Exploring Haptics with Advanced Piezoelectric Sensors

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Haptic Tech Evolution

Haptic technology has undergone a remarkable evolution since its inception in the 1970s. Initially developed for flight simulators, haptic feedback has expanded into various fields, including gaming, medical training, and mobile devices. The journey of haptic technology can be traced through several key milestones and technological advancements.

In the 1980s, the focus was primarily on force feedback systems for industrial applications. These early haptic devices were large, expensive, and limited in their capabilities. The 1990s saw a significant leap forward with the introduction of consumer-grade haptic devices, such as force feedback joysticks and steering wheels for gaming consoles.

The turn of the millennium marked a new era for haptic technology with the miniaturization of actuators and sensors. This advancement enabled the integration of haptic feedback into smaller devices, paving the way for its incorporation into mobile phones and handheld gaming devices. The introduction of the iPhone in 2007 revolutionized the mobile industry and brought haptic feedback to the masses through its vibration motor.

As we entered the 2010s, haptic technology became more sophisticated, with the development of advanced actuators capable of producing more nuanced and realistic sensations. The emergence of linear resonant actuators (LRAs) and electroactive polymers (EAPs) allowed for more precise and varied haptic feedback in consumer electronics.

The integration of piezoelectric sensors into haptic systems marks a significant advancement in the field. Piezoelectric materials, which generate an electric charge in response to mechanical stress, enable more accurate and responsive haptic feedback. This technology has opened up new possibilities for creating more immersive and realistic tactile experiences.

Recent years have seen a focus on creating more complex and multi-modal haptic experiences. Researchers and companies are exploring ways to combine different types of haptic feedback, such as pressure, texture, and temperature, to create more realistic and engaging tactile sensations. The development of haptic gloves and suits for virtual reality applications exemplifies this trend towards more comprehensive haptic experiences.

Looking forward, the integration of artificial intelligence and machine learning with haptic technology promises to create more adaptive and personalized tactile experiences. Additionally, advancements in materials science, such as the development of smart fabrics and flexible electronics, are likely to further expand the possibilities of haptic feedback in wearable devices and everyday objects.

In the 1980s, the focus was primarily on force feedback systems for industrial applications. These early haptic devices were large, expensive, and limited in their capabilities. The 1990s saw a significant leap forward with the introduction of consumer-grade haptic devices, such as force feedback joysticks and steering wheels for gaming consoles.

The turn of the millennium marked a new era for haptic technology with the miniaturization of actuators and sensors. This advancement enabled the integration of haptic feedback into smaller devices, paving the way for its incorporation into mobile phones and handheld gaming devices. The introduction of the iPhone in 2007 revolutionized the mobile industry and brought haptic feedback to the masses through its vibration motor.

As we entered the 2010s, haptic technology became more sophisticated, with the development of advanced actuators capable of producing more nuanced and realistic sensations. The emergence of linear resonant actuators (LRAs) and electroactive polymers (EAPs) allowed for more precise and varied haptic feedback in consumer electronics.

The integration of piezoelectric sensors into haptic systems marks a significant advancement in the field. Piezoelectric materials, which generate an electric charge in response to mechanical stress, enable more accurate and responsive haptic feedback. This technology has opened up new possibilities for creating more immersive and realistic tactile experiences.

Recent years have seen a focus on creating more complex and multi-modal haptic experiences. Researchers and companies are exploring ways to combine different types of haptic feedback, such as pressure, texture, and temperature, to create more realistic and engaging tactile sensations. The development of haptic gloves and suits for virtual reality applications exemplifies this trend towards more comprehensive haptic experiences.

Looking forward, the integration of artificial intelligence and machine learning with haptic technology promises to create more adaptive and personalized tactile experiences. Additionally, advancements in materials science, such as the development of smart fabrics and flexible electronics, are likely to further expand the possibilities of haptic feedback in wearable devices and everyday objects.

Haptic Market Analysis

The haptic technology market has been experiencing significant growth in recent years, driven by the increasing demand for enhanced user experiences across various industries. The global haptic technology market size was valued at approximately $12.9 billion in 2020 and is projected to reach $40.9 billion by 2027, growing at a CAGR of 12.0% during the forecast period. This growth is primarily attributed to the rising adoption of haptic technology in consumer electronics, automotive, healthcare, and gaming sectors.

In the consumer electronics segment, smartphones and wearable devices are the major contributors to market growth. The integration of advanced haptic feedback systems in these devices enhances user interaction and provides a more immersive experience. The automotive industry is also embracing haptic technology to improve driver safety and comfort, with applications in touchscreens, steering wheels, and seat vibrations for navigation alerts.

The healthcare sector is another key market for haptic technology, particularly in surgical simulation and training. The use of haptic feedback in robotic-assisted surgeries and medical simulations is improving surgical precision and reducing training costs. The gaming and virtual reality industries are also driving market growth, as haptic feedback enhances the immersive experience for users.

Geographically, North America dominates the haptic technology market, followed by Europe and Asia-Pacific. The presence of major technology companies and high adoption rates of advanced technologies contribute to North America's market leadership. However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by the increasing smartphone penetration and growing automotive and gaming industries in countries like China, Japan, and South Korea.

The market for advanced piezoelectric sensors in haptic applications is also showing promising growth. Piezoelectric sensors offer advantages such as high sensitivity, fast response times, and durability, making them ideal for haptic feedback systems. The global piezoelectric devices market, which includes sensors, is expected to reach $35.4 billion by 2026, growing at a CAGR of 4.88% from 2021 to 2026.

Key market players in the haptic technology and piezoelectric sensor space include Texas Instruments, Immersion Corporation, Johnson Electric, ON Semiconductor, and Alps Electric. These companies are focusing on research and development to introduce innovative haptic solutions and expand their market presence.

Despite the positive market outlook, challenges such as high implementation costs and technical complexities in integrating haptic feedback systems may hinder market growth. However, ongoing technological advancements and increasing applications across various industries are expected to create new opportunities for market expansion in the coming years.

In the consumer electronics segment, smartphones and wearable devices are the major contributors to market growth. The integration of advanced haptic feedback systems in these devices enhances user interaction and provides a more immersive experience. The automotive industry is also embracing haptic technology to improve driver safety and comfort, with applications in touchscreens, steering wheels, and seat vibrations for navigation alerts.

The healthcare sector is another key market for haptic technology, particularly in surgical simulation and training. The use of haptic feedback in robotic-assisted surgeries and medical simulations is improving surgical precision and reducing training costs. The gaming and virtual reality industries are also driving market growth, as haptic feedback enhances the immersive experience for users.

Geographically, North America dominates the haptic technology market, followed by Europe and Asia-Pacific. The presence of major technology companies and high adoption rates of advanced technologies contribute to North America's market leadership. However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by the increasing smartphone penetration and growing automotive and gaming industries in countries like China, Japan, and South Korea.

The market for advanced piezoelectric sensors in haptic applications is also showing promising growth. Piezoelectric sensors offer advantages such as high sensitivity, fast response times, and durability, making them ideal for haptic feedback systems. The global piezoelectric devices market, which includes sensors, is expected to reach $35.4 billion by 2026, growing at a CAGR of 4.88% from 2021 to 2026.

Key market players in the haptic technology and piezoelectric sensor space include Texas Instruments, Immersion Corporation, Johnson Electric, ON Semiconductor, and Alps Electric. These companies are focusing on research and development to introduce innovative haptic solutions and expand their market presence.

Despite the positive market outlook, challenges such as high implementation costs and technical complexities in integrating haptic feedback systems may hinder market growth. However, ongoing technological advancements and increasing applications across various industries are expected to create new opportunities for market expansion in the coming years.

Piezo Sensor Challenges

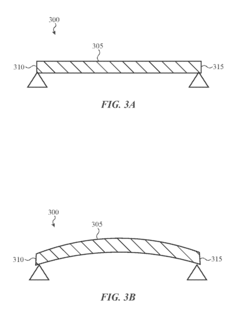

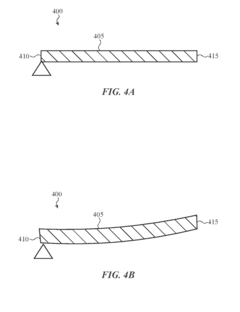

Despite the significant advancements in piezoelectric sensor technology, several challenges persist in their application to haptic systems. One of the primary obstacles is the limited frequency range of current piezoelectric sensors. While they excel at detecting high-frequency vibrations, they often struggle to accurately capture low-frequency tactile sensations, which are crucial for realistic haptic feedback.

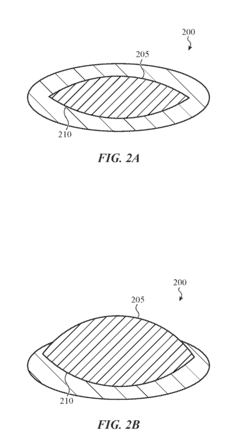

Another significant challenge lies in the miniaturization of piezoelectric sensors without compromising their performance. As haptic devices become increasingly compact and integrated into wearable technologies, there is a growing demand for smaller sensors. However, reducing the size of piezoelectric elements often results in decreased sensitivity and output power, limiting their effectiveness in haptic applications.

The durability and longevity of piezoelectric sensors in haptic systems also present ongoing challenges. Continuous exposure to mechanical stress and environmental factors can lead to degradation of the piezoelectric materials, affecting their long-term reliability and consistency in haptic feedback generation.

Furthermore, the integration of piezoelectric sensors with flexible and stretchable substrates remains a complex task. As haptic interfaces evolve to conform to various body shapes and dynamic surfaces, developing piezoelectric sensors that can maintain their functionality under bending, stretching, and twisting conditions becomes crucial.

Power consumption is another critical challenge, particularly for battery-operated haptic devices. While piezoelectric sensors are generally energy-efficient, optimizing their power usage without compromising sensitivity or response time is an ongoing area of research and development.

The cost-effectiveness of piezoelectric sensors for mass-market haptic applications is also a significant hurdle. High-quality piezoelectric materials and precision manufacturing processes often result in elevated production costs, limiting their widespread adoption in consumer-grade haptic devices.

Lastly, the challenge of cross-sensitivity in piezoelectric sensors can affect the accuracy of haptic feedback. These sensors may respond to unintended stimuli such as temperature changes or electromagnetic interference, potentially leading to distorted or inaccurate haptic sensations. Developing more selective and noise-resistant piezoelectric sensors is crucial for enhancing the fidelity of haptic experiences.

Another significant challenge lies in the miniaturization of piezoelectric sensors without compromising their performance. As haptic devices become increasingly compact and integrated into wearable technologies, there is a growing demand for smaller sensors. However, reducing the size of piezoelectric elements often results in decreased sensitivity and output power, limiting their effectiveness in haptic applications.

The durability and longevity of piezoelectric sensors in haptic systems also present ongoing challenges. Continuous exposure to mechanical stress and environmental factors can lead to degradation of the piezoelectric materials, affecting their long-term reliability and consistency in haptic feedback generation.

Furthermore, the integration of piezoelectric sensors with flexible and stretchable substrates remains a complex task. As haptic interfaces evolve to conform to various body shapes and dynamic surfaces, developing piezoelectric sensors that can maintain their functionality under bending, stretching, and twisting conditions becomes crucial.

Power consumption is another critical challenge, particularly for battery-operated haptic devices. While piezoelectric sensors are generally energy-efficient, optimizing their power usage without compromising sensitivity or response time is an ongoing area of research and development.

The cost-effectiveness of piezoelectric sensors for mass-market haptic applications is also a significant hurdle. High-quality piezoelectric materials and precision manufacturing processes often result in elevated production costs, limiting their widespread adoption in consumer-grade haptic devices.

Lastly, the challenge of cross-sensitivity in piezoelectric sensors can affect the accuracy of haptic feedback. These sensors may respond to unintended stimuli such as temperature changes or electromagnetic interference, potentially leading to distorted or inaccurate haptic sensations. Developing more selective and noise-resistant piezoelectric sensors is crucial for enhancing the fidelity of haptic experiences.

Current Haptic Solutions

01 Integration of piezoelectric sensors in haptic devices

Piezoelectric sensors are incorporated into haptic devices to detect user interactions and provide precise feedback. These sensors convert mechanical stress into electrical signals, allowing for accurate measurement of force and pressure. This integration enables more responsive and nuanced haptic feedback in various applications.- Integration of piezoelectric sensors in haptic devices: Piezoelectric sensors are incorporated into haptic devices to detect user interactions and provide precise feedback. These sensors convert mechanical stress into electrical signals, allowing for accurate measurement of force and pressure. This integration enables more responsive and realistic haptic experiences in various applications.

- Haptic feedback systems using piezoelectric actuators: Piezoelectric actuators are utilized in haptic feedback systems to generate tactile sensations. These actuators convert electrical signals into mechanical vibrations or movements, providing users with a range of haptic effects. The precise control of piezoelectric actuators allows for the creation of complex and nuanced haptic experiences.

- Wearable haptic devices with piezoelectric elements: Wearable devices incorporate piezoelectric elements to provide haptic feedback. These devices can be worn on various parts of the body, such as fingers, hands, or arms, and use piezoelectric technology to generate tactile sensations. The compact nature of piezoelectric elements makes them suitable for integration into wearable form factors.

- Piezoelectric sensors for prosthetic limb feedback: Piezoelectric sensors are used in prosthetic limbs to provide sensory feedback to users. These sensors detect pressure and force applied to the prosthetic, translating this information into tactile sensations for the wearer. This technology enhances the user's ability to interact with their environment and improves the overall functionality of prosthetic devices.

- Haptic interfaces with piezoelectric sensing for virtual reality: Virtual reality systems incorporate haptic interfaces with piezoelectric sensing capabilities. These interfaces use piezoelectric sensors to detect user movements and interactions within virtual environments. The data from these sensors is then used to generate appropriate haptic feedback, enhancing the immersion and realism of virtual reality experiences.

02 Haptic feedback systems using piezoelectric actuators

Piezoelectric actuators are utilized in haptic feedback systems to generate tactile sensations. These actuators can produce rapid, precise movements in response to electrical signals, creating a wide range of haptic effects. The technology is applied in touchscreens, wearable devices, and virtual reality interfaces to enhance user experience.Expand Specific Solutions03 Piezoelectric sensors for prosthetic limb feedback

Piezoelectric sensors are employed in prosthetic limbs to provide sensory feedback to users. These sensors detect pressure and force applied to the prosthetic, translating this information into tactile sensations for the wearer. This technology aims to improve the natural feel and control of prosthetic devices.Expand Specific Solutions04 Wearable haptic devices with piezoelectric elements

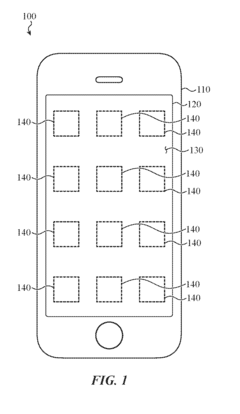

Wearable haptic devices incorporate piezoelectric elements for both sensing and actuation. These devices can be integrated into clothing, accessories, or directly attached to the skin, providing tactile feedback for various applications such as navigation, communication, or augmented reality experiences.Expand Specific Solutions05 Piezoelectric-based haptic interfaces for touchscreens

Touchscreen devices utilize piezoelectric technology to create haptic interfaces that simulate the feel of physical buttons or textures. This approach enhances user interaction by providing tactile feedback on flat surfaces, improving usability and user experience in smartphones, tablets, and other touch-based devices.Expand Specific Solutions

Haptic Industry Players

The haptics market with advanced piezoelectric sensors is in a growth phase, driven by increasing demand for tactile feedback in various applications. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing quickly but still has room for innovation. Key players like TDK Electronics, Immersion Corp., and Aito BV are pushing the boundaries of piezoelectric sensor technology for haptics. Companies such as Apple, Google, and Samsung are integrating these advanced haptic solutions into consumer electronics, while others like BOE Technology and Murata Manufacturing are focusing on component development. The competitive landscape is diverse, with both established tech giants and specialized haptics firms vying for market share.

TDK Electronics AG

Technical Solution: TDK Electronics has made significant advancements in piezoelectric sensor technology for haptic applications. They have developed PowerHap piezo actuators, which offer high acceleration, fast response times, and a wide frequency range for haptic feedback[13]. TDK's PiezoHapt actuators provide a thin form factor and low power consumption, making them suitable for mobile devices and wearables[14]. They have also created multilayer piezo actuators that can generate strong forces in compact sizes, enabling more powerful and precise haptic sensations[15]. TDK's solutions are designed to enhance user experiences in touchscreens, automotive interfaces, and industrial control panels.

Strengths: High performance actuators, compact designs, wide range of applications. Weaknesses: May face competition from emerging technologies, potential cost concerns for high-end solutions.

Immersion Corp.

Technical Solution: Immersion Corporation specializes in haptic technology and has developed advanced piezoelectric sensor-based solutions. Their TouchSense technology uses piezoelectric actuators to create high-definition haptic effects[4]. They have also developed a system that combines piezoelectric sensors with electrostatic actuation for more precise haptic feedback[5]. Immersion's technology can simulate textures, edges, and even 3D objects on flat surfaces, enhancing the tactile experience in various applications[6]. Their solutions are widely used in automotive, mobile, and gaming industries, providing a rich haptic experience across different platforms.

Strengths: Versatile applications across industries, high-definition haptic effects, extensive patent portfolio. Weaknesses: Reliance on licensing model, potential competition from in-house solutions of large tech companies.

Piezo Sensor Innovations

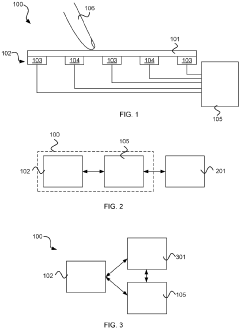

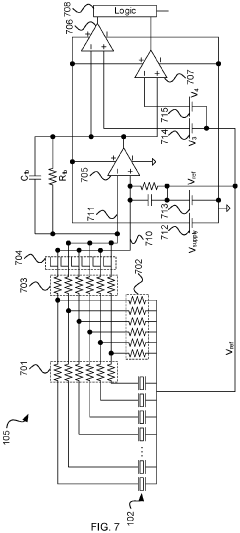

Techniques for Providing a Haptic Output and Sensing a Haptic Input Using a Piezoelectric Body

PatentActiveUS20190027674A1

Innovation

- Incorporating an overcurrent protection circuit within the control circuit of the haptic interface to limit current flow into the sensing portion while the actuation portion charges the piezoelectric body, allowing for simultaneous haptic output and input sensing by protecting the sensing circuit from excessive currents.

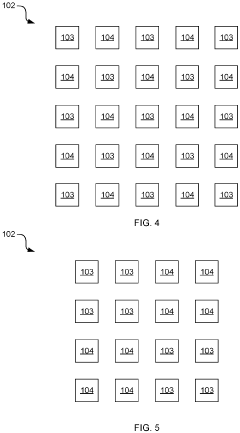

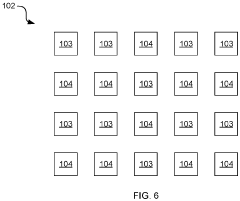

A piezoelectric sensing device

PatentPendingEP4040265A1

Innovation

- A device comprising a touch surface with a plurality of piezoelectric sensors, where a subset of sensors is assigned positive and another subset negative signs, and a wakeup circuitry that produces a sum signal by combining these signals, allowing for differentiation between localized pressure and common-mode signals, and providing a wakeup signal only when specific threshold conditions are met.

Haptic Standards & Regs

The development of haptic technologies incorporating advanced piezoelectric sensors necessitates adherence to various standards and regulations to ensure safety, interoperability, and performance consistency. These standards play a crucial role in shaping the industry and facilitating widespread adoption of haptic technologies.

ISO 9241-910 and ISO 9241-920 are fundamental standards that provide guidelines for tactile and haptic interactions. They define terminology, design considerations, and evaluation methods for haptic devices. These standards help manufacturers and developers create haptic interfaces that are consistent and user-friendly across different applications.

The IEEE 1622 standard focuses on haptic feedback for mobile devices, addressing the specific challenges and requirements of implementing haptics in portable electronics. This standard is particularly relevant for the integration of piezoelectric sensors in smartphones, tablets, and wearable devices.

In the automotive sector, the SAE J3134 standard governs the implementation of haptic feedback in vehicle interfaces. As advanced piezoelectric sensors find applications in automotive haptics, compliance with this standard ensures safe and effective integration into vehicle control systems.

The IEC 60601-1-2 standard is crucial for medical applications of haptic technologies. It specifies electromagnetic compatibility requirements for medical electrical equipment, including haptic devices used in medical training, rehabilitation, and surgical systems.

For consumer electronics, the CE marking in Europe and FCC certification in the United States are essential. These certifications ensure that haptic devices meet safety and electromagnetic compatibility requirements. Manufacturers must demonstrate compliance with these regulations before bringing their products to market.

The ASTM F2592-17 standard provides guidelines for the durability and reliability testing of haptic devices. This is particularly important for piezoelectric sensor-based haptics, as it helps ensure long-term performance and user satisfaction.

As haptic technologies advance, new standards are emerging to address specific applications. For instance, the Haptics Industry Forum is working on developing standards for haptic content creation and playback, which will be crucial for the growth of immersive haptic experiences in virtual and augmented reality.

Compliance with these standards and regulations not only ensures product quality and safety but also facilitates market acceptance and interoperability. As the field of haptics with advanced piezoelectric sensors continues to evolve, staying abreast of these standards and actively participating in their development will be crucial for industry players to maintain a competitive edge and drive innovation.

ISO 9241-910 and ISO 9241-920 are fundamental standards that provide guidelines for tactile and haptic interactions. They define terminology, design considerations, and evaluation methods for haptic devices. These standards help manufacturers and developers create haptic interfaces that are consistent and user-friendly across different applications.

The IEEE 1622 standard focuses on haptic feedback for mobile devices, addressing the specific challenges and requirements of implementing haptics in portable electronics. This standard is particularly relevant for the integration of piezoelectric sensors in smartphones, tablets, and wearable devices.

In the automotive sector, the SAE J3134 standard governs the implementation of haptic feedback in vehicle interfaces. As advanced piezoelectric sensors find applications in automotive haptics, compliance with this standard ensures safe and effective integration into vehicle control systems.

The IEC 60601-1-2 standard is crucial for medical applications of haptic technologies. It specifies electromagnetic compatibility requirements for medical electrical equipment, including haptic devices used in medical training, rehabilitation, and surgical systems.

For consumer electronics, the CE marking in Europe and FCC certification in the United States are essential. These certifications ensure that haptic devices meet safety and electromagnetic compatibility requirements. Manufacturers must demonstrate compliance with these regulations before bringing their products to market.

The ASTM F2592-17 standard provides guidelines for the durability and reliability testing of haptic devices. This is particularly important for piezoelectric sensor-based haptics, as it helps ensure long-term performance and user satisfaction.

As haptic technologies advance, new standards are emerging to address specific applications. For instance, the Haptics Industry Forum is working on developing standards for haptic content creation and playback, which will be crucial for the growth of immersive haptic experiences in virtual and augmented reality.

Compliance with these standards and regulations not only ensures product quality and safety but also facilitates market acceptance and interoperability. As the field of haptics with advanced piezoelectric sensors continues to evolve, staying abreast of these standards and actively participating in their development will be crucial for industry players to maintain a competitive edge and drive innovation.

Haptic User Experience

Haptic user experience has become a crucial aspect of modern technology, enhancing the way users interact with devices and digital interfaces. Advanced piezoelectric sensors are at the forefront of this revolution, offering unprecedented levels of tactile feedback and precision. These sensors enable a wide range of haptic experiences, from subtle vibrations to complex textures, significantly improving user engagement and immersion.

The integration of advanced piezoelectric sensors in haptic systems has led to more realistic and responsive touch interactions. Users can now experience a variety of tactile sensations that closely mimic real-world textures and forces. This enhanced feedback contributes to a more intuitive and natural user experience, reducing the learning curve for new technologies and improving overall usability.

In mobile devices, haptic feedback powered by piezoelectric sensors has evolved beyond simple vibrations. Users can now feel distinct textures when interacting with on-screen elements, adding a new dimension to touchscreen interfaces. This technology has also found applications in virtual and augmented reality systems, where realistic haptic feedback is essential for creating immersive environments.

The automotive industry has embraced haptic user experience to improve safety and driver engagement. Advanced piezoelectric sensors in steering wheels and control panels provide drivers with tactile cues, reducing the need for visual attention and potentially decreasing distracted driving. This haptic feedback can convey important information about road conditions, navigation directions, and vehicle status without requiring the driver to take their eyes off the road.

In gaming and entertainment, haptic feedback has transformed the user experience by adding a tactile dimension to visual and auditory stimuli. Game controllers equipped with piezoelectric sensors can deliver nuanced vibrations that correspond to in-game events, enhancing player immersion and providing crucial gameplay information through touch.

The medical field has also benefited from advancements in haptic technology. Surgical simulators now incorporate advanced piezoelectric sensors to provide realistic tactile feedback, allowing medical professionals to practice complex procedures in a safe, virtual environment. This haptic experience closely mimics the feel of real surgical instruments and tissue interactions, improving training outcomes and potentially enhancing patient safety.

As haptic technology continues to evolve, user expectations for tactile feedback in digital interactions are likely to increase. The challenge for designers and engineers will be to create haptic experiences that are not only technologically advanced but also meaningful and contextually appropriate. The future of haptic user experience lies in seamlessly integrating touch sensations into our digital interactions, making technology more intuitive, accessible, and human-centric.

The integration of advanced piezoelectric sensors in haptic systems has led to more realistic and responsive touch interactions. Users can now experience a variety of tactile sensations that closely mimic real-world textures and forces. This enhanced feedback contributes to a more intuitive and natural user experience, reducing the learning curve for new technologies and improving overall usability.

In mobile devices, haptic feedback powered by piezoelectric sensors has evolved beyond simple vibrations. Users can now feel distinct textures when interacting with on-screen elements, adding a new dimension to touchscreen interfaces. This technology has also found applications in virtual and augmented reality systems, where realistic haptic feedback is essential for creating immersive environments.

The automotive industry has embraced haptic user experience to improve safety and driver engagement. Advanced piezoelectric sensors in steering wheels and control panels provide drivers with tactile cues, reducing the need for visual attention and potentially decreasing distracted driving. This haptic feedback can convey important information about road conditions, navigation directions, and vehicle status without requiring the driver to take their eyes off the road.

In gaming and entertainment, haptic feedback has transformed the user experience by adding a tactile dimension to visual and auditory stimuli. Game controllers equipped with piezoelectric sensors can deliver nuanced vibrations that correspond to in-game events, enhancing player immersion and providing crucial gameplay information through touch.

The medical field has also benefited from advancements in haptic technology. Surgical simulators now incorporate advanced piezoelectric sensors to provide realistic tactile feedback, allowing medical professionals to practice complex procedures in a safe, virtual environment. This haptic experience closely mimics the feel of real surgical instruments and tissue interactions, improving training outcomes and potentially enhancing patient safety.

As haptic technology continues to evolve, user expectations for tactile feedback in digital interactions are likely to increase. The challenge for designers and engineers will be to create haptic experiences that are not only technologically advanced but also meaningful and contextually appropriate. The future of haptic user experience lies in seamlessly integrating touch sensations into our digital interactions, making technology more intuitive, accessible, and human-centric.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!