coiled heating elements, greatly increasing the surface area and heat output of nichrome-based devices. This advancement paved the way for more efficient and compact heating solutions in appliances and industrial equipment.

The integration of nichrome wire into alternative energy applications marks a new phase in its evolution. In solar thermal systems, nichrome wire is being utilized in heat exchangers and thermal storage units, leveraging its excellent heat retention properties. For wind energy, nichrome-based heating elements are employed in de-icing systems for turbine blades, enhancing operational efficiency in cold climates.

Recent developments have focused on enhancing the durability and performance of nichrome wire in extreme environments. This includes the development of protective coatings to resist corrosion and oxidation, extending the lifespan of nichrome components in high-temperature applications. Additionally, research into nano-structured nichrome alloys has shown promise in improving electrical and thermal properties, potentially opening new avenues for energy harvesting and storage.

The evolution of nichrome wire has also been driven by the demand for more energy-efficient solutions. This has led to the exploration of composite materials, combining nichrome with other elements or compounds to create hybrid wires with enhanced characteristics. These innovations are particularly relevant in the context of alternative energy, where efficiency and durability are paramount.

As the alternative energy sector continues to grow, the evolution of nichrome wire is expected to accelerate. Future developments may include smart nichrome-based materials that can adapt their properties based on environmental conditions, further improving energy efficiency and performance in renewable energy systems.

The evolution of nichrome wire can be traced through several key stages. In its early days, the focus was on refining the composition to achieve optimal electrical and thermal properties. This led to the development of different grades of nichrome, each tailored for specific applications. As manufacturing techniques improved, the production of thinner and more uniform wire became possible, expanding its potential uses.

A significant milestone in nichrome wire evolution came with the advent of precision winding techniques. This allowed for the creation of tightly coiled heating elements, greatly increasing the surface area and heat output of nichrome-based devices. This advancement paved the way for more efficient and compact heating solutions in appliances and industrial equipment.

The integration of nichrome wire into alternative energy applications marks a new phase in its evolution. In solar thermal systems, nichrome wire is being utilized in heat exchangers and thermal storage units, leveraging its excellent heat retention properties. For wind energy, nichrome-based heating elements are employed in de-icing systems for turbine blades, enhancing operational efficiency in cold climates.

Recent developments have focused on enhancing the durability and performance of nichrome wire in extreme environments. This includes the development of protective coatings to resist corrosion and oxidation, extending the lifespan of nichrome components in high-temperature applications. Additionally, research into nano-structured nichrome alloys has shown promise in improving electrical and thermal properties, potentially opening new avenues for energy harvesting and storage.

The evolution of nichrome wire has also been driven by the demand for more energy-efficient solutions. This has led to the exploration of composite materials, combining nichrome with other elements or compounds to create hybrid wires with enhanced characteristics. These innovations are particularly relevant in the context of alternative energy, where efficiency and durability are paramount.

As the alternative energy sector continues to grow, the evolution of nichrome wire is expected to accelerate. Future developments may include smart nichrome-based materials that can adapt their properties based on environmental conditions, further improving energy efficiency and performance in renewable energy systems.

Alternative Energy Demand

The demand for alternative energy sources has been steadily increasing in recent years, driven by growing environmental concerns, the need for energy security, and the push for sustainable development. This trend has created a significant market opportunity for technologies that can support the expansion of renewable energy systems. Nichrome wire, known for its high resistance and heat-generating properties, is finding new applications in this burgeoning sector.

In the solar energy market, which is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, nichrome wire is being explored for use in solar thermal collectors. These systems require efficient heat transfer mechanisms, and nichrome wire's ability to generate consistent heat makes it a promising component in improving the overall efficiency of solar thermal systems.

Wind energy, another rapidly expanding sector, is also presenting opportunities for nichrome wire applications. As wind turbines grow larger and more powerful, there is an increasing need for de-icing systems to prevent ice buildup on turbine blades. Nichrome wire-based heating elements are being developed to address this challenge, potentially extending the operational range of wind farms into colder climates.

The geothermal energy sector, while smaller than solar and wind, is showing steady growth. Here, nichrome wire is finding applications in geothermal heat pumps, where its heat-generating properties can be utilized to enhance the efficiency of heat exchange processes. This could lead to more widespread adoption of geothermal systems in residential and commercial settings.

In the emerging field of ocean thermal energy conversion (OTEC), nichrome wire is being investigated for use in heat exchangers. OTEC systems rely on temperature differences between surface and deep ocean waters to generate electricity, and efficient heat transfer is crucial to their operation. Nichrome wire's properties make it a candidate for improving the performance of these systems.

The hydrogen economy, often considered a key component of future energy systems, also presents opportunities for nichrome wire. In electrolysis processes used to produce hydrogen, nichrome wire could be employed in heating elements to maintain optimal operating temperatures, potentially increasing the efficiency of hydrogen production.

As the alternative energy sector continues to evolve, the demand for materials that can withstand high temperatures and provide precise heat control is likely to grow. Nichrome wire, with its unique properties, is well-positioned to meet these needs across various alternative energy applications, contributing to the overall growth and efficiency of the renewable energy market.

In the solar energy market, which is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, nichrome wire is being explored for use in solar thermal collectors. These systems require efficient heat transfer mechanisms, and nichrome wire's ability to generate consistent heat makes it a promising component in improving the overall efficiency of solar thermal systems.

Wind energy, another rapidly expanding sector, is also presenting opportunities for nichrome wire applications. As wind turbines grow larger and more powerful, there is an increasing need for de-icing systems to prevent ice buildup on turbine blades. Nichrome wire-based heating elements are being developed to address this challenge, potentially extending the operational range of wind farms into colder climates.

The geothermal energy sector, while smaller than solar and wind, is showing steady growth. Here, nichrome wire is finding applications in geothermal heat pumps, where its heat-generating properties can be utilized to enhance the efficiency of heat exchange processes. This could lead to more widespread adoption of geothermal systems in residential and commercial settings.

In the emerging field of ocean thermal energy conversion (OTEC), nichrome wire is being investigated for use in heat exchangers. OTEC systems rely on temperature differences between surface and deep ocean waters to generate electricity, and efficient heat transfer is crucial to their operation. Nichrome wire's properties make it a candidate for improving the performance of these systems.

The hydrogen economy, often considered a key component of future energy systems, also presents opportunities for nichrome wire. In electrolysis processes used to produce hydrogen, nichrome wire could be employed in heating elements to maintain optimal operating temperatures, potentially increasing the efficiency of hydrogen production.

As the alternative energy sector continues to evolve, the demand for materials that can withstand high temperatures and provide precise heat control is likely to grow. Nichrome wire, with its unique properties, is well-positioned to meet these needs across various alternative energy applications, contributing to the overall growth and efficiency of the renewable energy market.

Nichrome Challenges

Despite its widespread use in various applications, Nichrome wire faces several challenges when expanding its applications in alternative energy sectors. One of the primary issues is the material's limited temperature resistance. While Nichrome can withstand high temperatures, it begins to degrade and lose its desirable properties at extremely elevated temperatures, which are often encountered in certain alternative energy systems such as concentrated solar power plants or high-temperature fuel cells.

Another significant challenge is the wire's susceptibility to oxidation, especially at high temperatures. This oxidation can lead to a decrease in electrical conductivity and thermal efficiency over time, potentially reducing the lifespan and performance of energy systems utilizing Nichrome wire. The oxidation process can also result in the formation of a brittle oxide layer, which may compromise the structural integrity of the wire in long-term applications.

Corrosion resistance is another area of concern, particularly in environments with aggressive chemicals or high humidity. While Nichrome generally exhibits good corrosion resistance, certain alternative energy applications may expose the wire to corrosive substances that can accelerate degradation and failure. This limitation necessitates careful consideration of the operating environment and potential protective measures.

The relatively high cost of Nichrome wire, compared to some alternative materials, poses an economic challenge for large-scale implementation in alternative energy projects. As the demand for renewable energy solutions grows, cost-effectiveness becomes increasingly crucial, and the expense associated with Nichrome wire may limit its adoption in certain applications where cheaper alternatives are available.

Manufacturability and scalability present additional hurdles. While Nichrome wire production is well-established, creating complex geometries or large-scale structures for specific alternative energy applications may require advanced manufacturing techniques. This can increase production costs and complexity, potentially limiting the wire's use in certain innovative energy systems.

Lastly, the environmental impact of Nichrome wire production and disposal must be considered. As the world moves towards more sustainable practices, the energy-intensive manufacturing process of Nichrome and the potential for nickel and chromium contamination during disposal raise concerns about its long-term environmental sustainability in alternative energy applications.

Addressing these challenges will be crucial for expanding the use of Nichrome wire in alternative energy systems. Research into improved alloy compositions, surface treatments, and manufacturing processes may help overcome some of these limitations and unlock new possibilities for Nichrome in the renewable energy sector.

Another significant challenge is the wire's susceptibility to oxidation, especially at high temperatures. This oxidation can lead to a decrease in electrical conductivity and thermal efficiency over time, potentially reducing the lifespan and performance of energy systems utilizing Nichrome wire. The oxidation process can also result in the formation of a brittle oxide layer, which may compromise the structural integrity of the wire in long-term applications.

Corrosion resistance is another area of concern, particularly in environments with aggressive chemicals or high humidity. While Nichrome generally exhibits good corrosion resistance, certain alternative energy applications may expose the wire to corrosive substances that can accelerate degradation and failure. This limitation necessitates careful consideration of the operating environment and potential protective measures.

The relatively high cost of Nichrome wire, compared to some alternative materials, poses an economic challenge for large-scale implementation in alternative energy projects. As the demand for renewable energy solutions grows, cost-effectiveness becomes increasingly crucial, and the expense associated with Nichrome wire may limit its adoption in certain applications where cheaper alternatives are available.

Manufacturability and scalability present additional hurdles. While Nichrome wire production is well-established, creating complex geometries or large-scale structures for specific alternative energy applications may require advanced manufacturing techniques. This can increase production costs and complexity, potentially limiting the wire's use in certain innovative energy systems.

Lastly, the environmental impact of Nichrome wire production and disposal must be considered. As the world moves towards more sustainable practices, the energy-intensive manufacturing process of Nichrome and the potential for nickel and chromium contamination during disposal raise concerns about its long-term environmental sustainability in alternative energy applications.

Addressing these challenges will be crucial for expanding the use of Nichrome wire in alternative energy systems. Research into improved alloy compositions, surface treatments, and manufacturing processes may help overcome some of these limitations and unlock new possibilities for Nichrome in the renewable energy sector.

Current Nichrome Apps

01 Composition and properties of nichrome wire

Nichrome wire is an alloy primarily composed of nickel and chromium. It is known for its high electrical resistance and heat resistance, making it suitable for various applications in heating elements and electrical devices. The specific composition and properties of nichrome wire can be tailored to meet different requirements for temperature resistance and electrical conductivity.- Composition and properties of nichrome wire: Nichrome wire is an alloy primarily composed of nickel and chromium. It is known for its high electrical resistance and excellent heat resistance, making it suitable for various heating applications. The specific composition and properties of nichrome wire can be tailored to meet different requirements in terms of resistivity, temperature coefficient, and mechanical strength.

- Applications in heating elements: Nichrome wire is widely used in the manufacturing of heating elements for various devices and appliances. Its high resistance to oxidation at elevated temperatures makes it ideal for use in electric heaters, toasters, hair dryers, and other heating appliances. The wire can be formed into different shapes and configurations to suit specific heating requirements.

- Use in sensors and measurement devices: Nichrome wire finds applications in sensors and measurement devices due to its stable electrical properties and temperature coefficient. It is used in thermocouples, resistance thermometers, and other temperature sensing applications. The wire's predictable resistance change with temperature makes it suitable for precise temperature measurements in various industrial and scientific settings.

- Coating and surface treatment of nichrome wire: Various coating and surface treatment techniques are applied to nichrome wire to enhance its properties or provide additional functionality. These treatments can improve corrosion resistance, reduce oxidation, or modify the wire's electrical characteristics. Coatings may include ceramic materials, precious metals, or other alloys, depending on the specific application requirements.

- Manufacturing processes and quality control: The production of nichrome wire involves specific manufacturing processes to ensure consistent quality and properties. These processes may include precise alloying, wire drawing, annealing, and quality control measures. Advanced manufacturing techniques and equipment are employed to produce nichrome wire with uniform composition, dimensions, and electrical characteristics across its length.

02 Applications in heating elements

Nichrome wire is widely used in the manufacturing of heating elements for various appliances and industrial equipment. Its high resistance to heat and oxidation makes it ideal for electric heaters, toasters, hair dryers, and other devices that require controlled heating. The wire can be formed into coils or other shapes to create efficient heating elements with precise temperature control.Expand Specific Solutions03 Use in sensors and measurement devices

Nichrome wire finds applications in sensors and measurement devices due to its stable electrical properties and temperature coefficient. It is used in thermocouples, strain gauges, and other instruments for measuring temperature, pressure, and other physical parameters. The wire's resistance changes predictably with temperature, making it useful for accurate sensing and measurement applications.Expand Specific Solutions04 Fabrication techniques for nichrome wire

Various fabrication techniques are employed to produce nichrome wire with specific characteristics. These may include drawing, annealing, and surface treatments to achieve desired diameter, resistivity, and surface properties. Advanced manufacturing processes can create ultra-thin or specially shaped nichrome wires for specific applications in microelectronics or specialized heating elements.Expand Specific Solutions05 Innovations in nichrome wire technology

Ongoing research and development in nichrome wire technology focus on improving its performance and expanding its applications. This includes developing new alloy compositions, enhancing durability and lifespan, and creating composite materials incorporating nichrome wire. Innovations also explore the use of nichrome wire in emerging fields such as flexible electronics and advanced thermal management systems.Expand Specific Solutions

Key Nichrome Players

The expanding applications of Nichrome Wire in alternative energy are driving a competitive landscape characterized by rapid growth and technological innovation. The market is in an early growth stage, with increasing demand for efficient heating elements in renewable energy systems. While the market size is expanding, it remains relatively niche compared to broader energy sectors. Technologically, companies like SANYO Electric, LG Energy Solution, and Toyota Motor Corp. are at the forefront, developing advanced applications for Nichrome Wire in solar panels, wind turbines, and energy storage systems. The technology's maturity varies across applications, with established uses in traditional heating elements evolving alongside emerging applications in cutting-edge alternative energy solutions.

Heraeus Precious Metals GmbH & Co. KG (New)

Technical Solution: Heraeus has developed advanced nichrome wire applications for alternative energy systems, particularly in solar and wind power. Their innovative approach involves using high-purity nichrome alloys with optimized compositions to enhance durability and performance in harsh environments. The company has created specialized coatings for nichrome wires that significantly improve corrosion resistance and electrical conductivity, crucial for long-term operation in renewable energy installations[1]. Heraeus has also pioneered the use of nano-structured nichrome wires, which offer increased surface area and improved heat transfer capabilities, enhancing the efficiency of thermal energy conversion in solar thermal plants[3].

Strengths: Superior material quality, advanced coating technology, and expertise in nano-structuring. Weaknesses: Higher production costs compared to standard nichrome wires, potentially limiting widespread adoption in cost-sensitive markets.

Raytheon Co.

Technical Solution: Raytheon has leveraged its aerospace expertise to develop nichrome wire applications for alternative energy, focusing on high-temperature sensors and control systems for renewable energy plants. The company has engineered precision nichrome wire elements that can withstand extreme temperatures and maintain accuracy in harsh operating conditions, crucial for optimizing energy production in solar thermal and geothermal power plants[2]. Raytheon's nichrome-based sensors incorporate advanced signal processing algorithms to provide real-time data on system performance and environmental conditions, enabling more efficient energy generation and distribution[4].

Strengths: High-precision engineering, integration with advanced control systems, and proven reliability in extreme environments. Weaknesses: Limited focus on mass-market applications, potentially restricting growth in consumer-oriented renewable energy sectors.

Nichrome Innovations

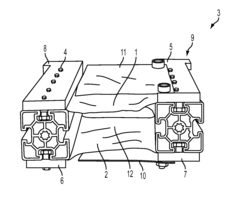

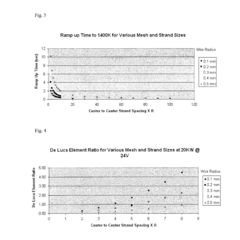

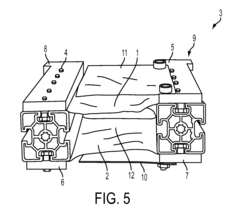

Wire mesh thermal radiative element and use in a radiative oven

PatentInactiveUS20150184867A1

Innovation

- A resistive mesh element with a calibrated De Luca Element Ratio, using nichrome wire with a specific strand diameter and spacing, operates at 24V to achieve efficient heat distribution and rapid temperature rise, allowing for quick cooking times while being cost-effective and easy to assemble.

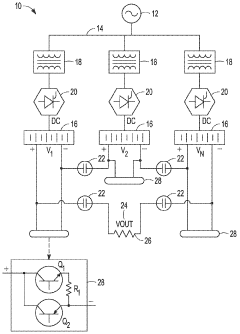

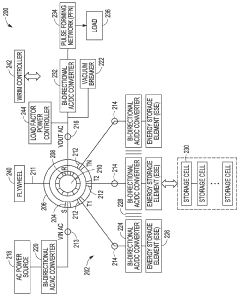

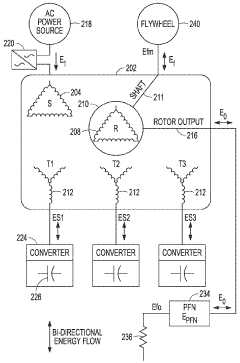

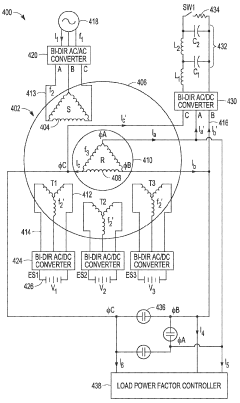

Energy storage power source using a wound-rotor induction machine (WRIM) to charge and discharge energy storage elements (ESES)

PatentWO2023122084A1

Innovation

- A wound-rotor induction machine (WRIM) is used to receive energy from an external source, store it in energy storage elements, and discharge it to deliver high-level AC and DC output voltages, utilizing tertiary windings and bi-directional AC/DC converters to manage energy transfer efficiently and safely.

Environmental Impact

The environmental impact of expanding applications of Nichrome wire in alternative energy is a critical consideration that requires thorough analysis. Nichrome wire, primarily composed of nickel and chromium, offers excellent heat resistance and electrical conductivity, making it increasingly attractive for various alternative energy applications. However, its widespread adoption raises concerns about potential environmental consequences throughout its lifecycle.

The production of Nichrome wire involves mining and processing nickel and chromium, which can lead to significant environmental disturbances. Open-pit mining, often used for nickel extraction, can result in habitat destruction, soil erosion, and water pollution. Chromium mining and processing also pose risks of contamination, particularly if proper safeguards are not in place. These activities contribute to increased carbon emissions and energy consumption, potentially offsetting some of the environmental benefits gained from alternative energy applications.

During the use phase, Nichrome wire's durability and resistance to corrosion contribute to extended product lifespans, reducing the need for frequent replacements and associated environmental impacts. Its high efficiency in energy transfer also minimizes energy losses, potentially leading to reduced overall energy consumption in alternative energy systems. However, the increased demand for Nichrome wire in expanding applications may lead to intensified mining activities, exacerbating associated environmental issues.

End-of-life considerations for Nichrome wire present both challenges and opportunities. While the material is recyclable, the separation of nickel and chromium can be energy-intensive and may involve chemical processes with potential environmental risks. Improper disposal of Nichrome wire can lead to soil and water contamination, as both nickel and chromium can be toxic to ecosystems in high concentrations. Developing efficient recycling technologies and implementing robust waste management strategies are crucial to mitigating these risks.

The net environmental impact of expanding Nichrome wire applications in alternative energy depends on the balance between its benefits in improving energy efficiency and its lifecycle environmental costs. Advancements in cleaner production methods, such as using renewable energy in manufacturing processes and developing more environmentally friendly mining techniques, could significantly reduce the negative impacts. Additionally, innovations in recycling technologies and the establishment of circular economy principles for Nichrome wire could further enhance its environmental profile.

As the demand for alternative energy solutions grows, it is imperative to conduct comprehensive life cycle assessments of Nichrome wire applications. These assessments should consider not only the immediate environmental benefits of improved energy efficiency but also the long-term impacts on ecosystems, resource depletion, and global climate change. Balancing these factors will be crucial in determining the true sustainability of expanding Nichrome wire applications in the alternative energy sector.

The production of Nichrome wire involves mining and processing nickel and chromium, which can lead to significant environmental disturbances. Open-pit mining, often used for nickel extraction, can result in habitat destruction, soil erosion, and water pollution. Chromium mining and processing also pose risks of contamination, particularly if proper safeguards are not in place. These activities contribute to increased carbon emissions and energy consumption, potentially offsetting some of the environmental benefits gained from alternative energy applications.

During the use phase, Nichrome wire's durability and resistance to corrosion contribute to extended product lifespans, reducing the need for frequent replacements and associated environmental impacts. Its high efficiency in energy transfer also minimizes energy losses, potentially leading to reduced overall energy consumption in alternative energy systems. However, the increased demand for Nichrome wire in expanding applications may lead to intensified mining activities, exacerbating associated environmental issues.

End-of-life considerations for Nichrome wire present both challenges and opportunities. While the material is recyclable, the separation of nickel and chromium can be energy-intensive and may involve chemical processes with potential environmental risks. Improper disposal of Nichrome wire can lead to soil and water contamination, as both nickel and chromium can be toxic to ecosystems in high concentrations. Developing efficient recycling technologies and implementing robust waste management strategies are crucial to mitigating these risks.

The net environmental impact of expanding Nichrome wire applications in alternative energy depends on the balance between its benefits in improving energy efficiency and its lifecycle environmental costs. Advancements in cleaner production methods, such as using renewable energy in manufacturing processes and developing more environmentally friendly mining techniques, could significantly reduce the negative impacts. Additionally, innovations in recycling technologies and the establishment of circular economy principles for Nichrome wire could further enhance its environmental profile.

As the demand for alternative energy solutions grows, it is imperative to conduct comprehensive life cycle assessments of Nichrome wire applications. These assessments should consider not only the immediate environmental benefits of improved energy efficiency but also the long-term impacts on ecosystems, resource depletion, and global climate change. Balancing these factors will be crucial in determining the true sustainability of expanding Nichrome wire applications in the alternative energy sector.

Nichrome Supply Chain

The Nichrome supply chain plays a crucial role in the expanding applications of Nichrome wire in alternative energy. This supply chain encompasses the entire process from raw material extraction to the final delivery of Nichrome wire products to end-users in the alternative energy sector.

The primary components of Nichrome, nickel and chromium, are sourced from various global locations. Nickel is predominantly mined in countries such as Indonesia, the Philippines, and Russia, while chromium is primarily extracted from South Africa, Kazakhstan, and India. The global distribution of these raw materials necessitates a complex logistics network to ensure a steady supply to Nichrome wire manufacturers.

Once the raw materials are procured, they undergo refining processes to achieve the required purity levels. The refined metals are then alloyed in precise proportions to create Nichrome. This alloying process is typically carried out by specialized metallurgical companies that possess the necessary expertise and equipment to produce high-quality Nichrome alloy.

The Nichrome alloy is subsequently drawn into wire form through a series of manufacturing steps. These steps include hot rolling, cold drawing, and heat treatment processes to achieve the desired physical and electrical properties. The manufacturing of Nichrome wire requires specialized equipment and skilled labor, which are often concentrated in specific regions with a strong industrial base.

Quality control is a critical aspect of the Nichrome supply chain, particularly for applications in alternative energy. Rigorous testing and inspection procedures are implemented at various stages of production to ensure that the wire meets the stringent specifications required for its intended use. This includes testing for electrical resistance, tensile strength, and corrosion resistance.

Distribution networks play a vital role in delivering Nichrome wire to manufacturers of alternative energy systems. These networks often involve multiple intermediaries, including wholesalers and specialized distributors who cater to specific industries. The increasing demand for Nichrome wire in alternative energy applications has led to the development of more efficient and responsive supply chain strategies.

The Nichrome supply chain is subject to various external factors that can impact its efficiency and reliability. These include fluctuations in raw material prices, geopolitical tensions affecting mining regions, and changes in global trade policies. As a result, companies involved in the Nichrome supply chain must continuously adapt their strategies to mitigate risks and ensure a stable supply to meet the growing demands of the alternative energy sector.

The primary components of Nichrome, nickel and chromium, are sourced from various global locations. Nickel is predominantly mined in countries such as Indonesia, the Philippines, and Russia, while chromium is primarily extracted from South Africa, Kazakhstan, and India. The global distribution of these raw materials necessitates a complex logistics network to ensure a steady supply to Nichrome wire manufacturers.

Once the raw materials are procured, they undergo refining processes to achieve the required purity levels. The refined metals are then alloyed in precise proportions to create Nichrome. This alloying process is typically carried out by specialized metallurgical companies that possess the necessary expertise and equipment to produce high-quality Nichrome alloy.

The Nichrome alloy is subsequently drawn into wire form through a series of manufacturing steps. These steps include hot rolling, cold drawing, and heat treatment processes to achieve the desired physical and electrical properties. The manufacturing of Nichrome wire requires specialized equipment and skilled labor, which are often concentrated in specific regions with a strong industrial base.

Quality control is a critical aspect of the Nichrome supply chain, particularly for applications in alternative energy. Rigorous testing and inspection procedures are implemented at various stages of production to ensure that the wire meets the stringent specifications required for its intended use. This includes testing for electrical resistance, tensile strength, and corrosion resistance.

Distribution networks play a vital role in delivering Nichrome wire to manufacturers of alternative energy systems. These networks often involve multiple intermediaries, including wholesalers and specialized distributors who cater to specific industries. The increasing demand for Nichrome wire in alternative energy applications has led to the development of more efficient and responsive supply chain strategies.

The Nichrome supply chain is subject to various external factors that can impact its efficiency and reliability. These include fluctuations in raw material prices, geopolitical tensions affecting mining regions, and changes in global trade policies. As a result, companies involved in the Nichrome supply chain must continuously adapt their strategies to mitigate risks and ensure a stable supply to meet the growing demands of the alternative energy sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!