Exploring Cross-Industry Collaborations for HEV Breakthroughs

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEV Technology Evolution and Objectives

Hybrid Electric Vehicles (HEVs) have undergone significant evolution since their inception in the late 20th century. The technology has progressed from simple parallel hybrid systems to more complex power-split and series-parallel architectures. This evolution has been driven by the dual objectives of improving fuel efficiency and reducing emissions while maintaining or enhancing vehicle performance.

The primary goal of HEV technology development has been to optimize the integration of internal combustion engines with electric propulsion systems. This involves sophisticated energy management strategies, advanced battery technologies, and intelligent control systems. Over time, the focus has shifted towards increasing the electric-only driving range and improving overall system efficiency.

A key milestone in HEV evolution was the introduction of plug-in hybrid electric vehicles (PHEVs), which allowed for extended electric-only operation and grid charging capabilities. This development marked a significant step towards full electrification and bridged the gap between conventional hybrids and pure electric vehicles.

The objectives of current HEV technology development are multifaceted. Firstly, there is a push towards higher voltage systems, typically 48V or above, to enable more powerful electric motors and greater energy recuperation. Secondly, the industry aims to enhance battery technology, focusing on energy density, charging speed, and longevity. Thirdly, there is a growing emphasis on lightweight materials and aerodynamic designs to further improve efficiency.

Another critical objective is the development of more advanced and integrated powertrains. This includes the optimization of engine-motor coupling, transmission systems, and thermal management. The goal is to create seamless power delivery while maximizing energy efficiency across various driving conditions.

Looking ahead, the HEV technology roadmap is increasingly aligned with broader automotive trends such as connectivity, autonomy, and shared mobility. Future objectives include the integration of HEV systems with vehicle-to-grid (V2G) technology, enabling bidirectional energy flow and supporting smart grid initiatives. Additionally, there is a growing focus on developing modular HEV platforms that can be easily adapted across different vehicle segments and markets.

Cross-industry collaboration has become crucial in achieving these objectives. Partnerships between automotive manufacturers, technology companies, and energy providers are driving innovation in areas such as battery chemistry, power electronics, and smart charging infrastructure. These collaborations are essential for overcoming technical challenges and accelerating the adoption of advanced HEV technologies.

The primary goal of HEV technology development has been to optimize the integration of internal combustion engines with electric propulsion systems. This involves sophisticated energy management strategies, advanced battery technologies, and intelligent control systems. Over time, the focus has shifted towards increasing the electric-only driving range and improving overall system efficiency.

A key milestone in HEV evolution was the introduction of plug-in hybrid electric vehicles (PHEVs), which allowed for extended electric-only operation and grid charging capabilities. This development marked a significant step towards full electrification and bridged the gap between conventional hybrids and pure electric vehicles.

The objectives of current HEV technology development are multifaceted. Firstly, there is a push towards higher voltage systems, typically 48V or above, to enable more powerful electric motors and greater energy recuperation. Secondly, the industry aims to enhance battery technology, focusing on energy density, charging speed, and longevity. Thirdly, there is a growing emphasis on lightweight materials and aerodynamic designs to further improve efficiency.

Another critical objective is the development of more advanced and integrated powertrains. This includes the optimization of engine-motor coupling, transmission systems, and thermal management. The goal is to create seamless power delivery while maximizing energy efficiency across various driving conditions.

Looking ahead, the HEV technology roadmap is increasingly aligned with broader automotive trends such as connectivity, autonomy, and shared mobility. Future objectives include the integration of HEV systems with vehicle-to-grid (V2G) technology, enabling bidirectional energy flow and supporting smart grid initiatives. Additionally, there is a growing focus on developing modular HEV platforms that can be easily adapted across different vehicle segments and markets.

Cross-industry collaboration has become crucial in achieving these objectives. Partnerships between automotive manufacturers, technology companies, and energy providers are driving innovation in areas such as battery chemistry, power electronics, and smart charging infrastructure. These collaborations are essential for overcoming technical challenges and accelerating the adoption of advanced HEV technologies.

Market Demand Analysis for HEVs

The market demand for Hybrid Electric Vehicles (HEVs) has been steadily growing over the past decade, driven by increasing environmental concerns, stricter emissions regulations, and rising fuel costs. This trend is expected to continue, with the global HEV market projected to expand significantly in the coming years.

Consumer awareness and acceptance of HEV technology have improved substantially, leading to a broader adoption across various vehicle segments. Initially limited to compact cars, HEVs are now available in a wide range of vehicle types, including SUVs, luxury sedans, and even sports cars. This diversification has opened up new market opportunities and expanded the potential customer base for HEV manufacturers.

Government incentives and policies have played a crucial role in stimulating HEV demand. Many countries have implemented tax breaks, subsidies, and other financial incentives to encourage the purchase of hybrid vehicles. Additionally, stricter emissions standards and fuel economy regulations have pushed automakers to invest more heavily in HEV technology, further driving market growth.

The corporate fleet sector has emerged as a significant driver of HEV demand. Companies are increasingly adopting hybrid vehicles to reduce their carbon footprint and operating costs. This trend is particularly evident in industries with large vehicle fleets, such as taxi services, delivery companies, and car rental agencies.

Technological advancements in HEV powertrains have led to improved performance, efficiency, and reliability. These improvements have addressed many of the early concerns about hybrid technology, such as limited range and power output. As a result, consumer confidence in HEVs has grown, contributing to increased market demand.

The rising cost of fossil fuels and growing awareness of their environmental impact have made HEVs an attractive option for cost-conscious and environmentally-conscious consumers. The long-term cost savings associated with improved fuel efficiency have become a key selling point for HEVs, particularly in regions with high fuel prices.

Market research indicates that the Asia-Pacific region, particularly countries like Japan and China, is expected to lead HEV market growth. However, North America and Europe also show strong potential for increased HEV adoption, driven by a combination of consumer preferences and regulatory pressures.

Despite the positive outlook, challenges remain in the HEV market. The higher upfront cost of hybrid vehicles compared to conventional internal combustion engine vehicles continues to be a barrier for some consumers. Additionally, the growing popularity of fully electric vehicles (EVs) may impact future HEV demand, as some consumers may opt for EVs as battery technology improves and charging infrastructure expands.

Consumer awareness and acceptance of HEV technology have improved substantially, leading to a broader adoption across various vehicle segments. Initially limited to compact cars, HEVs are now available in a wide range of vehicle types, including SUVs, luxury sedans, and even sports cars. This diversification has opened up new market opportunities and expanded the potential customer base for HEV manufacturers.

Government incentives and policies have played a crucial role in stimulating HEV demand. Many countries have implemented tax breaks, subsidies, and other financial incentives to encourage the purchase of hybrid vehicles. Additionally, stricter emissions standards and fuel economy regulations have pushed automakers to invest more heavily in HEV technology, further driving market growth.

The corporate fleet sector has emerged as a significant driver of HEV demand. Companies are increasingly adopting hybrid vehicles to reduce their carbon footprint and operating costs. This trend is particularly evident in industries with large vehicle fleets, such as taxi services, delivery companies, and car rental agencies.

Technological advancements in HEV powertrains have led to improved performance, efficiency, and reliability. These improvements have addressed many of the early concerns about hybrid technology, such as limited range and power output. As a result, consumer confidence in HEVs has grown, contributing to increased market demand.

The rising cost of fossil fuels and growing awareness of their environmental impact have made HEVs an attractive option for cost-conscious and environmentally-conscious consumers. The long-term cost savings associated with improved fuel efficiency have become a key selling point for HEVs, particularly in regions with high fuel prices.

Market research indicates that the Asia-Pacific region, particularly countries like Japan and China, is expected to lead HEV market growth. However, North America and Europe also show strong potential for increased HEV adoption, driven by a combination of consumer preferences and regulatory pressures.

Despite the positive outlook, challenges remain in the HEV market. The higher upfront cost of hybrid vehicles compared to conventional internal combustion engine vehicles continues to be a barrier for some consumers. Additionally, the growing popularity of fully electric vehicles (EVs) may impact future HEV demand, as some consumers may opt for EVs as battery technology improves and charging infrastructure expands.

HEV Technical Challenges and Constraints

The development of Hybrid Electric Vehicles (HEVs) faces several significant technical challenges and constraints that require innovative solutions and cross-industry collaborations. One of the primary hurdles is the optimization of energy management systems to effectively balance power distribution between the internal combustion engine and electric motor. This complex task involves real-time decision-making algorithms that must adapt to various driving conditions and user preferences while maximizing fuel efficiency and minimizing emissions.

Battery technology remains a critical constraint in HEV advancement. Current lithium-ion batteries, while improved, still face limitations in energy density, charging speed, and longevity. The search for alternative battery chemistries and improved cell designs continues, with a focus on increasing power output and reducing costs. Additionally, thermal management of battery packs poses a significant challenge, particularly in extreme weather conditions, affecting both performance and safety.

The integration of power electronics and control systems presents another set of technical challenges. Developing robust, efficient, and compact power converters and inverters that can handle high voltages and currents while maintaining reliability under various operating conditions is crucial. Moreover, the complexity of control systems increases with the need for seamless transitions between power sources and regenerative braking optimization.

Weight reduction and packaging constraints continue to challenge HEV designers. The addition of electric components, including batteries and motors, increases vehicle weight, which can negatively impact fuel efficiency and performance. Engineers must find innovative ways to integrate these components within existing vehicle architectures without compromising safety, comfort, or design aesthetics.

Durability and reliability of HEV components under diverse operating conditions remain ongoing concerns. The increased complexity of HEV systems compared to conventional vehicles necessitates rigorous testing and validation processes to ensure long-term reliability and customer satisfaction. This includes addressing issues such as battery degradation over time and the longevity of electric motors and power electronics in harsh environments.

Manufacturing scalability and cost reduction present significant constraints to widespread HEV adoption. Current production processes for specialized HEV components are often complex and expensive, limiting the ability to achieve economies of scale. Innovations in manufacturing techniques and materials are needed to reduce costs and increase production efficiency without compromising quality or performance.

Lastly, the development of standardized charging infrastructure for plug-in hybrid electric vehicles (PHEVs) remains a challenge. The lack of a unified charging standard and limited availability of charging stations in many regions hinder the adoption of PHEVs, which offer extended electric-only driving ranges compared to traditional HEVs.

Battery technology remains a critical constraint in HEV advancement. Current lithium-ion batteries, while improved, still face limitations in energy density, charging speed, and longevity. The search for alternative battery chemistries and improved cell designs continues, with a focus on increasing power output and reducing costs. Additionally, thermal management of battery packs poses a significant challenge, particularly in extreme weather conditions, affecting both performance and safety.

The integration of power electronics and control systems presents another set of technical challenges. Developing robust, efficient, and compact power converters and inverters that can handle high voltages and currents while maintaining reliability under various operating conditions is crucial. Moreover, the complexity of control systems increases with the need for seamless transitions between power sources and regenerative braking optimization.

Weight reduction and packaging constraints continue to challenge HEV designers. The addition of electric components, including batteries and motors, increases vehicle weight, which can negatively impact fuel efficiency and performance. Engineers must find innovative ways to integrate these components within existing vehicle architectures without compromising safety, comfort, or design aesthetics.

Durability and reliability of HEV components under diverse operating conditions remain ongoing concerns. The increased complexity of HEV systems compared to conventional vehicles necessitates rigorous testing and validation processes to ensure long-term reliability and customer satisfaction. This includes addressing issues such as battery degradation over time and the longevity of electric motors and power electronics in harsh environments.

Manufacturing scalability and cost reduction present significant constraints to widespread HEV adoption. Current production processes for specialized HEV components are often complex and expensive, limiting the ability to achieve economies of scale. Innovations in manufacturing techniques and materials are needed to reduce costs and increase production efficiency without compromising quality or performance.

Lastly, the development of standardized charging infrastructure for plug-in hybrid electric vehicles (PHEVs) remains a challenge. The lack of a unified charging standard and limited availability of charging stations in many regions hinder the adoption of PHEVs, which offer extended electric-only driving ranges compared to traditional HEVs.

Current HEV Technological Solutions

01 Thermal management systems for HEVs

Hybrid Electric Vehicles (HEVs) require efficient thermal management systems to regulate the temperature of various components, including batteries, electric motors, and power electronics. These systems often incorporate cooling circuits, heat exchangers, and advanced control strategies to optimize performance and extend the lifespan of critical components.- Thermal management systems for HEVs: Hybrid Electric Vehicles (HEVs) require efficient thermal management systems to regulate the temperature of various components, including batteries, electric motors, and power electronics. These systems often incorporate cooling circuits, heat exchangers, and temperature sensors to maintain optimal operating conditions and improve overall vehicle performance.

- Power distribution and control in HEVs: HEVs utilize sophisticated power distribution and control systems to manage the flow of energy between the internal combustion engine, electric motor(s), and battery pack. These systems optimize power usage, improve fuel efficiency, and enhance vehicle performance through intelligent control algorithms and power electronics.

- Battery management and charging systems for HEVs: Effective battery management and charging systems are crucial for HEVs to maximize battery life, performance, and safety. These systems monitor battery state of charge, temperature, and health, while also controlling charging processes and implementing regenerative braking to recover energy during deceleration.

- Hybrid powertrain configurations: HEVs employ various powertrain configurations to combine internal combustion engines with electric motors. These configurations include series, parallel, and power-split hybrid systems, each offering different advantages in terms of efficiency, performance, and complexity. The choice of configuration depends on the vehicle's intended use and design goals.

- HEV safety and diagnostics: Safety systems and diagnostic tools are essential for HEVs to ensure proper operation and protect occupants. These include high-voltage isolation monitoring, fault detection algorithms, and advanced driver assistance systems tailored for hybrid powertrains. Diagnostic systems help identify and address potential issues in the complex hybrid drivetrain.

02 Power distribution and control in HEVs

HEVs utilize sophisticated power distribution and control systems to manage the flow of energy between the internal combustion engine, electric motor(s), and battery pack. These systems optimize fuel efficiency, performance, and emissions by intelligently switching between power sources and managing regenerative braking.Expand Specific Solutions03 Battery technologies for HEVs

Advanced battery technologies are crucial for HEVs, focusing on improving energy density, charging efficiency, and longevity. Innovations in battery chemistry, cell design, and battery management systems contribute to enhanced vehicle range and overall performance.Expand Specific Solutions04 Lightweight materials and aerodynamic design for HEVs

HEV manufacturers employ lightweight materials and aerodynamic designs to improve fuel efficiency and extend electric range. This includes the use of advanced composites, high-strength steels, and optimized body shapes to reduce drag and overall vehicle weight.Expand Specific Solutions05 Integration of renewable energy sources in HEV charging

Innovative approaches to integrate renewable energy sources, such as solar panels or wind turbines, into HEV charging infrastructure are being developed. These systems aim to reduce the carbon footprint of HEVs by utilizing clean energy for battery charging, both on-board and at charging stations.Expand Specific Solutions

Key Players in HEV Industry

The competitive landscape for "Exploring Cross-Industry Collaborations for HEV Breakthroughs" is characterized by a diverse mix of established automotive manufacturers, emerging electric vehicle companies, and research institutions. The industry is in a transitional phase, with significant market growth potential as hybrid electric vehicles (HEVs) gain traction. Major players like Ford, GM, Hyundai, and BYD are investing heavily in HEV technology, while newer entrants such as Chery and Geely are rapidly advancing their capabilities. The technology is maturing, with companies like Toyota leading in HEV commercialization, but there's still room for innovation through cross-industry partnerships, particularly in areas like battery technology, power electronics, and lightweight materials.

BYD Co., Ltd.

Technical Solution: BYD has developed a revolutionary Dual Mode (DM) technology for HEVs, which combines plug-in hybrid and pure electric modes. Their DM-i super hybrid system integrates a high-efficiency engine, an EHS electronic hybrid transmission, and a blade battery[1]. This system achieves a fuel consumption as low as 3.8L/100km, with electric-only range up to 120km[2]. BYD's cross-industry collaboration is evident in their partnership with Toyota to develop EVs and battery technology, leveraging both companies' strengths in hybrid systems[3]. They've also introduced the e-platform 3.0, an open-source platform for EVs that can be adapted for various vehicle types, encouraging cross-industry innovation[4].

Strengths: Advanced hybrid technology, high fuel efficiency, long electric-only range, and open-source platform promoting collaboration. Weaknesses: Heavy reliance on in-house technology may limit some cross-industry opportunities.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has made significant strides in HEV technology through cross-industry collaborations. Their Hybrid Blue Drive architecture, developed in partnership with LG Chem for battery technology, combines a gasoline engine with an electric motor and a lithium polymer battery[1]. Hyundai's latest IONIQ platform, designed for various electrified powertrains including HEVs, incorporates technologies from multiple industries, such as advanced materials from chemical companies and power electronics from semiconductor firms[2]. In collaboration with Kia and Solar Cells Hellas Group, Hyundai has developed solar roof technology for HEVs, which can charge the battery while driving or parked[3]. Their partnership with Aptiv has resulted in autonomous driving technologies that can be integrated into HEVs, potentially improving energy efficiency through optimized driving patterns[4].

Strengths: Versatile hybrid platform, innovative energy-generating technologies, integration of autonomous driving with HEVs. Weaknesses: Potential complexity in managing multiple technological integrations across different vehicle models.

Core HEV Innovations Analysis

Multi-function damper

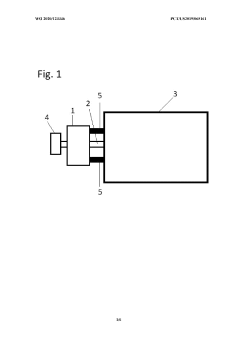

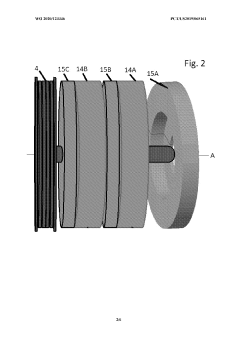

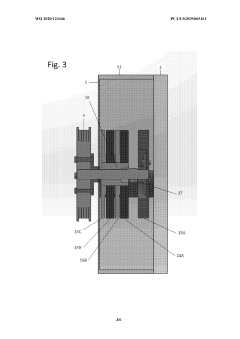

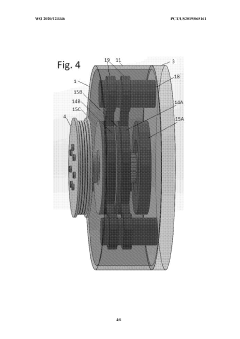

PatentWO2020123346A2

Innovation

- A hybrid electric vehicle system is positioned at the front end of the engine, co-axially arranged with the crankshaft, featuring a narrow-depth motor-generator unit that is selectively engageable with the crankshaft, allowing for the elimination of a dedicated crankshaft vibration damper and enabling efficient energy recovery and torque supplementation without substantial modifications to the engine compartment.

Hybrid electric vehicle with electric motor providing strategic power assist to load balance internal combustion engine

PatentPendingIN202441000035A

Innovation

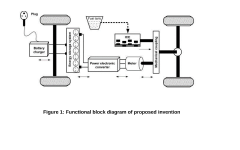

- A Hybrid Electric Vehicle (HEV) system with an electric motor providing strategic power assist to the internal combustion engine, optimizing power distribution and energy management through advanced control algorithms.

Cross-Industry Collaboration Opportunities

Cross-industry collaboration presents a wealth of opportunities for advancing Hybrid Electric Vehicle (HEV) technology. By leveraging expertise and resources from diverse sectors, HEV development can benefit from innovative solutions and accelerated progress. The automotive industry can partner with energy companies to enhance battery technology and improve energy management systems. This collaboration could lead to more efficient and longer-lasting batteries, addressing one of the key challenges in HEV adoption.

Partnerships with electronics manufacturers can drive advancements in power electronics and control systems, crucial components for optimizing HEV performance. These collaborations may result in more compact, efficient, and cost-effective electronic components, contributing to overall vehicle efficiency and affordability. Additionally, collaborations with materials science companies can lead to the development of lighter, stronger materials for vehicle construction, directly impacting fuel efficiency and performance.

The IT and software industry can play a significant role in enhancing HEV technology through collaborations focused on developing advanced algorithms for energy management, predictive maintenance, and autonomous driving features. These partnerships can result in smarter, more efficient HEVs that offer improved user experiences and reduced maintenance costs.

Collaborations with renewable energy companies can explore innovative ways to integrate HEVs into the broader energy ecosystem. This could include developing vehicle-to-grid technologies, enabling HEVs to serve as mobile energy storage units and contribute to grid stability. Such partnerships could also lead to advancements in charging infrastructure, making HEVs more practical and appealing to consumers.

The aerospace industry, known for its cutting-edge lightweight materials and advanced propulsion systems, can offer valuable insights and technologies applicable to HEV development. Collaborations in this area could result in more aerodynamic designs and efficient powertrains, further enhancing HEV performance and range.

Partnerships with academic institutions and research organizations can provide access to fundamental research and emerging technologies that may not be immediately apparent within the automotive industry. These collaborations can foster innovation in areas such as new battery chemistries, advanced materials, and novel powertrain configurations.

By fostering these cross-industry collaborations, the HEV sector can accelerate technological advancements, overcome existing limitations, and pave the way for more sustainable and efficient transportation solutions. The synergies created through these partnerships have the potential to drive breakthroughs that could revolutionize the automotive industry and contribute significantly to global efforts in reducing carbon emissions and promoting sustainable mobility.

Partnerships with electronics manufacturers can drive advancements in power electronics and control systems, crucial components for optimizing HEV performance. These collaborations may result in more compact, efficient, and cost-effective electronic components, contributing to overall vehicle efficiency and affordability. Additionally, collaborations with materials science companies can lead to the development of lighter, stronger materials for vehicle construction, directly impacting fuel efficiency and performance.

The IT and software industry can play a significant role in enhancing HEV technology through collaborations focused on developing advanced algorithms for energy management, predictive maintenance, and autonomous driving features. These partnerships can result in smarter, more efficient HEVs that offer improved user experiences and reduced maintenance costs.

Collaborations with renewable energy companies can explore innovative ways to integrate HEVs into the broader energy ecosystem. This could include developing vehicle-to-grid technologies, enabling HEVs to serve as mobile energy storage units and contribute to grid stability. Such partnerships could also lead to advancements in charging infrastructure, making HEVs more practical and appealing to consumers.

The aerospace industry, known for its cutting-edge lightweight materials and advanced propulsion systems, can offer valuable insights and technologies applicable to HEV development. Collaborations in this area could result in more aerodynamic designs and efficient powertrains, further enhancing HEV performance and range.

Partnerships with academic institutions and research organizations can provide access to fundamental research and emerging technologies that may not be immediately apparent within the automotive industry. These collaborations can foster innovation in areas such as new battery chemistries, advanced materials, and novel powertrain configurations.

By fostering these cross-industry collaborations, the HEV sector can accelerate technological advancements, overcome existing limitations, and pave the way for more sustainable and efficient transportation solutions. The synergies created through these partnerships have the potential to drive breakthroughs that could revolutionize the automotive industry and contribute significantly to global efforts in reducing carbon emissions and promoting sustainable mobility.

Environmental Impact of HEV Technologies

The environmental impact of Hybrid Electric Vehicle (HEV) technologies is a critical consideration in the ongoing development and adoption of these vehicles. HEVs have shown significant potential in reducing greenhouse gas emissions and improving air quality, particularly in urban areas. The combination of internal combustion engines and electric motors allows for more efficient energy use, resulting in lower fuel consumption and reduced carbon dioxide emissions compared to conventional vehicles.

One of the primary environmental benefits of HEVs is their ability to operate in electric-only mode for short distances, which is particularly advantageous in congested urban environments. This feature helps to reduce local air pollution, including particulate matter and nitrogen oxides, which are major contributors to poor air quality in cities. Furthermore, the regenerative braking systems in HEVs capture and store energy that would otherwise be lost as heat, further improving overall energy efficiency.

However, the environmental impact of HEVs extends beyond their operational phase. The production of batteries and electric components for HEVs can have significant environmental implications. The mining and processing of rare earth elements and other materials used in battery production can lead to habitat destruction, water pollution, and increased carbon emissions. Additionally, the energy-intensive manufacturing processes for these components can offset some of the environmental gains achieved during the vehicle's use phase.

The end-of-life management of HEV components, particularly batteries, presents both challenges and opportunities. Proper recycling and disposal of batteries are crucial to mitigate potential environmental hazards and recover valuable materials. Advances in battery recycling technologies and the development of circular economy principles in the automotive industry are helping to address these concerns.

As HEV technologies continue to evolve, there is a growing focus on improving the environmental performance across the entire lifecycle of these vehicles. This includes efforts to develop more sustainable battery technologies, improve manufacturing processes, and enhance the recyclability of components. Cross-industry collaborations are playing a crucial role in these advancements, bringing together expertise from automotive, energy, and materials science sectors to address environmental challenges holistically.

The shift towards renewable energy sources for electricity generation further enhances the environmental benefits of HEVs. As power grids become cleaner, the overall carbon footprint of HEVs decreases, making them an increasingly attractive option for environmentally conscious consumers and policymakers alike. This synergy between clean energy production and electrified transportation is a key factor in the long-term environmental sustainability of HEV technologies.

One of the primary environmental benefits of HEVs is their ability to operate in electric-only mode for short distances, which is particularly advantageous in congested urban environments. This feature helps to reduce local air pollution, including particulate matter and nitrogen oxides, which are major contributors to poor air quality in cities. Furthermore, the regenerative braking systems in HEVs capture and store energy that would otherwise be lost as heat, further improving overall energy efficiency.

However, the environmental impact of HEVs extends beyond their operational phase. The production of batteries and electric components for HEVs can have significant environmental implications. The mining and processing of rare earth elements and other materials used in battery production can lead to habitat destruction, water pollution, and increased carbon emissions. Additionally, the energy-intensive manufacturing processes for these components can offset some of the environmental gains achieved during the vehicle's use phase.

The end-of-life management of HEV components, particularly batteries, presents both challenges and opportunities. Proper recycling and disposal of batteries are crucial to mitigate potential environmental hazards and recover valuable materials. Advances in battery recycling technologies and the development of circular economy principles in the automotive industry are helping to address these concerns.

As HEV technologies continue to evolve, there is a growing focus on improving the environmental performance across the entire lifecycle of these vehicles. This includes efforts to develop more sustainable battery technologies, improve manufacturing processes, and enhance the recyclability of components. Cross-industry collaborations are playing a crucial role in these advancements, bringing together expertise from automotive, energy, and materials science sectors to address environmental challenges holistically.

The shift towards renewable energy sources for electricity generation further enhances the environmental benefits of HEVs. As power grids become cleaner, the overall carbon footprint of HEVs decreases, making them an increasingly attractive option for environmentally conscious consumers and policymakers alike. This synergy between clean energy production and electrified transportation is a key factor in the long-term environmental sustainability of HEV technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!