Exploring natural material use in KERS construction

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

KERS Natural Materials Background and Objectives

Kinetic Energy Recovery Systems (KERS) have been a significant focus in the automotive and renewable energy sectors for their potential to improve energy efficiency and reduce environmental impact. The exploration of natural materials in KERS construction represents a cutting-edge approach to enhancing sustainability and performance in these systems.

The evolution of KERS technology can be traced back to the early 2000s, primarily in Formula 1 racing. Initially, these systems were predominantly mechanical or electrical, utilizing materials such as carbon fiber and high-strength alloys. However, the growing emphasis on sustainability has shifted attention towards natural and biodegradable materials, marking a new era in KERS development.

The primary objective of incorporating natural materials in KERS construction is to reduce the environmental footprint while maintaining or improving system efficiency. This aligns with global initiatives to decrease reliance on non-renewable resources and minimize waste in industrial processes. Additionally, natural materials often offer unique properties that can enhance system performance, such as improved energy absorption or reduced weight.

Current research in this field focuses on several key areas. Biomimicry plays a crucial role, with scientists studying natural energy storage mechanisms in plants and animals to inspire novel KERS designs. For instance, the elastic properties of certain plant fibers are being investigated for their potential in creating more efficient energy storage components.

Another significant area of exploration is the use of biodegradable polymers derived from renewable sources. These materials could potentially replace traditional plastics in various KERS components, offering similar performance characteristics while being more environmentally friendly. Researchers are also investigating natural composites, combining materials like bamboo fibers with bio-based resins to create strong, lightweight structures suitable for KERS applications.

The integration of natural materials in KERS construction faces several challenges. Durability and long-term performance under varying environmental conditions remain key concerns. Additionally, scaling up production of these materials to meet industrial demands while maintaining consistency in quality presents logistical hurdles.

Despite these challenges, the potential benefits of using natural materials in KERS are substantial. Beyond environmental advantages, these materials could lead to cost reductions in manufacturing and end-of-life disposal. Furthermore, the development of natural material-based KERS could spur innovation in other areas of automotive and energy technology, contributing to broader advancements in sustainable engineering.

The evolution of KERS technology can be traced back to the early 2000s, primarily in Formula 1 racing. Initially, these systems were predominantly mechanical or electrical, utilizing materials such as carbon fiber and high-strength alloys. However, the growing emphasis on sustainability has shifted attention towards natural and biodegradable materials, marking a new era in KERS development.

The primary objective of incorporating natural materials in KERS construction is to reduce the environmental footprint while maintaining or improving system efficiency. This aligns with global initiatives to decrease reliance on non-renewable resources and minimize waste in industrial processes. Additionally, natural materials often offer unique properties that can enhance system performance, such as improved energy absorption or reduced weight.

Current research in this field focuses on several key areas. Biomimicry plays a crucial role, with scientists studying natural energy storage mechanisms in plants and animals to inspire novel KERS designs. For instance, the elastic properties of certain plant fibers are being investigated for their potential in creating more efficient energy storage components.

Another significant area of exploration is the use of biodegradable polymers derived from renewable sources. These materials could potentially replace traditional plastics in various KERS components, offering similar performance characteristics while being more environmentally friendly. Researchers are also investigating natural composites, combining materials like bamboo fibers with bio-based resins to create strong, lightweight structures suitable for KERS applications.

The integration of natural materials in KERS construction faces several challenges. Durability and long-term performance under varying environmental conditions remain key concerns. Additionally, scaling up production of these materials to meet industrial demands while maintaining consistency in quality presents logistical hurdles.

Despite these challenges, the potential benefits of using natural materials in KERS are substantial. Beyond environmental advantages, these materials could lead to cost reductions in manufacturing and end-of-life disposal. Furthermore, the development of natural material-based KERS could spur innovation in other areas of automotive and energy technology, contributing to broader advancements in sustainable engineering.

Market Analysis for Eco-Friendly KERS

The market for eco-friendly Kinetic Energy Recovery Systems (KERS) is experiencing significant growth, driven by increasing environmental concerns and stringent regulations on vehicle emissions. As automotive manufacturers seek to improve fuel efficiency and reduce carbon footprints, the demand for sustainable KERS solutions has surged. The global KERS market is expected to expand at a compound annual growth rate of 8.5% from 2021 to 2026, with the eco-friendly segment showing even stronger growth potential.

Natural materials in KERS construction offer several advantages over traditional synthetic components. These include reduced environmental impact, improved recyclability, and potential weight reduction. Biomaterials such as natural fibers, bio-based resins, and sustainable composites are gaining traction in the automotive industry, aligning with the broader trend towards sustainable manufacturing practices.

The market for eco-friendly KERS is primarily driven by passenger vehicles, particularly in hybrid and electric car segments. However, there is growing interest from commercial vehicle manufacturers and the motorsport industry. Geographically, Europe leads the adoption of eco-friendly KERS, followed by North America and Asia-Pacific. Emerging markets in South America and Africa are also showing increased interest in sustainable automotive technologies.

Consumer demand for environmentally responsible vehicles is a key factor propelling the eco-friendly KERS market. Studies indicate that over 60% of car buyers consider environmental impact when making purchasing decisions. This shift in consumer preferences is pushing automakers to invest in green technologies, including natural material-based KERS.

Regulatory pressures also play a crucial role in market growth. Stringent emissions standards in the European Union, United States, and China are compelling automotive manufacturers to adopt more sustainable technologies. Government incentives for eco-friendly vehicles further stimulate the market for natural material KERS.

The supply chain for natural materials in KERS is still developing, presenting both challenges and opportunities. While some materials like natural fibers are readily available, others require further research and development to meet the performance standards of traditional KERS components. This creates a dynamic market landscape where innovation in material science directly influences market potential.

In conclusion, the market for eco-friendly KERS using natural materials is poised for substantial growth. The convergence of environmental consciousness, regulatory pressures, and technological advancements is creating a favorable ecosystem for sustainable KERS solutions. As the technology matures and production scales up, we can expect to see wider adoption across various vehicle segments, potentially reshaping the automotive industry's approach to energy recovery and sustainability.

Natural materials in KERS construction offer several advantages over traditional synthetic components. These include reduced environmental impact, improved recyclability, and potential weight reduction. Biomaterials such as natural fibers, bio-based resins, and sustainable composites are gaining traction in the automotive industry, aligning with the broader trend towards sustainable manufacturing practices.

The market for eco-friendly KERS is primarily driven by passenger vehicles, particularly in hybrid and electric car segments. However, there is growing interest from commercial vehicle manufacturers and the motorsport industry. Geographically, Europe leads the adoption of eco-friendly KERS, followed by North America and Asia-Pacific. Emerging markets in South America and Africa are also showing increased interest in sustainable automotive technologies.

Consumer demand for environmentally responsible vehicles is a key factor propelling the eco-friendly KERS market. Studies indicate that over 60% of car buyers consider environmental impact when making purchasing decisions. This shift in consumer preferences is pushing automakers to invest in green technologies, including natural material-based KERS.

Regulatory pressures also play a crucial role in market growth. Stringent emissions standards in the European Union, United States, and China are compelling automotive manufacturers to adopt more sustainable technologies. Government incentives for eco-friendly vehicles further stimulate the market for natural material KERS.

The supply chain for natural materials in KERS is still developing, presenting both challenges and opportunities. While some materials like natural fibers are readily available, others require further research and development to meet the performance standards of traditional KERS components. This creates a dynamic market landscape where innovation in material science directly influences market potential.

In conclusion, the market for eco-friendly KERS using natural materials is poised for substantial growth. The convergence of environmental consciousness, regulatory pressures, and technological advancements is creating a favorable ecosystem for sustainable KERS solutions. As the technology matures and production scales up, we can expect to see wider adoption across various vehicle segments, potentially reshaping the automotive industry's approach to energy recovery and sustainability.

Current Challenges in Natural Material KERS

The integration of natural materials in Kinetic Energy Recovery Systems (KERS) presents several significant challenges that researchers and engineers must overcome. One of the primary obstacles is the limited durability and strength of many natural materials compared to their synthetic counterparts. This poses a considerable risk in high-stress applications such as KERS, where components are subjected to intense mechanical forces and rapid energy transfers.

Another critical challenge lies in the inconsistency of natural materials' properties. Unlike engineered materials, natural substances often exhibit variations in their structural and mechanical characteristics, making it difficult to achieve uniform performance across different batches or sources. This variability can lead to unpredictable behavior in KERS components, potentially compromising the system's reliability and efficiency.

The environmental sensitivity of natural materials also presents a significant hurdle. Many organic substances are susceptible to degradation from exposure to heat, moisture, and UV radiation. In the context of KERS, which often operates in demanding automotive or industrial environments, this sensitivity could lead to premature material failure or reduced system longevity.

Scalability and cost-effectiveness pose additional challenges. While natural materials may offer sustainability benefits, their production and processing methods are often less developed than those for synthetic materials. This can result in higher costs and limited availability, making it difficult to implement natural material solutions on a large scale in KERS manufacturing.

Compatibility issues between natural materials and existing KERS components further complicate integration efforts. Many current KERS designs are optimized for synthetic materials, and incorporating natural alternatives may require significant redesigns of system architecture and manufacturing processes.

Moreover, the energy storage capacity and transfer efficiency of natural materials in KERS applications remain largely unproven. Synthetic materials used in current KERS designs have been extensively engineered to maximize energy capture and release. Natural materials may struggle to match these performance metrics without substantial modification or enhancement.

Lastly, regulatory compliance and safety standards present a complex challenge. The automotive and energy industries have established rigorous safety protocols and performance requirements for KERS components. Natural materials must not only meet these standards but also demonstrate long-term reliability and consistency to gain widespread acceptance and approval for use in critical energy recovery systems.

Another critical challenge lies in the inconsistency of natural materials' properties. Unlike engineered materials, natural substances often exhibit variations in their structural and mechanical characteristics, making it difficult to achieve uniform performance across different batches or sources. This variability can lead to unpredictable behavior in KERS components, potentially compromising the system's reliability and efficiency.

The environmental sensitivity of natural materials also presents a significant hurdle. Many organic substances are susceptible to degradation from exposure to heat, moisture, and UV radiation. In the context of KERS, which often operates in demanding automotive or industrial environments, this sensitivity could lead to premature material failure or reduced system longevity.

Scalability and cost-effectiveness pose additional challenges. While natural materials may offer sustainability benefits, their production and processing methods are often less developed than those for synthetic materials. This can result in higher costs and limited availability, making it difficult to implement natural material solutions on a large scale in KERS manufacturing.

Compatibility issues between natural materials and existing KERS components further complicate integration efforts. Many current KERS designs are optimized for synthetic materials, and incorporating natural alternatives may require significant redesigns of system architecture and manufacturing processes.

Moreover, the energy storage capacity and transfer efficiency of natural materials in KERS applications remain largely unproven. Synthetic materials used in current KERS designs have been extensively engineered to maximize energy capture and release. Natural materials may struggle to match these performance metrics without substantial modification or enhancement.

Lastly, regulatory compliance and safety standards present a complex challenge. The automotive and energy industries have established rigorous safety protocols and performance requirements for KERS components. Natural materials must not only meet these standards but also demonstrate long-term reliability and consistency to gain widespread acceptance and approval for use in critical energy recovery systems.

Existing Natural Material Solutions for KERS

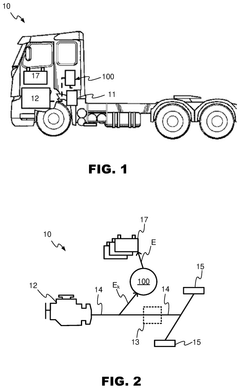

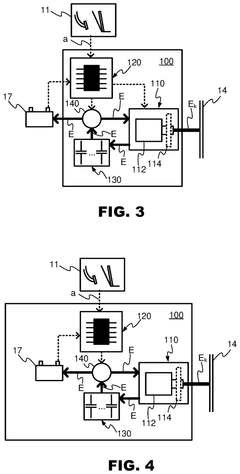

01 KERS integration in vehicles

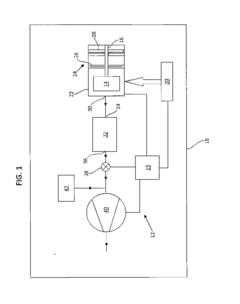

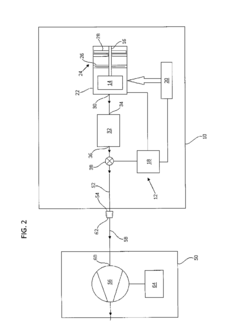

Kinetic Energy Recovery Systems (KERS) are being integrated into various types of vehicles, including cars and motorcycles. These systems capture and store energy during braking, which can then be used to provide additional power during acceleration. This technology improves overall vehicle efficiency and performance.- Energy recovery and storage systems in vehicles: KERS technology is implemented in vehicles to recover and store kinetic energy during braking. This stored energy can then be used to provide additional power during acceleration, improving overall vehicle efficiency and performance. The system typically includes components for energy capture, storage, and release.

- Hydraulic and pneumatic KERS: Some KERS designs utilize hydraulic or pneumatic systems for energy recovery and storage. These systems use fluid or compressed air to store and release energy, offering advantages in certain applications such as heavy vehicles or industrial equipment. The technology can provide rapid energy storage and release capabilities.

- Electric and hybrid KERS: Electric and hybrid KERS systems use electric motors/generators and energy storage devices like batteries or supercapacitors. These systems are commonly used in hybrid and electric vehicles, as well as in motorsports. They offer high efficiency in energy conversion and storage, contributing to improved fuel economy and reduced emissions.

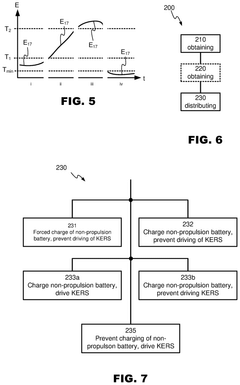

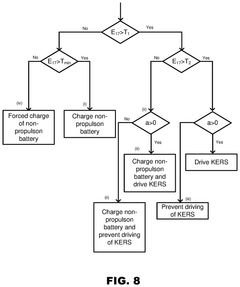

- KERS integration with powertrain and control systems: Advanced KERS implementations focus on seamless integration with vehicle powertrains and control systems. This includes sophisticated control algorithms for optimizing energy recovery, storage, and deployment based on driving conditions and vehicle parameters. Such integration enhances overall system efficiency and vehicle performance.

- Novel KERS applications and improvements: Ongoing research and development in KERS technology explores novel applications and improvements. This includes adapting KERS for use in non-automotive applications, enhancing energy storage capacity and efficiency, and developing new materials and components to optimize system performance and reduce costs.

02 Energy storage mechanisms in KERS

KERS utilizes different energy storage mechanisms to capture and release kinetic energy. Common storage methods include flywheels, hydraulic systems, and electric batteries. Each method has its own advantages in terms of energy density, response time, and integration complexity.Expand Specific Solutions03 KERS applications in motorsports

KERS technology has found significant applications in motorsports, particularly in Formula 1 racing. These systems provide drivers with additional power for overtaking and improve overall race strategy. The use of KERS in motorsports has led to advancements in energy recovery efficiency and system reliability.Expand Specific Solutions04 Hybrid KERS configurations

Hybrid KERS configurations combine different energy recovery and storage methods to optimize system performance. These may include combinations of electrical, mechanical, and hydraulic systems working together to maximize energy recovery and utilization in various driving conditions.Expand Specific Solutions05 KERS control systems and algorithms

Advanced control systems and algorithms are crucial for optimizing KERS performance. These systems manage energy recovery, storage, and deployment based on factors such as vehicle speed, driver input, and road conditions. Intelligent control strategies enhance overall system efficiency and vehicle performance.Expand Specific Solutions

Key Players in Natural KERS Development

The exploration of natural material use in KERS (Kinetic Energy Recovery System) construction is in its early stages, with a growing market driven by sustainability concerns and energy efficiency demands. The technology's maturity is still developing, as evidenced by the diverse range of players involved. Universities like Southeast University, National University of Singapore, and South China University of Technology are conducting foundational research, while companies such as DuPont de Nemours, Technocarbon Technologies France, and Applied Research Associates are focusing on practical applications. The involvement of established firms like ExxonMobil and Hexcel Composites, alongside innovative startups like Biomason, indicates a competitive landscape that spans traditional and emerging players, suggesting a market poised for significant growth and technological advancements in the coming years.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed bio-based materials for KERS (Kinetic Energy Recovery Systems) construction, focusing on sustainable and high-performance solutions. Their approach involves using renewable resources to create durable and lightweight composites. For instance, they have engineered a bio-based resin system that can be used in fiber-reinforced composites for KERS flywheels. This resin system is derived from plant-based sources and offers comparable strength and stiffness to traditional petroleum-based resins[1]. Additionally, DuPont has developed natural fiber reinforcements, such as those derived from flax or hemp, which can be integrated into KERS components to reduce weight while maintaining structural integrity[2]. These materials are designed to withstand the high rotational speeds and energy storage demands of KERS systems.

Strengths: Sustainable sourcing, reduced carbon footprint, potential for weight reduction. Weaknesses: May have higher initial costs, potential limitations in extreme temperature or humidity conditions compared to synthetic materials.

Technocarbon Technologies France SAS

Technical Solution: Technocarbon Technologies has pioneered the use of carbon-fiber reinforced wood composites in KERS construction. Their innovative approach combines the natural properties of wood with the strength of carbon fibers to create a hybrid material suitable for high-performance applications. The company has developed a process to infuse wood with carbon fibers, creating a material that is both lightweight and capable of withstanding the high stresses involved in KERS operations[3]. This technology allows for the creation of KERS components that have a significantly lower environmental impact compared to traditional materials while maintaining the necessary mechanical properties. Technocarbon's materials have been tested in prototype KERS flywheels, demonstrating improved energy density and reduced inertia compared to conventional metal-based systems[4].

Strengths: Combines natural and synthetic materials for optimal performance, potential for significant weight reduction. Weaknesses: Limited long-term performance data, may require specialized manufacturing processes.

Innovative Natural Materials for KERS

Kinetic energy recovery system

PatentPendingUS20240326574A1

Innovation

- A Kinetic Energy Recovery System (KERS) connected to the propulsion shaft, utilizing an internal energy storage device and processing circuitry to distribute energy to both propulsion and non-propulsion batteries based on energy levels, reducing the need for generators and enhancing energy efficiency.

Kinetic energy recovery system

PatentInactiveUS20160369807A1

Innovation

- A dual vacuum enclosure system where a first vacuum enclosure is supported on a shaft with a rotating vacuum pumping mechanism, and a second vacuum enclosure provides backing pressure to reduce the energy required for pumping, allowing periodic evacuation to maintain a pressure less than atmosphere, thereby reducing energy losses and operational costs.

Environmental Impact Assessment

The environmental impact assessment of natural material use in Kinetic Energy Recovery System (KERS) construction reveals both positive and negative implications. On the positive side, utilizing natural materials can significantly reduce the carbon footprint associated with KERS production. Traditional KERS components often rely on energy-intensive materials like metals and synthetic polymers. By incorporating natural alternatives such as bio-based composites or sustainable fibers, manufacturers can decrease greenhouse gas emissions and overall energy consumption during the production phase.

Furthermore, natural materials often possess biodegradable properties, potentially mitigating end-of-life disposal issues. This characteristic aligns with circular economy principles, reducing the long-term environmental burden of KERS components. Additionally, the sourcing of natural materials can promote sustainable agriculture and forestry practices, contributing to ecosystem preservation and biodiversity conservation.

However, the environmental impact assessment also highlights potential challenges. The cultivation and harvesting of natural materials may lead to land-use changes, potentially affecting local ecosystems and biodiversity. Careful consideration must be given to sustainable sourcing practices to avoid deforestation or habitat destruction. Moreover, the processing of natural materials may require water-intensive treatments or chemical modifications, which could offset some of the environmental benefits if not managed properly.

The assessment also considers the lifecycle performance of natural materials in KERS applications. While these materials often offer weight reduction benefits, potentially improving vehicle fuel efficiency, their durability and longevity compared to traditional materials must be carefully evaluated. If natural materials require more frequent replacement, the cumulative environmental impact could be higher over the system's lifespan.

Water consumption and pollution risks associated with natural material processing are additional factors addressed in the environmental impact assessment. Some natural fibers require extensive washing or treatment processes, which may strain local water resources or introduce pollutants into aquatic ecosystems if not properly managed. Implementing closed-loop water systems and eco-friendly processing techniques can help mitigate these risks.

In conclusion, the environmental impact assessment of natural material use in KERS construction reveals a complex balance of benefits and challenges. While the potential for reduced carbon emissions and improved end-of-life management is significant, careful consideration must be given to sourcing, processing, and lifecycle performance to ensure a net positive environmental impact. Future research and development efforts should focus on optimizing these aspects to fully realize the environmental benefits of natural materials in KERS applications.

Furthermore, natural materials often possess biodegradable properties, potentially mitigating end-of-life disposal issues. This characteristic aligns with circular economy principles, reducing the long-term environmental burden of KERS components. Additionally, the sourcing of natural materials can promote sustainable agriculture and forestry practices, contributing to ecosystem preservation and biodiversity conservation.

However, the environmental impact assessment also highlights potential challenges. The cultivation and harvesting of natural materials may lead to land-use changes, potentially affecting local ecosystems and biodiversity. Careful consideration must be given to sustainable sourcing practices to avoid deforestation or habitat destruction. Moreover, the processing of natural materials may require water-intensive treatments or chemical modifications, which could offset some of the environmental benefits if not managed properly.

The assessment also considers the lifecycle performance of natural materials in KERS applications. While these materials often offer weight reduction benefits, potentially improving vehicle fuel efficiency, their durability and longevity compared to traditional materials must be carefully evaluated. If natural materials require more frequent replacement, the cumulative environmental impact could be higher over the system's lifespan.

Water consumption and pollution risks associated with natural material processing are additional factors addressed in the environmental impact assessment. Some natural fibers require extensive washing or treatment processes, which may strain local water resources or introduce pollutants into aquatic ecosystems if not properly managed. Implementing closed-loop water systems and eco-friendly processing techniques can help mitigate these risks.

In conclusion, the environmental impact assessment of natural material use in KERS construction reveals a complex balance of benefits and challenges. While the potential for reduced carbon emissions and improved end-of-life management is significant, careful consideration must be given to sourcing, processing, and lifecycle performance to ensure a net positive environmental impact. Future research and development efforts should focus on optimizing these aspects to fully realize the environmental benefits of natural materials in KERS applications.

Regulatory Framework for Green KERS

The regulatory framework for green Kinetic Energy Recovery Systems (KERS) is evolving rapidly to address the growing emphasis on sustainability in automotive and industrial applications. These regulations aim to promote the use of natural materials in KERS construction while ensuring safety, performance, and environmental protection.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the International Organization for Standardization (ISO) are developing guidelines for sustainable manufacturing practices. These guidelines increasingly focus on the use of renewable and biodegradable materials in energy recovery systems, including KERS.

In the European Union, the End-of-Life Vehicles (ELV) Directive and the Restriction of Hazardous Substances (RoHS) Directive have significant implications for KERS manufacturers. These regulations mandate the use of recyclable materials and restrict the use of certain hazardous substances, encouraging the adoption of natural materials in KERS construction.

The United States Environmental Protection Agency (EPA) has implemented the Environmentally Preferable Purchasing (EPP) program, which promotes the use of environmentally friendly products in government procurement. This initiative indirectly influences KERS manufacturers to incorporate more natural materials into their designs to remain competitive in the market.

In Asia, countries like Japan and South Korea have introduced stringent recycling laws and green procurement policies. These regulations incentivize KERS manufacturers to use natural, easily recyclable materials in their products to meet compliance requirements and gain market access.

Emerging economies, such as China and India, are also developing regulatory frameworks to promote sustainable manufacturing. China's "Green Manufacturing" initiative and India's "National Manufacturing Policy" both emphasize the use of eco-friendly materials in industrial processes, including energy recovery systems.

Certification systems, such as the Leadership in Energy and Environmental Design (LEED) and the Cradle to Cradle Certified™ Product Standard, are gaining prominence in the KERS industry. These voluntary standards provide a framework for assessing and recognizing products that use natural, sustainable materials in their construction.

As the regulatory landscape continues to evolve, KERS manufacturers are increasingly required to consider the entire lifecycle of their products, from raw material sourcing to end-of-life disposal. This holistic approach is driving innovation in the use of natural materials, such as bio-based composites and recyclable metals, in KERS construction.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the International Organization for Standardization (ISO) are developing guidelines for sustainable manufacturing practices. These guidelines increasingly focus on the use of renewable and biodegradable materials in energy recovery systems, including KERS.

In the European Union, the End-of-Life Vehicles (ELV) Directive and the Restriction of Hazardous Substances (RoHS) Directive have significant implications for KERS manufacturers. These regulations mandate the use of recyclable materials and restrict the use of certain hazardous substances, encouraging the adoption of natural materials in KERS construction.

The United States Environmental Protection Agency (EPA) has implemented the Environmentally Preferable Purchasing (EPP) program, which promotes the use of environmentally friendly products in government procurement. This initiative indirectly influences KERS manufacturers to incorporate more natural materials into their designs to remain competitive in the market.

In Asia, countries like Japan and South Korea have introduced stringent recycling laws and green procurement policies. These regulations incentivize KERS manufacturers to use natural, easily recyclable materials in their products to meet compliance requirements and gain market access.

Emerging economies, such as China and India, are also developing regulatory frameworks to promote sustainable manufacturing. China's "Green Manufacturing" initiative and India's "National Manufacturing Policy" both emphasize the use of eco-friendly materials in industrial processes, including energy recovery systems.

Certification systems, such as the Leadership in Energy and Environmental Design (LEED) and the Cradle to Cradle Certified™ Product Standard, are gaining prominence in the KERS industry. These voluntary standards provide a framework for assessing and recognizing products that use natural, sustainable materials in their construction.

As the regulatory landscape continues to evolve, KERS manufacturers are increasingly required to consider the entire lifecycle of their products, from raw material sourcing to end-of-life disposal. This holistic approach is driving innovation in the use of natural materials, such as bio-based composites and recyclable metals, in KERS construction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!